Hi, having an expensive and somewhat high performance subwoofer be out of order some 13 months out of warranty and met by several hundred of dollars (excluding shipping, fees and import tax) for a replacement amplifier is somewhat a sour customer experience. Now, SVS or their amp supplier 6-8 years ago (very likely this is a rebranded IMG Stage Line STA-400D with some custom DSP firmware and perhaps features added) won't supply anyone with a service manual or schematic 🙁

This post have 2 main reasons, the obvious one is to get my amp, safely, running. The other is to help other SVS customers with similar problems find this post and evaluate their situation and possible get some insights from our discussion. I'm hoping you EE experts can help the bass community [emoji16]

The symptom are: when powered on and fed a signal, the audio can be heard from the driver, only very very faint. The "power on LED" is on but no dials are having any effect on anything. Improper connected low level cable did produce some loud (!) 50Hz buzz from time to time during the unit's operational life. Could be the reason it stopped working but that's not 100% certain.

Other notes: Fuse ok. Internal connections ok. No components show any visible burn marks, holes or distress (cap tops ok). All solder joints I've looked at seems good. Have only checked 1 out of 3 power resistors (access to leads..), all look the same, fine.

Best guess from an amateur (watching eevblog and playing with an arduino for years are my qualifications [emoji23]): the limiter didn't shut down quick enough on one 50Hz occasion and some of the output stage was fried in some way.

Anyway, having another, identical (I hope) SB12-NSD but not being a EE by trade, I know I would not be qualified to troubleshoot this live, 220V and a floating ground but doing identical measurements on both amps off should shed some light into the issue. Said and done, I got the working one out and it's caps drained as well.

Pretty straightforward. A power supply board, input/control and then the output board. Cables were disconnected when measurements were taken and caps drained.

Out of all the measurements I've made (Fluke 87V) the only differences I've found are for the yellow marked smaller caps (most 16V, 10-22uF) on the "moset side" of the heat sink. They get their values (within 15%) on the working amp but show OL on the broken one..

Here's the output up close:

And some identified parts with their datasheets.

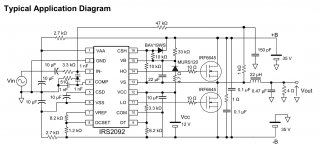

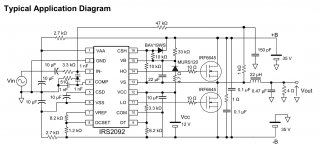

- IRS2092 amplifier (http://www.infineon.com/dgdl/irs2092.pdf?fileId=5546d462533600a401535675f1be2790) Example circuit looks pretty similar in regards to the resistors/caps value I've measured (in circuit)

- 2 IRF840 power MOSFETs (https://www.vishay.com/docs/91070/sihf840.pdf)

Given the above..

A. Would it be a good idea to desolder the small caps and replace them if they turn out to actually not be OK (out of circuit so to speak)?

B. Should I also remove the MOSFETs and measure them in my ebay-LCR meter/component tester?

C. Anything else to check/desolder at this stage?

D. Is there a logical explanation to why the small resistors, diodes and smd caps were measured ok but the through holed caps (seemingly) not? I would have thought to find some more discrepancies between the good and the bad amp.

E. Given I don't want to have 220V on my desk, can my 30V, 5A bench supply or my Analog Discovery be of any help here? How?

So, anyone care to give his or hers $0.02, I would be very thankful for thoughts. Hopefully helping other SVS owners with bad luck (or fumbling cable management).

[emoji120][emoji2309]

Regards

/Niclas

This post have 2 main reasons, the obvious one is to get my amp, safely, running. The other is to help other SVS customers with similar problems find this post and evaluate their situation and possible get some insights from our discussion. I'm hoping you EE experts can help the bass community [emoji16]

The symptom are: when powered on and fed a signal, the audio can be heard from the driver, only very very faint. The "power on LED" is on but no dials are having any effect on anything. Improper connected low level cable did produce some loud (!) 50Hz buzz from time to time during the unit's operational life. Could be the reason it stopped working but that's not 100% certain.

Other notes: Fuse ok. Internal connections ok. No components show any visible burn marks, holes or distress (cap tops ok). All solder joints I've looked at seems good. Have only checked 1 out of 3 power resistors (access to leads..), all look the same, fine.

Best guess from an amateur (watching eevblog and playing with an arduino for years are my qualifications [emoji23]): the limiter didn't shut down quick enough on one 50Hz occasion and some of the output stage was fried in some way.

Anyway, having another, identical (I hope) SB12-NSD but not being a EE by trade, I know I would not be qualified to troubleshoot this live, 220V and a floating ground but doing identical measurements on both amps off should shed some light into the issue. Said and done, I got the working one out and it's caps drained as well.

Pretty straightforward. A power supply board, input/control and then the output board. Cables were disconnected when measurements were taken and caps drained.

Out of all the measurements I've made (Fluke 87V) the only differences I've found are for the yellow marked smaller caps (most 16V, 10-22uF) on the "moset side" of the heat sink. They get their values (within 15%) on the working amp but show OL on the broken one..

Here's the output up close:

And some identified parts with their datasheets.

- IRS2092 amplifier (http://www.infineon.com/dgdl/irs2092.pdf?fileId=5546d462533600a401535675f1be2790) Example circuit looks pretty similar in regards to the resistors/caps value I've measured (in circuit)

- 2 IRF840 power MOSFETs (https://www.vishay.com/docs/91070/sihf840.pdf)

Given the above..

A. Would it be a good idea to desolder the small caps and replace them if they turn out to actually not be OK (out of circuit so to speak)?

B. Should I also remove the MOSFETs and measure them in my ebay-LCR meter/component tester?

C. Anything else to check/desolder at this stage?

D. Is there a logical explanation to why the small resistors, diodes and smd caps were measured ok but the through holed caps (seemingly) not? I would have thought to find some more discrepancies between the good and the bad amp.

E. Given I don't want to have 220V on my desk, can my 30V, 5A bench supply or my Analog Discovery be of any help here? How?

So, anyone care to give his or hers $0.02, I would be very thankful for thoughts. Hopefully helping other SVS owners with bad luck (or fumbling cable management).

[emoji120][emoji2309]

Regards

/Niclas

The description of the symptoms sounds like you have an input signal problem. That could be the input cable, the plug(s), potentiometer or internal cabling at fault. That includes the gnd/- aswell . Not the only possible problem but you can easily check that yourself if you have a multimeter.

The description of the symptoms sounds like you have an input signal problem. That could be the input cable, the plug(s), potentiometer or internal cabling at fault. That includes the gnd/- aswell . Not the only possible problem but you can easily check that yourself if you have a multimeter.

Thanks for your time and input, I just thought having the signal getting to the driver ruled that side out but I'll do some measurements on both and see if they show something. Adding a sinus tone to the input without any power supplied should help a bit on the input board?

Thanks for your time and input, I just thought having the signal getting to the driver ruled that side out but I'll do some measurements on both and see if they show something. Adding a sinus tone to the input without any power supplied should help a bit on the input board?

The 'faint' was the part which made me suspect a ground issue because you likely get 'some ground potential' from somewhere who knows but it makes the + less likely to be the issue. And yes, adding a sine makes it easier to follow the signal. The input stage or the pots are still not ruled out but that is a bit more complicated, let's just try to check and rule out the easier and faster parts.

The membrane isn't moving in (or out) and stays there when you hear the signal? That would be an indicator of one rail voltage or power transistor is faulty. Though, the power stage can be ruled out with quite high certainty, you would not get a very loud hum with it not working.

The pre stage with the level, phase and frequency pots is a further possible error source. After checking the cables, plugs and pots, the OPs for the filters etc are the next to test, measure then the positive and negative rail for them (if wrong -> power supply). If that checks working, it could be the OPs. It's possible to inject the signal after them but before doing that some precautions have to be taken (cap + resistor/voltage divider, if possible galvanic separation of the source signal) to protect the source and power stage.

The amplifier used is STA-400D Sledge with 400 watts RMS continuous power (800 watts peak dynamic power)

You can purchase it from SVS expert service here:

SVS Sound Experts Customer Support

but it is probably out of production. I would do an attempt

You can purchase it from SVS expert service here:

SVS Sound Experts Customer Support

but it is probably out of production. I would do an attempt

Last edited:

Try a powered down and discharged visual inspection then a check of all transistors for shorts. Less dangerous turned off and sometimes the careful visual inspection reveals something. Bad/loose connector etc etc

The amplifier used is STA-400D Sledge with 400 watts RMS continuous power (800 watts peak dynamic power)

You can purchase it from SVS expert service here: [...]

That's a valuable information. I haven't found a service manual yet but maybe it pops up somewhere. The amplifier is now over 10 years old, I doubt it's still available, and it will likely be expensive ..or just not available at all anymore.

From the pictures I've seen (thanks, Google!) it got a SMPS, which means it's potentially more dangerous than a linear power supply. So, if you don't exactly know what you're doing, maybe leave it to someone else because it can get dangerous.

Please don't be mad at me but if you can't fix it, there's still the option to get a different amplifier, the IRS2092 amps on ebay and ali are pretty cheap and quite good in the bass, your plate amp uses probably the IRS2092 driver IC too as it was common for many amps ~10 yrs ago. The TDA8954TH amps are also quite cheap in that power range. Please don't misunderstand me, I'm all for repairs and not trash amplifiers if it can be fixed for a reasonable price but that also depends on how much time for diagnostic it is worth for you and if you are confident enough to follow the search for the fault and repair.

Look for a MONACOR SAM-300D. It should have everything integrated.

That's a good replacement. If you got more identical subs, it can be a hassle to match the settings, pot scale positions will be different.

troubleshooting

The smaller ELE caps are measuring OL sounds like the low voltage rails feeding the IRS2092 are shorted. This can be confirmed by measuring resistance from IRS2092 Pin 2 (ground) to Pin 1 (~+5V,VAA) and Pin 2 to Pin 6 (~-5V,VSS). This should be measured with the output board not connected to the SMPS.

If the above is confirmed, we need find the source of the short. It could be the IRS2092. If you have the equipment to desolder the IC, I would start by removing it and repeating the above test on the IC out of circuit.

If the LV rails are still shorted, the two 5.1V zener diodes (D15, D16) used to regulate the +\-5V rails could be shorted. Remove from PCB to test.

If the LV rails are still shorted on the output PCB, one or more of the ten small signal NPN and PNP transistors could be shorted. Check the PN junction diode drops on the PCB first. If you find a short, remove the transistor from the PCB and retest to ensure there wasn't another shorted transistor on the PCB shorting out the one you first tested.

When you find the culprit, I suggest digging a little deeper to try and understand what happened before trying to power it back up.

Although the OP didn't specifically confirm this, I am assuming OP determined the problem was the output board by testing the good output board with the SMPS and Control board from the bad amp? This will have confirmed that the SMPS is not also at fault.

The smaller ELE caps are measuring OL sounds like the low voltage rails feeding the IRS2092 are shorted. This can be confirmed by measuring resistance from IRS2092 Pin 2 (ground) to Pin 1 (~+5V,VAA) and Pin 2 to Pin 6 (~-5V,VSS). This should be measured with the output board not connected to the SMPS.

If the above is confirmed, we need find the source of the short. It could be the IRS2092. If you have the equipment to desolder the IC, I would start by removing it and repeating the above test on the IC out of circuit.

If the LV rails are still shorted, the two 5.1V zener diodes (D15, D16) used to regulate the +\-5V rails could be shorted. Remove from PCB to test.

If the LV rails are still shorted on the output PCB, one or more of the ten small signal NPN and PNP transistors could be shorted. Check the PN junction diode drops on the PCB first. If you find a short, remove the transistor from the PCB and retest to ensure there wasn't another shorted transistor on the PCB shorting out the one you first tested.

When you find the culprit, I suggest digging a little deeper to try and understand what happened before trying to power it back up.

Although the OP didn't specifically confirm this, I am assuming OP determined the problem was the output board by testing the good output board with the SMPS and Control board from the bad amp? This will have confirmed that the SMPS is not also at fault.

That's a good replacement. If you got more identical subs, it can be a hassle to match the settings, pot scale positions will be different.

Unfortunately no amp will be a good replacement. The limiters and EQ are carefully calibrated to work with the woofer in the SB12-NSD cabinet.

Sure any amp driving the woofer will produce bass but the frequency response will be way off and there will be no protection from over driving the woofer.

You can of course be careful with the volume but if a track suddenly contains significant bass and you can't turn it down fast enough, permanent woofer damage is possible.

Having said all that, damage is much less likely in a sealed cabinet with 300-400W of power into this particular 12" driver.

Last edited:

Unfortunately no amp will be a good replacement. The limiters and EQ are carefully calibrated to work with the woofer in the SB12-NSD cabinet.

Sure any amp driving the woofer will produce bass but the frequency response will be way off and there will be no protection from over driving the woofer.

You can of course be careful with the volume but if a track suddenly contains significant bass and you can't turn it down fast enough, permanent woofer damage is possible.

Having said all that, damage is much less likely in a sealed cabinet with 300-400W of power into this particular 12" driver.

A subwoofer isn't rocket science. You can calculate the tuning by measuring the port and enclosure dimensions, that gives you the low cut frequency (tad below the fb). That means you are already safe in regards mechanical damage. The monacor SAM-300D plate amp got soft clipping and a bit less power, there's no danger there either.

For the EQ: Yes, there will be some differences but not much, you can't jerk-EQ anyway because that swallows tons of power. Like I already wrote, with a low cut there's no danger there. However, to make it a sealed sub robs it of at least 12dB on the lower end and maximum spl and that sounds so much differently I would definitely not recommend it if you want it to sound the same as before! There's nothing wrong in having a sealed enclosure but it will have a very early drop in the response because the enclosure is too big for sealed and needs a LOT more power if you want to compensate that with an EQ. If you want to go sealed, build a new enclosure that fits, that driver got the wrong parameters for sealed in that volume.

Nothing is rocket science except for rocket science 🙂

Based on his original post, do you really think the OP can properly modify the EQ ,dynamic multi-band limiter thresholds and their time constants? Oh, wait, the Monocor doesn't even have those.

Maybe he should design his own FPGA based DSP front end for the replacement amp too? 🙄

Based on his original post, do you really think the OP can properly modify the EQ ,dynamic multi-band limiter thresholds and their time constants? Oh, wait, the Monocor doesn't even have those.

Maybe he should design his own FPGA based DSP front end for the replacement amp too? 🙄

Nothing is rocket science except for rocket science 🙂

Based on his original post, do you really think the OP can properly modify the EQ ,dynamic multi-band limiter thresholds and their time constants? Oh, wait, the Monocor doesn't even have those.

Maybe he should design his own FPGA based DSP front end for the replacement amp too? 🙄

Hey guys, really appreciate the ideas and, in sphinx case, the very detailed and easy to follow steps and explanations. I have been short on quality time with the amp this past week but Saturday I'll go for it and very carefully take the smps out of the equation (I did not dare to power any of them up when out of their enclosures but I think I have the necessary respect and understanding for that now. And two steady hands). Then I'll do the steps around the IC and/or some sine wave to the input if I have the time.

Since the three boards are connected by leads, if the smps seems fine, I can possible swap in the known good output one to the bad amp (it can obviously be fully unmounted) and see if that will make it happy and prove the output side is at fault. Or if that won't fly, I'll have to measure more around the input board.

Thanks again everyone! [emoji120] Let's hope the US's Right to repair ruling/bill/law (?) is extending to Europe and also includes stuff like mandated service manuals be supplied on sales for electronic goods [emoji1694]

PS

I do have a miniDSP 2x4 in my audio chain and can peq two subs with that after some room measurements (calibrated umik 1 mic). Having two working subs in the end is my planned "reward" for going with another SB12-NSD and not just getting a used Crown amp (some even have DSP/PEQ built in) or similar for the same amount of money. And of course, learning a thing or two.

Based on his original post, do you really think the OP can properly modify the EQ ,dynamic multi-band limiter thresholds and their time constants? Oh, wait, the Monocor doesn't even have those.

The sub is not a PA-high-power-max-spl-sub. Unless he wants to use the subwoofer on 115dB levels for hours, there's no danger at all. Heck, the sub does not even have multi band limiters, it does not even have a single limiter! The only thing it got is EQ, lowcut and input level limit as soft clipping/peak limiter. Where do you get that nonsense from there are any multi-band limiters in place? That sub got a 3,15A/220V fuse, on 110V it got a 5A fuse, it got the same 'marketing power rating' as every other sub! No, that does not make it a bad sub but that shows you don't know anything about that sub at all, you've not even looked at the pictures of the sub!

Maybe he should design his own FPGA based DSP front end for the replacement amp too? 🙄

I've got the impression you don't even know that sub. Or in other words: you don't even know what you are talking about. Alone the suggestion to make it a sealed sub 'to be safe' shows how little knowledge you've got. Yes, the maximum excursion is limited but it also is on a lowcut. What else? The spl goes down by ~12dB. What happens then? Yes, he increases the gain, to get the same loudness like before. What does that mean for the amp? Instead of 100W which the amp and driver can easily handle he uses at least 400W! That means, the subwoofer has to dissipate four times the power. There isn't even the power compression in it! And why is that so bad? Because on a sealed enclosure there's no air exchange! That means, the driver can't dissipate the heat and the amp got to do really heavy work and goes to its limit. And you suggested that for 'safety'?!

Thanks again everyone! [emoji120] Let's hope the US's Right to repair ruling/bill/law (?) is extending to Europe and also includes stuff like mandated service manuals be supplied on sales for electronic goods [emoji1694]

Unfortunately, it does not extend to EU. And for an amp which was designed over 10 years ago, the law only covers a timespan of 7-10 years. That means, the subwoofer isn't covered in it. And even if it would be, the law got a lot of things excluded as it is mostly just applicable to larger companies. On many items it only covers replacable parts and since the ICs, transistors, resistors etc are mostly available or got substitutes, you will likely not get parts from them. What's irreplacable is the programming of the DSP. If the DSP is defective, you won't be able to get the amp to the former functioning state since you neither got the settings nor the programming hardware for it.

I do have a miniDSP 2x4 in my audio chain and can peq two subs with that after some room measurements (calibrated umik 1 mic). Having two working subs in the end is my planned "reward" for going with another SB12-NSD and not just getting a used Crown amp (some even have DSP/PEQ built in) or similar for the same amount of money. And of course, learning a thing or two.

You can replace the whoe amp, the DSP and the settings with your miniDSP. It will not be absolutely identical but you can get it very close. Unless you want to use the sub for an extended period of time close to the limit, you'll not have trouble using it. How the sub sounds is also a matter of placement in the room, please keep that in mind if you compare the subs to each other. REW can create a setup to compensate for that and it also replaces the programming of the internal dsp, the settings for both subs will differ but as it is compensated by REW, it does not actually really matter.

I bought 2 of these subs in non working condition at the distributor when I was buying an SB1000 for a great price. Both subs had failing plate amps so instead of tinkering with the amp I bought Dayton SPA250 dsp amps to replace the sledge amps and had to make a small wood plate because the dayton was a bit smaller than the original amp. REW and UMIK to adjust the EQ and the subs are happy now.

- Home

- Amplifiers

- Class D

- Repair a plate amp (SVS subwoofer). Weapon of choice: another plate amp?