Hello All,

I wanted to post photographs and text together in this new thread but my nice Sigma digital camera stopped working and I had to switch to a canon digital Elph borrowed from a friend. I did not want to delay the thread and I will post photographs the day after tomorrow at the latest.

Sincerely,

Ralf

TONE ARM 4, MODEL 7

The Inception

During my lunch break, when there were no customers, I would go down to the demo room, eat my sandwich, and listen to whatever was on the 2 inch tape on that particular day. The experience of listening to that professional sound equipment was overwhelming. It started me on the path of designing my geometrically perfect tone arm. My co-workers all had an interest in music in one way or another. Some played musical instruments and one was a part-time recording engineer. I played acoustic guitar and sang folk and country music.

Upon the advice of my co-workers I purchased a Thorens TD-124 turntable and a separate SME 3009/S2 improved tone arm. I started to purchase LPs and soon realized that a pivoting tone arm could not faithfully reproduce music the way it was recorded.

Being fascinated by all things mechanical, I set out to design my own pivoting tangentially tracking tone arm. Although my hat is off to the designers of tone arms like the Rabco and the Goldmund, I did not like the fact that those tone arms occupied so much space on a turntable. I also did not like the various pivoting tangential tone arms like the Garrand Zero 100 because they still skated and had tracking errors. Being a perfectionist, I could not understand why all the talented tone arm designers would stop short of zero tracking error and zero skating force designs.

This thread does not concern air-bearing and Souther style tone arms which are mostly perfect.

I always liked the classical appearance of pivoting tone arms, so I concentrated on them. I designed, built and patented my first tone arm in the early 1980s, and I would have continued if it were not for the fact that CDs came on the market. It wasn’t until 2009 that I found out that vinyl LPs had made a come-back. By this time, however, I owned a CAD program, had built a shop and purchased an almost new Bridgeport vertical milling machine.

By 2010 I had redesigned my original 1980s tone arm by moving its tracks and the carriage into the base underneath the tone arm. It required an active servo and was featured in a thread on the DIY website. In 2012 I improved the tone arm by inventing the “FLOATING HEAD-SHELL” which is shown as the third item in the group picture. Like the 2010 tone arm, it also required an active servo. Not knowing electronic design, I listened to LPs without the necessary servo by nudging the tone arm’s carriage along its track every 30 seconds or so. That became possible, because I separated the head-shell from the tone arm proper. Not knowing anyone who could design the servo circuitry for me, I kept making mechanical improvements until in 2015 I invented the “OFFSET HEAD-SHELL CRADLE”.

Then in 2016 I changed my design from a carriage rolling on a track to a swing arm to support the tone arm. Of course many inventors before me discovered that a swinging support arm is far superior to a rolling carriage. Then, early in 2017 a kind gentleman whom I met on the internet, designed the servo circuitry for me. I transferred that circuit to a printed circuit board and showed it to the public at the Rocky Mountain Audio Fest (RMAF) in October 2017, in Denver, Colorado. The transition to the swing arm reduced friction to the point where the tone arm started to float across the LP purely from the drag force between the LP and the stylus. The servo has become a “passive” servo and only controls the variations in the drag force. Some of the servo components were visible when looking down on the tone arm, which I did not like, and in late 2017 I moved those components to the underside of what I call the tone arm shelf. That way the tone arm would retain its classic appearance and it would make it harder for intellectual property thieves to steal my invention. That being said, anyone who wants to build a copy of my tone arm is free to do so, as long as it’s not for sale to others.

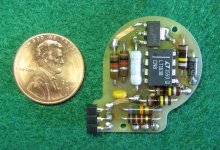

My original 2017 servo’s printed circuit board (PCB) utilized “through-hole” components. In 2018 I redesigned the PCB to utilize “surface mount devices”.

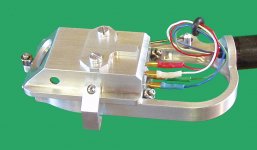

To summarize, I have invented a pivoting, tangentially tracking tone arm with a “FLOATING HEAD-SHELL” carried by an “OFFSET TONE ARM CRADLE”. Please note, that the HEAD-SHELL and CRADLE are NOT offset to reduce tracking error, as in a conventional pivoting tone arm. The offset cradle serves a new and different purpose.

I have a complete set of 3D solid model CAD files and paper drawings for my tone arm. I also have a number of simple but precise aluminum fixtures that I have made.

Now, after several years of machining, testing and experimenting, I am finally able to listen to my favorite music played back with a tone arm of my own design. That experience cannot be described and those of you who have designed and built your own audio equipment know what I am talking about. I have kept my modest collection of 250 LPs, which I purchased in the 1970s and 1980s in almost new condition and recently, a lady friend of mine gave me around 35 boxed sets of LPs that had belonged to her deceased son. There is enough music there to last for the rest of my life.

I hope that the members of the DIY website will forgive me for not making public all the design features of my tone arm, because I want to make it difficult for the copy-cats to profit from my invention.

And, last but not least, I would like to find a manufacturer to make and sell my tone arm.

Please watch for 14 photographs in my next post. I promise, you will be amazed.

Sincerely,

Ralf

Last edited:

Hello All,

Here are the first ten photographs. I made several attempts at uploading, and failed because of excess file size. I'll upload the final five photographs in the next post.

Sincerely,

Ralf

11. Tone arm wiring can be assembled and disassembled to and from the

tone arm without soldering.

12. Pivot to stylus distance is: 8.238” (209.24mm)

13. Tracking force is adjustable from 0 to 3g.

14. Materials used are 7075 aluminum, brass, stainless steel, copper and

carbon fiber tubing. All fasteners are stainless steel.

1. GROUP 1980 – 2018

A. SME 3009/S2 improved.

This is the one that started my fascination with tone arms.

B. My first attempt at tone arm design. Its tracking error was ±.1°. It had

an optical sensor by H.P. and was driven by a stepping motor. I

patented it in the early 1980s.

C. My design from 2012. The first to use my invention of the “FLOATING

HEAD-SHELL”.

D. My design from 2015, having a ‘FLOATING HEAD-SHELL” and an

“OFFSET HEAD-SHELL CRADLE”

MY 2018 TONE ARM

2. CHIPS

I started with a billet of 7075 aircraft aluminum and simply removed all material that didn’t look like a tone arm.

3. Right hand view.

4. Left hand view.

5. “FLOATING HEAD-SHELL”, right hand view.

6. “FLOATING HEAD-SHELL”, left hand view.

7. “FLOATING HEAD-SHELL”, front view.

8. Tone arm base, right hand view.

9. Tone arm base, left hand view.

10. Tone arm base, rear view.

11. Tone arm base only, start of play.

12. Tone arm base only, end of play.

13. 2017 Servo P.C.B.

14. 2018 Servo P.C.B.

15. Alignment gage.

Here are the first ten photographs. I made several attempts at uploading, and failed because of excess file size. I'll upload the final five photographs in the next post.

Sincerely,

Ralf

TONE ARM 4, MODEL 7

Specifications

- Pivoting tangentially tracking tone arm with revolutionary “FLOATING, OFFSET HEAD-SHELL”.

- ZERO tracking error.

- ZERO skating.

- Head-shell tracks in a straight line for zero eccentricity wow.

- Tone arm is solely driven by the frictional drag between the vinyl LP and the stylus.

- Built-in electronic servo controls the constantly varying drag force.

- Tone arm is supported by flexural pivots for motion in the vertical plane and is dynamically balanced.

- A wall-pluggable USB power supply provides 5V DC to the servo circuitry.

- Tone arm fits into one corner of any turn table.

11. Tone arm wiring can be assembled and disassembled to and from the

tone arm without soldering.

12. Pivot to stylus distance is: 8.238” (209.24mm)

13. Tracking force is adjustable from 0 to 3g.

14. Materials used are 7075 aluminum, brass, stainless steel, copper and

carbon fiber tubing. All fasteners are stainless steel.

LIST OF PHOTOGRAPHS

A. SME 3009/S2 improved.

This is the one that started my fascination with tone arms.

B. My first attempt at tone arm design. Its tracking error was ±.1°. It had

an optical sensor by H.P. and was driven by a stepping motor. I

patented it in the early 1980s.

C. My design from 2012. The first to use my invention of the “FLOATING

HEAD-SHELL”.

D. My design from 2015, having a ‘FLOATING HEAD-SHELL” and an

“OFFSET HEAD-SHELL CRADLE”

MY 2018 TONE ARM

2. CHIPS

I started with a billet of 7075 aircraft aluminum and simply removed all material that didn’t look like a tone arm.

3. Right hand view.

4. Left hand view.

5. “FLOATING HEAD-SHELL”, right hand view.

6. “FLOATING HEAD-SHELL”, left hand view.

7. “FLOATING HEAD-SHELL”, front view.

8. Tone arm base, right hand view.

9. Tone arm base, left hand view.

10. Tone arm base, rear view.

11. Tone arm base only, start of play.

12. Tone arm base only, end of play.

13. 2017 Servo P.C.B.

14. 2018 Servo P.C.B.

15. Alignment gage.

Attachments

-

1_GROUP_1980_TO_2018.jpg890.1 KB · Views: 3,216

1_GROUP_1980_TO_2018.jpg890.1 KB · Views: 3,216 -

10_TONE_ARM_BASE_REAR_VIEW.JPG581 KB · Views: 1,989

10_TONE_ARM_BASE_REAR_VIEW.JPG581 KB · Views: 1,989 -

9_TONE_ARM_BASE_LEFT_HAND_VIEW.JPG848.9 KB · Views: 2,387

9_TONE_ARM_BASE_LEFT_HAND_VIEW.JPG848.9 KB · Views: 2,387 -

8_TONE_ARM_BASE_RIGHT_HAND_VIEW.JPG554.7 KB · Views: 1,874

8_TONE_ARM_BASE_RIGHT_HAND_VIEW.JPG554.7 KB · Views: 1,874 -

7_FLOATING_HEADSHELL_FRONT_VIEW.jpg119.8 KB · Views: 1,855

7_FLOATING_HEADSHELL_FRONT_VIEW.jpg119.8 KB · Views: 1,855 -

6_FLOATING_HEADSHELL_LEFT_HAND_VIEW.jpg170 KB · Views: 3,577

6_FLOATING_HEADSHELL_LEFT_HAND_VIEW.jpg170 KB · Views: 3,577 -

5_FLOATING_HEADSHELL_RIGHT_HAND_VIEW.JPG260.1 KB · Views: 2,987

5_FLOATING_HEADSHELL_RIGHT_HAND_VIEW.JPG260.1 KB · Views: 2,987 -

4_LEFT_HAND_VIEW.jpg341.1 KB · Views: 3,309

4_LEFT_HAND_VIEW.jpg341.1 KB · Views: 3,309 -

3_RIGHT_HAND_VIEW.JPG289.5 KB · Views: 3,001

3_RIGHT_HAND_VIEW.JPG289.5 KB · Views: 3,001 -

2_CHIPS_AND_GREEN_SALSA.jpg966.5 KB · Views: 3,125

2_CHIPS_AND_GREEN_SALSA.jpg966.5 KB · Views: 3,125

A lot of TLC in there. Just beautiful work to see.

The wait was worth it and you should start selling them !

Very very nice accomplishment Ralf , and thanx for finally sharing your creation !

Regards

David

The wait was worth it and you should start selling them !

Very very nice accomplishment Ralf , and thanx for finally sharing your creation !

Regards

David

I would like to find a manufacturer to make and sell my tone arm.

Wonderful, but you will have to build them yourself to make things work out financially.

Pairing with a turntable mfr or direct sales, are both possible.

Last edited:

Hello again,

Here are the remaining five photographs.

I plan on more photos and a video, once I figure out how to use my friends digital Elph.

Sincerely,

Ralf

Here are the remaining five photographs.

I plan on more photos and a video, once I figure out how to use my friends digital Elph.

Sincerely,

Ralf

Attachments

you guys still have pennies?

dave

Hi Dave,

Yeah. And if you ever find a 1945 steel penny, it's worth a lot more than a penny.

Ralf

Thank you for revealing your creation, Ralf! Congrats!

I wish I am smart enough to figure out what's going on in that arm. I'm just glad someone is out there fighting the good fight!

I wish I am smart enough to figure out what's going on in that arm. I'm just glad someone is out there fighting the good fight!

> 2018 — you guys still have pennies?

The US has Zinc production. Not like Australia or China, but US Zinc probably seeks a premium price and national coin-production is an obvious outlet.

I hate them. They are worth nearly nothing. If I can't get a penny right into the bankroll bin, I throw it away "safely". If a dog eats a Zinc cent he can be very very sick; I hear children also. I agree with Canada's decision to drop the cent. However the US has been very conservative about changing the currency, and has been focused on big-denomination security more than routine small change.

The US has Zinc production. Not like Australia or China, but US Zinc probably seeks a premium price and national coin-production is an obvious outlet.

I hate them. They are worth nearly nothing. If I can't get a penny right into the bankroll bin, I throw it away "safely". If a dog eats a Zinc cent he can be very very sick; I hear children also. I agree with Canada's decision to drop the cent. However the US has been very conservative about changing the currency, and has been focused on big-denomination security more than routine small change.

What I see is a Birch-like geometry, but Straight Tracker stated, that the headshell tracks in a straight line.

He stated also that there is no skating, although the headshell is angled .

The „floating headshell” can move laterally on the „offset headshell cradle” on five ball bearings, but what for? Is the friction of the five ball bearings lower than the friction of the main horizontal bearing, attenuated by the length of the tonearm? What is the function of the small counterweight on the floating headshell? It is fixed asymmetrically. On the design from 2015 it is symmetrical.

Questions, questions…

He stated also that there is no skating, although the headshell is angled .

The „floating headshell” can move laterally on the „offset headshell cradle” on five ball bearings, but what for? Is the friction of the five ball bearings lower than the friction of the main horizontal bearing, attenuated by the length of the tonearm? What is the function of the small counterweight on the floating headshell? It is fixed asymmetrically. On the design from 2015 it is symmetrical.

Questions, questions…

What is the function of the small counterweight on the floating headshell?

Another question is what is the black rectangle under that small counterweight that looks like some kind of sensor mechanism?

- Home

- Source & Line

- Analogue Source

- A Revolutionary Pivoting Tangential Tone Arm