I just obtained a PE 3046 turntable that I would like to repair (ca 1974-1978). The PE 3046 turntable features automatic playing, however, I can only get manual playing mode to work. I have obtained the German PE 3046 manual (which I can't read unfortunately) as well as the manual for the similar Dual 1226.

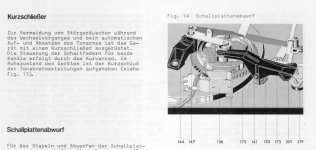

The problem is this: there is a cam in the turntable that activates a black lever (number 155 in the attached photo from the service manual) which both raises and lowers the tone arm, as well as pushes on another lever down and sideways, using friction to move the tonearm horizontally to move it from the tonearm rest to the edge of the record (number 201). Whatever surface treatment was used to provide this friction has worn away and therefore the black lever simply slips when pushing on the lever sideways and the tonearm does not move horizontally automatically.

If I disconnect the return spring, I can get it so that I can manually place the tonearm and play a record, however, I would like this feature to work. What can be done to restore the friction? It feels like some gritty material was used to provide it. I tried to place a piece of rubber between the two but it doesn't work, it seems to require a lot of force.

If anyone has experience repairing such friction mechanisms please let me know.

The problem is this: there is a cam in the turntable that activates a black lever (number 155 in the attached photo from the service manual) which both raises and lowers the tone arm, as well as pushes on another lever down and sideways, using friction to move the tonearm horizontally to move it from the tonearm rest to the edge of the record (number 201). Whatever surface treatment was used to provide this friction has worn away and therefore the black lever simply slips when pushing on the lever sideways and the tonearm does not move horizontally automatically.

If I disconnect the return spring, I can get it so that I can manually place the tonearm and play a record, however, I would like this feature to work. What can be done to restore the friction? It feels like some gritty material was used to provide it. I tried to place a piece of rubber between the two but it doesn't work, it seems to require a lot of force.

If anyone has experience repairing such friction mechanisms please let me know.

Attachments

What has happened is that the contact part of the arm --the operational area has worn away .

If this is plastic well that a natural occurrence what you need to do is a bit of practical engineering -not electrical but mechanical and ADD a hardened pad to the contact area of the arm--NOT what it contacts .

The only hard part is determining the cross-section of the pad and that is achieved by temporary adding layers to a pad to achieve the correct operation.

I take it if you use your hands you can operate the actual cam to prove its not jammed/stuck or even sticky ?

Take your time ,while it doesn't look like a precision piece of machinery it must operate within the correct working design --its not a "5 minute job " .

If this is plastic well that a natural occurrence what you need to do is a bit of practical engineering -not electrical but mechanical and ADD a hardened pad to the contact area of the arm--NOT what it contacts .

The only hard part is determining the cross-section of the pad and that is achieved by temporary adding layers to a pad to achieve the correct operation.

I take it if you use your hands you can operate the actual cam to prove its not jammed/stuck or even sticky ?

Take your time ,while it doesn't look like a precision piece of machinery it must operate within the correct working design --its not a "5 minute job " .

Perhaps the same viscous silicone material used on cue shafts could work. Give it a try.

I have some of this. Is this the same kind of silicone material you are talking about?

https://www.amazon.com/Mission-Automotive-Dielectric-Silicone-Waterproof/dp/B016E5E59G/

I've once repaired my old Pioneer TT and cleaned the shaft grease. Believe me I've tried everything even Araldite solo one component only and nothing worked. The arm descended too fast when the cue lever was released.

Then I had the idea and went to a bearing shop and asked for a sticky grease.

What worked was a tube of this stuff. It sticks to Your fingers.

OKS 1110 - Multi-Silicone Grease | OKS Spezialschmierstoffe GmbH

Then I had the idea and went to a bearing shop and asked for a sticky grease.

What worked was a tube of this stuff. It sticks to Your fingers.

OKS 1110 - Multi-Silicone Grease | OKS Spezialschmierstoffe GmbH

The problem is this: there is a cam in the turntable that activates a black lever (number 155 in the attached photo from the service manual) which both raises and lowers the tone arm, as well as pushes on another lever down and sideways, using friction to move the tonearm horizontally to move it from the tonearm rest to the edge of the record (number 201). Whatever surface treatment was used to provide this friction has worn away and therefore the black lever simply slips when pushing on the lever sideways and the tonearm does not move horizontally automatically.

The black Main Lever 155 - the paddle area that lifts and moves the arm - should have a mildly rough surface - it wears over time.

Removing the lever and you'll see a wear mark.

Re-rough it using emery cloth or sandpaper.

Inspect the lift pin that it contacts, there should be that famous plastic steurpimpl on the tip of the pin - this pimple wears, falls off, etc. new ones are available.

lastly, a smear - sparingly - of good old red wheel bearing grease on the paddle area.

I've done hundreds of Duals in the shop for customers.

Apparently "steuerpimpel" is the word I was looking for here. There appear to be many videos on youtube about replacing it, so it appears to be a common problem.

Replacement Steuerpimpel for Dual Turntables - YouTube

Dual turntable steuerpimpel replacement (701, 1209, 1219, 1229 etc.) - YouTube

Dual 1228 Turntable Video #6 - Another Steuerpimpel - YouTube

I am going to try to see if I can design and 3D print a new steuerpimpel. I can 3D print some friction patterns on the top of the part to try to improve the traction between the lever arm and the top of the steuerpimpel.

The pin that the steuerpimpel sits on appears to be 2 mm in diameter and about 4 mm tall (though getting my caliper in to measure that is a little difficult). If this works it shouldn't be difficult to provide the part for others to repair their turntables with.

Replacement Steuerpimpel for Dual Turntables - YouTube

Dual turntable steuerpimpel replacement (701, 1209, 1219, 1229 etc.) - YouTube

Dual 1228 Turntable Video #6 - Another Steuerpimpel - YouTube

I am going to try to see if I can design and 3D print a new steuerpimpel. I can 3D print some friction patterns on the top of the part to try to improve the traction between the lever arm and the top of the steuerpimpel.

The pin that the steuerpimpel sits on appears to be 2 mm in diameter and about 4 mm tall (though getting my caliper in to measure that is a little difficult). If this works it shouldn't be difficult to provide the part for others to repair their turntables with.

The black Main Lever 155 - the paddle area that lifts and moves the arm - should have a mildly rough surface - it wears over time.

Removing the lever and you'll see a wear mark.

Re-rough it using emery cloth or sandpaper.

Inspect the lift pin that it contacts, there should be that famous plastic steurpimpl on the tip of the pin - this pimple wears, falls off, etc. new ones are available.

lastly, a smear - sparingly - of good old red wheel bearing grease on the paddle area.

I've done hundreds of Duals in the shop for customers.

Apparently "steuerpimpel" is the word I was looking for here. There appear to be many videos on youtube about replacing it, so it appears to be a common problem.

Replacement Steuerpimpel for Dual Turntables - YouTube

Dual turntable steuerpimpel replacement (701, 1209, 1219, 1229 etc.) - YouTube

Dual 1228 Turntable Video #6 - Another Steuerpimpel - YouTube

I am going to try to see if I can design and 3D print a new steuerpimpel. I can 3D print some friction patterns on the top of the part to try to improve the traction between the lever arm and the top of the steuerpimpel.

The pin that the steuerpimpel sits on appears to be 2 mm in diameter and about 4 mm tall (though getting my caliper in to measure that is a little difficult). If this works it shouldn't be difficult to provide the part for others to repair their turntables with.

There are already suppliers for these steuerpimpels if you research the audio sites like vinylengine.com and other sites.

I'd highly recommend that approach instead of making them.

The "home made" ones that others have tried to make simply don't work properly, and become noisy chattering of the tonearms.

Additionally, these plastic tips are different for different models of Duals/PE.

Some have rounded tips, others flat, etc. And different dimensions.

It's not a "one size fits all" part.

- Home

- Source & Line

- Analogue Source

- Repairing PE 3046 automatic turntable