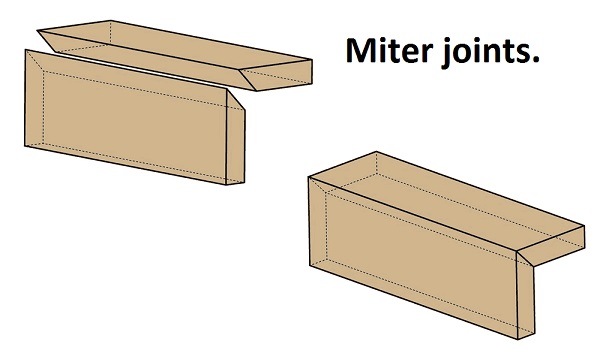

Hi guys, what do you think about this? I think that definitely, the best or more convenient method to joint the boards of our MDF enclosures, is to do miter joints.

Why? because I think that when we talk about MDF joinery, the hard work is always made by the glue, and screws do almost nothing because MDF is very fragile in the edge. So keeping this in mind, I thought that if glue does the hard work, you definitely want more glue contact area between boards, so it obviously would result in a stronger joint and without the need of any screw.

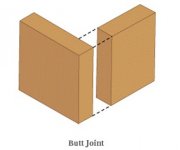

Working with 3/4 MDF. When you do simple (butt) joints, there will only be 19mm of glue contact area, but when you do miter joints, you find that contact area now has increased to 28mm! which means that now there's more surface area for glue, which will result in a stronger joint without the need of any screw.

Only problem with this method, is that when you do butt joints, screws help to keep all pieces together while glue dries, thing that may not be possible with miter joints, that minor problem can easily solved by making two angles, so you clamp the boards while glue dries, I made two for my projects, they are very useful for any enclosure construction task.

I just designed a one foot enclosure for a 8" subwoofer, and will joint every board with the miter joint method, hope to have this done soon.

Why? because I think that when we talk about MDF joinery, the hard work is always made by the glue, and screws do almost nothing because MDF is very fragile in the edge. So keeping this in mind, I thought that if glue does the hard work, you definitely want more glue contact area between boards, so it obviously would result in a stronger joint and without the need of any screw.

Working with 3/4 MDF. When you do simple (butt) joints, there will only be 19mm of glue contact area, but when you do miter joints, you find that contact area now has increased to 28mm! which means that now there's more surface area for glue, which will result in a stronger joint without the need of any screw.

Only problem with this method, is that when you do butt joints, screws help to keep all pieces together while glue dries, thing that may not be possible with miter joints, that minor problem can easily solved by making two angles, so you clamp the boards while glue dries, I made two for my projects, they are very useful for any enclosure construction task.

I just designed a one foot enclosure for a 8" subwoofer, and will joint every board with the miter joint method, hope to have this done soon.

Attachments

Last edited:

I use miter joints on all my MDF box builds. My trick is to use low-tack duct tape to join all the pieces inside up. Then you put on the wood glue and smooth it out and then just fold up the box and tape the last two edges together. Leave it to dry for an hour or more and you're done. Works great, super easy and WAY more stable than trying to use clamps.

Wow that's interesting, and what about bracing for the internal edges? For the 1 cubic foot enclosure I am making, I am planning to use some 19x19x80mm blocks that I made in order to reinforce the corners, I designed about half liter of them (about 19 pieces), and will place them strategically along the corners, all of them glued only.

I use miter joints on all my MDF box builds. My trick is to use low-tack duct tape to join all the pieces inside up. Then you put on the wood glue and smooth it out and then just fold up the box and tape the last two edges together. Leave it to dry for an hour or more and you're done. Works great, super easy and WAY more stable than trying to use clamps.

Attachments

Last edited:

I typically used window braces cut in a dado glued in while I wrap it all up. If you really need corner blocks you can add prior to gluing the ends. I typically don't see any reason (nor do they really add structural rigidity) after using 3/4-1" MDF and braces.

Paul

Paul

I agree with the miter strategy. Plus they look so much better than butt joints. Keeps exposed end grain to a minimum.

A bit of feedback on the square blocks to support the miter joints.......consider cutting the square block in half with a 45 degree angle from corner-to-corner. You will get the same support on each miter joint, but you would eliminate the "unused" half of the support block that is not contacting wood.

A bit of feedback on the square blocks to support the miter joints.......consider cutting the square block in half with a 45 degree angle from corner-to-corner. You will get the same support on each miter joint, but you would eliminate the "unused" half of the support block that is not contacting wood.

A bit of feedback on the square blocks to support the miter joints.......consider cutting the square block in half with a 45 degree angle from corner-to-corner. You will get the same support on each miter joint, but you would eliminate the "unused" half of the support block that is not contacting wood.

I initially planned to do it like you say, triangles, but because I only have a circular saw and a guide to do the cuts

, I thought I would have problems making those thin cuts (I can only attack by a side, so the circular saw has place to seat and be stable while cutting), but after all I just realized it can be done doing everything by just one side, so I will do it like this. Thanks.

, I thought I would have problems making those thin cuts (I can only attack by a side, so the circular saw has place to seat and be stable while cutting), but after all I just realized it can be done doing everything by just one side, so I will do it like this. Thanks.Attachments

Last edited:

The miter joints sure do look nicer. Not sure if the additional surface area really helps from a bonding standpoint, though. If anything, I would say that it's disadvantageous if your angles are off even the smallest amounts or cuts deviate from straight, yielding very minimal contact area for glue up. This is where butt joints are much more forgiving, however; as stated before, the exposed end grain is the obvious downside. I guess it really all depends on the finish being applied to the cabinet.

sent from my mobile look-at device

sent from my mobile look-at device

Double rabbit.

More surface, clamps still work without the pieces sliding around and you can still use screws or brads to hold things together.

DT

Wow, that's also an unbeatable way to joint the mdf enclosure, if I knew about this before, I would rather apply it to my enclosure instead, but I just already did some miter cuts to my boards. One still can say that miter joints win aesthetically, thing that does not matter when you are going to carpet the enclosure, which was my case.

Double rabbit.

More surface, clamps still work without the pieces sliding around and you can still use screws or brads to hold things together.

DT

+1...really need to try that on the next project.

Paul

Double rabbit is fine if you do not use material that has veneer already attached or plan on adding veneer later or other finish like material.

I wish I had the skills to make nice mitre joints using pre-veneered mdf or ply.

We made all the kitchen cabinets, in the living room, with 3/4"(19mm) maple veneer ply from HD, butt joints, brads, iron on tape, 4 coats of water based polyurethane.

I wish I had the skills to make nice mitre joints using pre-veneered mdf or ply.

We made all the kitchen cabinets, in the living room, with 3/4"(19mm) maple veneer ply from HD, butt joints, brads, iron on tape, 4 coats of water based polyurethane.

I always treat any veneer as a separate operation.

I just butt the straight cut parts together with a tiny bit hanging over, and then router and sand it off.

The small difference in contact area has been made up by the fact that you can clamp much better with this arrangement. Always use quality yellow wood glue, never had anything come apart even after ten years in a hot and cold attic.

I just butt the straight cut parts together with a tiny bit hanging over, and then router and sand it off.

The small difference in contact area has been made up by the fact that you can clamp much better with this arrangement. Always use quality yellow wood glue, never had anything come apart even after ten years in a hot and cold attic.

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Miter joints for MDF enclosures because glue covers much more.