Should I continue with making my new tone arm public in this thread or should I start a new thread?

Keep it all in this thread. These are normal design refinements.

Hi Everyone,

In order to continue this thread with the new and improved version of my tangentially tracking tone arm and its "floating head-shell", I have to digress and post some pictures of a tone arm I designed and built in 2021-2022.

When I wrote my application for US patent, I discovered that, my floating head-shell would be of benefit to conventional pivoting tone arms. When I mentioned that to a European manufacturer, he asked me to design a conventional pivoting tone arm incorporating my floating head-shell. The tone arm was to conform to Bearwald geometry and have a tone arm pivot to turntable spindle distance of 222mm.

I now have five of those tone arms and have not heard another word from that manufacturer. The tonearm only, minus the base for rotation, was designed very much like my tangentially tracking tone arm. but with improvements. After looking at that tone arm for a while, I decided to apply these improvements to a new version of my existing tangential tone arm and while I was at it, I decided to improve my existing tangentially tracking tone arm from top to bottom.

Even though the pictures I am going to post, don't belong in this thread, I need to show them so that everyone understands what lead me to this improvement craze.

I also intend to start a new thread featuring the tone arm I designed for the above mentioned European.

The last two PDF files are of my new tangentially tracking tone arm and they are CAD only, because no metal has been cut yet.

Sincerely,

Ralf

In order to continue this thread with the new and improved version of my tangentially tracking tone arm and its "floating head-shell", I have to digress and post some pictures of a tone arm I designed and built in 2021-2022.

When I wrote my application for US patent, I discovered that, my floating head-shell would be of benefit to conventional pivoting tone arms. When I mentioned that to a European manufacturer, he asked me to design a conventional pivoting tone arm incorporating my floating head-shell. The tone arm was to conform to Bearwald geometry and have a tone arm pivot to turntable spindle distance of 222mm.

I now have five of those tone arms and have not heard another word from that manufacturer. The tonearm only, minus the base for rotation, was designed very much like my tangentially tracking tone arm. but with improvements. After looking at that tone arm for a while, I decided to apply these improvements to a new version of my existing tangential tone arm and while I was at it, I decided to improve my existing tangentially tracking tone arm from top to bottom.

Even though the pictures I am going to post, don't belong in this thread, I need to show them so that everyone understands what lead me to this improvement craze.

I also intend to start a new thread featuring the tone arm I designed for the above mentioned European.

The last two PDF files are of my new tangentially tracking tone arm and they are CAD only, because no metal has been cut yet.

Sincerely,

Ralf

Attachments

-

Tone_arm_complete_at_rest.pdf89.9 KB · Views: 149

-

Tone_arm_complete_at_rest_rear.pdf69 KB · Views: 143

-

TA7M1_right_side.jpg186.1 KB · Views: 190

TA7M1_right_side.jpg186.1 KB · Views: 190 -

TA7M1_right_close_up.jpg304.1 KB · Views: 193

TA7M1_right_close_up.jpg304.1 KB · Views: 193 -

TA7M1_left_side_close_up.jpg300.9 KB · Views: 190

TA7M1_left_side_close_up.jpg300.9 KB · Views: 190 -

tone_arm_2023_at_rest_right_assy.pdf82.3 KB · Views: 107

-

tone_arm_2023_at_rest_left_assy.pdf91.5 KB · Views: 108

Hello everyone,

I have made great progress since I announced that I would build two improved tangentially tracking tone arms. At that time, I had finished all the CAD work and I was ready to start making hardware. Since then, I have ordered all the materials and off the shelf items. I divided all the parts to be made into four groups: 1), Lathe parts that I would make in my friends shop, using his lathe, 2), Lathe parts that I would pay another friend to make in his shop, 3), CNC parts that I would make in still another friends shop, using his CNC vertical milling machine and 4), parts that I would make in my own shop using my own Bridgeport milling machine. The parts in the first group are completely finished, while the parts in groups 2) and 3) require secondary work in my own shop.

The pictures I am posting, are from all four groups; some are completely finished and some need secondary operations.

This weekend I am going to try to make a video of my 3D solid model of the new tone arm explaining its various features.

Sincerely,

Ralf

I have made great progress since I announced that I would build two improved tangentially tracking tone arms. At that time, I had finished all the CAD work and I was ready to start making hardware. Since then, I have ordered all the materials and off the shelf items. I divided all the parts to be made into four groups: 1), Lathe parts that I would make in my friends shop, using his lathe, 2), Lathe parts that I would pay another friend to make in his shop, 3), CNC parts that I would make in still another friends shop, using his CNC vertical milling machine and 4), parts that I would make in my own shop using my own Bridgeport milling machine. The parts in the first group are completely finished, while the parts in groups 2) and 3) require secondary work in my own shop.

The pictures I am posting, are from all four groups; some are completely finished and some need secondary operations.

This weekend I am going to try to make a video of my 3D solid model of the new tone arm explaining its various features.

Sincerely,

Ralf

Attachments

Hi Ralf,

Kudos for your dedication to this project! 🙏👍And empathy regarding the difficulty in bring it to market.

At the risk of stating the obvious, have you considered the way some tonearm developers have gone the independent route? Kind of like self publishing. Jeff Spall's Audiomods comes to mind -- http://www.audiomods.co.uk/ -- if only because I bought and built a couple of his kits, and I like his products. For a limited, high ticket niche product, this might be a viable route. You'll probably need help with logistics. I know this kind of business can quickly become too much for one person to handle.

Kudos for your dedication to this project! 🙏👍And empathy regarding the difficulty in bring it to market.

At the risk of stating the obvious, have you considered the way some tonearm developers have gone the independent route? Kind of like self publishing. Jeff Spall's Audiomods comes to mind -- http://www.audiomods.co.uk/ -- if only because I bought and built a couple of his kits, and I like his products. For a limited, high ticket niche product, this might be a viable route. You'll probably need help with logistics. I know this kind of business can quickly become too much for one person to handle.

Straight Tracker, your ingenuity and perseverence is to be applauded. Well done!

It strikes me that your tonearm is sort of the opposite to the Technics linear-tracking tonearm.

They have a linear servo for low-frequency traversing movement and a rotary (pivoting) passive assembly for high-frequency traversing movement, whereas yours has a rotary servo for low-frequency traversing movement and a linear passive assembly for high-frequency traversing movement.

That's oversimplified of course, but an interesting comparison!

Cheers,

Mike

It strikes me that your tonearm is sort of the opposite to the Technics linear-tracking tonearm.

They have a linear servo for low-frequency traversing movement and a rotary (pivoting) passive assembly for high-frequency traversing movement, whereas yours has a rotary servo for low-frequency traversing movement and a linear passive assembly for high-frequency traversing movement.

That's oversimplified of course, but an interesting comparison!

Cheers,

Mike

Hi Mike,

Thank you for your kind words.

I am not at all familiar with the Technics tangentially tracking tone arm although it must be a good one considering the manufacturer.

My tone arm is actually not servo controlled. Its tangential accuracy is mechanically controlled by two precision machined cams. The geometry of the cams allows the tone arm to track an LP with zero tracking error. However, the "inward force" (my term for antiskating force) still exists but is controlled by a servo.

Because the "inward force" varies considerably, I designed the head-shell to move independently of the tone arm itself with a clearance of plus or minus .090".

If you knew all that, my apologies.

Sincerely,

Ralf

Thank you for your kind words.

I am not at all familiar with the Technics tangentially tracking tone arm although it must be a good one considering the manufacturer.

My tone arm is actually not servo controlled. Its tangential accuracy is mechanically controlled by two precision machined cams. The geometry of the cams allows the tone arm to track an LP with zero tracking error. However, the "inward force" (my term for antiskating force) still exists but is controlled by a servo.

Because the "inward force" varies considerably, I designed the head-shell to move independently of the tone arm itself with a clearance of plus or minus .090".

If you knew all that, my apologies.

Sincerely,

Ralf

Hi zincho,

Both. I have a Bridgeport vertical milling machine with a variable speed head and I have three friends who have CNC machines. The three friends are former colleagues at the manufacturing company from which I retired. I took one semester of CNC programming, set-up and operating at a local community college in Prescott Arizona. I can set-up and operate their machinery without them having to do it for me.

Sincerely,

Ralf

Both. I have a Bridgeport vertical milling machine with a variable speed head and I have three friends who have CNC machines. The three friends are former colleagues at the manufacturing company from which I retired. I took one semester of CNC programming, set-up and operating at a local community college in Prescott Arizona. I can set-up and operate their machinery without them having to do it for me.

Sincerely,

Ralf

Hello everyone,

In 2022 while I was preparing my application for US patent, I discovered that, my design of the floating head-shell would also be of benefit to conventional pivoting tone arms. So, at the behest of a European manufacturer I designed and built five conventional pivoting tone arms with floating head-shells. The overall design incorporates certain improvements over my original 2019 tangential tone arm.

When I decided to build the new improved version of my tangential tone arm which is the subject of this thread from now on, I decided to include some of the improvements from the conventional pivoting tone arm.

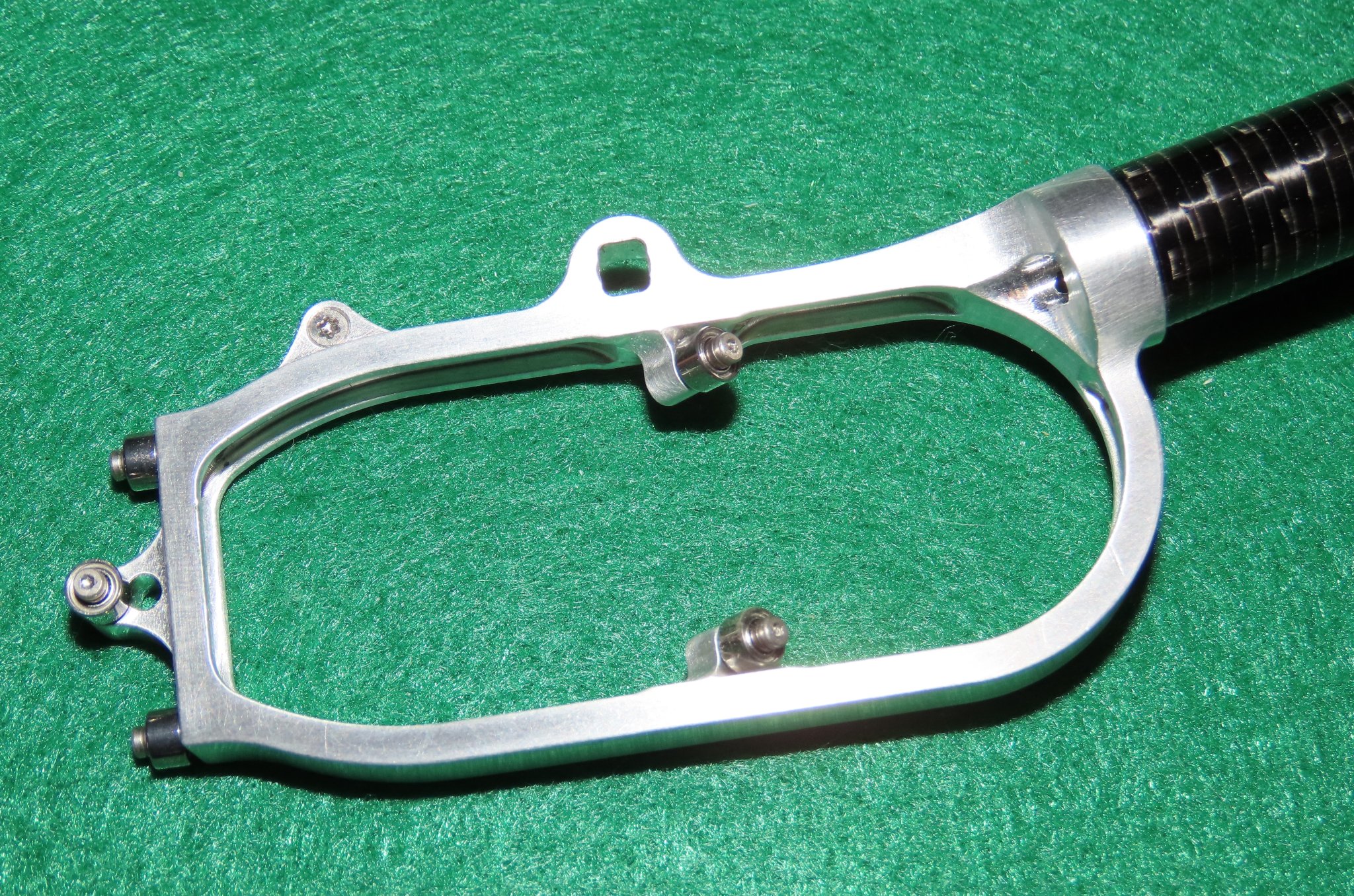

The first photograph shows the conventional pivoting tone arm and underneath it shows my new and improved tangential tone arm. You will notice, that both arms have an off-set cradle. The off-set of the top tone arm is of conventional Baerwald construction while the off-set of the bottom arm is ~12 degrees.

You might rightfully ask, why a tangential tone arm would need an off-set head-shell?

There are two reasons for the off-set: A pivoting tangential tone arm's pivot has to be moved from point A to point B during the playing of an LP. If the tone arm has a straight head-shell, that distance would be ~1.6". By off-setting the head-shell, that distance can be reduced by close to 50%, resulting in a less bulky support structure. The second reason for off-setting the head-shell is that, it makes the arm "self-propelled" as it traverses the LP.

My 2019 tangential tone arm featured diameter 5/32" flex pivots, whereas in my improved version I doubled the diameter of the flex pivots to 5/16". They have the same spring rate but are sturdier and easier to handle.

The second photograph shows a side view of my new tone arm.

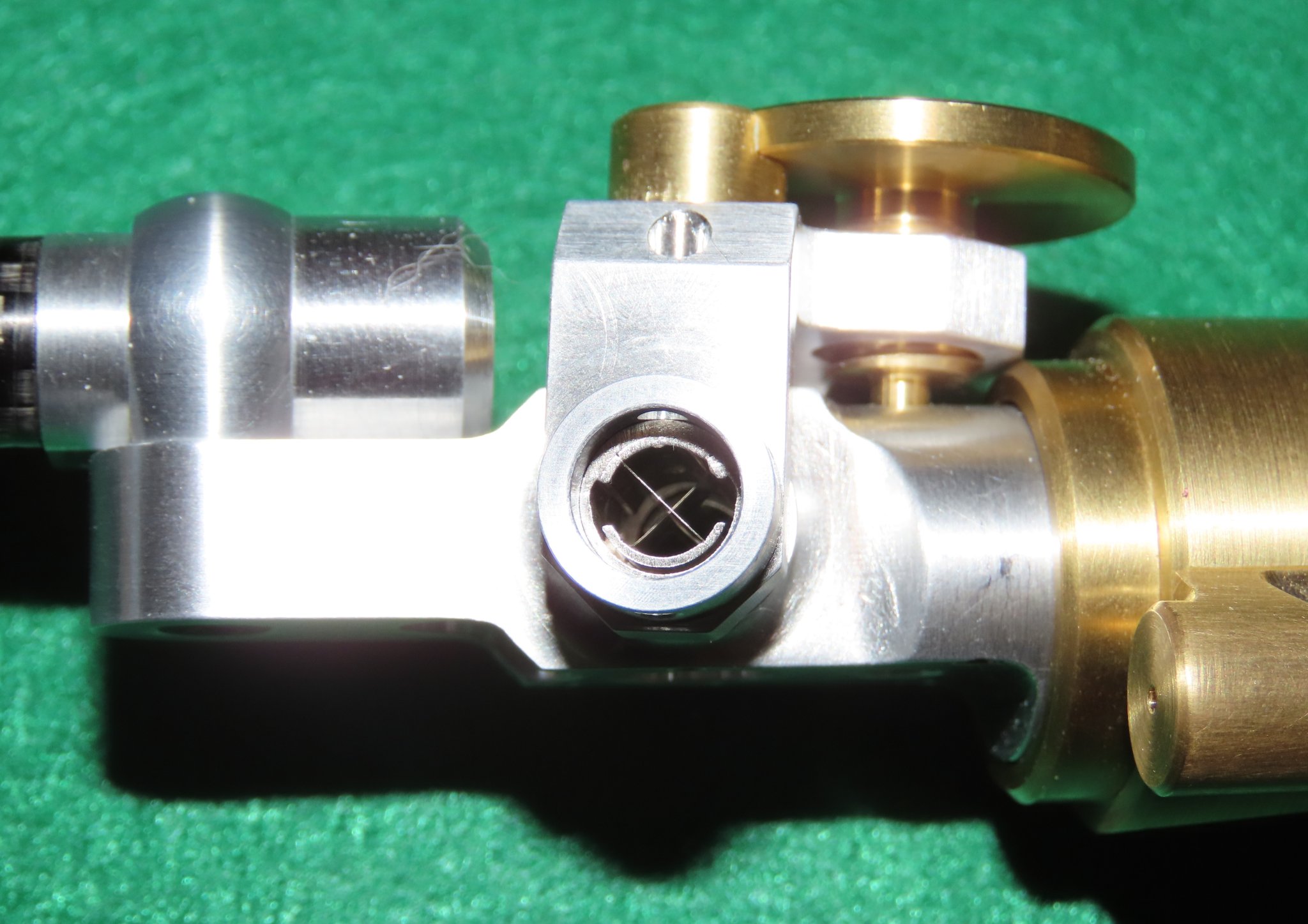

The third photograph shows a close-up of the flex pivots. I didn't give that away until now, but I twist the flex pivots to apply tracking force. The arm always remains dynamically balanced.

The fourth photograph shows the cradle, featuring a spike to set tracking force without resting the stylus on the tracking force gage. This website inserted the fourth photograph as if it were the first. WTF?

Sincerely,

Ralf

In 2022 while I was preparing my application for US patent, I discovered that, my design of the floating head-shell would also be of benefit to conventional pivoting tone arms. So, at the behest of a European manufacturer I designed and built five conventional pivoting tone arms with floating head-shells. The overall design incorporates certain improvements over my original 2019 tangential tone arm.

When I decided to build the new improved version of my tangential tone arm which is the subject of this thread from now on, I decided to include some of the improvements from the conventional pivoting tone arm.

The first photograph shows the conventional pivoting tone arm and underneath it shows my new and improved tangential tone arm. You will notice, that both arms have an off-set cradle. The off-set of the top tone arm is of conventional Baerwald construction while the off-set of the bottom arm is ~12 degrees.

You might rightfully ask, why a tangential tone arm would need an off-set head-shell?

There are two reasons for the off-set: A pivoting tangential tone arm's pivot has to be moved from point A to point B during the playing of an LP. If the tone arm has a straight head-shell, that distance would be ~1.6". By off-setting the head-shell, that distance can be reduced by close to 50%, resulting in a less bulky support structure. The second reason for off-setting the head-shell is that, it makes the arm "self-propelled" as it traverses the LP.

My 2019 tangential tone arm featured diameter 5/32" flex pivots, whereas in my improved version I doubled the diameter of the flex pivots to 5/16". They have the same spring rate but are sturdier and easier to handle.

The second photograph shows a side view of my new tone arm.

The third photograph shows a close-up of the flex pivots. I didn't give that away until now, but I twist the flex pivots to apply tracking force. The arm always remains dynamically balanced.

The fourth photograph shows the cradle, featuring a spike to set tracking force without resting the stylus on the tracking force gage. This website inserted the fourth photograph as if it were the first. WTF?

Sincerely,

Ralf

Hello everyone,

I am back with three new drawings, showing the construction of my tone arm and how I assemble the tone arm with precision.

I manufacture my tone arm parts with an accuracy of +or-.003" and in some cases +or- .0002". Because of an unavoidable build-up of tolerances, it is impossible to guarantee the precise dimensional relationship of the cradle to the tone arm pivot housing without building a special assembly gage.

The first drawing shows an exploded view of the various parts of the tone arm and how they relate to each other.

The second drawing shows an isometric view of the assembled tone arm parts held in their correct relationship to each other within a specially designed alignment fixture. This fixture is made to an accuracy of +or-.0002".

The third drawing shows an isometric view of the alignment fixture including the tone arm parts minus the tone arm tube. This tube would have a nominal length of 4.9294" if all the other parts of the tone arm had zero tolerances. The missing tone arm tube is replaced by two "measuring tubes", each measuring 2.410" in length, leaving an approximate gap of .1094" between them. By sliding gage blocks of differing thicknesses into the gap, I determine the exact length of the tone arm tube of this particular assembly, by adding the lengths of the measuring tubes to the one gage block that provides a "sliding fit" in the gap between the measuring tubes. The parts comprising this tone arm assembly should be kept together thereafter and not be mixed with the parts of other tonearm assemblies.

More photos, next post.

Sincerely,

Ralf

I am back with three new drawings, showing the construction of my tone arm and how I assemble the tone arm with precision.

I manufacture my tone arm parts with an accuracy of +or-.003" and in some cases +or- .0002". Because of an unavoidable build-up of tolerances, it is impossible to guarantee the precise dimensional relationship of the cradle to the tone arm pivot housing without building a special assembly gage.

The first drawing shows an exploded view of the various parts of the tone arm and how they relate to each other.

The second drawing shows an isometric view of the assembled tone arm parts held in their correct relationship to each other within a specially designed alignment fixture. This fixture is made to an accuracy of +or-.0002".

The third drawing shows an isometric view of the alignment fixture including the tone arm parts minus the tone arm tube. This tube would have a nominal length of 4.9294" if all the other parts of the tone arm had zero tolerances. The missing tone arm tube is replaced by two "measuring tubes", each measuring 2.410" in length, leaving an approximate gap of .1094" between them. By sliding gage blocks of differing thicknesses into the gap, I determine the exact length of the tone arm tube of this particular assembly, by adding the lengths of the measuring tubes to the one gage block that provides a "sliding fit" in the gap between the measuring tubes. The parts comprising this tone arm assembly should be kept together thereafter and not be mixed with the parts of other tonearm assemblies.

More photos, next post.

Sincerely,

Ralf

Attachments

- Home

- Source & Line

- Analogue Source

- A Revolutionary Pivoting Tangential Tone Arm