I learned something about reverberation yesterday through experience. I always knew that panel damping is important, that less 'ringing' in panels is a goal, but I didn't understand how it sounds.Hello Christian.

So , how long does it take for the reverberation to stop altogether (flat line).

Panels do have an internal sound, this is part of the panel self noise I go on about.

I showed how to change this sound and significantly remove it in my finger positions recording.

Steve.

I was testing a treated 1/4" XPS panel and it sounded like my tests sounds were playing in a long tube. This effect was quite dramatic; in a way it sounded like this thin panel was a huge room. Then I realized that a lot of panels, EPS and XPS in particular, sound this way through a section of FR, especially around 300-600 hz. Panel material, thickness, and surface treatment have a big effect on this and it can be easy to mistake this reverb for modal response if you are only paying attention to volume and not timing. Panel mounting methods also have a big effect and changing panel dimensions also changes the damping effectiveness of the mounting.

Thanks to Christian's hint I was looking at 3rd order distortion yesterday and it does seem like there is a good correlation with high 3rd order distortion and reverb in the panel. Idk if high 3rd ONLY comes from reverb inside panel, or if ALL reverb in panel reflects as 3rd order distortion, but there does seem to be a correlation.

So, if vocals sounds strange and if it sounds like a reverb effect, then panel 'ringing' might be the cause.

Oh, and here's a cool video I watched about reverb last year. It's a very different use of an exciter and a large panel:

Hello Eric,Christian,

I have one of those and it weighs 125 g.

Eric

This gives 180g for the panel so 600g/m².Mister Audio said:

My foil-coated EPS panels > 600mm x 500 mm ( 2' x 1'7.5" ) = 430 grams with exciters attached.

Christian

The spectrogram view using wavelet or CWT is also an excellent tool to get information about the level in frequency AND time.I was looking at 3rd order distortion yesterday

XPS was the first material I tested before coming to plywood. I remember from it an important energy stored in the range you mention. For the plywood I don't know The current small EPS panel for testing at the moment shows level in this frequency range at about 10ms.

All of that doesn't give the recipe to built a good panel for sure!

Steve were these panels sanded and 50/50 coated and does the flat response of the 70 grade 25mm board translate when building small panels like your 6x9 inch panels? It seems these day you prefer thinner small panels of EPS with several grades working well from low grade white EPS to higher grade/density both in thin thicknesses. Could you comment on your current thoughts on this? Thank you.Uploaded Pictures

The pictures show some of my panels I'd tested.

The 5x2ftx1inch probably 70 grade? Response is shown in three pics at 1ft, and 10ft into the room,with and without the transmission line LF units.

As can be seen ,a pretty flat response can be achieved without eq.

Steve

Hi moray.

When making smaller panels it is best to use thinner panel materials.

Smaller panels are easier to work with and to store away.

I still have my large 1inch panels in the loft and they sound just as good as as ever.

I have some 4ft, 1inch panels as well , and yes they are still my favourite.

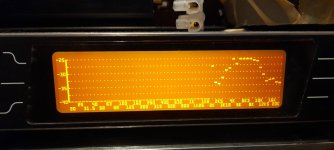

And by the way ,this is a peak hold of the sibilance caused by George Michael singing.

Obviously nobody told him his sibilance goes up higher than 7k ?

I sent the actual recording to Christian for him to hear for himself.

But it is not the sibilance that is the problem, it is the distortion caused by the sibilance.

I have gone into this in detail and find it hard to understand why certain people are still struggling to understand the problem.

I must stop now as I do not want this to sound like a lecture 🙄

Give me strength 🫣

Steve.

When making smaller panels it is best to use thinner panel materials.

Smaller panels are easier to work with and to store away.

I still have my large 1inch panels in the loft and they sound just as good as as ever.

I have some 4ft, 1inch panels as well , and yes they are still my favourite.

And by the way ,this is a peak hold of the sibilance caused by George Michael singing.

Obviously nobody told him his sibilance goes up higher than 7k ?

I sent the actual recording to Christian for him to hear for himself.

But it is not the sibilance that is the problem, it is the distortion caused by the sibilance.

I have gone into this in detail and find it hard to understand why certain people are still struggling to understand the problem.

I must stop now as I do not want this to sound like a lecture 🙄

Give me strength 🫣

Steve.

Attachments

so can you elaborate on your favourite set of 1' eps (four foot) panels? As I mentioned before I would like to build a set of small panels as a reference and a larger set and your fav's sound like a good place to start. This way I can experiment and we can have a common point of reference.

as I look for materials I am beginning to believe that card stock panels will be easier to find affordable materials for which will be much easier to process without need for a work shop. I do have access to a work shop and can use that to build any EPS panels to have them to compare the card stock panels to. thanks Steve.

as I look for materials I am beginning to believe that card stock panels will be easier to find affordable materials for which will be much easier to process without need for a work shop. I do have access to a work shop and can use that to build any EPS panels to have them to compare the card stock panels to. thanks Steve.

Re. sibilance >Hi moray.

When making smaller panels it is best to use thinner panel materials.

Smaller panels are easier to work with and to store away.

I still have my large 1inch panels in the loft and they sound just as good as as ever.

I have some 4ft, 1inch panels as well , and yes they are still my favourite.

And by the way ,this is a peak hold of the sibilance caused by George Michael singing.

Obviously nobody told him his sibilance goes up higher than 7k ?

I sent the actual recording to Christian for him to hear for himself.

But it is not the sibilance that is the problem, it is the distortion caused by the sibilance.

I have gone into this in detail and find it hard to understand why certain people are still struggling to understand the problem.

I must stop now as I do not want this to sound like a lecture 🙄

Give me strength 🫣

Steve.

I wrote that my Pioneer Bullet Tweeters seemed to "SING" a bit around 18Khz.

Apon further listening & consideration, it actually appears to be more like 14/15Khz.

This would indicate 'true sibilance' being exacerbated by the tweeter design to an extent >

A form of distortion

Here's an article for professional sound engineers.

https://www.izotope.com/en/learn/the-dos-and-donts-of-de-essing.html

The de-essers are limited to 8khz! What a bunch of amateurs eh?... Maybe some of us should coach them how to design their gear properly.

https://www.izotope.com/en/learn/the-dos-and-donts-of-de-essing.html

The de-essers are limited to 8khz! What a bunch of amateurs eh?... Maybe some of us should coach them how to design their gear properly.

perhaps a very light damping layer on the tweeter diaphragm? I am thinking a PVA coating in the form of one part PVA to five parts water mixed well then use a spray mister to apply a light mist to the diaphragm. Make sure that you have totally cleaned the diaphragm surface with alcohol prior to application of the PVA. Let dry and listen. Additional PCA coats can be applied this way until you find the diaphragm has attained the desired improvement. Let each layer fully cure for a day in a warm place.This would indicate 'true sibilance' being exacerbated by the tweeter design to an extent >

A form of distortion

Whaou! Coating the metallic diaphragm into a bullet tweeter is more than high level surgery! ;-)perhaps a very light damping layer on the tweeter diaphragm?

Christian

Christian: I have been doing projects like that sine I was a kid. That would probably be a reversible project (depending upon the actual tweeter diaphragm). Here is a simpler modification to try. You could make a gasket to go between the under side of the tweeter butterfly and the motor assembly, make it out of a layer of thin skived Teflon plumbers tape. That may be all that is needed to quiet the distortion.

Oops 😬Here's an article for professional sound engineers.

https://www.izotope.com/en/learn/the-dos-and-donts-of-de-essing.html

The de-essers are limited to 8khz! What a bunch of amateurs eh?... Maybe some of us should coach them how to design their gear properly.

It looks like someone disagrees with you 😱

https://www.antarestech.com/community/what-is-sibilance-in-audio

Steve.

Steve, can you point me to this George Michael recording please? My goto recording for testing sibilance is Katie Melua's song - I'd Love to Kill You. Wonder if they used de-essing on this recording? I was not aware of de-essing before.the sibilance caused by George Michael singing.

oops should be 0.2540.010 inch = 25.4 mm

So I brought some panels home this weekend to try out in place of my bookshelf speakers in the lounge. Safe to say it was a frustrating time as I couldn't get them to sound good. In my workshop they sounded great and I thought they had potential to replace what I have at home.

I spent a lot of time trying different positions distances from walls, heights and angles but always found they sounded too spacious without a good centre if that makes sense, they were in phase by the way. I had all but given up when I thought to try a blanket over the backs to limit the rear output and thankfully that was the answer. I was relieved to find a solution, now to make semi closed backs and stands for the panels.

The lounge is around 5 x 7m with carpet soft furnishings, curtains a sloping ceiling and large opening to kitchen one end, I thought it would be fine as it's pretty dead reverb wise. The workshop has an uneven fabric lined ceiling with fibreglass batts so much better absorbtion of the reflections I guess.

Anyway I thought this might help someone who has 'too much' space in the sound of the panels.

I spent a lot of time trying different positions distances from walls, heights and angles but always found they sounded too spacious without a good centre if that makes sense, they were in phase by the way. I had all but given up when I thought to try a blanket over the backs to limit the rear output and thankfully that was the answer. I was relieved to find a solution, now to make semi closed backs and stands for the panels.

The lounge is around 5 x 7m with carpet soft furnishings, curtains a sloping ceiling and large opening to kitchen one end, I thought it would be fine as it's pretty dead reverb wise. The workshop has an uneven fabric lined ceiling with fibreglass batts so much better absorbtion of the reflections I guess.

Anyway I thought this might help someone who has 'too much' space in the sound of the panels.

Hi there folks

I have been reflecting on my experience building my DML panels ( which now sound great ) and how

the initial sound was 'horrible & honky'. It required EQ to get them sounding good.

I also recall a post by another member - calling the sound "honky".

It occurred to me that if both I and another person experienced this same 'Honky' sound, then there would

surely be other people that have also found this shortcoming with their panels. That honky sound.

This got me thinking to present a very simple solution to solve/improve this problem for those experiencing it.

The solution/modification is a simple passive filter requiring only 2 components of standard value. (easy to get)

One coil/inductor and one capacitor.

( this modification will also improve upper region sound by removing a 'masking effect' )

I have been reflecting on my experience building my DML panels ( which now sound great ) and how

the initial sound was 'horrible & honky'. It required EQ to get them sounding good.

I also recall a post by another member - calling the sound "honky".

It occurred to me that if both I and another person experienced this same 'Honky' sound, then there would

surely be other people that have also found this shortcoming with their panels. That honky sound.

This got me thinking to present a very simple solution to solve/improve this problem for those experiencing it.

The solution/modification is a simple passive filter requiring only 2 components of standard value. (easy to get)

One coil/inductor and one capacitor.

( this modification will also improve upper region sound by removing a 'masking effect' )

Attachments

Good link.

Yes there are some middle-aged "golden eared" hi-fi pundits who think they can hear sibilance beyond 10kHz. But what they're most likely (mis)hearing is second-order distortion of a 4 or 5khz signal. This would most likely be caused by the improper setup of a stylus/head/arm or the tracking force on a turntable, or the break-up modes of a cone driver working beyond its pistonic mode. There are multiple possible sources of HF break-up in home "hi-fi." Sometimes ears themselves can be to blame since ear drums can also introduce distortions due to injuries, disease or even having had grommets. Sometimes a boost at 10kHz (found on low-quality vinyl pressings) will have an effect on the signal from 7khz up to 13khz, depending on the filter Q.

This high-frequency boost plays havoc with sibilance on vinyl pressings.

But a professional recording studio will not allow any kind of sibilance to be released to an album. It would be like a surgeon leaving tools inside after he's sewn you up. I'm not referring here to home studios or self-proclaimed 'producers" who wouldn't know the back end from the front end of a ribbon mic.

There seem to be basic misunderstandings abounding here regarding what "sibilance" actually is, and how a de-esser works to minimise it.

De-essing IS NOT a broad-band EQ or a shelving filter just tacked onto a vocal track. Such an EQ would simply make the vocal track dull and lifeless.

De-essing is also NOT tacked onto the final mix. Sometimes the mastering engineer cannot correct a final mix that has not had the vocal (or drum) tracks properly de-essed.

De-essing IS a high-Q, narrow-band filter that drives a dedicated narrow-band compressor. The de-esser is set to the correct target frequency which is found by manually sweeping a narrow-band peaking EQ over a looped section of that part of the vocal track that carries the objectionable sibilants. I have never, in 40 years in recording studios, ever seen any recording engineers find objectionable sibilants above 9kHz, except in one case where a lady vocalist had dental braces on the inside of her upper teeth.

The de-esser is triggered by the high-frequency "s" or "t" or "shh" signals, which fires the compressor to duck that part of the track without effecting any other frequencies on that track.

Sometimes a mix engineer might tack a de-esser onto a drum track to reduce the hi-hats or a snare attack without disturbing the rest of the drums EQ. It can also be used to reduce the plectrum sound on a very bright acoustic guitar mix. It's a powerful tool in the right hands.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker