Just don't use measurement points where we measure noise instead of THD.

I see now our misunderstanding.

Eg.

Behringer ECM8000 @94dB

H2/H3/H4/H5:

0.09/0.01/0.009/0.006 %

I will double check the figures in the tables and refine them to 2 decimal places, and provide supplementary information regarding noise obscuring distortion.

Last edited:

No need to be overprecise with calculations - these measurements have their limits and microphones their tolerances. As always with acoustic measurements - that's what makes them interesting compared to electronic measurements

Correct values for the Behringer @94dBSpl would be

H2 ~ 0,1% (tolerance for sure +-0,03 or more with these microphones!)

H3 ~ 0,0005%

H4-H28 < 0,00001%

@114dBSpl I would use

H2 ~ 1%

H3 ~ 0,05%

H4 ~ 0,001%

H5 < 0,0001%

Correct values for the Behringer @94dBSpl would be

H2 ~ 0,1% (tolerance for sure +-0,03 or more with these microphones!)

H3 ~ 0,0005%

H4-H28 < 0,00001%

@114dBSpl I would use

H2 ~ 1%

H3 ~ 0,05%

H4 ~ 0,001%

H5 < 0,0001%

Hi,

Not a very precise test, but it gives a glimpse about other popular Mics. The Dayton EMM-6 looks quite similar to mentioned above Behringer ECM-8000. A 4 way speaker system had been measured. Not many prepartions, with minimal covering of near by hard surfaces. Level about 90-91 dB. The results suggest sort of similar, like for behringer, rise of HD values by about 0.1% as compared to more quality Beyerdynamic MM1.

Regards

Not a very precise test, but it gives a glimpse about other popular Mics. The Dayton EMM-6 looks quite similar to mentioned above Behringer ECM-8000. A 4 way speaker system had been measured. Not many prepartions, with minimal covering of near by hard surfaces. Level about 90-91 dB. The results suggest sort of similar, like for behringer, rise of HD values by about 0.1% as compared to more quality Beyerdynamic MM1.

Regards

Attachments

Last edited:

As there was a lot of discussion about microphone distortion here recently and I'm actually working on a pressure chamber which can produce >160dBSpl ... I spent an afternoon to do some microphone measurements.

What is the point?

Why?

Compressed air is very much nonlinear and generates serious Harmonic Distortion. For an example take a look at JBL horn Compression Driver white papers. First Tech Note I think of #108 pops into mind, low diaphragm travel with high HD. Also Linkwitz speaks at length about compression distortion. Think of a mid-range driver in a relative small enclosure.

Often I place 1/4" GRAS microphones into sealed woofer and mid-range enclosures to test dampening and reflections. APx555 with APx1701 transducer test interface. There is a good chance that 1/2" microphones will be damaged at the SPLs you are speaking of. Or at a minimum they will be require recalibration as a result of being driven past their limits.

Thanks DT

A. Confirmation or independent testing to determine their 1% (or 3%) distortion limits.What is the point?

Why?

B. So one doesn’t drive them past their limits.

This is not @IamJF ’s first rodeo. Nor yours @DualTriode

Remember those science shows on TV?

“Don’t do this at home, kids”

he does it, so we don’t have to…

@DualTriodeOften I place 1/4" GRAS microphones into sealed woofer and mid-range enclosures to test dampening and reflections. APx555 with APx1701 transducer test interface. There is a good chance that 1/2" microphones will be damaged at the SPLs you are speaking of. Or at a minimum they will be require recalibration as a result of being driven past their limits.

Thanks DT

Have you considered using the RTA a reversed mounted driver method?

If anything ever goes go wrong, it’s a lot cheaper to replace a tweeter or midrange unit. Perhaps even lower than the cost of recalibrating a lab grade mic capsules…

And you can plug it into a standard audio interface. Save your G.R.A.S capsules for other work…

Of course, knowing your mic's SPL non-linearity limits is very important - but why do you limit yourself to 1/4" mic and stone-aged AP? You don't have to. I use a "measurement mic" only to calibrate 1" mic with 16x surface, and then I "do something .... with analyzing spectra". The results: 80dB dynamic range at 76dB SPL (70 at 1m) in a regular living room (dotted lines show the noise level).It's the Audio Precision stepped level sweep - there is no averaging or other stuff going on. The good thing is there are no calculation influences on the results. Downside - with some optimisations you could probably get a better S/N range. I wanted to be sure that at least the measurements we get are reliable.

You could try to do something similar with analysing spectra ... but that would be way more work as I spent here already. (cause you would need a lot of points to get a useful graph)

if I swap precision for resolution, I get a 100dB. I can learn about a driver that the designers had no idea of.

BTW, strictly speaking, AP does provide repeatable results, but these results are not measurements. Measurements must come as X+-Y, [say] 90% confidence interval. Just an X is not a measurement.

As @tktran303 already answered.What is the point?

Why?

Get to know the THD behaviour of your mic. You need a lot of SPL level to produce harmonics of a condenser capsule.

So you understand the theory. But that's not reality here.Compressed air is very much nonlinear and generates serious Harmonic Distortion. For an example take a look at JBL horn Compression Driver white papers. First Tech Note I think of #108 pops into mind, low diaphragm travel with high HD. Also Linkwitz speaks at length about compression distortion. Think of a mid-range driver in a relative small enclosure.

As you see in my first measurement - we can AT LEAST produce 150dBSpl with <1% THD and 160dBSpl <3% THD. Whatever THD that is (speaker, mic or air) - we are save when we stay below. And we did.

Did you ever damage a measurement capsule with SPL? This is VERY hard to achieve. The membrane is very tightly stretched, they are tough. High resonance frequency, very low mass - not like a dynamic mic.Often I place 1/4" GRAS microphones into sealed woofer and mid-range enclosures to test dampening and reflections. APx555 with APx1701 transducer test interface. There is a good chance that 1/2" microphones will be damaged at the SPLs you are speaking of. Or at a minimum they will be require recalibration as a result of being driven past their limits.

You can damage a mic with pressure shocks like smashing a door in an air sealed room, tapping on it or strongly blowing (normal mic, not a measurement mic). But these are big pressure changes, higher as 160dBSpl.

A condenser microphone with external polarisation voltage doesn't get damaged through that btw - switch it off and on and the membrane goes back to it's position. An electret microphone with "baked in" charge can "stick" - when the membrane sticks to the back electrode it doesn't come free any more - the mic is damaged.

These movements of the membrane are very little compared to the diameter! (that's also the reason for the low thd - very little movement -> linear behaviour) Even when the membrane touches the back electrode it's still not stretching the membrane in a normal case.

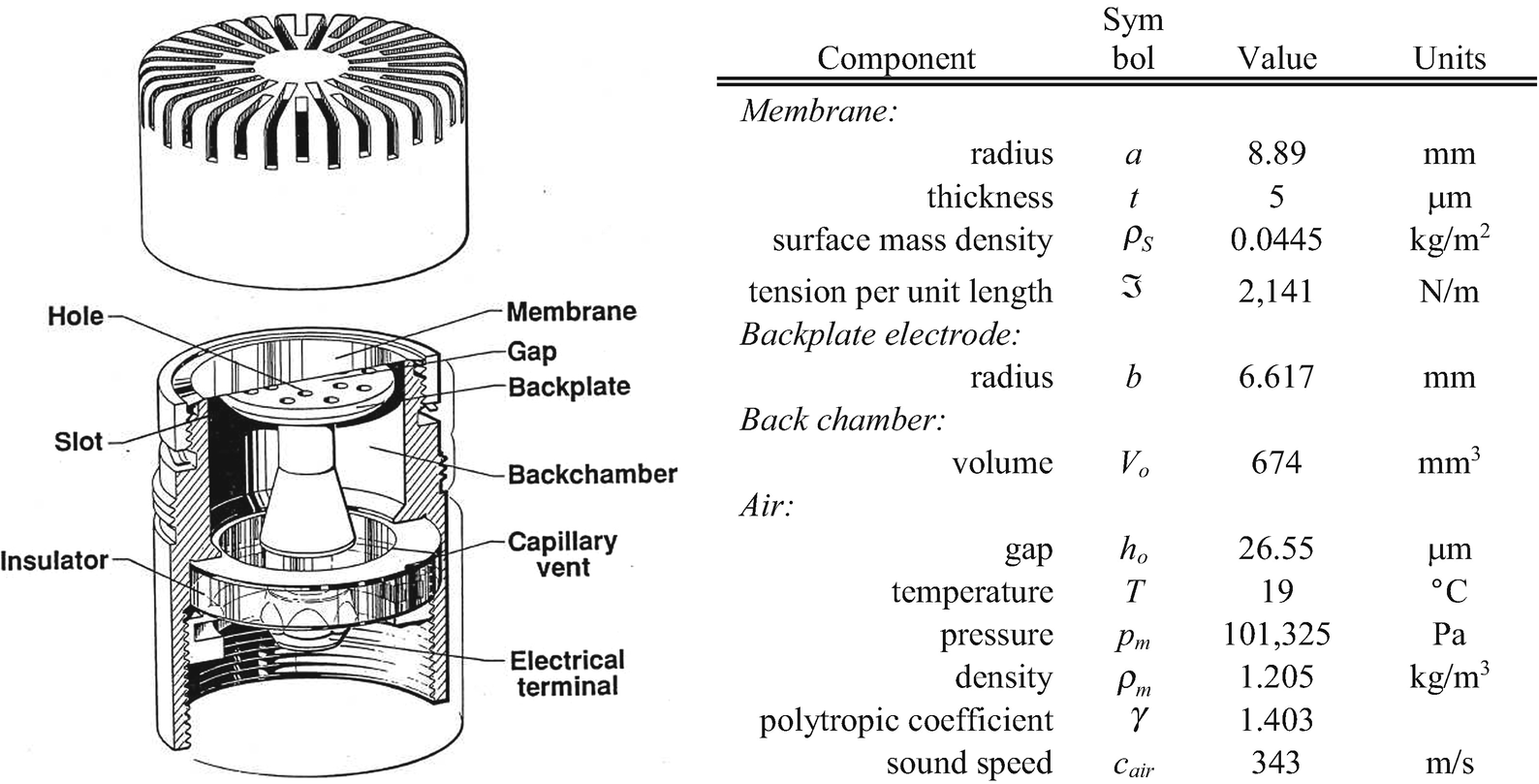

I just found a GREAT resource - the distance between the membrane and back electrode of a B&K 1/2" capsule is 19um! There is no stretching with that little movement of a 1/2" membrane!

https://doc.comsol.com/5.6/doc/com.comsol.help.models.aco.bk_4134_microphone/bk_4134_microphone.html

p.s.: I worked for AKG in the studio mic departmant many years ago ... don't worry, I know my mics. None of them got damaged, even the cheap electret capsule of the Behringer is fine after the torture. Don't do that over night but they are tougher as you might think. They need too cause a single slamming door is way harder as what I did here.

And a sketch of a 1" measurement capsule.

Distance is bigger here - 26,5um. It needs to be cause ... the membrane is less stiff and does more movement. To prevent sticking you need more distance.

You loose sensitivity with more distance - but you gain even more area, so overall sensitivity rises with bigger capsules.

Impedance converter design is WAY easier for bigger membranes cause they have a higher capacitance which means you can allow a lower input impedance of your electronics. These needs to be in the multible Giga Ohm area ... (yes, there are SMD resistors with 10G value.)

Distance is bigger here - 26,5um. It needs to be cause ... the membrane is less stiff and does more movement. To prevent sticking you need more distance.

You loose sensitivity with more distance - but you gain even more area, so overall sensitivity rises with bigger capsules.

Impedance converter design is WAY easier for bigger membranes cause they have a higher capacitance which means you can allow a lower input impedance of your electronics. These needs to be in the multible Giga Ohm area ... (yes, there are SMD resistors with 10G value.)

That narrative is still told from just the microphone perspective.A. Confirmation or independent testing to determine their 1% (or 3%) distortion limits.

B. So one doesn’t drive them past their limits.

This is not @IamJF ’s first rodeo. Nor yours @DualTriode

Remember those science shows on TV?

“Don’t do this at home, kids”

he does it, so we don’t have to…

If we put it all into context with loudspeaker design, I also don't see that much benefit to go into this rabbit hole to be perfectly honest.

Which is the (once again) chicken-egg story someone mentioned before.

Knowing absolute distortion values isn't that useful in practice I think.

The main reason being that we have to work with the drivers that are available.

Unlike an audio amplifier, where we can actually change the circuit to improve its performance.

So the only thing that is important are relative differences.

Also, it totally depends on the idea that distortion is a major factor for the quality of the performance.

According to Toole, Geddes and many many many others, that's debatable at best.

Which therefore automatically means there are other problems that have already a (much) higher significance in audibility (or practicality for that matter).

Besides, we can perfectly extrapolate results from lower SPLs to higher values.

Meaning: a driver that performs bad at a lower SPL will most certainly not perform better at a higher SPL all of a sudden.

Also all details you'll find at lower SPL we can extrapolate and will only get worse.

Like the distortion from cone resonances etc.

Other data can be taken from things like Klippel LSI measurements.

Things like long term power handling needs to be done practically anyway.

Power handling don't mean much in practice anyway.

System response can be taken from impedance measurements combined with freq resp measurements at lower SPL. (Ideally with cone excursion measurements as well)

So in the end we have all the information we need to know.

What other data do you think you'll find besides all the information you got beforehand?

I think you'll only get results that just mostly confirm earlier predictions.

Or there are other methods to get the same or very similar information.

The story will be entirely different if you want to make, design and develop your own microphones btw.

In that case you want to know all of this (plus more).

This is also one of the reasons why I stopped my own adventure with these things.

From a technical and theoretical point of view it's still extremely interesting though! 👍😎🤓

All that being said, it is important to confirm the performance of microphones.

Mostly because there is absolutely no data available AT ALL!!

We just (blindly) assume some brands and models are good.

But personally I would rather like to see the performance above 200Hz up to 20kHz.

Although, it kinda goes back to the extrapolation argument again.

Did you ever check your CALIBRATION ERROR?I use a "measurement mic" only to calibrate 1" mic with 16x surface, and then I "do something .... with analyzing spectra".

I spent a lot of work into setting up a measuring setup to do precise measurements of microphones - and you easily get a few dB of error at 20kHz when not being very careful. Just putten the 2 mics next to each other ... gives you these errors.

Getting the basics right is way more important as THD.

(We focus strongly on THD here of course but how important it is for a listener ... is a different debate. Here we check if we can measure it precisely with our microphones)

I always check my S/N range. If it's good enough I do measurements, otherwise I work on the setup. In my silent room - the ancient methods of AP work pretty goodThe results: 80dB dynamic range at 76dB SPL (70 at 1m) in a regular living room (dotted lines show the noise level).

View attachment 1295889

AP does exactly that with the methode I chose. They measure the value long enough until it is stable in a given range. But not 90%, more of 99,9%.if I swap precision for resolution, I get a 100dB. I can learn about a driver that the designers had no idea of.

BTW, strictly speaking, AP does provide repeatable results, but these results are not measurements. Measurements must come as X+-Y, [say] 90% confidence interval. Just an X is not a measurement.

This of course does not give a "real" value for "microphone type XY" - cause you would need to test hundreds of microphones! My model of the M50 could be defect or spectacular good - we don't know.

But I'm not writing a datasheet - I show the measurements of MY microphones. Can't do more.

@b_force Sorry - I didn't get your message. That's a lot of text but we are simply talking about how much THD is produced by the measurement microphone? To be sure we can measure THD of the speaker, not of the mic.

My point was to prove that you need to use a proper measurement mic for these measurements but then you are save.

Not how THD of speakers influences our lives.

Manufacturers datasheets are pretty bad for some of these microphones! Earthworks ... a mic for that much money should be precisely specified.

My point was to prove that you need to use a proper measurement mic for these measurements but then you are save.

Not how THD of speakers influences our lives.

All that being said, it is important to confirm the performance of microphones.

Mostly because there is absolutely no data available AT ALL!!

We just (blindly) assume some brands and models are good.

Manufacturers datasheets are pretty bad for some of these microphones! Earthworks ... a mic for that much money should be precisely specified.

I understand completely, but I thought it was important to provide some context 😎🙂My point was to prove that you need to use a proper measurement mic for these measurements but then you are save.

Not how THD of speakers influences our lives.

I agree that datasheets are really bad, but unfortunately it's the same for drivers as well

I do not know what made you think that I do not understand the basics of acoustical measurements when I am demonstratively capable of coming up with ... quite advanced methods. Could you enlighten me on this topic?Did you ever check your CALIBRATION ERROR?

I spent a lot of work into setting up a measuring setup to do precise measurements of microphones - and you easily get a few dB of error at 20kHz when not being very careful. Just putten the 2 mics next to each other ... gives you these errors.

Not ever - every time I take measurements I also check for calibration mismatch, automatically.

BTW, I am not very concerned about 20kHz per se for I am mostly interested in midrange drivers transparency. I do not care much if the third harmonic of 7kHz is on the level of -70.1 dB re main or -70.3 dB due to the mic placement discrepancy as far as it's a repeatable bias. That's good enough for me.

I would have to disagree - to the best of my knowledge, AP belongs to the Stone Age.

This thread proves that nearfield THD measurements are to be taken with a grain of salt when using a mic like the Behringer ECM8000 or the DBX RTA-M. You have to be in a narrow sweet spot of distance between the self noise floor and early rise in the capsule's own HD, which can vary wildly in manufacturers tolerance.

Measuring at a distance of a few cm at 90 dB ends up around 120dB at the mic capsule. So with that, you can't count on a meaningful THD measurement with a budget mic. I was given a brand new ECM8000 and ended up getting so disgusted at trying to get any decent measurements with it, that I threw the thing in the garbage. The capsule in the DATS V3 mic isn't far behind the Behringer.

Measuring at a distance of a few cm at 90 dB ends up around 120dB at the mic capsule. So with that, you can't count on a meaningful THD measurement with a budget mic. I was given a brand new ECM8000 and ended up getting so disgusted at trying to get any decent measurements with it, that I threw the thing in the garbage. The capsule in the DATS V3 mic isn't far behind the Behringer.

I've also come to the conclusion most back plate polarized electret mics show higher distortion and self noise figures than true condenser capsules. The beloved SM81 used to record alot of high hats, acoustic guitar and percussion actually disttort quite early depending on how they're loaded by the preamp.

For measurements, I've built a battery source as 48V phantom supply consisting of 5 x 9V Duracell batteries in series fed by 6.8k holco resistors and filtered with 10uF stacked plate PP caps. The feed resistors alone can contribute a few dB of self noise depending on the current draw of the mic and rejection ratio of the mic's internal preamp.

Its important to understand that all 9V batteries are capable of producing a little LF noise - I prefer the Duracell brand because they have spot welded cell contacts as opposed to contacts made by simply just stacking individual cells loosly on top of each other. The contact resistance causes measurable noise, which easily worsens an electret mic's noise floor. Something as simple as a battery can hurt mic performance. Its also important not to place the filter caps after the 6.8k resistors, as this can cause discharge current transients in the FET preamp circuits. I read some of these potential problems in a paper written by Rupert Neve himself.

For measurements, I've built a battery source as 48V phantom supply consisting of 5 x 9V Duracell batteries in series fed by 6.8k holco resistors and filtered with 10uF stacked plate PP caps. The feed resistors alone can contribute a few dB of self noise depending on the current draw of the mic and rejection ratio of the mic's internal preamp.

Its important to understand that all 9V batteries are capable of producing a little LF noise - I prefer the Duracell brand because they have spot welded cell contacts as opposed to contacts made by simply just stacking individual cells loosly on top of each other. The contact resistance causes measurable noise, which easily worsens an electret mic's noise floor. Something as simple as a battery can hurt mic performance. Its also important not to place the filter caps after the 6.8k resistors, as this can cause discharge current transients in the FET preamp circuits. I read some of these potential problems in a paper written by Rupert Neve himself.

Very valid point @profiguy.

If someone want to take measurements of bass-midrange frequencies, typically from ~10-20Hz to around 250-500Hz, one needs to have

a) access to have an anechoic chamber

b) access to a large area without nearby boundaries for a ground plane measurement

c) Klippel Near Field Scanner

d) near field

Each have their advantages and disadvantages. For most DIYers, the near field is undoubtedly the most convenient as it the only method that can be completed in the living/kitchen/hotel room (Monte Kay). There are a number of caveats to this- 1. one needs to perform compensation for the baffle diffraction loss and 2. measure sufficiently close (millimetres) from the cone to get an accurate frequency response.

There are a number of caveats to this- 1. one needs to perform compensation for the baffle diffraction loss and 2. measure sufficiently close (millimetres) from the cone to get an accurate frequency response.

If one wants to measure distortion in the near field, the microphone used MUST be able to measure the required SPL without contributing significant distortion itself.

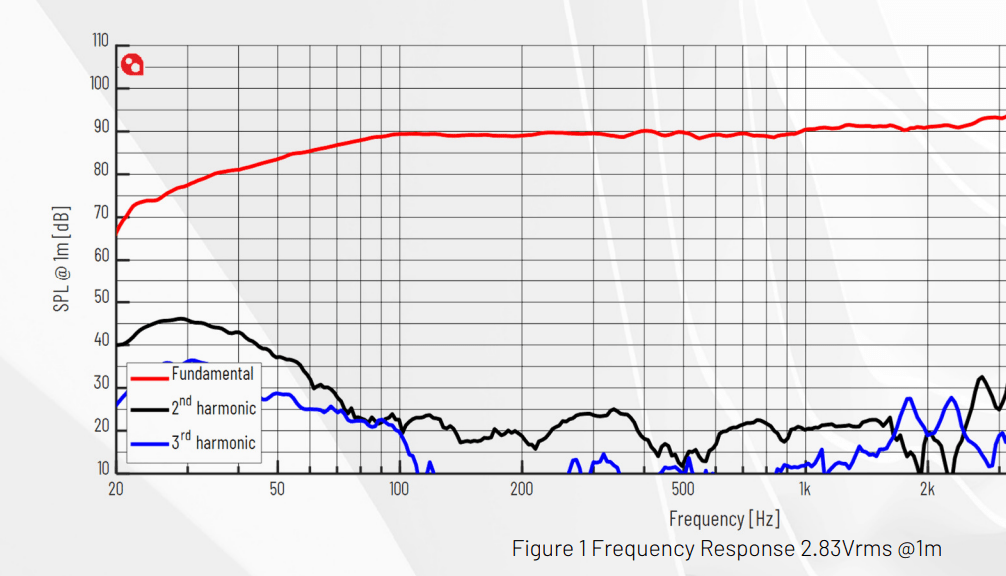

eg. To verify the H2 <-70dB and H3 <-80dB for 100Hz to 500Hz for a transducer that is fed 2.83V, as below:

How can a microphone measure distortion at < -70 or -80 dB, when it is observing some 116dB? *

Reference

* https://www.diyaudio.com/community/threads/measurement-mics.406766/post-7634814

This author's preliminary assessment shows that the microphone must be capable of 156dB (3% THD) if it to measure distortion of H2 of 0.03% and H3 of 0.01% for frequencies below Shroeder in the nearfield.

If someone want to take measurements of bass-midrange frequencies, typically from ~10-20Hz to around 250-500Hz, one needs to have

a) access to have an anechoic chamber

b) access to a large area without nearby boundaries for a ground plane measurement

c) Klippel Near Field Scanner

d) near field

Each have their advantages and disadvantages. For most DIYers, the near field is undoubtedly the most convenient as it the only method that can be completed in the living/kitchen/hotel room (Monte Kay).

If one wants to measure distortion in the near field, the microphone used MUST be able to measure the required SPL without contributing significant distortion itself.

eg. To verify the H2 <-70dB and H3 <-80dB for 100Hz to 500Hz for a transducer that is fed 2.83V, as below:

How can a microphone measure distortion at < -70 or -80 dB, when it is observing some 116dB? *

Reference

* https://www.diyaudio.com/community/threads/measurement-mics.406766/post-7634814

This author's preliminary assessment shows that the microphone must be capable of 156dB (3% THD) if it to measure distortion of H2 of 0.03% and H3 of 0.01% for frequencies below Shroeder in the nearfield.

Last edited:

It seems many people are not aware of the microphone-in-box technique, which does away with many of the issues you described.If someone want to take measurements of bass-midrange frequencies, typically from ~10-20Hz to around 250-500Hz, one needs to have

a) access to have an anechoic chamber

b) access to a large area without nearby boundaries for a ground plane measurement

c) Klippel Near Field Scanner

d) near field

Each have their advantages and disadvantages. For most DIYers, the near field is undoubtedly the most convenient as it the only method that can be completed in the living/kitchen/hotel room (Monte Kay).There are a number of caveats to this- 1. one needs to perform compensation for the baffle diffraction loss and 2. measure sufficiently close (millimetres) from the cone to get an accurate frequency response.

https://audioxpress.com/article/measuring-loudspeaker-low-frequency-response

Good thought @mbrennwa

I intentionally left the microphone in a box method out. But I have mentioned it in the past, you may not have had the opportunity to follow the link in post 46 .It's main advantages is low frequency response measurements via the use of a single measurement.

But suppose you had a pair of woofers (or more) and a port (or more). What SPL does the microphone observe, when it placed inside of the box, compared to outside, near the cone?

I intentionally left the microphone in a box method out. But I have mentioned it in the past, you may not have had the opportunity to follow the link in post 46 .It's main advantages is low frequency response measurements via the use of a single measurement.

But suppose you had a pair of woofers (or more) and a port (or more). What SPL does the microphone observe, when it placed inside of the box, compared to outside, near the cone?

Last edited:

The result of the measurement is the 2pi farfield response. Read the Thielle paper for the full explanation.But suppose you had a pair of woofers (or more) and a port (or more). What SPL does the microphone observe, when it placed inside of the box, compared to outside, near the cone?

- Home

- Loudspeakers

- Multi-Way

- Distortion in Measurement Microphones - actual measurements