I have enough knowledge to be dangerous.

Lately I have been working on re educating myself on transistors. The project is the HK Citation 12 which I have two of them. Both needing some work I am enjoying the adventure. Wanting to keep the HK design as well a I can with updated caps and what is needed to make operational.

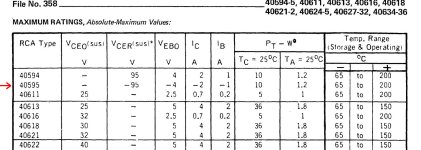

I have a bad driver and am looking for suitable replacements which is why i am researching. Q705 has shorted and is unobtainable in fact a outright replacement is as well. It is a RCA 40595. Replacement I have found is 2N5322 which also is unavailable.

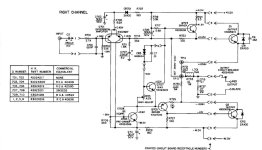

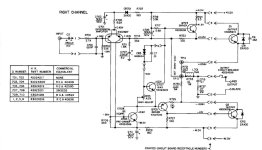

Schematic is here as well as a pic of the board with the transisters

https://www.diyaudio.com/forums/att...820264t-hot-output-citation-12-a-img_6809-jpg

Digging I found a NTE 16004 which has a low Beta, I think, of 80. Again I am re-education myself.

Of course no specs are available on the OEM and so I feel it would be best to also replace Q 709 with a matching Beta. So here is my question.

are there any publications for a spec for the OEM drivers? Somewhere i read of a low beta of 70.

What are the the considerations necessary to find a replacement?

I am debating removing the good Transistor from the other channel and testing for Hfe to see what to look for for replacements. What else I do not know, is the OEM silicon or germanium? This is a bottle neck in my projects.

Any help will be appreciated.

Lately I have been working on re educating myself on transistors. The project is the HK Citation 12 which I have two of them. Both needing some work I am enjoying the adventure. Wanting to keep the HK design as well a I can with updated caps and what is needed to make operational.

I have a bad driver and am looking for suitable replacements which is why i am researching. Q705 has shorted and is unobtainable in fact a outright replacement is as well. It is a RCA 40595. Replacement I have found is 2N5322 which also is unavailable.

Schematic is here as well as a pic of the board with the transisters

https://www.diyaudio.com/forums/att...820264t-hot-output-citation-12-a-img_6809-jpg

Digging I found a NTE 16004 which has a low Beta, I think, of 80. Again I am re-education myself.

Of course no specs are available on the OEM and so I feel it would be best to also replace Q 709 with a matching Beta. So here is my question.

are there any publications for a spec for the OEM drivers? Somewhere i read of a low beta of 70.

What are the the considerations necessary to find a replacement?

I am debating removing the good Transistor from the other channel and testing for Hfe to see what to look for for replacements. What else I do not know, is the OEM silicon or germanium? This is a bottle neck in my projects.

Any help will be appreciated.

A transfer ratio of 80 is quite high. I encountered transistors in a TO3 package with a transfer ratio of just 10. There are also small signal transistors with transfer ratios much less than 80.champco said:Digging I found a NTE 16004 which has a low Beta, I think, of 80

In your case you have to search for the original transistors data sheets. You have to compare beta, the frequency at which the gain is unity, the current rating, the maximum collector voltage and the parasitic capacitance of the base collector junction.

Since the major issue of amplifiers is stability or better the lack of it, the value of the base collector capacitance is very important to consider. This is because capacitances cause phase changes in the signal path.

The maximum collector voltage of the replacement transistor can higher but not lower unless you are sure a lower values is never exceeded.

The maximum current can be higher but not lower unless you are sure any lower current you choose is never exceeded.

The gain/beta has to be more or less the same.

The base collector capacitance can be lower. Avoid a bigger capacitance.

The frequency at which the gain becomes unity, usually denoted by Ft, has to be more or less the same. Higher values may cause the amplifier to self oscillate.

Last edited:

You're in luck. 2n5322 is a pnp to39 transistor, which substitutes still are available. Had you been replacing a TO5 transistor, you would have been completely out of luck. bce pinout is going the way of the dodo bird, only to39 is left.

Farnell has 10 W capable (with heat sink) 2n5415 (200v) in US and mp001173 in the UK. Be sure to buy the heat sinks for drivers. The originals fail because the manufacture was too cheap to install a heat sink. HK is not a brand with a high resale value.

There are various NTE subs available. I think if you check the datasheets from NTE, all the important specifications have been left off.

Farnell has 10 W capable (with heat sink) 2n5415 (200v) in US and mp001173 in the UK. Be sure to buy the heat sinks for drivers. The originals fail because the manufacture was too cheap to install a heat sink. HK is not a brand with a high resale value.

There are various NTE subs available. I think if you check the datasheets from NTE, all the important specifications have been left off.

A transfer ratio of 80 is quite high. I encountered transistors in a TO3 package with a transfer ratio of just 10. There are also small signal transistors with transfer ratios much less than 80.

In your case you have to search for the original transistors data sheets. You have to compare beta, the frequency at which the gain is unity, the current rating, the maximum collector voltage and the parasitic capacitance of the base collector junction.

Since the major issue of amplifiers is stability or better the lack of it, the value of the base collector capacitance is very important to consider. This is because capacitances cause phase changes in the signal path.

The maximum collector voltage of the replacement transistor can higher but not lower unless you are sure a lower values is never exceeded.

The maximum current can be higher but not lower unless you are sure any lower current you choose is never exceeded.

The gain/beta has to be more or less the same.

The base collector capacitance can be lower. Avoid a bigger capacitance.

The frequency at which the gain becomes unity, usually denoted by Ft, has to be more or less the same. Higher values may cause the amplifier to self oscillate.

Thankyou. I need to chew on this, soften it up. The BC capacitance value. How is that expressed?

You're in luck. 2n5322 is a pnp to39 transistor, which substitutes still are available. Had you been replacing a TO5 transistor, you would have been completely out of luck. bce pinout is going the way of the dodo bird, only to39 is left.

Farnell has 10 W capable (with heat sink) 2n5415 (200v) in US and mp001173 in the UK. Be sure to buy the heat sinks for drivers. The originals fail because the manufacture was too cheap to install a heat sink. HK is not a brand with a high resale value.

There are various NTE subs available. I think if you check the datasheets from NTE, all the important specifications have been left off.

Looking on Central semi it looks like this is canned as is the OEM so it may be a direct fit to the heat sink.

I agree on the NTE data sheets so far.

Should I be looking for a matching NPN driver as well??

In To39 you will be very lucky to find two different processes for npn/pnp with matching Vce. I found 2n5415 on farnells site by selecting pnp & TO39 case, then visually screening out the parts with too low a Vce. Farnell usually keep a few TO39 metal parts in their house brand, which have 10 times the heat loss capacity of TO92 plastic parts.

If you re-manufacture your pcb's to fit TO126 or TO220, the world of modern matching parts opens up. BCE transistors. I tried twisting the legs around on my TO5 driver board, but over time a leg broke off. My favorite driver right now is 20 watt MJE15028/29 but some people swear by 6 watt BD139/140. I ended up making a different board entirely to my TO5 driver board, an AX6.

Ed barx match process is postulating a perfect world, which in metal case ebc transistors, you are not going to find.

If you re-manufacture your pcb's to fit TO126 or TO220, the world of modern matching parts opens up. BCE transistors. I tried twisting the legs around on my TO5 driver board, but over time a leg broke off. My favorite driver right now is 20 watt MJE15028/29 but some people swear by 6 watt BD139/140. I ended up making a different board entirely to my TO5 driver board, an AX6.

Ed barx match process is postulating a perfect world, which in metal case ebc transistors, you are not going to find.

Last edited:

Posters should describe their amp under repair completely. I remembered after some delay that a citation 12 was a harmon-karden citation 12. I do have that service manual stored.

From the outline of Q705 on page 5, 40595 appears to be one of those RCA TO5 transistors sold with an integrated heat sink welded on at the factory. Those have not been available for four decades IMHO. I do not even have that datasheet to confirm that suspicion.

One increases the power dissipation of a TO39 part by adding an external heat sink and heat sink compound. Per the multicomp datasheet for 2n5415, power dissipation at 25 C case temperature is 10 W. One achieves case temperature of 25 C by installing a big honking heat sink with lots of fins and some air flow. Or one can install TO220 MJE15029 with smaller heat sink by twisting the legs around. Doing that substitution (NTE50 only available TO220 driver to me before debit cards were invented) broke a transistor leg after a year or so in my ST120. When I attempted to replace the transistor again, the land lifted on the PCB and I had to scrap the board PC14. Was over two decades before I corrected that damage by building an AX6 board point to point that is drilled for TO220 drivers. So I am in favor of TO39 parts that have the same pinout as TO5 parts from the seventies. During the 2 decades without a working ST120 amp, and ST70 output tubes unavailable to those ignorant of guitar amps(sovtek), I listened to a GE clock radio with a 2" speaker. Some ire resulted.

From the outline of Q705 on page 5, 40595 appears to be one of those RCA TO5 transistors sold with an integrated heat sink welded on at the factory. Those have not been available for four decades IMHO. I do not even have that datasheet to confirm that suspicion.

One increases the power dissipation of a TO39 part by adding an external heat sink and heat sink compound. Per the multicomp datasheet for 2n5415, power dissipation at 25 C case temperature is 10 W. One achieves case temperature of 25 C by installing a big honking heat sink with lots of fins and some air flow. Or one can install TO220 MJE15029 with smaller heat sink by twisting the legs around. Doing that substitution (NTE50 only available TO220 driver to me before debit cards were invented) broke a transistor leg after a year or so in my ST120. When I attempted to replace the transistor again, the land lifted on the PCB and I had to scrap the board PC14. Was over two decades before I corrected that damage by building an AX6 board point to point that is drilled for TO220 drivers. So I am in favor of TO39 parts that have the same pinout as TO5 parts from the seventies. During the 2 decades without a working ST120 amp, and ST70 output tubes unavailable to those ignorant of guitar amps(sovtek), I listened to a GE clock radio with a 2" speaker. Some ire resulted.

Last edited:

And how much base current would be demanded by the output transistor? Way the hell less than two amps. They’ve got to be above 80V, preferably 100+. 1 amp is fine. The only real issue is getting heat sinking, if the originals have that flanged heat sink. The little push on porcupine heat sinks for TO-5/39 can’t even get close on Rth. Is it good enough here? Maybe. One solution is a higher gain output transistor, such as MJ15003 or MJ802. The higher gain above 5 amps will reduce the peak heat loading on the drivers.

Citation 12 is only a 120 w amp. Dynaco ST120 got away with 40409/40410 drivers with little spring on TO5 heatsinks, no fan, and crummy ventilation through slots in the base 3/32" off the floor. 40636 outputs allegedly.

If I wanted to I could make 1"x2" heatsink out of aluminum window frame, fins sawed out of the vertical flanges, TO5 hole drilled in. Thompson 2n5320/22 datasheet says body dimension of TO-39 is 8.5 mm or .334" max. If you cannot buy a 8.5 mm drill then letter drill Q is .332 and R is .339. You could sand or ream out a Q hole a little to fit. To avoid breaking the TO39 legs I would support a 1"x2" heat sink from the board with two or 3 4-40 screw standoffs, or dabs of RTV or siliicon sealant.

If I wanted to I could make 1"x2" heatsink out of aluminum window frame, fins sawed out of the vertical flanges, TO5 hole drilled in. Thompson 2n5320/22 datasheet says body dimension of TO-39 is 8.5 mm or .334" max. If you cannot buy a 8.5 mm drill then letter drill Q is .332 and R is .339. You could sand or ream out a Q hole a little to fit. To avoid breaking the TO39 legs I would support a 1"x2" heat sink from the board with two or 3 4-40 screw standoffs, or dabs of RTV or siliicon sealant.

Last edited:

Yep, the originals in the H/K Citation Twelve have the large, welded heat sinks. Sounds like 2N5415 should be ok at 1 amp (schematic below) if I can figure out adequate heat sinking.

Re the TO-220 options, if I go with say, the MJE15029, would there be any anticipated tweaks I should make to the circuit to avoid issues?

Re the TO-220 options, if I go with say, the MJE15029, would there be any anticipated tweaks I should make to the circuit to avoid issues?

Dynaco ST120 was intended to be biased fully class B. If you intend to bias higher (as I assume this is) one must ensure that the drivers don’t run any hotter than they originally did, ie, keep Rth to ambient just as good or better. It’s no issue just idling, but if drivers run hotter than originally intended the bias rises. If they don’t cool down fast enough when returning to idling you can run away. I suspect this happened to a lot of modded ST120’s.

If you go the TO-220 (or even TO-126) route the driver thermal issue is solved. A little piece of angle aluminum goes a long way. Modern drivers are better in every way, but you don’t get those cute little metal cans.

I wouldn’t worry at all about transistor characteristics causing oscillations here, if one uses types intended for like purposes. It’s a run of the mill QC double, on sane rail voltage. With a VAS using a 150 pf Miller capacitor, which doesn’t exactly make for crazy high GBW. If you don’t do anything stupid, it will work.

If you go the TO-220 (or even TO-126) route the driver thermal issue is solved. A little piece of angle aluminum goes a long way. Modern drivers are better in every way, but you don’t get those cute little metal cans.

I wouldn’t worry at all about transistor characteristics causing oscillations here, if one uses types intended for like purposes. It’s a run of the mill QC double, on sane rail voltage. With a VAS using a 150 pf Miller capacitor, which doesn’t exactly make for crazy high GBW. If you don’t do anything stupid, it will work.

One possible problem is modern epitaxial output transistors as MJ15003 or MJ802. The old homotaxial 40636 was too slow to oscillate. Ft 400 khz. Remote mounting of the outputs with long wires from the drivers was fine. If you still have 40636, you are fine. New 2n3055H are 99% likely to have Ft 3 mhz or higher, being really epitaxial. The RCA homotaxial fab site is now a NJ county park. Mooly and others have had trouble with modern outputs transistors oscillating on 1960's 2n3055H amps. I used 1 watt 1 ohm carbon comp resistors instead of wires to the bases of the outputs on my ST120 with NTE180 outputs (same SOA as MJ15003, probably where they got them.) That turns out to be the solution Mooly used on his British amp. With carbon comps dead as the dodo, and Vishay rating 1 watt metal film resistors at 200 C, You have to be careful where you mount them. My theory for the base resistors was if the output blew again, a 1 watt resistor as base driver would burn up before all the drivers zener diodes on the PCB did.Re the TO-220 options, if I go with say, the MJE15029, would there be any anticipated tweaks I should make to the circuit to avoid issues?

Main problem with TO220 part, or TO126 you have to twist the legs to fit the old holes. I destroyed my PC14 that way when the replacement leg of a NTE50 broke after a year. I probably should have supported the heat sink with struts or glue, instead of letting the transistor body carry the weight. It was only 12 mm heatsink. If you put on a heat sink as big as the 40595 was, definitely support the weight by running 4-40 or 3 mm screws through it to the bare patches of the PCB. Don't use TIP32 or TIP42, 6 mhz Ft makes a dull sound. ****y highs. MJE15029 was much better. I did not use BC556 because the fairchild ones in stock had no Ft spec. I have an On datasheet that says theirs are 280 Mhz Ft.

BTW you can get 8.5 mm drill for TO39 heatsink fab from mcmaster.com or fastenal. https://www.mcmaster.com/2951A142 Grainger.com storefront is okay but when I order 3 items from them on internet, I usually pay 3 shipping charges of $11 per box. Mcmaster sometimes ships two $11 boxes but usually just one. Both are UPS only which means a minimum size box can be $22 if shipped across the country. $11 UPS surface is from Mcmaster Cleveland to my house near Louisville.

Last edited:

That is not true IMHO. If you ran the ST120 loud enough, or let them warm up, C6 would charge up and push the emitters of the drivers apart same as other amps. The crossover distortion happened cold and low volume, when C6 would stay near zero volts and make the outputs made nasty sounds.Dynaco ST120 was intended to be biased fully class B.

Dynaco should have stolen the circuit from Armstrong 621, but maybe there were patent problems. There sure weren't any 621 appliances in the US to copy. I have never seen one. That 100 ohm bias pot Armstrong used could have caused warrenty problems if the wiper contact opened up and let output transistor bias current run wild.

Last edited:

One is never supposed to support a large weight by a transistor’s leads alone. That failure mode is on the user.

3 MHz outputs won’t oscillate in a normal circuit configuration with 6” leads. They might with inadequate supply bypassing but that is easily remedied without making any significant changes. You normally wont have to go messing with the global loop compensation. The original design may have “done something stupid” that they get away with when hometaxial outputs were used, but that doesn’t change the fact that best practices were ignored. 30 or 80 MHz outputs may be a bridge too far, especially if you exceed the speed of the drivers. That requires re-compensation, and certainly need base stoppers. Lets see you find a 30 MHz TO-3 anymore anyway. ON wanted a million piece order to put MJL3281’s in a TO-3 for Krell. I’m sure they’d offer you the same deal. How much you got in the account tied to that debit card?

If an amplifier starts out way under biased to the point where it sounds terrible and comes up to an optimum bias after being blasted for a while that is evidence of thermal instability. It’s undercompensated. Then if you go turning up the idle bias so it sounds decent cold you run a real risk of runaway.

3 MHz outputs won’t oscillate in a normal circuit configuration with 6” leads. They might with inadequate supply bypassing but that is easily remedied without making any significant changes. You normally wont have to go messing with the global loop compensation. The original design may have “done something stupid” that they get away with when hometaxial outputs were used, but that doesn’t change the fact that best practices were ignored. 30 or 80 MHz outputs may be a bridge too far, especially if you exceed the speed of the drivers. That requires re-compensation, and certainly need base stoppers. Lets see you find a 30 MHz TO-3 anymore anyway. ON wanted a million piece order to put MJL3281’s in a TO-3 for Krell. I’m sure they’d offer you the same deal. How much you got in the account tied to that debit card?

If an amplifier starts out way under biased to the point where it sounds terrible and comes up to an optimum bias after being blasted for a while that is evidence of thermal instability. It’s undercompensated. Then if you go turning up the idle bias so it sounds decent cold you run a real risk of runaway.

Re sticking with a TO-39 for this driver, which heat sink would you guys use? These are what I have.

The big RCA sink on the bottom is the same type as was originally used with the 40595. While I was able to remove the old transistor from it, I have doubts as to whether I can install a new transistor without damage.

The big RCA sink on the bottom is the same type as was originally used with the 40595. While I was able to remove the old transistor from it, I have doubts as to whether I can install a new transistor without damage.

If you can look these up in the thermalloy or wakefield catalog, the one with the lowest heat resistance is the best.

For what it is worth, the one on the upper right is what dynaco used for TO5 drivers in the Stereo120. The one on the left could be useful only in products with air flow.parallel to the fins.

With a dial or vernier calipers, and a twist of 60 to 100 aluminum oxide cloth, you might be able to ream the bottom sink to fit your new TO-39 transistors. Look on internet for a video of enlarging a hole with a twist of abrasive cloth.

For what it is worth, the one on the upper right is what dynaco used for TO5 drivers in the Stereo120. The one on the left could be useful only in products with air flow.parallel to the fins.

With a dial or vernier calipers, and a twist of 60 to 100 aluminum oxide cloth, you might be able to ream the bottom sink to fit your new TO-39 transistors. Look on internet for a video of enlarging a hole with a twist of abrasive cloth.

I'll take a look at the catalogs/datasheets to match up and check the heat resistances.

Obviously those big RCA heat sinks (called "heat radiators" by them) were never meant to be reused, but I thought it might be worth seeing if it could be done. Looking at the mating point under my cheapie USB microscope I can see that there's a groove that the edge of the TO-39 is supposed to fit into (first photo). But an area of the heat sink shown is closed up (second pic), likely as a result of me knocking out the original. So yeah, not reusable. Still, kind of interesting to see.

Obviously those big RCA heat sinks (called "heat radiators" by them) were never meant to be reused, but I thought it might be worth seeing if it could be done. Looking at the mating point under my cheapie USB microscope I can see that there's a groove that the edge of the TO-39 is supposed to fit into (first photo). But an area of the heat sink shown is closed up (second pic), likely as a result of me knocking out the original. So yeah, not reusable. Still, kind of interesting to see.

These amps, Citation 12 & ST120, were produced during the era of the FTC watt rating. FTC mandated a standard test procedure for power amps. There was a low power "soak period" then a one hour test at full wattage. If an amp passed that test, the test wattage could be advertised in the USA.

When a shorted output transistor set the base resistor on fire 3 1/2 hours into a choir Christmas rehearsal, it was obvious my ST120 was designed to make the 60 w/ch as cheaply as possible. I was probably drawing 10-15 watts/ch during that rehearsal. The side that blew was on a 4 ohm speaker, two 8 ohms in parallel.

So the best heat strategy for your drivers IMHO is adding a fan. I did for the ST120, two of them like mickey mouse ears, one blowing through the grill on each output transistor flange. I used 12 v fans from blown PCAT power supplies, and I ran them at 9v instead of 12. There was a bar (channel) under the chassis base to hold the fans against the grill and support the 9VDC socket. DC wires ran from one side to the other through the channel of the bar. With fans, I have run the ST120 14 hours a day in my music room. With the amp hidden behind the 6' high record rack with 12' RCA cables and 8' speaker cables, the fans cannot be heard in my music room. With power strips having come into consumer use after 1990, how to power the amp, wall transformer for fans, preamp or mixer, tuner and CD player is now obvious. They even make infrared controlled power strips. Not in 1961, when my preamp came with sockets for the power amp and tuner in the back loaded on the internal switch.

I do not know what the case of the Citation 12 looks like, how adding a fan would be possible. That design could be up to you, if you are worried that your driver heat sinks are not adequate. I suggest putting the fan outside the faraday cage (steel chassis) provides some protection against electrical noise from the motor interfering in the high gain circuits.

When a shorted output transistor set the base resistor on fire 3 1/2 hours into a choir Christmas rehearsal, it was obvious my ST120 was designed to make the 60 w/ch as cheaply as possible. I was probably drawing 10-15 watts/ch during that rehearsal. The side that blew was on a 4 ohm speaker, two 8 ohms in parallel.

So the best heat strategy for your drivers IMHO is adding a fan. I did for the ST120, two of them like mickey mouse ears, one blowing through the grill on each output transistor flange. I used 12 v fans from blown PCAT power supplies, and I ran them at 9v instead of 12. There was a bar (channel) under the chassis base to hold the fans against the grill and support the 9VDC socket. DC wires ran from one side to the other through the channel of the bar. With fans, I have run the ST120 14 hours a day in my music room. With the amp hidden behind the 6' high record rack with 12' RCA cables and 8' speaker cables, the fans cannot be heard in my music room. With power strips having come into consumer use after 1990, how to power the amp, wall transformer for fans, preamp or mixer, tuner and CD player is now obvious. They even make infrared controlled power strips. Not in 1961, when my preamp came with sockets for the power amp and tuner in the back loaded on the internal switch.

I do not know what the case of the Citation 12 looks like, how adding a fan would be possible. That design could be up to you, if you are worried that your driver heat sinks are not adequate. I suggest putting the fan outside the faraday cage (steel chassis) provides some protection against electrical noise from the motor interfering in the high gain circuits.

Last edited:

- Home

- Amplifiers

- Solid State

- Choosing replacement Transistors