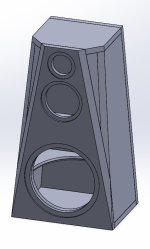

I am in the process of finalizing my cabinet design for a 3 way 10" woofer build that will be very similar to hifijim's budget 3 way speakers he has been working. The speakers will be passive, even if it sacrifices some performance away from ideal, because I enjoy the ability to mess with different amps, preamps, DACs, ect. It will use:

Woofer: RS270-4, vented 30L, Fb 32Hz, port length 18cm, port dia 5.5cm

Mid: SB15NBAC30-4, sealed 4L

Tweeter: SB26ADC

I have already used Vituix to simulate most aspects of the design including the baffle diffraction and enclosure volumes/port sizes. However, I am having trouble figuring out the ideal placement of the port based on internal geometry (not distance between room wall and speaker port). The cabinet is quite shallow, not leaving much room between the front baffle internal wall and where internal port entrance is as seen in the images.

I am wondering whether this will be enough room (~1.5 inches from port to wall) or if moving to an elbowed port will be necessary. If anyone has experience/ideas for the internal port clearances or suggestions as to what I can do differently please let me know. Thanks!

Woofer: RS270-4, vented 30L, Fb 32Hz, port length 18cm, port dia 5.5cm

Mid: SB15NBAC30-4, sealed 4L

Tweeter: SB26ADC

I have already used Vituix to simulate most aspects of the design including the baffle diffraction and enclosure volumes/port sizes. However, I am having trouble figuring out the ideal placement of the port based on internal geometry (not distance between room wall and speaker port). The cabinet is quite shallow, not leaving much room between the front baffle internal wall and where internal port entrance is as seen in the images.

I am wondering whether this will be enough room (~1.5 inches from port to wall) or if moving to an elbowed port will be necessary. If anyone has experience/ideas for the internal port clearances or suggestions as to what I can do differently please let me know. Thanks!

Attachments

The generally accepted best practice is that if the port is flared on one end, it should be flared on the other. Another generally accepted rule is that the distance from the port exit to an internal wall should be at least one radius. So with a 55 mm port, a distance of 38 mm (1.5 inch) would be acceptable. However, you are leaving yourself very little room for adjustment. When you measure the port response, you may find it is several Hz above or below the target. If you need to make the port tube longer, you will have some complexity to deal with.

Rather than make a recommendation regarding an elbow, I would prefer that others offer an opinion. I have built so few ported speakers that I don't think my advice would be worth much...

Good luck to you !

j.

Rather than make a recommendation regarding an elbow, I would prefer that others offer an opinion. I have built so few ported speakers that I don't think my advice would be worth much...

Good luck to you !

j.

1) I'm not sure I'd be too concerned with the 1.5 inch distance, but as Jim pointed out, you make not get the tuning you are targeting

2) If you can add a flare to the internal end that will help

3) I just built a design with the RS270P-4A. Lined with the new 50mm Sonic Barrier denim damping material. My port was MUCH shorter than what WinISD had predicted. Of course you can't really count on this as you build the cabinet, but in the end you may have room to spare.

2) If you can add a flare to the internal end that will help

3) I just built a design with the RS270P-4A. Lined with the new 50mm Sonic Barrier denim damping material. My port was MUCH shorter than what WinISD had predicted. Of course you can't really count on this as you build the cabinet, but in the end you may have room to spare.

Round and straight work better than any other easily diy port. I would avoid elbows and turns if you can. I use 1 diameter or 3”, whichever is greater as a bare minimum for distance from port end to wall.

I would not call myself an expert but have built hundreds of ported enclosures. Most of these things are documented if you look around.

I would not call myself an expert but have built hundreds of ported enclosures. Most of these things are documented if you look around.

Sharing a wall like a triangle port or slot port.

There is known correction factors to get models to match real life closer.

But those numbers jump up above decimal point for end correction.

Say triangle port 1.7 or slot port 2.27

Not related to free standing round ports.

But example shown and mentioned to show, how if a port is near or shares a wall.

To make models maybe match real life. Thiele/ Small worked out

correction factors to improve models.

Basically a shared wall or boundary makes the actual port length

needed to be shorter. Since it behaves as if were longer from a wall

boundary.

.732 is considered for a port sharing no walls in your case.

Or round port with no wall boundaries.

And when you start to add flares highest correction factor

usually no more than .850 to .9

So if you have a round port with say one flare.

Correction factor of .732 would be raised to .850

And then if you had a round port mounted very close to a wall.

Your case likely use .860 to .910 to slightly shorten the length.

With a reflex enclosure if the box is small say under 25 liters

like a 10 or 15 liter bookshelf. That is when you worry about being

critical about port length. Because in small boxes, slight change

it port length will cause larger jumps.

In larger boxes around 40 to 60 liters.

Slight inaccuracy of port length wont matter as much.

And very very large boxes say 100 to 160 liters.

Then port length needs pretty long lengths to cause

any change. So slight inaccuracy wont cause a big jump

like a small box.

There is known correction factors to get models to match real life closer.

But those numbers jump up above decimal point for end correction.

Say triangle port 1.7 or slot port 2.27

Not related to free standing round ports.

But example shown and mentioned to show, how if a port is near or shares a wall.

To make models maybe match real life. Thiele/ Small worked out

correction factors to improve models.

Basically a shared wall or boundary makes the actual port length

needed to be shorter. Since it behaves as if were longer from a wall

boundary.

.732 is considered for a port sharing no walls in your case.

Or round port with no wall boundaries.

And when you start to add flares highest correction factor

usually no more than .850 to .9

So if you have a round port with say one flare.

Correction factor of .732 would be raised to .850

And then if you had a round port mounted very close to a wall.

Your case likely use .860 to .910 to slightly shorten the length.

With a reflex enclosure if the box is small say under 25 liters

like a 10 or 15 liter bookshelf. That is when you worry about being

critical about port length. Because in small boxes, slight change

it port length will cause larger jumps.

In larger boxes around 40 to 60 liters.

Slight inaccuracy of port length wont matter as much.

And very very large boxes say 100 to 160 liters.

Then port length needs pretty long lengths to cause

any change. So slight inaccuracy wont cause a big jump

like a small box.

People care to much for the wrong things.

The tuning of the finished enclosure has quite some variables, throwing your .0017" exact simulation out of orbit.

First, the driver has not the TSP of the data sheet. Maybe near, but not exactly. Some manufacturer use 20 year old measurements for TSP. Since then any component and tollerance has changed. Some just write down some numbers they think are good for sales.

Next you can not predict the exact volume of your cabinet, actually seen by the driver.

Braces (I hope you use them!), and build in cavities, like from a midrange speaker enclosure, just as damping (not neccesary if you cross over low) change the volume.

Best is to adjust the tuning with the finished cabinet. You can measure impedance or output of the vent, then make it longer or shorten it.

Takes you maybe 10 minutes and you are spot on.

Best is to precondition your woofers, measure the TSP and take the average for your simulation. Then adjust in the finished build as described.

The tuning of the finished enclosure has quite some variables, throwing your .0017" exact simulation out of orbit.

First, the driver has not the TSP of the data sheet. Maybe near, but not exactly. Some manufacturer use 20 year old measurements for TSP. Since then any component and tollerance has changed. Some just write down some numbers they think are good for sales.

Next you can not predict the exact volume of your cabinet, actually seen by the driver.

Braces (I hope you use them!), and build in cavities, like from a midrange speaker enclosure, just as damping (not neccesary if you cross over low) change the volume.

Best is to adjust the tuning with the finished cabinet. You can measure impedance or output of the vent, then make it longer or shorten it.

Takes you maybe 10 minutes and you are spot on.

Best is to precondition your woofers, measure the TSP and take the average for your simulation. Then adjust in the finished build as described.

Not to be controversially critical but I've always understood that the clearance between the internal end of a port and an internal wall should be 1 diameter, not 1 radius? "Fudging" a little is okay, however.The generally accepted best practice is that if the port is flared on one end, it should be flared on the other. Another generally accepted rule is that the distance from the port exit to an internal wall should be at least one radius. So with a 55 mm port, a distance of 38 mm (1.5 inch) would be acceptable. However, you are leaving yourself very little room for adjustment. When you measure the port response, you may find it is several Hz above or below the target. If you need to make the port tube longer, you will have some complexity to deal with.

Rather than make a recommendation regarding an elbow, I would prefer that others offer an opinion. I have built so few ported speakers that I don't think my advice would be worth much...

Good luck to you !

j.

Paul

Probably true...I've always understood that the clearance between the internal end of a port and an internal wall should be 1 diameter, not 1 radius?

Sorry to throw a wrench in, but 5.5 cm is way too small a diameter for a 10 inch woofer. Most people make their ports too small. They get anemic bass and they don’t know it because it’s just like everyone else’s designs.

The RS 270 is a very good driver. It can displace a lot of air, and at box resonance at full excursion, you will get a lot of chuffing and air noise.

For a 10” woofer I wouldn’t use anything smaller than a 3 inch diameter port. I would also use a port that is flared on both ends.

I acknowledge this may mess up your existing design, it will require a port that’s about twice as long, but it makes a major difference to use a port that is generously sized, especially at high SPL levels. You get much more authoritative bass and more dynamic range.

The RS 270 is a very good driver. It can displace a lot of air, and at box resonance at full excursion, you will get a lot of chuffing and air noise.

For a 10” woofer I wouldn’t use anything smaller than a 3 inch diameter port. I would also use a port that is flared on both ends.

I acknowledge this may mess up your existing design, it will require a port that’s about twice as long, but it makes a major difference to use a port that is generously sized, especially at high SPL levels. You get much more authoritative bass and more dynamic range.

Last edited:

If you can't fit a well sized vent, concider a passive radiator on the back. Soundwise the best solution. Simple to tune.

For a larger port just take two, with elbows. With larger, longer vents you can use simple ends, no absolute need for large flares.

I heat plastic pipe up and press it on a bottle the right size, that way you get a flared inside end for free. The other end can be cut round in the wood of the cabinet with a router bit. Just glue a round or square piece of wood with a matching hole on the inside, doubling up the wood to solidly mount the pipe.

For a larger port just take two, with elbows. With larger, longer vents you can use simple ends, no absolute need for large flares.

I heat plastic pipe up and press it on a bottle the right size, that way you get a flared inside end for free. The other end can be cut round in the wood of the cabinet with a router bit. Just glue a round or square piece of wood with a matching hole on the inside, doubling up the wood to solidly mount the pipe.

All,

Thanks for your replies and discussion. To clarify some things or conglomerate things I have noticed.

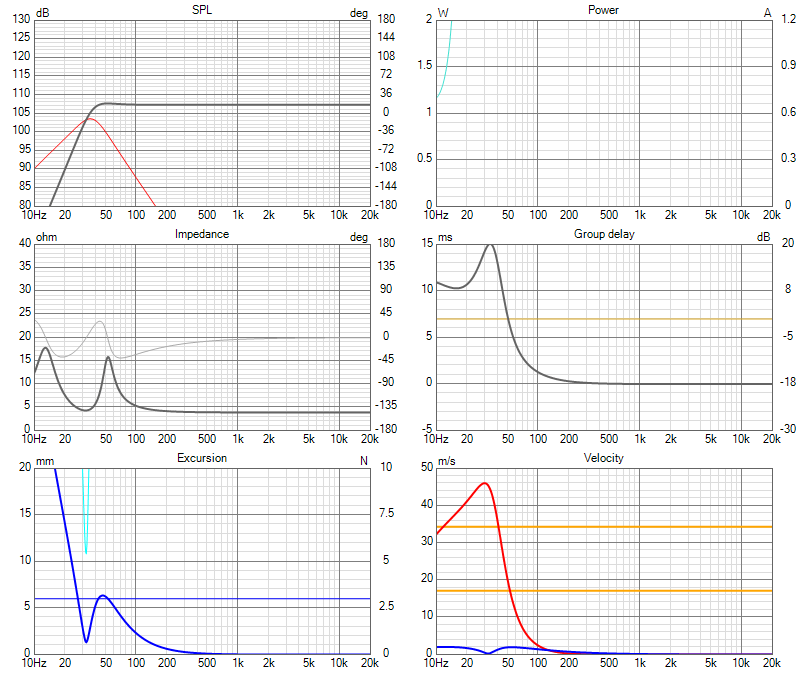

1) I have ran a port simulation with a max air velocity of 30 m/s at Xmax. With the flared port I am less concerned about turbulence but will take the tip and move to a larger diameter due to responsiveness.

2) Seems like double flared is the way to go.

3) Passive radiator may be an option but would increase the price out of my ideal range.

4) True port length to achieve a tuning never follows the calculated values exactly (obviously haha).

5) Ideally keep port distance 1 diameter (worst case 1 R) from cabinet wall.

I appreciate everyone's dialogue and being helpful with this. I may mess with the modeling a bit to try and do a 2.75-3in port. I am going to be custom modeling and printing these ports (ABS vapor smoothed so there won't be layer lines which could increase boundary layer turbulence) so I'm not worried about exact dimensions as it's custom anyway.

I like the current form factor of the cabinets, so I will mess with port location/geometry to fit before modifying cabinet dimensions. Most likely I will look at a top mounted port (not ideal) or an elbowed rear port in the top section behind the mid enclosure. If anyone has further suggestions I am all ears.

Thanks for your replies and discussion. To clarify some things or conglomerate things I have noticed.

1) I have ran a port simulation with a max air velocity of 30 m/s at Xmax. With the flared port I am less concerned about turbulence but will take the tip and move to a larger diameter due to responsiveness.

2) Seems like double flared is the way to go.

3) Passive radiator may be an option but would increase the price out of my ideal range.

4) True port length to achieve a tuning never follows the calculated values exactly (obviously haha).

5) Ideally keep port distance 1 diameter (worst case 1 R) from cabinet wall.

I appreciate everyone's dialogue and being helpful with this. I may mess with the modeling a bit to try and do a 2.75-3in port. I am going to be custom modeling and printing these ports (ABS vapor smoothed so there won't be layer lines which could increase boundary layer turbulence) so I'm not worried about exact dimensions as it's custom anyway.

I like the current form factor of the cabinets, so I will mess with port location/geometry to fit before modifying cabinet dimensions. Most likely I will look at a top mounted port (not ideal) or an elbowed rear port in the top section behind the mid enclosure. If anyone has further suggestions I am all ears.

All,

1) I have ran a port simulation with a max air velocity of 30 m/s at Xmax. With the flared port I am less concerned about turbulence but will take the tip and move to a larger diameter due to responsiveness.

A couple of comments...

30 m/s is almost surely too high. The one caveat I'd mention is at what frequency? If it is at 25hz then this is probably not where you should be looking as there isn't much music content that low and your speaker is probably pretty far down at that point. My guess is that with the RS270 it was in the 30-40Hz range and it does matter.

With a large flare I usually target 24 m/s max. Not scientific evidence showing that is a good number though. The typical "rule of thumb" is 17 m/s but I never target that.

If I'm working with a smaller cabinet and the port length is really going to be a problem, I'll model the power to reach x-max and then cut it in half and look at port velocity. I don't listen to my speakers at xmax. If I'm building a "no-compromise" speaker, then I wouldn't do this though.

Thanks for the suggestions. I just went back through and modified the port a bit based off of them. As this will be my most in-depth speaker design yet, I'll be trying to approach the "no compromises" side of the spectrumA couple of comments...

30 m/s is almost surely too high. The one caveat I'd mention is at what frequency? If it is at 25hz then this is probably not where you should be looking as there isn't much music content that low and your speaker is probably pretty far down at that point. My guess is that with the RS270 it was in the 30-40Hz range and it does matter.

With a large flare I usually target 24 m/s max. Not scientific evidence showing that is a good number though. The typical "rule of thumb" is 17 m/s but I never target that.

If I'm working with a smaller cabinet and the port length is really going to be a problem, I'll model the power to reach x-max and then cut it in half and look at port velocity. I don't listen to my speakers at xmax. If I'm building a "no-compromise" speaker, then I wouldn't do this though.

The new port diameter is 3" and ~14" long based with a correction factor of 1 due to a prior comment stating ~0.9 is reasonable for double flared. Figured double flare + elbow would be close to 1, but again I can change it once the cabinet is built. With this port Vmax is ~24 m/s like you mentioned at Xmax, happening at the tuning frequency of 32 Hz.

I have already updated my model, due to the large volume of the port I had to extent the depth of the box by 0.5". The total main chamber volume for the RS270 is now 31L instead of 30L, I figure I will be adjusting port length anyway so I can tune how I want then. I have checked clearances and there is enough room between the internal port flare and the driver, although its a bit close. Hoping that the port entrance being near the driver will lead to some better loading and not set up a funky pressure system in the box.

This may be looking too far forwards as well, but I would also like to gather some ideas about damping. My current plan is to use butyl rubber on all faces in the assembly to increasing damping and then fill with polyfill or wool. I have also heard good things about denim fill or rockwool. If anyone has some good recommendations, that would be great to guide my decisions.

Does anyone see any lapse of judgement or critical flaws I may have missed in the new revision?

You really should take a bit of time to read through @stv 's port design thread, even though it is quite long. https://www.diyaudio.com/community/...sonance-absorbers-and-port-geometries.388264/

A 90 degree elbow immediately before the flare will almost certianly increase port noise. A gentle curve would be better, as will a more gradual flare over the ports length. Time to get a 3D printer or use a service 😉

You might find the introduction to speaker ports in my paper insightful.

https://www.diyaudio.com/community/threads/design-study-of-3d-printed-loudspeaker-port.408535/

A 90 degree elbow immediately before the flare will almost certianly increase port noise. A gentle curve would be better, as will a more gradual flare over the ports length. Time to get a 3D printer or use a service 😉

You might find the introduction to speaker ports in my paper insightful.

https://www.diyaudio.com/community/threads/design-study-of-3d-printed-loudspeaker-port.408535/

Going active does in no way stop you from doing that. In fact it immediately triples your options of messing about with different amps.The speakers will be passive, even if it sacrifices some performance away from ideal, because I enjoy the ability to mess with different amps, preamps, DACs, ect.

For example you could use 2 different transistor amps for bass and mids with a valve amp for treble.

Here's your RS270-4 enclosure design with 130 watts, to reach RS270-4 Xmax. Note the port velocity:

If you want to maintain tuning, and get the port velocity down to ~ 17m/s peak, then you'll need a 53cm long * 9.0cm diameter port, or if 4" is the standard, then a 4" (ID) port that's 69.2cm long

If you want to maintain tuning, and get the port velocity down to ~ 17m/s peak, then you'll need a 53cm long * 9.0cm diameter port, or if 4" is the standard, then a 4" (ID) port that's 69.2cm long

- Home

- Loudspeakers

- Multi-Way

- 3 Way 10" Port Recommendations