So I was giving my surrounds a renewal on a very old set of woofers and I noticed that one of the spiders was pretty concave down while the other was flat. I'm wondering which one these woofers is the "correct" one and which might be problematic? Is there any way to fix it that doesn't require replacing the spider?

From an educational perspective I'm also wondering what effects the out of place spider would have on the sound.

Thanks!

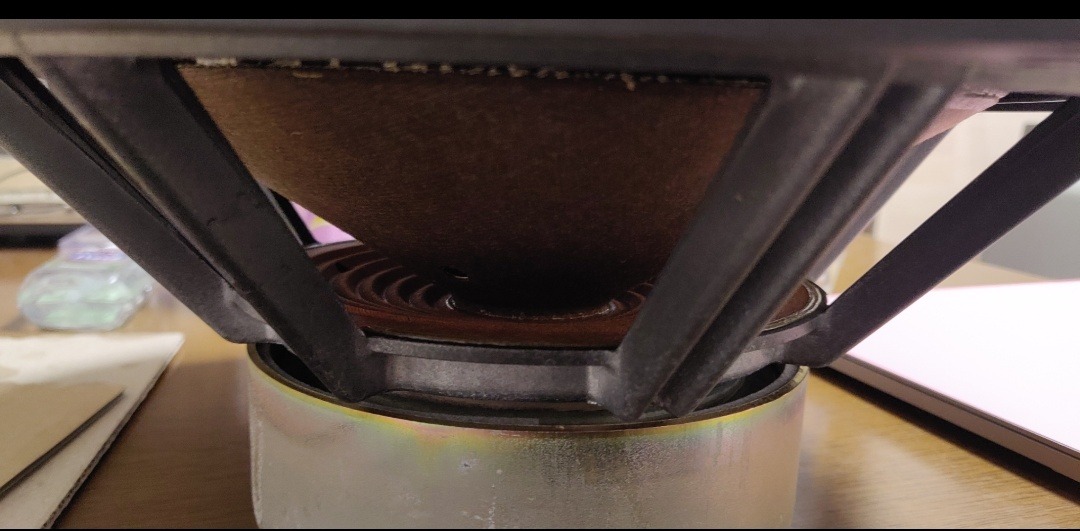

Woofer #1

Woofer #2

From an educational perspective I'm also wondering what effects the out of place spider would have on the sound.

Thanks!

Woofer #1

Woofer #2

Did you by chance have these stored in clamshell fashion on a shelf? If so, woofer 1 was on the bottom. You can try reversing them but it will take a long time to straighten them out. Do you have a way of testing these to see if they operate in a similar manner? In the future remember to store them as though they were mounted on a baffle and rotate them 180º every year.

You can reset the sagging cone and suspension fairly quickly by inverting it with some flat weights placed on the back of the cone so the suspension is being forced slightly outwards. Of course you need to make sure the woofers weight isn't resting on or touching the surround / cone when on its face. It would probably only take a day or two to fix it. Then you'll need to frequently rotate the drivers sitting face to face every so often.

The other possibly more important question is to ask is if the voice coil is centered in the gap up/down.

If you have an inductance meter you can measure inductance at center and see how many mm each way can you move the cone before inductance drops off.

Another less precise way to test is run a 500 hz tone at low volume and see how far each direction you can move the cone before you hear a drop in sound.

If response seems asymmetrical then you may see if laying the driver face down solves some of the problem.

Also, do the surrounds have the same amount of tension? It could be a matter of cone position when the surround was glued.

If you have an inductance meter you can measure inductance at center and see how many mm each way can you move the cone before inductance drops off.

Another less precise way to test is run a 500 hz tone at low volume and see how far each direction you can move the cone before you hear a drop in sound.

If response seems asymmetrical then you may see if laying the driver face down solves some of the problem.

Also, do the surrounds have the same amount of tension? It could be a matter of cone position when the surround was glued.

I’ve had luck lightly moistening the spider with water and using a rolled up towel to gently put the cone when it should be and letting it dry. Make sure it doesn’t rub in the correct looking position. If it does just leave it alone.

Thank you guys for the feedback, I'll give it a shot at straightening out the cone, but compared to the other one I think the sound is coming out fine. The voice coils do not rub when I press down as of yet.

Spiders are bought flat and in principle speaker assembler mounts them (before applying adhesive) without undue pressures so they stay flat.

So the concave one got that shape after assembly, and most probably because of poor/careless storage.

And yes, it indicates a voice coil winding not centered in the gap, in the axial direction.

But it will self-correct by itself when mounted in a cabinet and played loud and with lots of Bass.

So now you have an excuse to annoy neighbours and Family 🙂

So the concave one got that shape after assembly, and most probably because of poor/careless storage.

And yes, it indicates a voice coil winding not centered in the gap, in the axial direction.

But it will self-correct by itself when mounted in a cabinet and played loud and with lots of Bass.

So now you have an excuse to annoy neighbours and Family 🙂

There is no problem to the sound of the woofer with the concave spider as long a the voice coil is in the center of magnet gap and does not touch any side of the gap.

Voice coil must be centered not only in the gap thickness so as not to scratch either polepiece of top plate walls but also its winding length mus be centered relative to top plate thickness or displacement will not be symmetrical, creating lots of unneeded distortion.

X Max one way willbe very different from X Max the other way.

X Max one way willbe very different from X Max the other way.

I would think if it is laid face down on a suitable surface and run with not only a little bass as has been suggested but maybe if you use a hairdryer pointed it up at the spider intermittently that might help recondition it a little faster. I don't think the idea of strong weighting it is good. You are simply stretching it the other way, perhaps compounding the problem. I think what you want to do is allow gravity to do its job with a little assistance from the heat and maybe a small amount of weight but only things like a few coins, enough to speed the process but not reverse the sag.

Once the spider is stretched, its stretched.

It either needs replacing, or for a dodgy repair, you can add a stiffening product to it while you hold the spider back in its normal position (this stiffening process will change the spiders compliance)

Be careful applying heat to spiders, too much heat can deform them out of shape (been there done that 🙁 )

It either needs replacing, or for a dodgy repair, you can add a stiffening product to it while you hold the spider back in its normal position (this stiffening process will change the spiders compliance)

Be careful applying heat to spiders, too much heat can deform them out of shape (been there done that 🙁 )

In the OP's first post he doesn't make it clear:

The environments to be replaced were the original ones?

Were both changed in the same operation or were there intervals of time and/or environments of different origin? Could it be the case that only the environment was changed on the speaker with the sunken spider and a faulty job?

Because, in the event that both environments were the same and were replaced at the same time, if a very tight centering pin was used on the speaker with the spider sunken, and then the environment was glued.....there you have the result !

More data and/or photos are needed, or we are playing a guessing game.

The environments to be replaced were the original ones?

Were both changed in the same operation or were there intervals of time and/or environments of different origin? Could it be the case that only the environment was changed on the speaker with the sunken spider and a faulty job?

Because, in the event that both environments were the same and were replaced at the same time, if a very tight centering pin was used on the speaker with the spider sunken, and then the environment was glued.....there you have the result !

More data and/or photos are needed, or we are playing a guessing game.

Huh ? Ok so let it sit for a few years, use bitcoins to weight the coneHuh? Nothing was replaced

Sometimes it only takes a light application of surround doping compound like PVA coating and weighing the cone in the opposite direction a bit while it dries. That will get rid of the oil canning effect of the stretched surround. The spider usually has less spring force than an accordion type surround, so it will be the predominant return centering force of the moving assembly. Steaming the surround also can work as long as the cone isn't prone to moisture absorption (warping). The steam will soften and reset, but the cone needs to be pushed back to the correct resting position while the surround dries.

- Home

- Loudspeakers

- Multi-Way

- Spider on my woofer out of alignment?