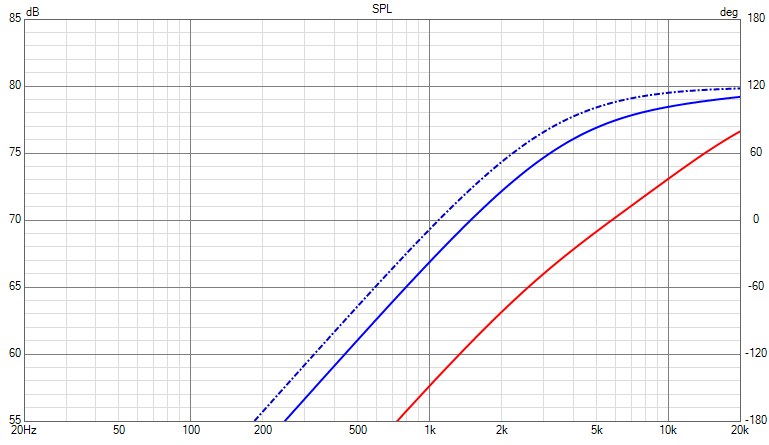

I don't think I understand either but let me show you some examples. Firstly understand that I'm using generic drivers for the simulation, so if the ST is louder than the T or has a different response, all this sim will show are the changes between circuits.. however that's all I'm really trying to show.

So, firstly we have T=blue and ST=red. If you disconnect the ST, the T gets louder on it's own (dotted trace)..

Now reconnect it. If you then connect ST+ to T+, they will each have the same drive signal and will both jump to the dotted trace.. ie T will get more quiet and ST will get more loud..

If you disconnect ST and connect the + together, nothing will happen.

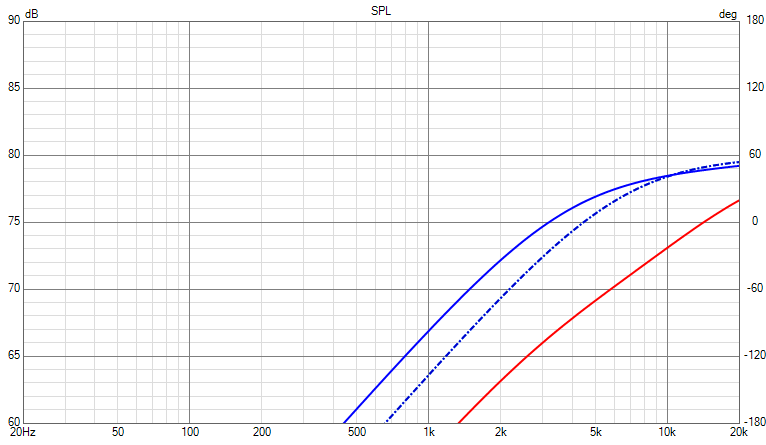

So, firstly we have T=blue and ST=red. If you disconnect the ST, the T gets louder on it's own (dotted trace)..

Now reconnect it. If you then connect ST+ to T+, they will each have the same drive signal and will both jump to the dotted trace.. ie T will get more quiet and ST will get more loud..

If you disconnect ST and connect the + together, nothing will happen.

I pulled out from the end of the line an amount to easy fill 2 cubic ft box!!

Emedeatly a felt/herd the difference. Shocking it was compressed into 1/4 ft area. I'm going to do behind the B139 later.

Not sure I follow. How did you get inside to return the wool in fluffed up form or replace it with something else?

I had some 70s DIY TLs in which the wool settled in the 80s (or more accurately I realised this had happened in the 80s!) and I could see no way to fix it other than breaking the front panel, replacing the wool with something else (hadn't settled on what), tidying up and replacing the front panel. It seemed like too much effort given I had moved on speaker-wise.

Hello Andy, well from the end of the line I fashend metal coat hanger to pull out what I could. I then because the line went up after about a foot in pulled out even more! I've read that as the TML (transmission line) ends it also thins and less damping is required.

Right, naw I went in behind the B139's, what did I see? Even more material packed tight. I put my hand in after removing the wool, i felt right at the back corner a curve very smooth directing the wave up. Before the back and about half way in their was a plank of wood angled about 45 degrees up, this was splitting the wave from the B139 up towards the centre and back. I will draw what I think the inside looks like.

I may take even more out Tomorrow

Right, naw I went in behind the B139's, what did I see? Even more material packed tight. I put my hand in after removing the wool, i felt right at the back corner a curve very smooth directing the wave up. Before the back and about half way in their was a plank of wood angled about 45 degrees up, this was splitting the wave from the B139 up towards the centre and back. I will draw what I think the inside looks like.

I may take even more out Tomorrow

You are not restoring the damping to the designed amount but removing whatever you can reach? Assuming the speaker was correctly designed and built initially this will alter the low frequency response away from design and increase the level of the lowest few line resonances. This will introduce an audible change but it is unlikely to be for the better unless the line was incorrectly stuffed. A degree of this is what happens when lightly stuffed wool settles.

Details of the line geometry are unlikely to be useful but measuring the response would be if you want to experiment with the degree of stuffing. A simple simulation program like this might help understand what is being traded for what as the degree of stuffing is altered and hence what to look for in the measurements.

Details of the line geometry are unlikely to be useful but measuring the response would be if you want to experiment with the degree of stuffing. A simple simulation program like this might help understand what is being traded for what as the degree of stuffing is altered and hence what to look for in the measurements.

The damping could well have sagged… in whichcase you need to remove and replace it. More damping will do more to suppress the unwanted harmonics of the pipe, less will allow for more fundemental and more ripple from the harmonics since the only extra LP filter is the pre-chamber and the ones at each bend (if there are no deflectors). The taper of the line pushes the harmonics up in frequency, making them easier to damp — and leading to the myth that teh damping slows the speed of sound.

And most of th eoffending ripple will be be below the Schroeder Frequency which complicates just listening.

Without removing a side there are parts of the line you wll not be able to get at some of the line … maybe a robotic snake-tool?

We dis take the side of an Ed Horn (Hornshoppe), to scope the design and build (crappy yhay last). Then Chris put it back together better than we got them (they needed reveenering anyway).

dave

And most of th eoffending ripple will be be below the Schroeder Frequency which complicates just listening.

Without removing a side there are parts of the line you wll not be able to get at some of the line … maybe a robotic snake-tool?

We dis take the side of an Ed Horn (Hornshoppe), to scope the design and build (crappy yhay last). Then Chris put it back together better than we got them (they needed reveenering anyway).

dave

Dave thanks, from bending bits of metals too use as tools I managed to pull out an horrendous amount of wool! compressed throughout the line. The only reason I felt the need to do so was 1-bass was pathetic and not what I was expecting why? I already have TL speakers bought from the maker himself "I wish I kept his number"

Naw that I have removed the wool the low frequencies I was not hearing/feeling before are free from the wool barrier that was.

I will naw put the speakers on cone/spikes and begin to fine tune.

Think I might use the ST's from other TL for a fair comparison.

Naw that I have removed the wool the low frequencies I was not hearing/feeling before are free from the wool barrier that was.

I will naw put the speakers on cone/spikes and begin to fine tune.

Think I might use the ST's from other TL for a fair comparison.

Can you tell me by the crossover how low does the B139 go? I'm hearing bass but when it goes low I mean low I'm feeling more than I should be hearing. The bass is there..and lots of it. I continue to change the amount of interior damping bit by bit. Any suggestions?

Pleeeese

should be quite capable--using the default settings pretty much, some polyfill to dampen the ripples, taking advantage of tapering the line a bit more than in the original plans. I never measured my old ones, but I recall they performed pretty well for the time. The new b139s might perform better but I haven't seen the specs.

It's the frequency below 30hz. The floor vibration I feel through my shoes the sofa everything! I hear nothing! But the thick dence bass is not there. My pro9 tl speakers get low and I can hear it, also other speakers I have. These i have walked out of the room stood in the corners and no.should be quite capable--using the default settings pretty much, some polyfill to dampen the ripples, taking advantage of tapering the line a bit more than in the original plans. I never measured my old ones, but I recall they performed pretty well for the time. The new b139s might perform better but I haven't seen the specs.

View attachment 1316098

Do I have to trial and fail approach. That's all I can do at the moment.

- Home

- Loudspeakers

- Multi-Way

- Transmission line speakers I have never seen before. Need help to figure every thing out