I’m starting this thread primarily as a place to exchange ideas for repairs, modifications, and photoelectric servo control systems to help keep the extant population of Rabco SL8E (and SL8) linear tonearms alive and working better than new. Ideas here could also be useful for other diy servo-linear arm projects, and conceivably spin off into new threads. First, a few requests for this thread that I hope everyone will respect and abide by:

This thread is intended for those who own, have built, like to tinker with, are addicted to, or otherwise admire electric/electronic servo-controlled linear tracking tonearms. Rabco SL8E owners move to the front of the line.

and:

PLEASE, no ‘servos are always in error’ arguments, no debates over servo linears vs passive linears, servo linears vs air linears, servo linears vs conventional pivoted tonearms, etc. Those skirmishes and battles have been fought out elsewhere on the internet, and invariably degrade into nuclear exchanges that trash the original thread. If you are anti-servo that’s fine, but you already have plenty of other forums to post your views and comments, and you’ve probably already done so.

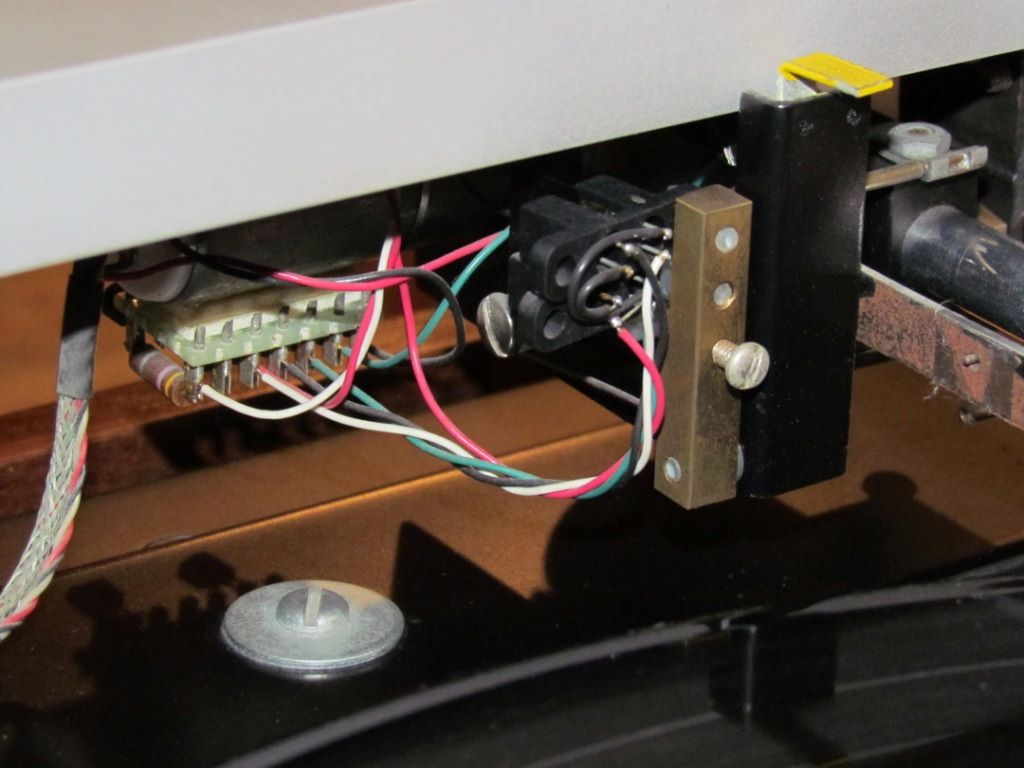

To launch this thread, I’m posting my most recent work - a minimally invasive diy photoelectric retrofit to replace the troublesome catwhisker contacts on the Rabco SL8E. By ‘minimally invasive’ I mean that it requires no drilling or cutting of the carriage or original structure and is totally reversible (although I can’t imagine why you ever would want to undo this modification). The modification requires detaching the carriage and battery/drive motor housing from the track but does not require disassembling the horizontal/vertical arm pivot bearing assembly or the lift switch assembly. I put together a shared public shopping cart on Digi-Key (no financial interest) that includes all the electronic parts for the project. There is one part that you will have to diy that requires cutting, drilling, tapping and that is to fabricate a mounting block for the two photoelectric sensors. If you want to do a more extensive tear-down and include modifications like re-wire the cartridge leads/interconnects, replace the bead chain with a timing belt, etc., that is up to you and whatever you think will yield the audible improvements that you are looking for. This modification is only for the servo control. It will require advanced soldering skills and dexterity with a normal temperature-controlled soldering station.

My journey into modifying SL8E’s began in 1973, when a friend of mine handed me a SL8E and said “here, see what you can do with this”. He gave me full artistic license, and the goal was to optimize the design for the original mega-high-compliance ADC XLM cartridge. At that time, I had access to the machine shop at my engineering college, and I had access to a pretty good imagination as well. I replaced the entire OEM arm assembly with a low mass viscous damped unipivot and this eventually turned into a construction project article that was published in the 3/76 issue of The Audio Amateur magazine. I built two more SL8E’s with the unipivot mod, one for another friend and the other for myself. Since minimizing effective mass was a primary objective of the original mod, I deleted the convenient OEM vernier adjustment mechanism for setting 90-degree tracking angle and replaced it with a lightweight semi-fixed wand. The original mod retained the OEM catwhisker servo control. More on that later.

The original TAA 3/76 mod

That arm has remained my mainstay ever since and has provided me with unparalleled performance. (I’m not sure if that’s a pun or an oxymoron). The unipivot mod initially had a Rube Goldberg-ish cueing system as shown in the TAA article, but it worked reasonably well. By far, the biggest reliability problem turned out to be the progressively worsening erratic behavior of the catwhisker contact system that controlled the carriage drive motor. The classic failure mode was airborne contamination, which resulted in the cue motor lifting in the middle of the record. I went through years of routine maintenance cleaning of the catwhisker contacts. This helped for a while, but eventually the situation became unworkable. I designed a non-contact photoelectric servo control system out of necessity. While working on that I devised a much-improved cueing mechanism as well, which reduced the ridiculously high cueing height to just above the record surface and made the cue height vernier adjustable. The new photoelectric servo control circuit and cueing system has since worked flawlessly.

The original photoelectric upgrade, with electronic parts mounted outboard.

I initially thought the photoelectric circuit should duplicate the on/off action of the OEM catwhisker contacts. I contemplated employing a Schmitt trigger, but was up against the limited real estate available within the carriage for all the added circuitry. I though I could get away with achieving sharp on/off switch action by just using a simple circuit with high gain transistors, but I ended up being wrong about that. The carriage motor ran

quickly at the lead-in groove, then settled down and ran

slowly during the program material. Instead of start/stop motion like the OEM servo control, the carriage motor kept running

continuously, and adjusted its speed in step with the varying groove pitch. Eureka! By serendipity, I ended up with continuous variable speed carriage control instead of mimicking the OEM on/off action. The continuous variable speed action has proven to have several advantages. First, it eliminated jackrabbit start, overshoot, and stop motion (“crabbing” as anti-servo crowd calls it). Second, and far more important in my estimation, the continuous slower speed operation of the carriage drive motor dramatically reduces physical motor noise.

I eventually tracked down the source of the beneficial ‘soft’ control action. It is the orientation of the aperture window in the photosensors and the fact that the aperture of the light-sensitive part of the phototransistor has a finite area. The sensor window is a rectangular slot. The manufacturer intended that the edge of the customer’s interrupting flag line up with the long edge of the sensor window, to minimize the transition time of the on/off state switching. Because of physical constraints I oriented the sensors at 90 degrees, such that the interrupting flag crossed the sensor window the ‘long’ way. Arm motion interrupts the optical beam gradually, much like the slow action of a solar eclipse, and provides the variable gain in the feedback loop which makes the carriage drive motor run smoothly in a continuous variable speed mode.

I’ve had several requests to share my servo control circuit and I have posted it on the Rabco SL8E Club thread over at LencoHeaven. The catch is, that the original circuit was developed for my unipivot configuration which had the photosenors mounted externally under the carriage and a semi-fixed wand on the arm pivot that

un-interrupted the beam to advance the servo. The only practical way to design the photosensors to be inside the carriage requires a mounting arrangement that

interrupts the light beam to activate the servo. This mounting arrangement is better suited as a retrofit mod because it retains the functionality of the OEM vernier adjustment mechanism for setting zero tracking error. I own two more OEM SL8E’s and decided to reconfigure and adapt my original photoelectric control circuit into a version that is optimized for installation on a stock SL8E. I retrofitted one of my extra SL8E’s with a redesigned photoelectric servo-control and I’m presenting those modification steps in this thread. I debated on whether to put most of the components on an externally mounted board as in my original mod, or to mount all the parts on/in the carriage for a clean, original look. Consider that a big advantage of the former is that an externally mounted components board makes it easy to tweak parts values in order to optimize performance. I felt confident that my circuit design should work because of the time I spent breadboarding and testing it so I opted for the latter. Both approaches have merit and you should choose a path based on your diy preferences.

OK, so what evidence can I show to demonstrate that this is more than just another mod that was done for the sake of satisfying some expectation bias? To test compare the performance of the mod’ed and the stock versions of the arm, I fabricated and attached a diagnostics cable to the photoelectric retrofitted SL8E and another to the OEM stock SL8E. I monitored the servo ‘command’ signal, the right channel audio, and the actual carriage drive motor voltage while playing a typical music LP and displayed the three traces on a storage oscilloscope set to operate in auto-erase mode. The effect is very similar to a heart rate monitor display that you see on one of those medical TV soap operas.

Here is the scope trace mp4 for the stock OEM SL8E with cat whisker contact servo control:

YouTube

The upper trace is the contact closure command signal from the cat whisker to the carriage drive servo. The middle trace is the audio, straight from the cartridge with no RIAA EQ. The bottom trace is actual carriage drive motor voltage. The cat whisker contact does not provide a clean control signal, particularly on the tail end release. The motor voltage exhibits a repetitive pattern of jackrabbit start to full speed, then coast to a stop, then sit and wait until the next burst. (Note: the polarity of the trace is inverted due to the Positive Ground power supply, sorry). Clearly, this drive is ‘crabbing’ its way across the record. In fairness, I did take this SL8E apart, cleaned the cat whisker and contact post wires, installed a new foam gripper pad, cleaned, lubed, and adjusted the complete operating assembly to what I believe is factory spec. How much angular error is introduced by the crabbing? I suppose it could be analyzed and calculated, with a probable result that the angular error is less than that of a 9” pivoted arm, but let’s let that sleeping dog lie.

Here is the scope trace mp4 for the modified SL8E with photoelectric servo control:

YouTube

The upper trace is the command signal from the photoelectric sensor to the carriage drive servo. The middle trace is the audio, straight from the cartridge with no RIAA EQ. The bottom trace is actual carriage drive motor voltage. My initial reaction (and maybe yours) upon seeing these traces was “jeez, after all that work, this looks like crap”. After stewing for a while, I started to pick this apart a bit. Neither the upper trace command signal from the photoelectric sensor nor the lower trace of the actual carriage drive motor voltage exhibit any of the “full-on/off” jackrabbit start/stop behavior of the OEM stock cat whisker servo control – that’s been eliminated. The motor is now running continuously. To explain the voltage vacillation, look at the timing. The vacillation period is 1.8 seconds or 0.55Hz. The servo is unidirectionally attempting to follow the record eccentricity! I found that the magnitude of the vacillation corresponded to the magnitude of the eccentricity of the record being played. Well, that’s settled –

all playback systems are compromised by eccentric records, so let’s move on.

It occurred to me that, if I had a record centering servo system on the spindle, and if I fed it a properly filtered and phased copy of this arm’s error correction signal, the record should perfectly center itself automatically while playing within a few revolutions. Hmmm.

Next post – the mod.

Ray K