Greetings to all of you.

After lurking in the shadows of the DIY community I decided to get socially involved in my next project, and present you the building process of THE LOUDSPEAKER 1 of Troels Gravesen.

Objectives:

-Taking the time in design. I truly believe in aesthetics. A nice presented dish is part of the meal, so is with speakers... I enjoy the process of trying and finding a pleasing form etc. Would be great if you could help me with this part of the process. I well know that tastes are different thou there is a common silver lining, I would like to find it with your help!

-going full monty in building process, meaning, giving 110% of my abilitys. I am a young carpenter, so I I have the tools. What I luck is experience...

-making this speaker as if I would make it for a costumer (and a wealthy one as well 🙂 thinking dubai luxury is a good guide line.

-sharing ideas and experiences with you guys, gone are the days of working alone in a basement. This part I am specially excited about!

Inspiration

As for now, the living voice vox project is my inspiration. I foresee disagreement on the aesthetic side but one thing is clear, the vox project is the most perfect, implacable wood working I've seen anywhere! That's exactly what I'm on about.

Disclaimer

So, to summarise, I will take the time with this one so please do not expect quick results.... 🙂 let's make it insane.

Could be cool if you could check other works of mine:

Troels Gravesen DIY loudspeakers - YouTube

And

NEXT4 DIY Loudspeaker Project - YouTube

So, looking forward for you insights. I take all comments as long as it's stays constructive and positive 🙂

Update 8.3.2013- you can now skip the page turning and see the video here:

After lurking in the shadows of the DIY community I decided to get socially involved in my next project, and present you the building process of THE LOUDSPEAKER 1 of Troels Gravesen.

Objectives:

-Taking the time in design. I truly believe in aesthetics. A nice presented dish is part of the meal, so is with speakers... I enjoy the process of trying and finding a pleasing form etc. Would be great if you could help me with this part of the process. I well know that tastes are different thou there is a common silver lining, I would like to find it with your help!

-going full monty in building process, meaning, giving 110% of my abilitys. I am a young carpenter, so I I have the tools. What I luck is experience...

-making this speaker as if I would make it for a costumer (and a wealthy one as well 🙂 thinking dubai luxury is a good guide line.

-sharing ideas and experiences with you guys, gone are the days of working alone in a basement. This part I am specially excited about!

Inspiration

As for now, the living voice vox project is my inspiration. I foresee disagreement on the aesthetic side but one thing is clear, the vox project is the most perfect, implacable wood working I've seen anywhere! That's exactly what I'm on about.

Disclaimer

So, to summarise, I will take the time with this one so please do not expect quick results.... 🙂 let's make it insane.

Could be cool if you could check other works of mine:

Troels Gravesen DIY loudspeakers - YouTube

And

NEXT4 DIY Loudspeaker Project - YouTube

So, looking forward for you insights. I take all comments as long as it's stays constructive and positive 🙂

Update 8.3.2013- you can now skip the page turning and see the video here:

Last edited:

Glad to see you start a thread about your project! I came across a picture of an older Tannoy speaker on one of the social media channels that made me think of your design queries. It was the way the grille was made that triggered it, I should have saved that picture. Looking for it today I cannot find anything like it.

Last edited:

Thanks! I am super excited to start working! But first I'll take this weekend to work on the design. I'll upload my ideas... Just have to figure how to upload photos on this thread... Seems complicated!

And putting this thread in its right play (category) multiway speakers and not full range... Doh...

It isn't that difficult. Just click 'Go Advanced' on a reply and with the button 'Manage Attachments' you can either upload from your PC/Phone/Tablet or in the box below it upload from a source on the net.

Just ask a moderator to have it moved. I'm sure @AllenB or @planet10 or any of the other moderators can move it for you.

Just ask a moderator to have it moved. I'm sure @AllenB or @planet10 or any of the other moderators can move it for you.

Last edited:

Wow... they are just wonderful... very infectious videos

I will follow this thread with great interest.

I will follow this thread with great interest.

Wow... they are just wonderful... very infectious videos

I will follow this thread with great interest.

I will do my best! and thanks!

Hello again Noam

this will be a great thread

Best Bjarne

Hey Bjarne, good to see you here 🙂

Beautiful speakers Noam.

Can you tell me what is the price of Sylodamp sheet, cant find it nowhere

Can you tell me what is the price of Sylodamp sheet, cant find it nowhere

Thanks!

I've got those sheets from ebay kleinanzeigen.. long time ago, since then I've been searching as well. seems that you cannot buy them only as pro companies and in big rolls. So I dropped the idea

I've got those sheets from ebay kleinanzeigen.. long time ago, since then I've been searching as well. seems that you cannot buy them only as pro companies and in big rolls. So I dropped the idea

Just watched your Next4 video: Very impressive work on the cabinets. Beautiful work and superb craftsmanship. Bravo!

I think you obviously believe that a cabinet that is as dead and dull of vibration is best. There is a point of diminishing returns, after which, one is satisfying one’s own OCD for something that probably is not audible or measurable.

I made a sealed cabinet for an 8in woofer for my 10F/RS225 FAST speaker out of 1in thick XPS foam. I made the baffle out of same foam covered with 3/16in thick plywood glued on with a semi flexible construction adhesive. Years later, I had a cabinet maker make the same cabinet from 18mm Baltic Birch, lined with Noico mass loaded butyl and interior covered with eggcrate foam. It sounded and measured about the same. Similar levels of harmonic distortion. Still great sounding but the improvement I was expecting from a much stiffer cabinet just did not prove itself to be true. So I think wood is more durable and looks much better. But I am not sure all the extra efforts in making the panels dead from vibration really make a huge difference in the sound. As long as the panels are braced and not ringing like a bell. More info here:

10F/8424 & RS225-8 FAST / WAW Ref Monitor

Btw, I saw your speaker feet with the vibration absorbing polymer. Have you ever heard of Noene? It is used in the liner of figure skaters’ boots to absorb micro vibrations. My daughter is a skater so I had these old insoles from years ago. Check out the absorption of energy on the marble (or steel ball bearing would be the same).

No-Ene Vibration Damper Material - YouTube

There is no bounce and the stuff is like about 1.5mm thick. I compared it against sorbothane and the sorbothane lost badly.

I think you obviously believe that a cabinet that is as dead and dull of vibration is best. There is a point of diminishing returns, after which, one is satisfying one’s own OCD for something that probably is not audible or measurable.

I made a sealed cabinet for an 8in woofer for my 10F/RS225 FAST speaker out of 1in thick XPS foam. I made the baffle out of same foam covered with 3/16in thick plywood glued on with a semi flexible construction adhesive. Years later, I had a cabinet maker make the same cabinet from 18mm Baltic Birch, lined with Noico mass loaded butyl and interior covered with eggcrate foam. It sounded and measured about the same. Similar levels of harmonic distortion. Still great sounding but the improvement I was expecting from a much stiffer cabinet just did not prove itself to be true. So I think wood is more durable and looks much better. But I am not sure all the extra efforts in making the panels dead from vibration really make a huge difference in the sound. As long as the panels are braced and not ringing like a bell. More info here:

10F/8424 & RS225-8 FAST / WAW Ref Monitor

Btw, I saw your speaker feet with the vibration absorbing polymer. Have you ever heard of Noene? It is used in the liner of figure skaters’ boots to absorb micro vibrations. My daughter is a skater so I had these old insoles from years ago. Check out the absorption of energy on the marble (or steel ball bearing would be the same).

No-Ene Vibration Damper Material - YouTube

There is no bounce and the stuff is like about 1.5mm thick. I compared it against sorbothane and the sorbothane lost badly.

Last edited:

Just watched your Next4 video: Very impressive work on the cabinets. Beautiful work and superb craftsmanship. Bravo!

I think you obviously believe that a cabinet that is as dead and dull of vibration is best. There is a point of diminishing returns, after which, one is satisfying one’s own OCD for something that probably is not audible or measurable.

I made a sealed cabinet for an 8in woofer for my 10F/RS225 FAST speaker out of 1in thick XPS foam. I made the baffle out of same foam covered with 3/16in thick plywood glued on with a semi flexible construction adhesive. Years later, I had a cabinet maker make the same cabinet from 18mm Baltic Birch, lined with Noico mass loaded butyl and interior covered with eggcrate foam. It sounded and measured about the same. Similar levels of harmonic distortion. Still great sounding but the improvement I was expecting from a much stiffer cabinet just did not prove itself to be true. So I think wood is more durable and looks much better. But I am not sure all the extra efforts in making the panels dead from vibration really make a huge difference in the sound. As long as the panels are braced and not ringing like a bell. More info here:

10F/8424 & RS225-8 FAST / WAW Ref Monitor

Btw, I saw your speaker feet with the vibration absorbing polymer. Have you ever heard of Noene? It is used in the liner of figure skaters’ boots to absorb micro vibrations. My daughter is a skater so I had these old insoles from years ago. Check out the absorption of energy on the marble (or steel ball bearing would be the same).

No-Ene Vibration Damper Material - YouTube

There is no bounce and the stuff is like about 1.5mm thick. I compared it against sorbothane and the sorbothane lost badly.

thanks for the comment and compliment I'll check it out.

As for the time being I fail miserably with the design. the 'Holy' front plate of the loudspeaker is huge and well... holy 😉 means I cannot change anything and thus creating something a bit more fine... dammit. What more, seems that I am working in hostile environment since my wife and my 5 years old daughter made it clear that what I'm trying to create is ugly no matter what I do! Kids are lovely!

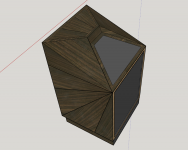

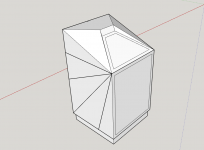

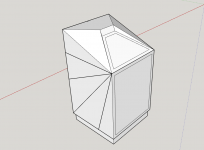

First sketch- with a window on top to show the crossover- looks fancy but.. I don't know could be also a speaker wearing a hat 😀

First sketch- with a window on top to show the crossover- looks fancy but.. I don't know could be also a speaker wearing a hat 😀

Hmm, if aesthetics is part of the deal, you will have to think about the speaker concept. Even the best craftsmanship and materials cannot bring elegance in a speaker whose outlines remind me of a dishwasher. If I had to sacrifice everything aesthetic for a speaker concept, I would'nt build it.

A dishwasher indeed, and a huge one as well... Big Loudspeakers, big Problems... yet the living voice managed to be Majestic in a way, if not quite beautiful. it has a very impressive presence. that's what I'm after.

- Home

- Loudspeakers

- Multi-Way

- Building process - The loudspeaker 1