I'm just wondering if the same design rules apply to valve mic output transformers (say 4:1) as to se valve amp output transformers as far as the insulation between layers goes. Is the enamel /poly insulating enough with such small voltages to not require paper? And do they still need an air gap?

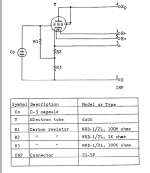

Please show the actual schematic.

IF said transformer is part of a miniature "power amp" and primary carries tube level voltages , it will need proper insulation.

And gap will be needed IF it carries a significant DC component.

So please show us actual use.

IF said transformer is part of a miniature "power amp" and primary carries tube level voltages , it will need proper insulation.

And gap will be needed IF it carries a significant DC component.

So please show us actual use.

Thanks.

AS shown, the 6uF capacitor blocks DC and there is a DC path to ground after it, so no DC on OT primary. Good.

No gain stages involved either, so voltages present will be "microphone level".

A big condenser capsule driving an ultra high impedance preamp as this one and picking up a floor drum hit hard WILL produce a HOT signal, but still microphone level, maybe 1 V or a little more, no problem as far as insulation is concerned.

Personally I would not try to hand wind one but use a good quality commercial one, think Jensen Transformers or better.

Yes, the "electronics" side of the project is quite DIYable.

I would also put PT on a separate box, away from the OT, say at least 1 meter away, and join them by a safe umbilical cable.

Remember voltage sources use female connectors so as not to have hand touchable exposed metal.

AS shown, the 6uF capacitor blocks DC and there is a DC path to ground after it, so no DC on OT primary. Good.

No gain stages involved either, so voltages present will be "microphone level".

A big condenser capsule driving an ultra high impedance preamp as this one and picking up a floor drum hit hard WILL produce a HOT signal, but still microphone level, maybe 1 V or a little more, no problem as far as insulation is concerned.

Personally I would not try to hand wind one but use a good quality commercial one, think Jensen Transformers or better.

Yes, the "electronics" side of the project is quite DIYable.

I would also put PT on a separate box, away from the OT, say at least 1 meter away, and join them by a safe umbilical cable.

Remember voltage sources use female connectors so as not to have hand touchable exposed metal.

Hi,

No dc so no airgap.

As far as i know yes same rules applies.

Page 8 of this could be of interest:

http://vintagewindings.com/tech swag/Audio Transformer Sound.pdf

http://vintagewindings.com/tech swag/Altec-Peerless 4665 Audio Transformer Addendum 10-12.pdf

I agree with JmFahey, if you can keep the transformer in the microphone body it is better ( and it is usually possible with CF as there is few parts).

Which tube do you plan to use?

No dc so no airgap.

As far as i know yes same rules applies.

Page 8 of this could be of interest:

http://vintagewindings.com/tech swag/Audio Transformer Sound.pdf

http://vintagewindings.com/tech swag/Altec-Peerless 4665 Audio Transformer Addendum 10-12.pdf

I agree with JmFahey, if you can keep the transformer in the microphone body it is better ( and it is usually possible with CF as there is few parts).

Which tube do you plan to use?

Last edited:

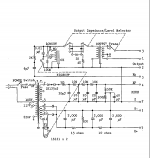

Hi , many thanks for the links . The valve will be 6au6 as per this model mic , and I'm going for an outboard in the first instance as my interest was aroused by people who'd owned one of these mics saying the mic ot was as big as a small amp ot , so I thought I'd try unwinding the primary from an old radio se ot having figured out the winding ratio , and rewind at 4:1 with suitable wire , just as an experiment - I realise it wouldn't compare with a Jensen etc.

6au6 might not be the 'best' choice as the original required very high b+ for a mic (270v iirc). Without an original capsule you'll have issue with capsule biasing. Better be inspired by the circuit and build one from scratch imho. I would lower B+ at 120v or 180v and capsule bias around 60v. As JmFahey explained you won't see anything greater than 1v at cathode follower input so the 120v b+ is more than enough in my view.

Any triode able to put a bit of current is a wiser choice imho, what matter for this kind of aplication ( mic) is that the tube is non microphonic ( the least possible) and it accept 'weird' grid current ( with 1g or more grid resistors for some circuit it is 'fringe' design) and low currents ( between 0,5ma to 3ma is the range for the circuits i played with- i found CF allowed a bit more current than grounded cathode) and the cathode to be 'non polluted' ( if you encounter intermitent popcorn noise, ploc,... it might be worth trying 'rejuvenating tube' as it will be unusable for mic circuit if the symptoms are presents anyway...).

I had great success with subminiature 6021(a small 6sn7 kind) and their russian equivalent.

Why do you want to use a 4:1 ratio?

It should be defined from the output impedance from your cf in my experience. But it is non critical ( tube circuits are forgiving).

The psu of original is big and heavy for a mic psu yes, but it integrate 2x transformers ( psu and signal) and a tapped inductor so it's bulky.

But transformer size isn't really a factor: a T14 ( used in Elam251, C12/24,...) is subminiature but these mic doesn't lack bass.

But as i told you previously i've used 1538xl and a Carnhill vtb 2291 (on this kind of cf) and there was different 'sound' but i settled on the 1538xl...

An other important point is how you'll bias the capsule and how it'll be conected to your tube grid. 😉

Any triode able to put a bit of current is a wiser choice imho, what matter for this kind of aplication ( mic) is that the tube is non microphonic ( the least possible) and it accept 'weird' grid current ( with 1g or more grid resistors for some circuit it is 'fringe' design) and low currents ( between 0,5ma to 3ma is the range for the circuits i played with- i found CF allowed a bit more current than grounded cathode) and the cathode to be 'non polluted' ( if you encounter intermitent popcorn noise, ploc,... it might be worth trying 'rejuvenating tube' as it will be unusable for mic circuit if the symptoms are presents anyway...).

I had great success with subminiature 6021(a small 6sn7 kind) and their russian equivalent.

Why do you want to use a 4:1 ratio?

It should be defined from the output impedance from your cf in my experience. But it is non critical ( tube circuits are forgiving).

The psu of original is big and heavy for a mic psu yes, but it integrate 2x transformers ( psu and signal) and a tapped inductor so it's bulky.

But transformer size isn't really a factor: a T14 ( used in Elam251, C12/24,...) is subminiature but these mic doesn't lack bass.

But as i told you previously i've used 1538xl and a Carnhill vtb 2291 (on this kind of cf) and there was different 'sound' but i settled on the 1538xl...

An other important point is how you'll bias the capsule and how it'll be conected to your tube grid. 😉

Last edited:

Hi , the 4:1 came from reading through a lot of forum threads and this was the ratio most often mentioned , although not the only one. I thought since I was winding it myself I could wind with taps at 2:1 , 4:1 , 6:1 , 8:1 and see what sounded best.

I have no expectations of how well the size will work or if it matters , but without buying high-nickel laminations it seems a reasonable way to go - besides the fact that my fingers and my eyesight prefer thicker wire these days!

I have no expectations of how well the size will work or if it matters , but without buying high-nickel laminations it seems a reasonable way to go - besides the fact that my fingers and my eyesight prefer thicker wire these days!

Ok. You'll have fun with transformer!

Yes don't be scared to experiment. Small Tube circuit like that are hard to break and react a lot to changes.

I already told you but i had filament/cathode leakage in one circuit with 5840, i had to elevate the filament reference some 30 or 60v above ground to solve it. This can happen and sound different than 'popcorn noise'.

About tubes: i played with 'classics' (and relative like ef14), ef806, 6072,... some of them are nice but: i found lot more reject than with subminis. Often because of microphonics and popcorn noise. Subminiatures are for most of them less prone to microphonic ( i think the frame are more sturdy relative to size so less vibrations) and their small size is a plus for microphones. And they are the 'latest' breakthrough the technology seen before swan song ( so more advanced designs).

There is some gems in them ( as well as some bigger octal metal russian tube and subminis- some russian sub are used in place of ac701k with great success!).

My experience with 6au6 is with the ones used in C800g. So they were selected items bought directly at Sony. In the c800g you always have two spares one availlable if the one in the mic die: they used the 6au6 as diode/rectifiers in the mic's psu!

You'll mod an existing microphone or you have a body and buy differents parts?

Yes don't be scared to experiment. Small Tube circuit like that are hard to break and react a lot to changes.

I already told you but i had filament/cathode leakage in one circuit with 5840, i had to elevate the filament reference some 30 or 60v above ground to solve it. This can happen and sound different than 'popcorn noise'.

About tubes: i played with 'classics' (and relative like ef14), ef806, 6072,... some of them are nice but: i found lot more reject than with subminis. Often because of microphonics and popcorn noise. Subminiatures are for most of them less prone to microphonic ( i think the frame are more sturdy relative to size so less vibrations) and their small size is a plus for microphones. And they are the 'latest' breakthrough the technology seen before swan song ( so more advanced designs).

There is some gems in them ( as well as some bigger octal metal russian tube and subminis- some russian sub are used in place of ac701k with great success!).

My experience with 6au6 is with the ones used in C800g. So they were selected items bought directly at Sony. In the c800g you always have two spares one availlable if the one in the mic die: they used the 6au6 as diode/rectifiers in the mic's psu!

You'll mod an existing microphone or you have a body and buy differents parts?

I have a mic body , plenty big enough. I've been looking at subminis and that would seem a way to go if I want to do more with mics. This schematic has heaters rectified to dc and at 2/3 of B+ so I'll probably do the same to start with.

As you say , lots of room to experiment.

As you say , lots of room to experiment.

We don't try to "match" a CF. Here the Zout is about 2K pull-up and 100K pull-down. For BIG signals we would try to load in over 200K (not practical in wideband transformer). Since signals are a small fraction of supply we may not clip. We still want hi-Z to reduce THD, low-Z to increase output level (though this is rarely a problem). Higher current in the CF improves the electrical situation but cooks the poor diaphragm.should be defined from the output impedance from your cf in my experience.

Yeah, throw in 4:1 (3200:200r) and call it done.

... Higher current in the CF improves the electrical situation but cooks the poor diaphragm.

Hi PRR,

Are you talking in general or about the C37 circuit?

For C37 i see cooking of capsule could happen from the very high b+ (diaphragm could be 'sucked' to backplate) and indeed higher current means higher grid current leakage, so damage could come from this?

Talking about Sony and current in tube mic capsule biasing, what are the advantage you could see from c800g capsule's biasing schem where they used something like almost a milliamp to this task? Apart for lowering noise a bit ( lower resistance used in the voltage divider (187k/47k) i still wonder why they made this choice? Even more as it ask for 47uf for bypass capacitor...

Do you have an idea on this PRR?

That´s the point.saying the mic ot was as big as a small amp ot

.......

without buying high-nickel laminations it seems a reasonable way to go - besides the fact that my fingers and my eyesight prefer thicker wire these days!

A proper, modern,commercially wound transformer will be, say, thumb tip size, use precisely cut high quality laminations and very very fine wire.

Not "impossible" but "not practical" for a DIYer so in general it´s better bought ready made.

In a few cases, now and then I need a line level size OT, because user/situation requires true floating / galvanically isolated output, the usual active balanced out does not cut it, and in that case only I dare to wind it.

Typically 1:1 out, since I do "everything else" active, and low impedance (150 to 600 ohm) which reduces needed turns, also allowing slightly thicker wire, and wound on regular silicon steel cores, the whole set of "relaxed" parameters making it "doable".

I fear you are working with a higher impedance values,those complicate wire choice (very thin) and winding (eyesight plus easier breaking) but hey, try it anyway.

I suggest you couple a small DC motor to the winding spindle with a pulley on each (check model plane or similar shops) and couple them using a thin office type rubber band.

It will soften coupling and worst case slip or break without breaking thin wire which is VERY frustrating (don´t ask).

- Home

- Amplifiers

- Tubes / Valves

- Mic Output Transformer Windings