I have been well and truly smitten by the Dual bug!

Just acquired a cosmetically very nice 721 that refuses to function in auto start and whose cueing lever does nothing to elevate or lower the tonearm. Consequently, in manual mode I have to rescue the tonearm at the end of the record to prevent the stylus being dragged across the lp on its way back to the (approximate) arm rest position. It is super quiet and sounds good though.

These problems can hopefully be fixed when I check out the steuerpimpel etc.

My question is: when I manually raise the tonearm from its rest, there is very little vertical upwards free movement, maybe 1/4”, until the arm will raise no more, and compared to every other turntable I have used, it seems too limited.

Is this normal for a 721?

The bearings appear to be fine and the arm balances readily. I cannot see a reason in that area that is limiting the vertical movement. Could there be a problem under the deck?

Any ideas?

Thanks

Peter

Just acquired a cosmetically very nice 721 that refuses to function in auto start and whose cueing lever does nothing to elevate or lower the tonearm. Consequently, in manual mode I have to rescue the tonearm at the end of the record to prevent the stylus being dragged across the lp on its way back to the (approximate) arm rest position. It is super quiet and sounds good though.

These problems can hopefully be fixed when I check out the steuerpimpel etc.

My question is: when I manually raise the tonearm from its rest, there is very little vertical upwards free movement, maybe 1/4”, until the arm will raise no more, and compared to every other turntable I have used, it seems too limited.

Is this normal for a 721?

The bearings appear to be fine and the arm balances readily. I cannot see a reason in that area that is limiting the vertical movement. Could there be a problem under the deck?

Any ideas?

Thanks

Peter

Hi,

in more or less every DUAL there is a "Steuerpimpel". Don't ask me what that is in english 🙂

3er-Set Steuerpimpel Pimpel Dual Plattenspieler 701 731Q 1219 1229 721 1249 u.a. | eBay

It's responsible for the arm movement. You should check if it's still there and how it looks.

Micha

in more or less every DUAL there is a "Steuerpimpel". Don't ask me what that is in english 🙂

3er-Set Steuerpimpel Pimpel Dual Plattenspieler 701 731Q 1219 1229 721 1249 u.a. | eBay

It's responsible for the arm movement. You should check if it's still there and how it looks.

Micha

Thank you Micha.

I am familiar with the little plastic device, but I suspect the restricted vertical movement of the tonearm is being caused by something else. Unless it is normal.

Just trying to gather information before I look underneath.

I am familiar with the little plastic device, but I suspect the restricted vertical movement of the tonearm is being caused by something else. Unless it is normal.

Just trying to gather information before I look underneath.

Have you tried to do what is written in the manual on page 8 under "Later transport" for freeing the arm?

This may be of some help

[Dual 721] Problems with auto tone arm set down. - Vinyl Engine

There are more if you search "Dual 721 auto function" in google.

Regards

[Dual 721] Problems with auto tone arm set down. - Vinyl Engine

There are more if you search "Dual 721 auto function" in google.

Regards

Micha...yes, I do that each time I unplug or move it.

I am thinking that the limited vertical up movement of the headshell/tonearm is the nature of the beast, since it tracks my test record well. I am not familiar with automatic turntables. The manual ones I have allow the headshell to be raised sufficiently to see and clean the stylus easily.

This 721 barely raises the much higher than the arm rest.

I’ll dig into the mechanics in a few days.

Thanks for you help.

I am thinking that the limited vertical up movement of the headshell/tonearm is the nature of the beast, since it tracks my test record well. I am not familiar with automatic turntables. The manual ones I have allow the headshell to be raised sufficiently to see and clean the stylus easily.

This 721 barely raises the much higher than the arm rest.

I’ll dig into the mechanics in a few days.

Thanks for you help.

Last thing you can check is the "Vertical tonearm control". It moves the whole tonearm bearing up and down.

On my 721 I get about 2cm rise from tonearm rest to top of vertical travel measured at the end of the headshell, this is max travel just by lifting with my finger...

Might want to keep this page handy

Dual 721 resto project - lost cause?- arm bearing damage? - Vinyl Engine

hope this helps

regards

james

Might want to keep this page handy

Dual 721 resto project - lost cause?- arm bearing damage? - Vinyl Engine

hope this helps

regards

james

James.....that is quite a bit more than mine.

I just now confirmed that there is an assembly and/or adjustment problem. I adjusted the tone arm height with the knurled adjuster at the base of the tonearm pivot to parallel the arm with the stylus on the record(I had to lower the bearing end) and the arm could not be placed on its rest, even manually. Raising the bearing end to where it was before provided enough clearance to do so. But it is nothing like 2cm. More like 0.5cm.

I just now confirmed that there is an assembly and/or adjustment problem. I adjusted the tone arm height with the knurled adjuster at the base of the tonearm pivot to parallel the arm with the stylus on the record(I had to lower the bearing end) and the arm could not be placed on its rest, even manually. Raising the bearing end to where it was before provided enough clearance to do so. But it is nothing like 2cm. More like 0.5cm.

James....thanks for the link. Could be very helpful. I’ll take a closer look at the bearing end to check for damage.

Tonearm

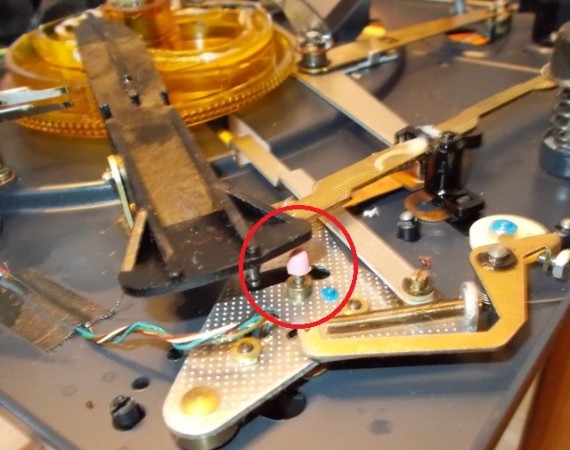

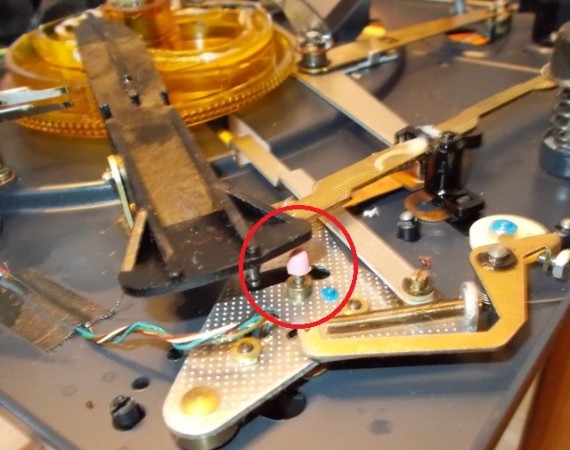

Here is a picture of the back of the tonearm tube. There appears to be a hex headed screw or something attached to the bottom of the tube which acts as a stop, maybe?

The clearance between the bottom face of its head and whatever it stops against is about .030” thus limiting the vertical movement. Is something adjustable here?

Peter

Here is a picture of the back of the tonearm tube. There appears to be a hex headed screw or something attached to the bottom of the tube which acts as a stop, maybe?

The clearance between the bottom face of its head and whatever it stops against is about .030” thus limiting the vertical movement. Is something adjustable here?

Peter

Attachments

Tonearm

Here is a picture of the back of the tonearm tube. There appears to be a hex headed screw or something attached to the bottom of the tube which acts as a stop, maybe?

The clearance between the bottom face of its head and whatever it stops against is about .030” thus limiting the vertical movement. Is something adjustable here?

Peter

Here is a picture of the back of the tonearm tube. There appears to be a hex headed screw or something attached to the bottom of the tube which acts as a stop, maybe?

The clearance between the bottom face of its head and whatever it stops against is about .030” thus limiting the vertical movement. Is something adjustable here?

Peter

Removed the tonearm to gain sufficient access to the suspect screw. Plus, it gave me the opportunity to see how it goes together. Fashioned a 4.5mm open ended wrench and snugged the culprit screw. It is one of two bayonet screws. Cleaned the steurepimpel and mating surface of grease.

Reinstalled, adjusted cueing mechanism and voila, with an AT140LC mounted at 1.5g, this things tracks and sounds wonderful.

All I need now is to figure out why the strobe lamp is not working. I cleaned contacts and reversed the lamp, but still doesn’t light up.

Thanks, guys.

Peter

Reinstalled, adjusted cueing mechanism and voila, with an AT140LC mounted at 1.5g, this things tracks and sounds wonderful.

All I need now is to figure out why the strobe lamp is not working. I cleaned contacts and reversed the lamp, but still doesn’t light up.

Thanks, guys.

Peter

Does this mean that your mechanical problems are solved now?

These neon strobe lamp often fail after four decades without any sign of wear. Some show silvery deposits inside the glass tube, some don't. I've replaced the neon in one of my 1229's by SMD LEDs. There's a vendor in Austria who offers a ready-for-use replacement.

Best regards!

These neon strobe lamp often fail after four decades without any sign of wear. Some show silvery deposits inside the glass tube, some don't. I've replaced the neon in one of my 1229's by SMD LEDs. There's a vendor in Austria who offers a ready-for-use replacement.

Best regards!

Yes, It seems that way. At least, for now. I’m not too concerned about the strobe lamp not working. I have spent 50 years with turntables without one.

I may make the diy one with smd leds.

The existing lamp appears to have a good filament but measured open circuit.

Many thanks

I may make the diy one with smd leds.

The existing lamp appears to have a good filament but measured open circuit.

Many thanks

The existing lamp appears to have a good filament but measured open circuit.

Many thanks

That's a neon (glow) lamp that doesn't feature a filament.

Best regards!

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Dual 721 question