I foud this page on the web

Moja wytawiarka "Spray Etching Machine" - elektroda.pl

unfortunately it is not in english or french .....

Did somebody saw a translation of this ??

I would like to know the diameter of the rotating tubes and the speed of them ..

Moja wytawiarka "Spray Etching Machine" - elektroda.pl

unfortunately it is not in english or french .....

Did somebody saw a translation of this ??

I would like to know the diameter of the rotating tubes and the speed of them ..

"Two conduits Ø 2.5 cm relatively simple.

Two miniature drills for tiles.

Heater. 50W

The holes along the tube a distance about 1 cm with a diameter of 1.5 mm"

No mention of "conduit" RPM. Drill motor running on variable DC supply.

Since "propeller" at bottom end of "conduit" works as pump to pressurize

fluid for spraying, it probably spins fairly fast (no clue here).

Google translate is your friend.

Two miniature drills for tiles.

Heater. 50W

The holes along the tube a distance about 1 cm with a diameter of 1.5 mm"

No mention of "conduit" RPM. Drill motor running on variable DC supply.

Since "propeller" at bottom end of "conduit" works as pump to pressurize

fluid for spraying, it probably spins fairly fast (no clue here).

Google translate is your friend.

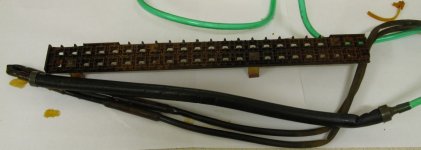

I build this

tested with green food colorant , but not tested with etchant

tub is a 20 liters pail

motor 60 hertz, 2 poles, 3450 RPM

pump-sprinkler is a 1 1/2 inch sewer pipe, actual outside diameter is 4,8 mm

pump blades made of lexan

pump throat is 10 mm

sprinkler have 27 holes, 3,1 mm diameter

tested with green food colorant , but not tested with etchant

tub is a 20 liters pail

motor 60 hertz, 2 poles, 3450 RPM

pump-sprinkler is a 1 1/2 inch sewer pipe, actual outside diameter is 4,8 mm

pump blades made of lexan

pump throat is 10 mm

sprinkler have 27 holes, 3,1 mm diameter

Attachments

-

100_2341.JPG317.9 KB · Views: 226

100_2341.JPG317.9 KB · Views: 226 -

100_2356.JPG326.3 KB · Views: 104

100_2356.JPG326.3 KB · Views: 104 -

100_2353.JPG324.8 KB · Views: 97

100_2353.JPG324.8 KB · Views: 97 -

100_2351.JPG326.9 KB · Views: 104

100_2351.JPG326.9 KB · Views: 104 -

100_2349.JPG324.5 KB · Views: 104

100_2349.JPG324.5 KB · Views: 104 -

100_2347.JPG325.9 KB · Views: 218

100_2347.JPG325.9 KB · Views: 218 -

100_2346.JPG324.3 KB · Views: 220

100_2346.JPG324.3 KB · Views: 220 -

100_2345.JPG322.7 KB · Views: 227

100_2345.JPG322.7 KB · Views: 227 -

100_2344.JPG320.1 KB · Views: 225

100_2344.JPG320.1 KB · Views: 225

All this for etching a pcb ? With ferric chloride possibly it's good to spray the etchant. Horrible method in any case. Stains everything !

I etch my boards in a plastic tray containing a Hydrogen peroxide solution ( somewhere between 10 and 20% ) and dilute Hydrochloric acid sold for cleaning tiles / toilets etc. Must be 10 % or 20%. Ratio is 2 parts hydrogen peroxide ( solution as you buy it ) to 1 part acid ( as you buy it ).

The boards etch in less than 5 minutes with a little rocking if the boards face upward. It's amazingly fast. Need a fresh mix each time.

I etch my boards in a plastic tray containing a Hydrogen peroxide solution ( somewhere between 10 and 20% ) and dilute Hydrochloric acid sold for cleaning tiles / toilets etc. Must be 10 % or 20%. Ratio is 2 parts hydrogen peroxide ( solution as you buy it ) to 1 part acid ( as you buy it ).

The boards etch in less than 5 minutes with a little rocking if the boards face upward. It's amazingly fast. Need a fresh mix each time.

Actually you just need to add more peroxide. No need to remake the mixture every time. Which also prevents having to figure out how to dispose the environmentally toxic copper solution every time you etch.All this for etching a pcb ? With ferric chloride possibly it's good to spray the etchant. Horrible method in any case. Stains everything !

I etch my boards in a plastic tray containing a Hydrogen peroxide solution ( somewhere between 10 and 20% ) and dilute Hydrochloric acid sold for cleaning tiles / toilets etc. Must be 10 % or 20%. Ratio is 2 parts hydrogen peroxide ( solution as you buy it ) to 1 part acid ( as you buy it ).

The boards etch in less than 5 minutes with a little rocking if the boards face upward. It's amazingly fast. Need a fresh mix each time.

I use ferric chloride solution.

Look at this .http://www.diyaudio.com/forums/solid-state/244903-vssa-through-hole-pcb-build-thread-38.html

and here on post 1152 the full explain.http://www.diyaudio.com/forums/solid-state/221741-dx-blame-st-together-dx-super-116.html

Thimios.

Look at this .http://www.diyaudio.com/forums/solid-state/244903-vssa-through-hole-pcb-build-thread-38.html

and here on post 1152 the full explain.http://www.diyaudio.com/forums/solid-state/221741-dx-blame-st-together-dx-super-116.html

Thimios.

Last edited:

This is the commercial version of that machine..Jet 34 d

Nice build.... what you might consider is a lower support bearing for the spray tube, to prevent wobbling. We had a Jet at work for close to 20 years. Worked flawlessly until the very last years. What actually killed it was a replacement of the mercury lid switches, which was not sufficiently tight, causing etchan to leak into the electrical compartment which was on the side of the old machine. We used it with Sodium peroxide as etchant, which is another possibillity. Wether you need a machine for home etching depends on how much you neeed it, I guess, or that you quite simply just want one...😀

Nice build.... what you might consider is a lower support bearing for the spray tube, to prevent wobbling. We had a Jet at work for close to 20 years. Worked flawlessly until the very last years. What actually killed it was a replacement of the mercury lid switches, which was not sufficiently tight, causing etchan to leak into the electrical compartment which was on the side of the old machine. We used it with Sodium peroxide as etchant, which is another possibillity. Wether you need a machine for home etching depends on how much you neeed it, I guess, or that you quite simply just want one...😀

Last edited:

A mechanically simpler solution (as in no moving parts in the tank itself) is to make a bubble tank, with some needle pricked plastic tubing in the bottom of the tank, driven by an aquarium pump.

When you go to your pet supply shop remember to also pick an aquarium heater.

Killer combination for fast even etching.

When you go to your pet supply shop remember to also pick an aquarium heater.

Killer combination for fast even etching.

Made a first real world test today

Simply preheat etchant by putting the gallon in a pail and keep the pail full of hot tap water, change hot water a few times.

used Mg chemicals stuff and had great results, works better than expected...

Simply preheat etchant by putting the gallon in a pail and keep the pail full of hot tap water, change hot water a few times.

used Mg chemicals stuff and had great results, works better than expected...

A mechanically simpler solution (as in no moving parts in the tank itself) is to make a bubble tank, with some needle pricked plastic tubing in the bottom of the tank, driven by an aquarium pump.

When you go to your pet supply shop remember to also pick an aquarium heater.

Killer combination for fast even etching.

What he says.

I made this out of perspex and pipe glue. The thing is as solid as a rock, we call it the 'fish tank'. It gets a lot of use and works great.

The next image shows how I heat it and agitate. The black tube is a 'bubble curtain' designed for creating lots of tiny bubbles in a fish tank, this is powered by a small aquarium pump. The heat is provided by 4 glass encased power resistors. These are then encapsulated in wide diameter heatshrink tubing. HS tubing is extremely inert stuff. The heater is about 60 watts total.

I had reservations about the resistors getting too hot inside the tubing, but in reality they don't at all. The heater is powered by an old laptop SMPS. I do have to preheat the solution in a water bath with hot water before etching, otherwise the heater would take hours to get it up to temperature.

The PCB support was made out of some packaging that came with an IC I bought a few years back, and lifted up on little perspex legs. The heater and bubble curtain weave and sit between/beneath the legs. You do have to place a cover over the top when it's working otherwise it spits etchant over the top. I usually use newspaper for this.

Certainly far cheaper than buying something specialised. I keep the etchant in a non reactive plastic bottle when it's not in use.

Attachments

- Status

- Not open for further replies.

- Home

- Design & Build

- Equipment & Tools

- etching tank