Paul Voigt was an audio pioneer, who left a legacy of patents that is fundamental to high quality reproduction today. One of his classic achievements is the Voigt Domestic Corner Horn.

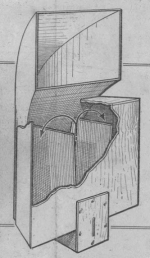

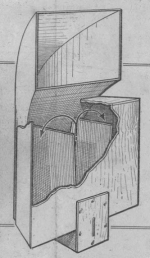

While I think it is probably more famous, it is actually a domestic adaptation of his Voigt Tractrix cinema horn. That was a square tractrix horn with probably a fullsize hornmouth for the calculated cutoff frequency. The domestic cornerhorn is intended to be placed in a corner, and has the horn pointing up. Because of the boundary loading, it has a smaller hornmouth and because the horn is pointing up, it also doesn’t stick out into the room as much. It is the smallest way to make a large frontloaded horn. Voigt added/integrated a quarter wave pipe to add bass to his fronthorn design.

While the big Western Electric Cinema horns are quite different (because they use a compression driver, a lot more length etc), the corner horns are similar in having a wide range and having a large mouth area.

I think anyone who has ever played around with building frontloaded horns for fullrange driver has probably experienced that bigger fronthorns have a more dynamic sound and a larger scale. There are of course also downsides, for instance that large horns beam a lot. Voigt solved this by adding an elaborate reflector to his horns. Instead of a simple 45 degree reflector or a single curve, he has a double curve reflector.

During and after World War II, materials for these loudspeakers were in short supply in England, and Voigt created a simplified cabinet design that could be made with fewer materials and made by consumers themselves. It was called the Voigt Home Constructors’Corner Horn. I am not entirely certain, but I think they are the same in terms of horn parameters, just laid out to use materials a bit more efficiently and to reduce complexity for the homebuilder.The reflector is now reduced to a single curve. I have actually seen photos of a version by a DIY-er that had added a reflector from the earlier model.

Due to its elegant simplicity, I believe the Home Constructor’s Horn is an ideal horn for DIY-ers that want to make ridiculously low frontloading horns for their fullrange drivers. We should/could basically use the existing plans to make our own horns for our drivers and requirements. However, it really helps when we know the horn parameters and can use them for simulations in software like hornresp or other software options. That way we can select suitable drivers, or adjust/scale the horn design to our drivers of choice.

So what we really need, is to understand and intimately know the horn. In this thread, I intend to ask questions and use some of your conscious and unconscious knowledge to assemble the best model and understanding of the Home Constructors’ Horn.

While I think it is probably more famous, it is actually a domestic adaptation of his Voigt Tractrix cinema horn. That was a square tractrix horn with probably a fullsize hornmouth for the calculated cutoff frequency. The domestic cornerhorn is intended to be placed in a corner, and has the horn pointing up. Because of the boundary loading, it has a smaller hornmouth and because the horn is pointing up, it also doesn’t stick out into the room as much. It is the smallest way to make a large frontloaded horn. Voigt added/integrated a quarter wave pipe to add bass to his fronthorn design.

While the big Western Electric Cinema horns are quite different (because they use a compression driver, a lot more length etc), the corner horns are similar in having a wide range and having a large mouth area.

I think anyone who has ever played around with building frontloaded horns for fullrange driver has probably experienced that bigger fronthorns have a more dynamic sound and a larger scale. There are of course also downsides, for instance that large horns beam a lot. Voigt solved this by adding an elaborate reflector to his horns. Instead of a simple 45 degree reflector or a single curve, he has a double curve reflector.

During and after World War II, materials for these loudspeakers were in short supply in England, and Voigt created a simplified cabinet design that could be made with fewer materials and made by consumers themselves. It was called the Voigt Home Constructors’Corner Horn. I am not entirely certain, but I think they are the same in terms of horn parameters, just laid out to use materials a bit more efficiently and to reduce complexity for the homebuilder.The reflector is now reduced to a single curve. I have actually seen photos of a version by a DIY-er that had added a reflector from the earlier model.

Due to its elegant simplicity, I believe the Home Constructor’s Horn is an ideal horn for DIY-ers that want to make ridiculously low frontloading horns for their fullrange drivers. We should/could basically use the existing plans to make our own horns for our drivers and requirements. However, it really helps when we know the horn parameters and can use them for simulations in software like hornresp or other software options. That way we can select suitable drivers, or adjust/scale the horn design to our drivers of choice.

So what we really need, is to understand and intimately know the horn. In this thread, I intend to ask questions and use some of your conscious and unconscious knowledge to assemble the best model and understanding of the Home Constructors’ Horn.

And my first question. Attached is a posthumous interview of Voigt by Bruce Edgar. Bruce Edgar made horn design accessible for DIY-ers and did have contact with Voigt to come to an interview for Speakerbuilder magazine. They had several conversations over phone, but in the end did not meet in person. Voigt's widow sent Bruce part of Voigt's archive and he used both this information and the telephone conversations as th basis for his mock/simulated interview.

What grabs my attention here, is that Voigt/VirtualVoigt says that the corner horn is a quarter of the square traxctrix horn, with a reflector placed above it. To me, this suggests that only the part of the horn pointing straight up is part of the intended horn design. And that the part of the Home Constructor's Horn above the straight section is merely a reflector.

The Cinema is referred to as a "four foot horn" in all references I have found. English is not my first language and I wonder what this means. Does it mean 4 feet times four feet"? Or does it mean "two feet times two feet"?

What grabs my attention here, is that Voigt/VirtualVoigt says that the corner horn is a quarter of the square traxctrix horn, with a reflector placed above it. To me, this suggests that only the part of the horn pointing straight up is part of the intended horn design. And that the part of the Home Constructor's Horn above the straight section is merely a reflector.

The Cinema is referred to as a "four foot horn" in all references I have found. English is not my first language and I wonder what this means. Does it mean 4 feet times four feet"? Or does it mean "two feet times two feet"?

Attachments

Last edited:

Dave, yes and no. It´s big and clunky and in modern times we work to reduce reflections and timing smearing. Yet we also design drivers with a high Xmax for dynamic range and use phase plugs and reflectors and waveguides to achieve a desired frequency response and directivity profile. Dynamic range, frequency response and directivity profile are exactly what Voigt targeted with his corner horn.

Thanks, that clears some things up for me.Means either 4 ft high or 4 ft axial length to me, but it's 5 ft tall, though it's terminus is ~2 x 2 ft = 4 square ft (4^2').

To complete this:Means either 4 ft high or 4 ft axial length to me, but it's 5 ft tall, though it's terminus is ~2 x 2 ft = 4 square ft (4^2').

Sides of the square horn are: 2 ft = 60.96cm

The area of the square horn are: 60.96^2 = 3716,1216cm^2

The corner horn has a horn mouth that is 1/4 of the full square mouth: 3716,1216 / 4 = 929,0304^2.

These are not exact numbers, but pretty close and give us a reference to determine whether the horn mouth of the corner horn is indeed the end of the vertical section, or whether it's actually the opening after the reflector, aiming straight at the listener.

I have calculated the area of the vertical section before the reflector, and the opening after the reflector aiming straight at the listener.

End of vertical section before the reflector: 1089,161128 cm^2

Opening after the reflector aiming straight at the listener: 3239,116038 cm^2

In the previous post, I concluded that the mouth of the corner horn is around 929,0304 cm^2. Comparing this to the two values calculated in this post, the end of the vertical section before the reflector has an area that is much (much!) closer than the other value. So I consider the end of the vertical section before the reflector confirmed as the actual horn mouth. It's interesting that the other value is quite close to the full size horn mouth. This might affect the acoustic behaviour of the horn. Something to be studied in a hornresp model and an actual construction.

So, the horn mouth is 1089.161128 cm^2 and the curved section/reflector is separate from the horn. When modeing the performance of the horn, chose this value as hornmouth.

End of vertical section before the reflector: 1089,161128 cm^2

Opening after the reflector aiming straight at the listener: 3239,116038 cm^2

In the previous post, I concluded that the mouth of the corner horn is around 929,0304 cm^2. Comparing this to the two values calculated in this post, the end of the vertical section before the reflector has an area that is much (much!) closer than the other value. So I consider the end of the vertical section before the reflector confirmed as the actual horn mouth. It's interesting that the other value is quite close to the full size horn mouth. This might affect the acoustic behaviour of the horn. Something to be studied in a hornresp model and an actual construction.

So, the horn mouth is 1089.161128 cm^2 and the curved section/reflector is separate from the horn. When modeing the performance of the horn, chose this value as hornmouth.

I would look at this thread and try contacting with the gentleman. Trieu could shed a lot of light on you quest.

He is very good at analyzing these older designs.

https://hifihaven.org/index.php?threads/voigt-domestic-corner-horn.5240/

He also has been been working on Western Electric horn modeling aswell.

He is very good at analyzing these older designs.

https://hifihaven.org/index.php?threads/voigt-domestic-corner-horn.5240/

He also has been been working on Western Electric horn modeling aswell.

@Ivo you seem to have it bad, so (when you get some free time to sit) check out some of the many references conveniently cited in the PFM voigt thread. if you haven't already.

Interesting none the less. The plans seem to be referenced a lot to being minimal low cost post war Lowther PW1

Compared to more elaborate designs like shown in post#5

Front loaded Tractrix Horn horn with 100 Hz cut off

Just follow the plans I guess, You could use the Horn Wizard in Horn Response to design a 100 Hz Tractrix Horn

for a 6" speaker of choice. The original design was for PM1/ PM2 Lowther 6" field coil speakers

It is just Tractrix Horn so you have minimal mouth size to achieve 100 Hz cutoff. Using the formula if the horn is made minimal size

it will be longer to get 100 Hz. Quick glance is likely what was done explaining such long length. To reduce the mouth size.

Normal everyday Tractrix which will emphasize the low-end as far as efficiency. To get high end from such a large horn.

Basic cheap 6" full range with rising top end response will work well.

Most people would use a low Qts .3 or so speaker for a modern horn. Rear chamber is really small.

Assuming the lowther field coil was completely opposite being typical High Qts .5 or higher radio speaker would explain the massive

Rear chamber. Quoted as rear horn at 50 Hz = blah blah blah being a just a ported rear chamber tuned to 50 Hz

with huge down firing vents.

Compared to more elaborate designs like shown in post#5

Front loaded Tractrix Horn horn with 100 Hz cut off

Just follow the plans I guess, You could use the Horn Wizard in Horn Response to design a 100 Hz Tractrix Horn

for a 6" speaker of choice. The original design was for PM1/ PM2 Lowther 6" field coil speakers

It is just Tractrix Horn so you have minimal mouth size to achieve 100 Hz cutoff. Using the formula if the horn is made minimal size

it will be longer to get 100 Hz. Quick glance is likely what was done explaining such long length. To reduce the mouth size.

Normal everyday Tractrix which will emphasize the low-end as far as efficiency. To get high end from such a large horn.

Basic cheap 6" full range with rising top end response will work well.

Most people would use a low Qts .3 or so speaker for a modern horn. Rear chamber is really small.

Assuming the lowther field coil was completely opposite being typical High Qts .5 or higher radio speaker would explain the massive

Rear chamber. Quoted as rear horn at 50 Hz = blah blah blah being a just a ported rear chamber tuned to 50 Hz

with huge down firing vents.

I've seen his work, yes. He didn't do the home constructor's horn yet, I believe. I may contact him, or respond to his threads over there. Exchange ideas.I would look at this thread and try contacting with the gentleman. Trieu could shed a lot of light on you quest.

He is very good at analyzing these older designs.

https://hifihaven.org/index.php?threads/voigt-domestic-corner-horn.5240/

He also has been been working on Western Electric horn modeling aswell.

I have the urge to know the insides of this horn very well, so I like to do the calculations and comparisons myself. I also appreciate the knowledge and extra eyes available here. I learned everything on just a few interesting forums, and this is both enjoying that, and giving others the opportunity to get interested and involved as well.

Yes, lots of stuff in that thread! After reading through a lot of it, my abbreviation of it is that the basic principles are well documented, but actual specifications are missing. Not strange, they were commercial products and the intellectial property was his livelihood.@Ivo you seem to have it bad, so (when you get some free time to sit) check out some of the many references conveniently cited in the PFM voigt thread. if you haven't already.

What I want to know is how he put his theoretical-mathematically derived design into a practical loudspeaker design. When we understand exactly how he made the corner horns, we can model response of different drivers accurately, but we can also "roll our own" horns of different expansion types and different sizes. That's what I want to know.

Interesting none the less. The plans seem to be referenced a lot to being minimal low cost post war Lowther PW1

Compared to more elaborate designs like shown in post#5

Front loaded Tractrix Horn horn with 100 Hz cut off

Just follow the plans I guess, You could use the Horn Wizard in Horn Response to design a 100 Hz Tractrix Horn

for a 6" speaker of choice. The original design was for PM1/ PM2 Lowther 6" field coil speakers

It is just Tractrix Horn so you have minimal mouth size to achieve 100 Hz cutoff. Using the formula if the horn is made minimal size

it will be longer to get 100 Hz. Quick glance is likely what was done explaining such long length. To reduce the mouth size.

Normal everyday Tractrix which will emphasize the low-end as far as efficiency. To get high end from such a large horn.

Basic cheap 6" full range with rising top end response will work well.

Most people would use a low Qts .3 or so speaker for a modern horn. Rear chamber is really small.

Assuming the lowther field coil was completely opposite being typical High Qts .5 or higher radio speaker would explain the massive

Rear chamber. Quoted as rear horn at 50 Hz = blah blah blah being a just a ported rear chamber tuned to 50 Hz

with huge down firing vents.

View attachment 1417411View attachment 1417412

View attachment 1417415View attachment 1417421

Two things:

- If you look at the very drawing you posted, it is definitely a tapered pipe, split in two paths. Kind of like a Voigt W-horn. It's visible in photographs of physical specimens of these horns. If you have built a variety of tapered pipes/pipe horns, it is a feasible design.

- In the available literature, Voigt says the horn has strong response to 100 Hz. A Tractrix horn does not have strong response down to its calculated cutoff. Its actual acoustic cutoff is sqrt(2)*Fc. So to achieve the an acoustic 100 Hz Fc as Voigt describes of his corner horn, you would need to design a horn with a cutoff of Fc/sqrt(2)= ~70 Hz.

- I think I need a few more days to confirm, but today I calculated the Fc of the most certain stretch of the horn, and its Fc does indeed appear to be 70 Hz.

To get high end from such a large horn.

Basic cheap 6" full range with rising top end response will work well.

Most people would use a low Qts .3 or so speaker for a modern horn. Rear chamber is really small.

Assuming the lowther field coil was completely opposite being typical High Qts .5 or higher radio speaker would explain the massive

Rear chamber.

Yes the original driver was a 6" field coil driver. Voigt commented that many drivers in the range of 5" to 8" would benefit from the horn. In some preliminary sims, I get the impression that Qts ~0.5 works best, but lower Qts performs fine as well. As you say, a complimentary rising top end is necessary for treble extension of the horn. No issue with Voigt/Lowther drivers, but there are some modern and budget options out there as well. Particularly Sica PA fullrange drivers seem very suitable. They are very affordable. Also very popular with horn fans in Europe.

Looks really fun for a corner build. The large rear chamber area leaves a lot of potential to play around with wood veneer.

The visual appearance could be rather stunning with veneer patterns. Another horn could be added for high end too.

Great introduction, was nice to have something new to search for and look at. The original plans conveniently posted.

Or inspiration to play around with lengths. My old phone got smashed so lost pictures of a recent Tractrix build.

Think everyone should just enjoy building least one Tractrix Horn. Something that crossed my mind was a low frequency cutoff up firing.

Here is a actual real world example from the 40's. Pretty fun search for more examples.

The visual appearance could be rather stunning with veneer patterns. Another horn could be added for high end too.

Great introduction, was nice to have something new to search for and look at. The original plans conveniently posted.

Or inspiration to play around with lengths. My old phone got smashed so lost pictures of a recent Tractrix build.

Think everyone should just enjoy building least one Tractrix Horn. Something that crossed my mind was a low frequency cutoff up firing.

Here is a actual real world example from the 40's. Pretty fun search for more examples.

As mentioned playing around with the Horn Wizard for Tractrix in Horn Response will really be a fun experience for you.We can also "roll our own" horns of different expansion types and different sizes. That's what I want to know.

Understanding the math between Horn size and length. Then being able to see the response quickly in software.

Really opens up a fast learning curve understanding how the Tractrix formula works. Has error warnings as well for too small or too large Horns

and tells you if what your trying to do is not possible with length following the Tractrix formula. Then of course you can export

the design and make the patterns. Did a Tractrix pedal horn myself. Amazing priceless software. You can play with a little compression

as well to see the results for mid/ high-end

Moving on.

In the Bruce Edgar "interview", Bruce lets Voigt say that the corner horn is the quarter of a full square cinema horn, when you it over its diagonals. That would suggest that the horn expansion is derived from the mouth section of the horn, where the mouth flares out into a 90 degree angle. It doesn't look that way in the plans, but I figured I might check whether Voigt did indeed start calculating with a full mouth and cut it in the diagonal manner stated, or simply recalculated starting from a reduced mouth size.

I used hornresp to pump out several tractrix curves and did some shuffling and comparisons in Excel. It has become a very messy series of graphs, which I am hesitant to show. 🤣

I see that the curve derived from dividing a full tractrix curve by four does not overlay as well as simply starting the calculation from the quarter size mouth. So, I think Bruce Edgar went a little too far in his interpretation of Voigts intention/method here.

By entering the throat and mouth size into hornresp, it will calculate the proper expansion, You don't have to do calculations based on a full horn and manipulate them.

In the Bruce Edgar "interview", Bruce lets Voigt say that the corner horn is the quarter of a full square cinema horn, when you it over its diagonals. That would suggest that the horn expansion is derived from the mouth section of the horn, where the mouth flares out into a 90 degree angle. It doesn't look that way in the plans, but I figured I might check whether Voigt did indeed start calculating with a full mouth and cut it in the diagonal manner stated, or simply recalculated starting from a reduced mouth size.

I used hornresp to pump out several tractrix curves and did some shuffling and comparisons in Excel. It has become a very messy series of graphs, which I am hesitant to show. 🤣

I see that the curve derived from dividing a full tractrix curve by four does not overlay as well as simply starting the calculation from the quarter size mouth. So, I think Bruce Edgar went a little too far in his interpretation of Voigts intention/method here.

By entering the throat and mouth size into hornresp, it will calculate the proper expansion, You don't have to do calculations based on a full horn and manipulate them.

- Home

- Loudspeakers

- Full Range

- Reconstructing the Voigt Home Constructors' Horn