I have the same question!Maybe I missed it, but which snubber capacitor should be used in the power supply?

It's one of the X1 safety rated 'across the line' types, usually 3300pf. The PN below isn't a long leaded one like you are seeing in these builds, it's a rectangular PC-mount style. Digikey 399-9501-1-ND

From 6L6 in post #808 of this thread "The same as always, an X1Y1 rated 3300pF safety cap."

Ah, thank you both!

Thanks ranshdow. Here is a direct link for easy access.It's one of the X1 safety rated 'across the line' types, usually 3300pf. The PN below isn't a long leaded one like you are seeing in these builds, it's a rectangular PC-mount style. Digikey 399-9501-1-ND

Best,

Anand.

On another topic,

I have had communication with people who are still not reassured as to the Harris vs Vishay P channel

Mosfets for this project, so I present the attached graphic to further quell attacks of Audio Nervosa...

You see here a gain test of five P channel power Mosfets, biased at 0.5 amps and 10 volts driving

8 ohms Common Source. At the top we see the Harris 9240, then below that are the Harris and

IR versions of 9140. Slightly below that is the Fairchild 12P20 and at the bottom, shelving down

about 3 dB going into the midrange, the IRFP9240.

Interesting, the devices with flat response all have very similar distortion numbers, but the IRFP9240

actually had about 1/2 the harmonic distortion when driven to the same output level.

In any case, you can use the supplied 9140's and sleep well....

I have had communication with people who are still not reassured as to the Harris vs Vishay P channel

Mosfets for this project, so I present the attached graphic to further quell attacks of Audio Nervosa...

You see here a gain test of five P channel power Mosfets, biased at 0.5 amps and 10 volts driving

8 ohms Common Source. At the top we see the Harris 9240, then below that are the Harris and

IR versions of 9140. Slightly below that is the Fairchild 12P20 and at the bottom, shelving down

about 3 dB going into the midrange, the IRFP9240.

Interesting, the devices with flat response all have very similar distortion numbers, but the IRFP9240

actually had about 1/2 the harmonic distortion when driven to the same output level.

In any case, you can use the supplied 9140's and sleep well....

Attachments

I recently bought the F5M essentials kit and it came with the PS V1R1 board. I see the full kit comes with 35V rated power supply caps. The 2005 First Watt PS 0 R1 power supply CRC filtered design calls for capacitors rated at 25V downstream of a bridge on each 18V secondary. I've used that design for my F6 and M2X builds with 25V caps and never had any problems. I just measured my M2X supply which uses the 300W AnTek transformer and I get just under 24V on each rail ahead of the RC when the PS is disconnected from the amp boards.

Any reason why I could not use some of the 15000uF 25V TDK/Epcos caps I already have with the new V1R1 PS design? It does not seem that the lack of the 2.2K bleeder would make much difference in the unloaded voltage. Coincidentally, they are the same part number capacitor used in the ACAmini (which I do realize uses a regulated 24V supply).

I also have a bunch of 10 ohm 6A thermistors. Any reason not to use those in all 5 positions?

Any reason why I could not use some of the 15000uF 25V TDK/Epcos caps I already have with the new V1R1 PS design? It does not seem that the lack of the 2.2K bleeder would make much difference in the unloaded voltage. Coincidentally, they are the same part number capacitor used in the ACAmini (which I do realize uses a regulated 24V supply).

I also have a bunch of 10 ohm 6A thermistors. Any reason not to use those in all 5 positions?

Attachments

https://www.diyaudio.com/community/threads/f5m-kit.408290/post-7683704

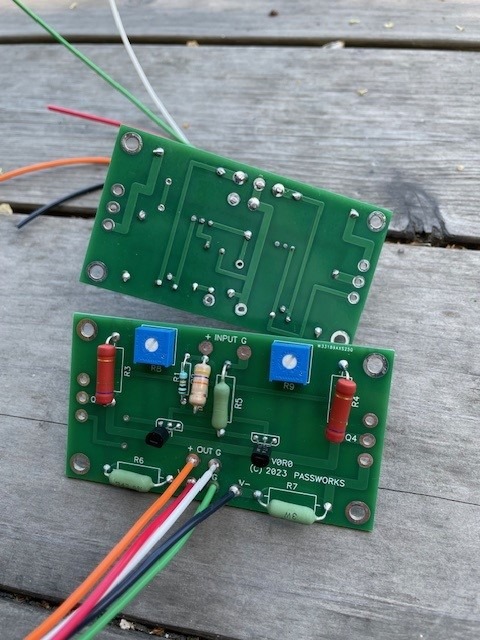

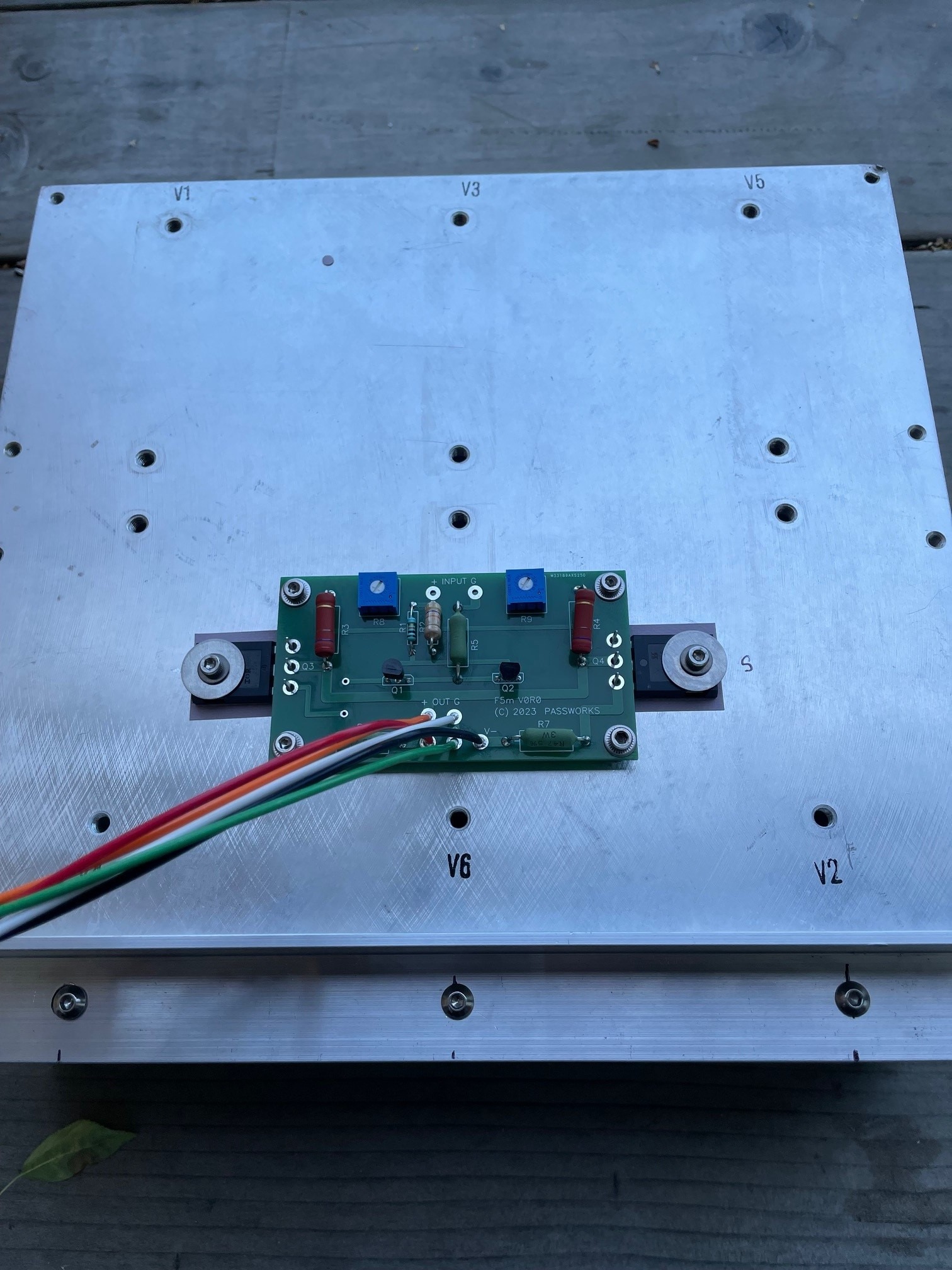

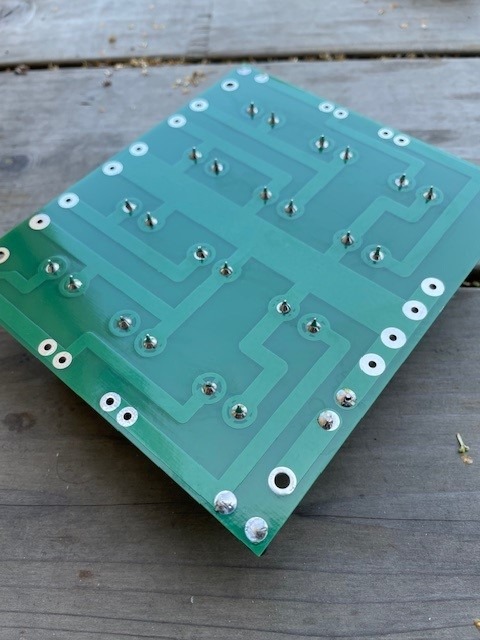

Flux, cleaned, for your inspection. And thanks NP re 9140s.

https://www.diyaudio.com/community/threads/f5m-kit.408290/post-7687559

This is my second drill/tap rodeo, getting slightly better results, but warn you I did strip the Q4 mount on one side, increased the fastener to M3.5 fortunately I had the drill / tap / and hardware.

Flux, cleaned, for your inspection. And thanks NP re 9140s.

https://www.diyaudio.com/community/threads/f5m-kit.408290/post-7687559

This is my second drill/tap rodeo, getting slightly better results, but warn you I did strip the Q4 mount on one side, increased the fastener to M3.5 fortunately I had the drill / tap / and hardware.

@JKiriakis

One bit of tap related info that you and others might find useful if you're tapping blind holes (as opposed to through holes) is to buy a Bottom Tap. Of the 3 common tap types, taper taps have the longest taper, plug taps are the most common and have a medium taper and bottom taps have a squared off tip to allow threading deeper into the hole. Start with your plug tap and finish with a bottom tap. This is particularly useful with HS that have thinner back plates. Cheers

One bit of tap related info that you and others might find useful if you're tapping blind holes (as opposed to through holes) is to buy a Bottom Tap. Of the 3 common tap types, taper taps have the longest taper, plug taps are the most common and have a medium taper and bottom taps have a squared off tip to allow threading deeper into the hole. Start with your plug tap and finish with a bottom tap. This is particularly useful with HS that have thinner back plates. Cheers

While blind tapping with small diameter taps such as M3, there is always the danger of breaking the tap and having the broken tap stuck in the hole (been there, done that). What I do now is try to align the hole between heatsink fins and drill through so blind tapping is avoided.

Maybe this question has been answered but with the V1R1 PS board, would it be better to leave out the jumpers and use at least double the minimum capacitance of 4700uF in each cap position? That looks like it would provide more isolation between the channel boards.

For stereo operation (one PS board for two channels), leave out the jumper. You can increase capacitance.

The jumpers are for monoblock or dual mono, where one PS board is used for one channel.

To add one can buy taps specific to aluminum. With the priciest a tap that removes swarf from the bottom to the top.One bit of tap related info that you and others might find useful if you're tapping blind holes (as opposed to through holes) is to buy a Bottom Tap. Of the 3 common tap types, taper taps have the longest taper, plug taps are the most common and have a medium taper and bottom taps have a squared off tip to allow threading deeper into the hole. Start with your plug tap and finish with a bottom tap. This is particularly useful with HS that have thinner back plates. Cheers

And even more important is Tap Magic to prevent the tap from galling, sticking then breaking.

I have found that liberal application of a cutting or tapping fluid (I use WD-40) and also very important, to reverse direction of the tap often to break and clear the cut material. And if the effort required suddenly increases, reverse and remove the tap and check for clogged tap or other issues.

Take it slow and don't rush it. A broken tap stuck in the hole will ruin your day.

Take it slow and don't rush it. A broken tap stuck in the hole will ruin your day.

Best advice^^^^I have found that liberal application of a cutting or tapping fluid (I use WD-40) and also very important, to reverse direction of the tap often to break and clear the cut material. And if the effort required suddenly increases, reverse and remove the tap and check for clogged tap or other issues.

Take it slow and don't rush it. A broken tap stuck in the hole will ruin your day.

Oil, turn only until slightest drag can be felt, don't wait for it to bind. It will break. Back all the way out and brush off the muck and carefully start again once or twice. No need to hurry.

As others have said, if you can get holes in PCB to align between the fins you can drill through and use a screw from the fin side. Last amp's heatsink I drilled and tapped was XA 252 from Zenmod. Holes lined up perfectly between fins. I drilled and tapped them as planned, but since they were between fins if tapping went badly I could just drill out and use screw from fin side.

Russellc

And even more important is Tap Magic to prevent the tap from galling, sticking then breaking.

I can attest that there's no guarantee that Tap Magic prevents any of those said issues.

In all machining operations from Manual to CNC lubricants are used to allow the cutter to bite (cut) and not drag which causes broken tooling. That said you don't need it. IF YOU are skilled and wish to take the time to keep the operation clean AND wear out the tooling prematurely without lubrication. Do you have the $ to pay for new drills, taps and can physically keep them sharp Don't use it then.I can attest that there's no guarantee that Tap Magic prevents any of those said issues.

There are specific expensive drills and taps designed for aluminum. Is that a DIY standard policy or does one just get crap tools and even expect it to cut without lube?

Even in woodwerking wax is used to cut threads.

Bottom line is the "skill" of the operator prevents broken tooling. Tap magic gives you a chance to prevent the immediate 'snap' by allowing you to back out the tap before your overzealous application of torque to get one more hole done creates something few have the skill to repair.

This is not even bringing up the subject of Tap Machines and collets designed to keep the hole and threads straight. How many DIY 's can drill a round straight hole without it walking all over?

Moduhop is running lube and have tap programs to get rid of operator error.

Last edited:

- Home

- Amplifiers

- Pass Labs

- F5m kit