@hifijim

Thanks for that.

I'll change the profiles of those braces to circles.

I do have a roll of car sound deadening like you mentioned so i'll use that.

I did draw the little enclosure for the mid/tweeter, i could easily CNC up the bottom panel of that enclosure to be sealed

and have openings around it to allow that area to be part of the bass enclosure.

The cabinet size ended up being based on the width of the SB34 and a tweeter height of ear level. So it just ended up being what it is.

I'll work on those top roundovers by hand and see what i can come up with that looks nice.

@Dave Bullet

Yes I will definately do that. Would you do it for the 12" driver also?

@Bon

Thanks for the examples, i'll make sure i roundover the circle.

All the mdf has been precut on a panel saw, so it will be tricky to recess the braces etc now, without recutting everything.

Thanks again all, really appreciate the guidance!

Thanks for that.

I'll change the profiles of those braces to circles.

I do have a roll of car sound deadening like you mentioned so i'll use that.

I did draw the little enclosure for the mid/tweeter, i could easily CNC up the bottom panel of that enclosure to be sealed

and have openings around it to allow that area to be part of the bass enclosure.

The cabinet size ended up being based on the width of the SB34 and a tweeter height of ear level. So it just ended up being what it is.

I'll work on those top roundovers by hand and see what i can come up with that looks nice.

@Dave Bullet

Yes I will definately do that. Would you do it for the 12" driver also?

@Bon

Thanks for the examples, i'll make sure i roundover the circle.

All the mdf has been precut on a panel saw, so it will be tricky to recess the braces etc now, without recutting everything.

Thanks again all, really appreciate the guidance!

Rounding the internal braces is nice, and it may have some benefit in theory... but I would not go to any big effort to do it. Simply cut holes are just fine.

It is more important to round or bevel the inside hole of the midrange as @Dave Bullet said. If you can do it for the woofer, that is good also... but it is really important for the mid.

It is more important to round or bevel the inside hole of the midrange as @Dave Bullet said. If you can do it for the woofer, that is good also... but it is really important for the mid.

Thanks heaps.

I had an hour in the shed today and got all the braces cut out. Glued up a few things. Got Covid at the moment so motivation is lacking lol.

I have modeled a roundover on the top of the front baffle, same distance as from the side of the tweeter.

Just working on modeling the roundover to the top to match. Slowly getting there.

With rounding the bevel for the mid, As they are quite thick baffles, should i leave say 10mm thickness on the front then bevel at 45 degrees, or leave it thicker?

Edit - Just realised I didn't attach the picture

I had an hour in the shed today and got all the braces cut out. Glued up a few things. Got Covid at the moment so motivation is lacking lol.

I have modeled a roundover on the top of the front baffle, same distance as from the side of the tweeter.

Just working on modeling the roundover to the top to match. Slowly getting there.

With rounding the bevel for the mid, As they are quite thick baffles, should i leave say 10mm thickness on the front then bevel at 45 degrees, or leave it thicker?

Edit - Just realised I didn't attach the picture

Attachments

Last edited:

I wouldn't bother for the 12" driver. The 3 main reasons are:Yes I will definately do that. Would you do it for the 12" driver also?

1. Wavelengths are sufficiently long that internal "edge" reflections from the baffle hole are far less likely to affect the bass / low frequency response

2. The basket of larger drivers like the SB34 is likely "blocking" any path to the inside baffle edge, therefore any air pressure variation from larger excursion will be seen by the frame first, rather than the thicker baffle

3. The basket window is much larger on a larger (12") driver than say a midrange driver, so less critical

Keeping the baffle thicker for the woofer may provide less resonance / movement under higher power.

I'm a kiwi but I'll forgive you 🤣

For sealed box stuffing, I just use Dacron / old pillows or duvets (dunas!) I just add stuffing until Fs gets to it's lowest frequency then when you add more stuffing, Fs starts to rise. I then remove some. There's probably a better method to work out weights per litre etc but I can't weigh accurately.

Of course for a vented enclosure stuffing can be detrimental. I think it will have greatest benefit in the midrange enclosure. For the woofer, if vented, I'd avoid or do it lightly avoiding fouling the port. Use near field measurements to see any effect / benefit.

For sealed box stuffing, I just use Dacron / old pillows or duvets (dunas!) I just add stuffing until Fs gets to it's lowest frequency then when you add more stuffing, Fs starts to rise. I then remove some. There's probably a better method to work out weights per litre etc but I can't weigh accurately.

Of course for a vented enclosure stuffing can be detrimental. I think it will have greatest benefit in the midrange enclosure. For the woofer, if vented, I'd avoid or do it lightly avoiding fouling the port. Use near field measurements to see any effect / benefit.

Oh my bad, just saw the flag near your name, didn't look too hard.

So for the dacron, you line the walls with that, then stuff with the pillows/dunas?

Both the midrange and bass are sealed, so i'll do similar to both.

Interesting method, How are you measuring FS in that scenario?

So for the dacron, you line the walls with that, then stuff with the pillows/dunas?

Both the midrange and bass are sealed, so i'll do similar to both.

Interesting method, How are you measuring FS in that scenario?

Don't bother lining the walls. Stuffing has greatest effect mid enclosure and least effect on the walls.

I think Dacron is a brand name for pillow stuffing? Unsure. I just mean use the one type. I prefer Dacron as the fibres don't seem to come away u like fibreglass which whilst effective, can cause issues for drivers with exposed voice coils

I use DATS to do impedance sweeps but you can make a jig yourself and use rew. Search for "rew impedance jig"

I think Dacron is a brand name for pillow stuffing? Unsure. I just mean use the one type. I prefer Dacron as the fibres don't seem to come away u like fibreglass which whilst effective, can cause issues for drivers with exposed voice coils

I use DATS to do impedance sweeps but you can make a jig yourself and use rew. Search for "rew impedance jig"

Hi all,

nice to see here the list of tips and tricks, there is a chance to put it together to some expensive DIY book about speaker building

i have only one additional observation to make

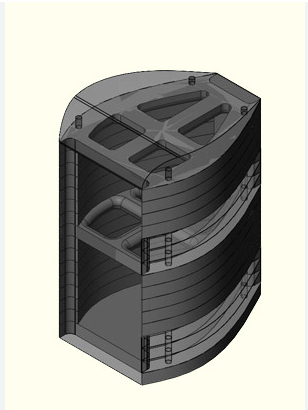

with your extraordinary CNC capabilities you may think about building an internal enclosure for the mid range speaker to reduce more the internal resonances like this here

for you of course the external shape is rectangular and only internally you use a drop-shaped cutout for every slice of your internal midrange cabinet

i am unfortunately a looser in CAD drawing and had to take an existing picture that do not fit precisely your needs

hope it helps anyway, Stefano

nice to see here the list of tips and tricks, there is a chance to put it together to some expensive DIY book about speaker building

i have only one additional observation to make

with your extraordinary CNC capabilities you may think about building an internal enclosure for the mid range speaker to reduce more the internal resonances like this here

for you of course the external shape is rectangular and only internally you use a drop-shaped cutout for every slice of your internal midrange cabinet

i am unfortunately a looser in CAD drawing and had to take an existing picture that do not fit precisely your needs

hope it helps anyway, Stefano

I think that would be fine. When I bevel the inside hole of a driver, I use a router bit with a bearing, and the bearing needs about 1/4 inch of unbeveled thickness. But I usually leave a thicker section than 1/4" (6.5 mm) to give the screws more material to bite into. So 10 mm sounds about right.With rounding the bevel for the mid, As they are quite thick baffles, should i leave say 10mm thickness on the front then bevel at 45 degrees, or leave it thicker?

I'm assuming theres no negative to lining the walls with sound deadener? I have a roll there from a car a few years back, so I might line all internal walls, then put some fill in.Don't bother lining the walls. Stuffing has greatest effect mid enclosure and least effect on the walls.

I think Dacron is a brand name for pillow stuffing? Unsure. I just mean use the one type. I prefer Dacron as the fibres don't seem to come away u like fibreglass which whilst effective, can cause issues for drivers with exposed voice coils

I use DATS to do impedance sweeps but you can make a jig yourself and use rew. Search for "rew impedance jig"

I got confused with the Dacron comment, i googled dacron and it all looked like they came in rolls, so I assume you meant that for lining.

Dacron (polyester fibers) is usually used for filling the cabinet:

https://foamforyou.com/soft-cluster-fill-dacron

ikea sells it as cheap pillows.

In my experience it's a quite loose material that can be stuffed densely.

https://foamforyou.com/soft-cluster-fill-dacron

ikea sells it as cheap pillows.

In my experience it's a quite loose material that can be stuffed densely.

I also lined the walls, but used gym floor tile (10mm rubberised mat). I never took any measurements to confirm benefit / detriment and certainly don't know how to measure panel acceleration / vibration to confirm such treatments do anything useful.I'm assuming theres no negative to lining the walls with sound deadener? I have a roll there from a car a few years back, so I might line all internal walls, then put some fill in.

I got confused with the Dacron comment, i googled dacron and it all looked like they came in rolls, so I assume you meant that for lining.

When Dave said this, he was not talking about the rubberized damping material. He was talking about lining the walls with acoustical damping such as polyester fiber stuffing or acoustical foam.Don't bother lining the walls. Stuffing has greatest effect mid enclosure and least effect on the walls.

There are two kinds of damping we need to consider, and sometimes our terminology and wording is not clear (1) acoustical damping is meant to control the resonance of the air space in the cabinet. It suppresses the standing wave resonances. (2) structural damping is meant to control the vibration resonance of the cabinet walls.

Acoustical damping can be very effective, and it is not difficult to get it right. Many different materials will work. In a sealed box system, it is a straight forward, almost simple process: simply fill the volume loosely with an appropriate stuffing material. With a vented box, it is a little more complicated because there has to be a clear air path between the woofer cone and the vent, and too much stuffing will cause a reduction in bass output. In a small vented box 2-way, it can be a challenge to get the balance just right.

Structural damping is a harder problem, and even the best methods do not fully dampen the structural resonances. I found that with the kind of well-braced cabinets that I build, a layer of 80 mil foil-backed-butyl-rubber-self-adhesive deadener works well on all interior surfaces.

j.

Hi @neo004 .... In another thread you asked about sealed vs vented box for this woofer

https://www.diyaudio.com/community/...ox-woofers-out-of-fashion.412687/post-7684788

It is true that with your large cabinet volume, a vented box system would work well with this woofer. In my post https://www.diyaudio.com/community/...ox-woofers-out-of-fashion.412687/post-7684468 I show an alignment where the vent tuning frequency Fb is set equal to the driver Fs. DSP EQ is used to bring the response up to flat. The result is a response that has group delay almost as good as a sealed box, but higher SPL capability.

A vent brings with it some added complications. This box would require a large vent, 10 cm diameter and a length of ~ 80 cm. There are always vent resonances (like a pipe organ) in the midrange band, and the level of internal damping and the vent location can affect the resonance. Finding the optimum vent location would require some experimentation (modifying your cabinet). Another complication is this designing the bracing to work around the large vent which snakes around the interior for 80 cm. Experimenting with the acoustical damping (stuffing) is yet another complication. You will have to find the right balance between suppressing standing wave resonances in the upper bass/lower midrange (more stuffing), and optimizing bass output (less stuffing).

Given how far your construction has come, it might be hard to integrate a vent at this point, but perhaps it would be no problem for you.

If I were in your situation, I would stay with a closed box. Assuming you do, I have another recommendation. In that other thread, @b_force recommended using a first order high pass filter or PEQ to protect the woofer from infrasonic content. I have modelled this and it works quite well. I may incorporate it into my system. Given your large box volume and given this woofer with a low Qts, I think this infrasonic filter would be an excellent idea for you.

j.

https://www.diyaudio.com/community/...ox-woofers-out-of-fashion.412687/post-7684788

It is true that with your large cabinet volume, a vented box system would work well with this woofer. In my post https://www.diyaudio.com/community/...ox-woofers-out-of-fashion.412687/post-7684468 I show an alignment where the vent tuning frequency Fb is set equal to the driver Fs. DSP EQ is used to bring the response up to flat. The result is a response that has group delay almost as good as a sealed box, but higher SPL capability.

A vent brings with it some added complications. This box would require a large vent, 10 cm diameter and a length of ~ 80 cm. There are always vent resonances (like a pipe organ) in the midrange band, and the level of internal damping and the vent location can affect the resonance. Finding the optimum vent location would require some experimentation (modifying your cabinet). Another complication is this designing the bracing to work around the large vent which snakes around the interior for 80 cm. Experimenting with the acoustical damping (stuffing) is yet another complication. You will have to find the right balance between suppressing standing wave resonances in the upper bass/lower midrange (more stuffing), and optimizing bass output (less stuffing).

Given how far your construction has come, it might be hard to integrate a vent at this point, but perhaps it would be no problem for you.

If I were in your situation, I would stay with a closed box. Assuming you do, I have another recommendation. In that other thread, @b_force recommended using a first order high pass filter or PEQ to protect the woofer from infrasonic content. I have modelled this and it works quite well. I may incorporate it into my system. Given your large box volume and given this woofer with a low Qts, I think this infrasonic filter would be an excellent idea for you.

j.

Thanks again @hifijim.

I really appreciate your knowledge and guidance on this.

I was just reading the forum and saw that post and my mind wandered again as to whether i'm doing the right thing or not lol.

Definitely can't accomodate that port size with the current setup so i'll continue on this path.

I've got the cabinately half built, ran some wiring last night and put some sound deadening panels on, today will be puttin the final side on then working on the front baffle.

Not long to go now

You need one of those "Buy me a coffee" links, I need to give you a little something for all your help

Thankyou again

I really appreciate your knowledge and guidance on this.

I was just reading the forum and saw that post and my mind wandered again as to whether i'm doing the right thing or not lol.

Definitely can't accomodate that port size with the current setup so i'll continue on this path.

I've got the cabinately half built, ran some wiring last night and put some sound deadening panels on, today will be puttin the final side on then working on the front baffle.

Not long to go now

You need one of those "Buy me a coffee" links, I need to give you a little something for all your help

Thankyou again

I appreciate the thought... I get a lot of satisfaction from helping other people succeed, it is enough reward for me.You need one of those "Buy me a coffee" links, I need to give you a little something for all your help

I am reading low Qts.Given your large box volume and given this woofer with a low Qts, I think this infrasonic filter would be an excellent idea for you.

Keep an eye on how much you're boosting with the LT.

Anything above 6dB can potentially lead into real problems.

This is basically twice the voltage, so that's asking a lot of the pre-amp stage as well as power amp.

You have to be careful not to clip against the voltage rails

I actually never really like to go above 3-4dB of boost.

- Home

- Loudspeakers

- Multi-Way

- SB Acoustics 3 way active build - Advice