Thought I would share this here, posted elsewhere before, nearing completion now.

I had the tweeters laying around, so I figured I would go for these.

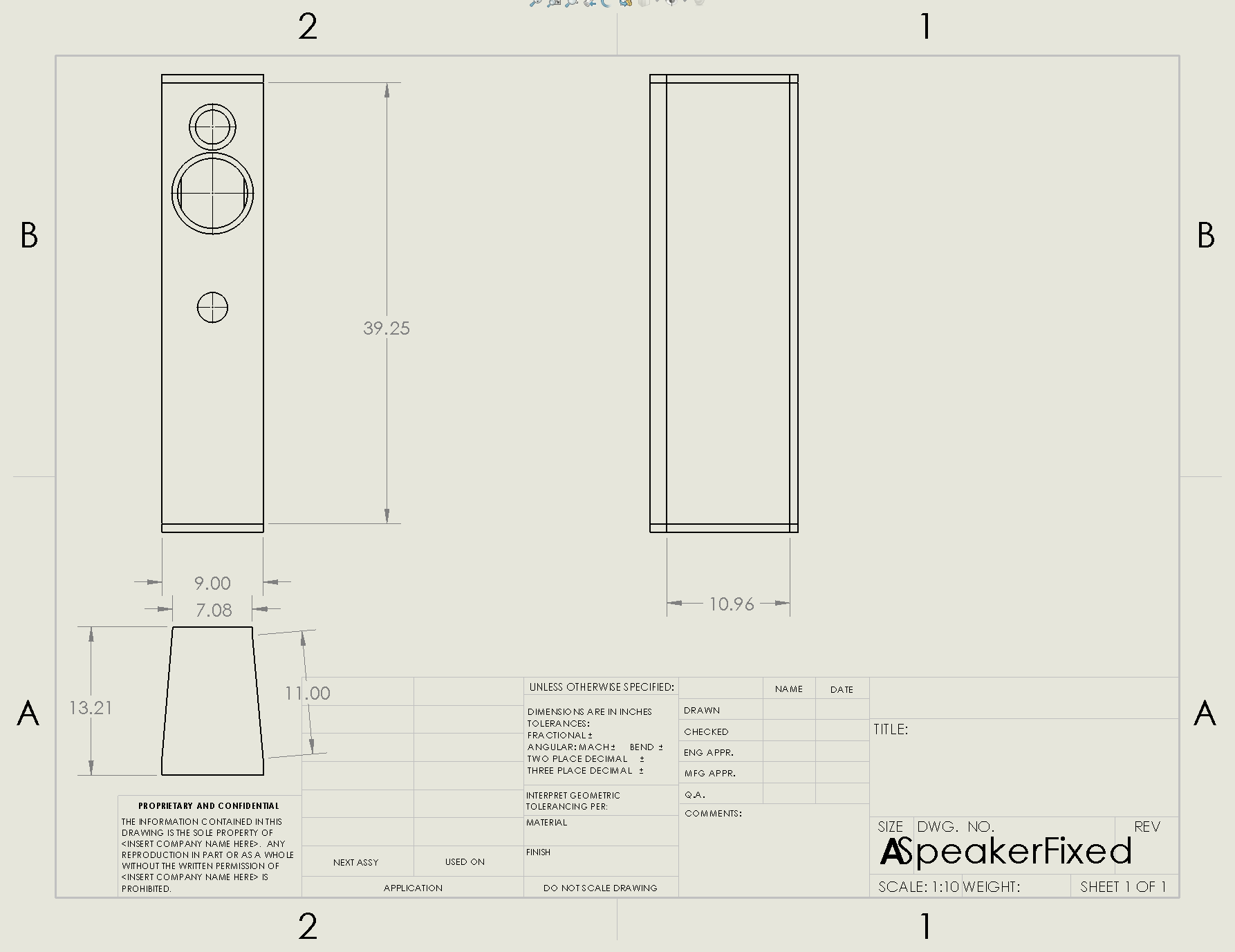

I am using a simplified geometry to make build easier, but keeping angled parts to eliminate standing waves. I modeled it in Solidworks so I could calculate internal volume with all bracing in place (have not done bracing yet). Here is the basic geometry:

Next step, build a little scale model section to make sure everything is going together well, I dont have that much woodworking experience.

So far so good, time to get the wood, got nice sheet of MDF

A few other notes on the build

I am using double thick front panel for rigidity.

Also, these speakers are very very similar to YG acoustics Carmel 2.

The tweeters all almost the same - YG uses scanspeak tweeters custom made for them, with I believe a slight difference.

The woofers are also very similar: Same size, same basket and motor structure. Only difference I see is YG makes machined aluminum cones that they send to scanspeak to be used, while the regular scanspeak drivers use pressed aluminum cones.

Other differences, the waveguide built into the YG speakers, crossover differences, YG have an internal resonation chamber instead of a port to outside, and of course, the YG cabinets are machined aluminum.

Front baffle going well, tweeter flush mount looking all good. I was a bit concerned, never built speakers before, or did a flush mount, but it seems to all be going well.

And woofer hole cut as well, ordering woofers now to test fitment

Woofers arrived

Sexy magnet structure

Test mounted, starting to look like a speaker

I had the tweeters laying around, so I figured I would go for these.

I am using a simplified geometry to make build easier, but keeping angled parts to eliminate standing waves. I modeled it in Solidworks so I could calculate internal volume with all bracing in place (have not done bracing yet). Here is the basic geometry:

Next step, build a little scale model section to make sure everything is going together well, I dont have that much woodworking experience.

So far so good, time to get the wood, got nice sheet of MDF

A few other notes on the build

I am using double thick front panel for rigidity.

Also, these speakers are very very similar to YG acoustics Carmel 2.

The tweeters all almost the same - YG uses scanspeak tweeters custom made for them, with I believe a slight difference.

The woofers are also very similar: Same size, same basket and motor structure. Only difference I see is YG makes machined aluminum cones that they send to scanspeak to be used, while the regular scanspeak drivers use pressed aluminum cones.

Other differences, the waveguide built into the YG speakers, crossover differences, YG have an internal resonation chamber instead of a port to outside, and of course, the YG cabinets are machined aluminum.

Front baffle going well, tweeter flush mount looking all good. I was a bit concerned, never built speakers before, or did a flush mount, but it seems to all be going well.

And woofer hole cut as well, ordering woofers now to test fitment

Woofers arrived

Sexy magnet structure

Test mounted, starting to look like a speaker

Both fronts done

Tweeter hole sealed off, and back of woofer hole widened to allow more breathing room (1.5" of MDF seemed to give it little breathing room with original hole)

Bracing and internal bottoms made

To do: Make tops, make bottoms, assemble, put in damping stuff, make crossovers, connect everything, finishing.

At some point Ill need to buy an amp too, dont have one right now.

Tweeter hole sealed off, and back of woofer hole widened to allow more breathing room (1.5" of MDF seemed to give it little breathing room with original hole)

Bracing and internal bottoms made

To do: Make tops, make bottoms, assemble, put in damping stuff, make crossovers, connect everything, finishing.

At some point Ill need to buy an amp too, dont have one right now.

And the gluing has begun

Now that's looking like A speaker to me. Thank you harbor freight for 6$ big clamps

Damping materials put in

And backs glued on

Now that's looking like A speaker to me. Thank you harbor freight for 6$ big clamps

Damping materials put in

And backs glued on