I'm trying to fix a broken Technics turntable which has a DC motor controlled by a servo feedback system. There is a magnet on the motor shaft which sends pulses to an IC (SVIBA6301) which produces a control voltage for the motor drive transistor. It is a very simple circuit with all the control functions built into the IC but unfortunately that IC has gone bad. All the input voltages and signals are correct but the output voltage is way off. I can't find any source of a replacement of the IC so I'm looking for simple options to get this turntable running again.

1) The easiest thing to do seems to be substitute a basic DC motor control. There is a strobe light on the platter so manually setting the speed correctly would be easy but there would obviously be some drift under load. How big a PSU would I need to keep it reasonably stable?

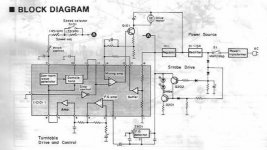

2) In the service manual there is a block diagram of the internals of the controller IC. From the voltages I can measure it looks like the problem is with last part of the comparator/buffer output - the "Mixing amp" in the attached diagram. Any chance I could just replace that stage with a simple OP-AMP?

3) Provide a complete replacement for the frequency feedback system. Anything already done in this area?

This is a friends ill-advised eBay purchase and simple/cheap would be what I'm looking for.

1) The easiest thing to do seems to be substitute a basic DC motor control. There is a strobe light on the platter so manually setting the speed correctly would be easy but there would obviously be some drift under load. How big a PSU would I need to keep it reasonably stable?

2) In the service manual there is a block diagram of the internals of the controller IC. From the voltages I can measure it looks like the problem is with last part of the comparator/buffer output - the "Mixing amp" in the attached diagram. Any chance I could just replace that stage with a simple OP-AMP?

3) Provide a complete replacement for the frequency feedback system. Anything already done in this area?

This is a friends ill-advised eBay purchase and simple/cheap would be what I'm looking for.

Attachments

Last edited:

You sir, are a genius (although if I had looked closer at the actual hardware, rather than the schematic, it would have been obvious to even a fool like me).

After a short search on the web (avoiding booking the flight from Cape Town to Durban) I secured a BA6301 for a few quid and I now have a turntable running at the correct speeds.

I wonder why such a simple, single IC, system isn't something that is used more widely as a turntable motor controller - although from my searches across the archives leads me to think that DC/AC motor control is pretty much a religious matter.

After a short search on the web (avoiding booking the flight from Cape Town to Durban) I secured a BA6301 for a few quid and I now have a turntable running at the correct speeds.

I wonder why such a simple, single IC, system isn't something that is used more widely as a turntable motor controller - although from my searches across the archives leads me to think that DC/AC motor control is pretty much a religious matter.

Good to hear it's back up and running. These ICs were designed back in the late '70s or so in order to make basic turntables easier to build, and would have gone EOL when the market for record players dwindled in the early/mid '90s.

What I don't like so much about this one is that 33 rpm speed depends on 45 adjustment and 33/45 switch contact as well. How's it doing in terms of keeping speed? While the trusty SL-BD20 that my dad bought in '91-ish may well have been keeping spinning at near-ideal speed all day, actually playing a record it would be down by about 0.3% or so - it uses much simpler control electronics mostly integrated into the motor though, and I am not sure whether there actually is feedback involved (not from the platter for sure, which would seem to be the case with yours).

I have, incidentally found no reason to swap out the original belt; it seems Technics used belts consisting of mostly synthetic rubber. A belt with higher natural rubber content gives more elasticity and as such would transmit less vibration, but degrades far more quickly, even turning into nasty sticky goo in some cases (Philips).

DC vs. AC drive isn't that much of a science either. DC motors tend to be small, high-rpm units whose vibrations need to be kept away from the platter as well as possible. Even if you have near-ideal elastic suspension, some would still be transmitted via the belt, mandating a heavier platter, all stuff that manufacturers tend to dislike for cost reasons. This is why direct drive made its way pretty far down the food chain in the '80s. A low-rpm synchronous motor may run so quietly that the turntable platter can actually be made part of it, and it simplifies assembly noticeably.

I still think that the way these cheap Technics 'tables are constructed is pretty clever. While the platter by itself is rather lightweight in order to achieve sane spin-up times, the heavy rubber mat damps it effectively. The only real weak point of this series would have to be the annoying wimpy dust cover hinges.

Incidentally, if you ever come across one of the similar-looking QD models for cheap, I wouldn't pass it by. They're not exactly lookers, but good 'tables nonetheless and a fair step up from yours. Oh, and don't discard the stock Technics cartridges (P23, P24, P30, P33). You can get some very nice Jico styli for 'em over the pond.

What I don't like so much about this one is that 33 rpm speed depends on 45 adjustment and 33/45 switch contact as well. How's it doing in terms of keeping speed? While the trusty SL-BD20 that my dad bought in '91-ish may well have been keeping spinning at near-ideal speed all day, actually playing a record it would be down by about 0.3% or so - it uses much simpler control electronics mostly integrated into the motor though, and I am not sure whether there actually is feedback involved (not from the platter for sure, which would seem to be the case with yours).

I have, incidentally found no reason to swap out the original belt; it seems Technics used belts consisting of mostly synthetic rubber. A belt with higher natural rubber content gives more elasticity and as such would transmit less vibration, but degrades far more quickly, even turning into nasty sticky goo in some cases (Philips).

DC vs. AC drive isn't that much of a science either. DC motors tend to be small, high-rpm units whose vibrations need to be kept away from the platter as well as possible. Even if you have near-ideal elastic suspension, some would still be transmitted via the belt, mandating a heavier platter, all stuff that manufacturers tend to dislike for cost reasons. This is why direct drive made its way pretty far down the food chain in the '80s. A low-rpm synchronous motor may run so quietly that the turntable platter can actually be made part of it, and it simplifies assembly noticeably.

I still think that the way these cheap Technics 'tables are constructed is pretty clever. While the platter by itself is rather lightweight in order to achieve sane spin-up times, the heavy rubber mat damps it effectively. The only real weak point of this series would have to be the annoying wimpy dust cover hinges.

Incidentally, if you ever come across one of the similar-looking QD models for cheap, I wouldn't pass it by. They're not exactly lookers, but good 'tables nonetheless and a fair step up from yours. Oh, and don't discard the stock Technics cartridges (P23, P24, P30, P33). You can get some very nice Jico styli for 'em over the pond.

Good to hear it's back up and running. These ICs were designed back in the late '70s or so in order to make basic turntables easier to build, and would have gone EOL when the market for record players dwindled in the early/mid '90s.

The datasheet lists VCR motor control as the main application so they probably would have scraped into the 21st century.

The speed stability seems pretty good in normal use, although I'm only going by the built in strobe on the platter. There is a big slow down at the end of the record when the auto park system for the arm takes a lot out of the motor.What I don't like so much about this one is that 33 rpm speed depends on 45 adjustment and 33/45 switch contact as well. How's it doing in terms of keeping speed? While the trusty SL-BD20 that my dad bought in '91-ish may well have been keeping spinning at near-ideal speed all day, actually playing a record it would be down by about 0.3% or so - it uses much simpler control electronics mostly integrated into the motor though, and I am not sure whether there actually is feedback involved (not from the platter for sure, which would seem to be the case with yours).

They certainly made the most of a limited component count and some low spec parts. Having the speed controlled by the feedback loop means you don't need very much power reserve, the transformer is tiny and the drive circuit doesn't need a regulator.I still think that the way these cheap Technics 'tables are constructed is pretty clever. While the platter by itself is rather lightweight in order to achieve sane spin-up times, the heavy rubber mat damps it effectively. The only real weak point of this series would have to be the annoying wimpy dust cover hinges.

It's not my turntable (I have a Roksan in my main system) but I am on the lookout for a retro turntable to go with my Quad 33/303 system. Not sure that a Technics TT would fit that bill.Incidentally, if you ever come across one of the similar-looking QD models for cheap, I wouldn't pass it by. They're not exactly lookers, but good 'tables nonetheless and a fair step up from yours. Oh, and don't discard the stock Technics cartridges (P23, P24, P30, P33). You can get some very nice Jico styli for 'em over the pond.

Many thanks again for your help.

A mid/late '70s-era 'table with S arm would certainly be a better match for a retro setup like that. Technics wise, that would be models up to D and Q 2/3, 22/33, 202/303; it seems they only made straight-arm T4Ps after about 1981. There's plenty of other nice 'tables from the time out there, too.

- Status

- Not open for further replies.