Meet Beepo: it is cheap and expendable yet robust, frugal but effective.

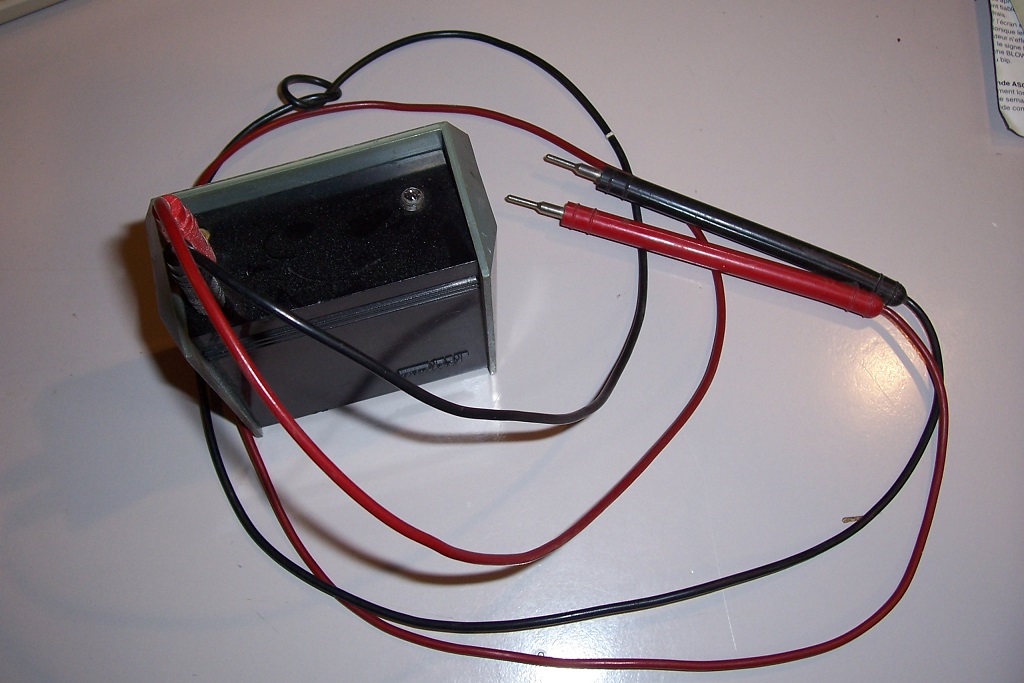

It mimics old-style tester like this one:

These electromechanical testers were quite effective and much loved, but they had a number of drawbacks: they were not very deterministic on the continuity threshold, and they happily passed 250mA or even more through the DUT, which is not very safe in modern, sensitive electronics.

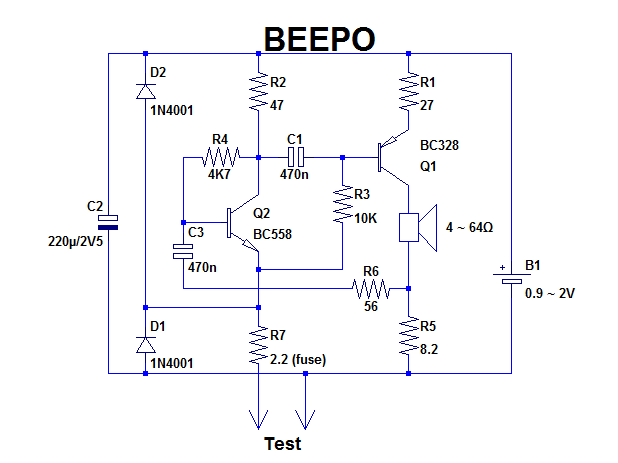

This design (based on a previous version) keeps the advantages of the mechanical device like robustness, simplicity and absence of power switch but without the drawbacks: the current through the DUT is more than an order of magnitude smaller, it does not generate inductive spikes and is even faster:

The circuit is terminally simple, and looks like some lousy multivibrator but it shouldn't be dismissed too quickly: it does its job with a redoubtable efficacy: it works consistently from 0.9V to 2.0V (a single cell), consumes zero power when idle, responds instantly and has a deterministic resistance threshold of 3.5Ω.

It is also capable of almost magical feats, but more on that later.

The connection to be tested acts as a power switch, meaning an idle consumption limited to the leakage currents.

The circuit is simply an oscillator having a well-defined oscillation condition: (R5/R1)*(R2/(R7+Rtest))>1 (neglecting the dynamic resistances of active devices).

With the values shown and the parasitics, Rtest needs to be smaller than 3.5Ω (it can easily be modified).

Other than the resistors values, the circuit is extremely tolerant and will accept any type of semi and capacitor.

The capacitors determine the oscillation frequency (3.5kHz in this case) and can be altered to suit any preference.

It is reasonably well protected, and will survive a test of a charged capacitor (not at 325V though).

Thanks to its resistance discrimination and fast response, it is possible to test reliably and quickly multicore cables, large connectors, etc.

The supply source can be a NiMh, alkaline or saline cell: worn-out cells can be recycled because operation remains possible below 1V.

The cell can be soldered in place because the average current consumption is extremely low.

With a NiMh or NiCad element, the test terminals can work as a charging input thanks to the protection diodes.

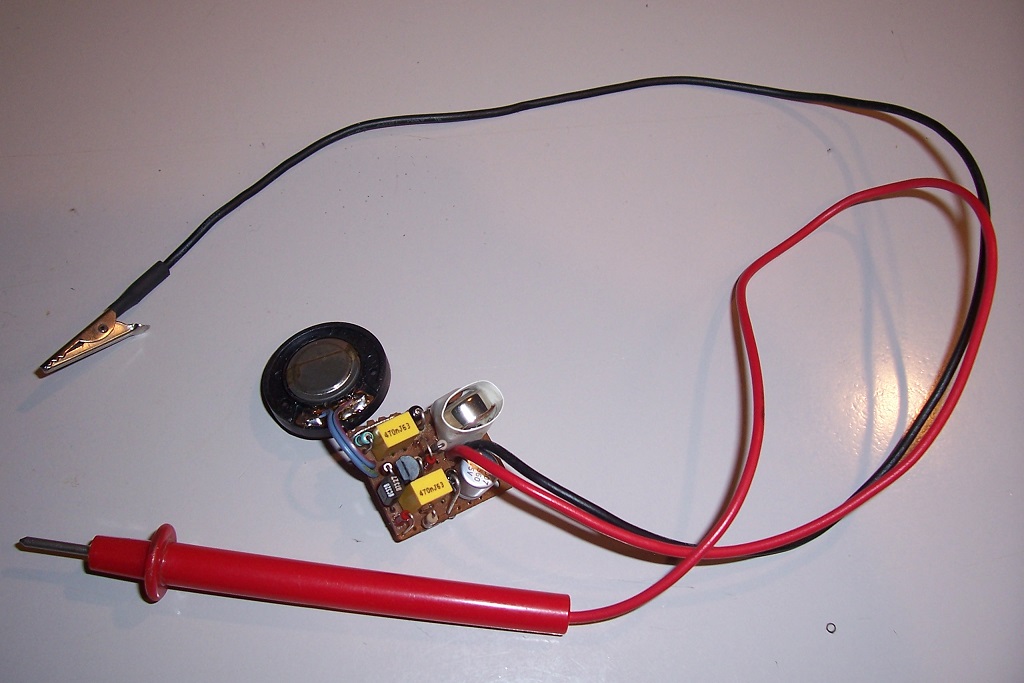

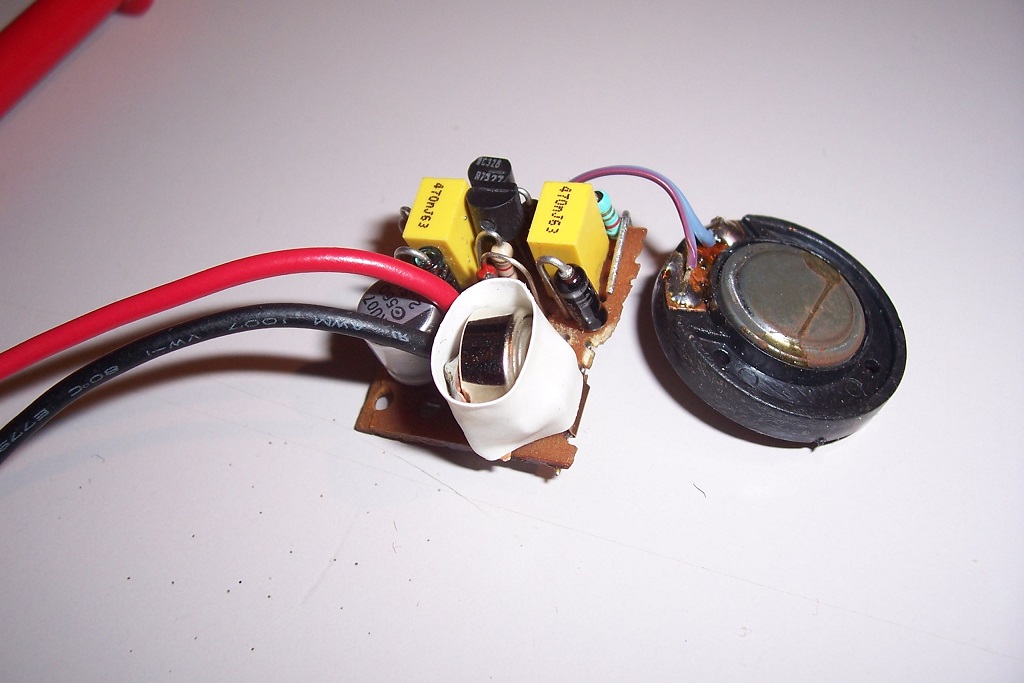

Here are some pics of my prototype:

It mimics old-style tester like this one:

These electromechanical testers were quite effective and much loved, but they had a number of drawbacks: they were not very deterministic on the continuity threshold, and they happily passed 250mA or even more through the DUT, which is not very safe in modern, sensitive electronics.

This design (based on a previous version) keeps the advantages of the mechanical device like robustness, simplicity and absence of power switch but without the drawbacks: the current through the DUT is more than an order of magnitude smaller, it does not generate inductive spikes and is even faster:

The circuit is terminally simple, and looks like some lousy multivibrator but it shouldn't be dismissed too quickly: it does its job with a redoubtable efficacy: it works consistently from 0.9V to 2.0V (a single cell), consumes zero power when idle, responds instantly and has a deterministic resistance threshold of 3.5Ω.

It is also capable of almost magical feats, but more on that later.

The connection to be tested acts as a power switch, meaning an idle consumption limited to the leakage currents.

The circuit is simply an oscillator having a well-defined oscillation condition: (R5/R1)*(R2/(R7+Rtest))>1 (neglecting the dynamic resistances of active devices).

With the values shown and the parasitics, Rtest needs to be smaller than 3.5Ω (it can easily be modified).

Other than the resistors values, the circuit is extremely tolerant and will accept any type of semi and capacitor.

The capacitors determine the oscillation frequency (3.5kHz in this case) and can be altered to suit any preference.

It is reasonably well protected, and will survive a test of a charged capacitor (not at 325V though).

Thanks to its resistance discrimination and fast response, it is possible to test reliably and quickly multicore cables, large connectors, etc.

The supply source can be a NiMh, alkaline or saline cell: worn-out cells can be recycled because operation remains possible below 1V.

The cell can be soldered in place because the average current consumption is extremely low.

With a NiMh or NiCad element, the test terminals can work as a charging input thanks to the protection diodes.

Here are some pics of my prototype:

Attachments

Attachments

More on the magic: imagine you test a regular 2 x 6V transformer, first in circuit.It is also capable of almost magical feats, but more on that later.

The resistance of one winding is 0.1 ohm or lower, so you think the tester is going sound: not so.

the inductance of 1mH or more presents an impedance larger than 3.5 ohm to the tester, and it doesn't react, except for a ticking sound when the DC path is established.

If it sounds, it means that the rectifier bridge is shorted.

If you test the transformer in isolation, no winding should not buzz.

However, if ones buzzes, the other will too: it simply means that a short is present somewhere (in the winding you test, but not only: it could be another secondary, or the primary).

Now, connect both secondaries in series or parallel and test them: if they are in good condition and properly phased, Beepo will not react: it will just tick once, when the connection is established.

If it sounds, it means that an antiphase connection is present.

Suppose that all goes well: no sound. You can test the primary circuit by shorting the mains plug and closing the power switch.

Now, Beepo should sound. If it doesn't, it means that something is interrupted: wiring, fuse, etc.

These are just examples: there are many ways of using Beepo's capabilities once you have understood how it works.

Note that in the examples above, mains was never involved: there were purely dry tests.

They will not catch exactly 100% of potential problems, but a great proportion of them