Hello. This is my first post here.

I have seen a number of helpful threads and thought I would give this a try to fix the issue I am having with my Bottlehead Crack tube amp.

Since a couple of months now I have been trying to fix a horrible noise that my amp is having, making it unusable.

The amp had worked fine for around 3 months, but then one night I heard a loud crackling noise in the right driver. Since then every once in a while I could hear a noise like crackling, always in the right channel, but I could interact with it and sometimes make it stop by moving the power tube a bit.

Fast forward a couple of weeks, the noise is always present and doesn't leave no matter what I do (messing with the tubes doesn't do anything anymore), meaning that I cannot use my beloved amplifier anymore.

I have tested and tried fixing this for a long time and this is a description of what I have found.

-The noise sounds like crackling and it comes and goes randomly. The intensity also changes randomly.

-The noise is not tube dependent: no matter how many tubes I try on the problem doesn't change.

-Wiggling either tube does not have an audible effect, and the socket and tube pins look rather clean.

-The crackling noise appears soon after the amp is on, I would say in about 10 second's time. When I turn the amp off it disappears after 3 or 4 seconds.

-The noise is exclusively in the right channel.

-The noise does not depend on whether I have the RCA's connected or not, and it does not change depending on which wall outlet I plug it in (not even going to a different house made a difference, so the noise is not coming from a wireless connection either).

-The noise doesn't change depending on volume. It's always there at the same volume.

-The chopstick test did not reveal any weak connection in the solder joints. Even lightly pulling/pushing on wires I couldn't notice any audible reaction. The possibility of me not noticing a bad joint is of course possible, but I have tested for so many hours that I would find it hard to believe.

-Applying pressure on the chassis in several different positions did not reveal any audible changes.

Here is a recording of the noise (please ignore the clock noises and the faint background static).

Of course I'm available to send any close up picture that might be needed.

I have gone back and resoldered each solder joint several times, making sure that they look as good as I could make them with the right amount of solder and not having them be cold. I used the reccommended 60/40 solder.

I have a rather long thread still open on the Bottlehead forum with some pictures, but even though the kind people over there tried suggesting some things, nothing has worked.

I have spent so many hours trying to fix this amp and I really miss listening to it, so if anyone has any idea on things to try I would greatly appreciate the advice. Please help me out.

I have seen a number of helpful threads and thought I would give this a try to fix the issue I am having with my Bottlehead Crack tube amp.

Since a couple of months now I have been trying to fix a horrible noise that my amp is having, making it unusable.

The amp had worked fine for around 3 months, but then one night I heard a loud crackling noise in the right driver. Since then every once in a while I could hear a noise like crackling, always in the right channel, but I could interact with it and sometimes make it stop by moving the power tube a bit.

Fast forward a couple of weeks, the noise is always present and doesn't leave no matter what I do (messing with the tubes doesn't do anything anymore), meaning that I cannot use my beloved amplifier anymore.

I have tested and tried fixing this for a long time and this is a description of what I have found.

-The noise sounds like crackling and it comes and goes randomly. The intensity also changes randomly.

-The noise is not tube dependent: no matter how many tubes I try on the problem doesn't change.

-Wiggling either tube does not have an audible effect, and the socket and tube pins look rather clean.

-The crackling noise appears soon after the amp is on, I would say in about 10 second's time. When I turn the amp off it disappears after 3 or 4 seconds.

-The noise is exclusively in the right channel.

-The noise does not depend on whether I have the RCA's connected or not, and it does not change depending on which wall outlet I plug it in (not even going to a different house made a difference, so the noise is not coming from a wireless connection either).

-The noise doesn't change depending on volume. It's always there at the same volume.

-The chopstick test did not reveal any weak connection in the solder joints. Even lightly pulling/pushing on wires I couldn't notice any audible reaction. The possibility of me not noticing a bad joint is of course possible, but I have tested for so many hours that I would find it hard to believe.

-Applying pressure on the chassis in several different positions did not reveal any audible changes.

Here is a recording of the noise (please ignore the clock noises and the faint background static).

Of course I'm available to send any close up picture that might be needed.

I have gone back and resoldered each solder joint several times, making sure that they look as good as I could make them with the right amount of solder and not having them be cold. I used the reccommended 60/40 solder.

I have a rather long thread still open on the Bottlehead forum with some pictures, but even though the kind people over there tried suggesting some things, nothing has worked.

I have spent so many hours trying to fix this amp and I really miss listening to it, so if anyone has any idea on things to try I would greatly appreciate the advice. Please help me out.

The Crack is in its stock configuration. The only modification made was the addition of two diodes between the chassis and the ground tab of the IEC power entry module, which is something that was reccommended by Paul Birkeland from Bottlehead to remove the noises coming from noisy sources (my pc for example).

My crackling issue was there since before I had installed the diodes though, so they shouldn't be the cause of the problem.

My crackling issue was there since before I had installed the diodes though, so they shouldn't be the cause of the problem.

sounds like flux arcing on a solder joint.Hello. This is my first post here.

I have seen a number of helpful threads and thought I would give this a try to fix the issue I am having with my Bottlehead Crack tube amp.

Since a couple of months now I have been trying to fix a horrible noise that my amp is having, making it unusable.

The amp had worked fine for around 3 months, but then one night I heard a loud crackling noise in the right driver. Since then every once in a while I could hear a noise like crackling, always in the right channel, but I could interact with it and sometimes make it stop by moving the power tube a bit.

Fast forward a couple of weeks, the noise is always present and doesn't leave no matter what I do (messing with the tubes doesn't do anything anymore), meaning that I cannot use my beloved amplifier anymore.

I have tested and tried fixing this for a long time and this is a description of what I have found.

-The noise sounds like crackling and it comes and goes randomly. The intensity also changes randomly.

-The noise is not tube dependent: no matter how many tubes I try on the problem doesn't change.

-Wiggling either tube does not have an audible effect, and the socket and tube pins look rather clean.

-The crackling noise appears soon after the amp is on, I would say in about 10 second's time. When I turn the amp off it disappears after 3 or 4 seconds.

-The noise is exclusively in the right channel.

-The noise does not depend on whether I have the RCA's connected or not, and it does not change depending on which wall outlet I plug it in (not even going to a different house made a difference, so the noise is not coming from a wireless connection either).

-The noise doesn't change depending on volume. It's always there at the same volume.

-The chopstick test did not reveal any weak connection in the solder joints. Even lightly pulling/pushing on wires I couldn't notice any audible reaction. The possibility of me not noticing a bad joint is of course possible, but I have tested for so many hours that I would find it hard to believe.

-Applying pressure on the chassis in several different positions did not reveal any audible changes.

Here is a recording of the noise (please ignore the clock noises and the faint background static).

Of course I'm available to send any close up picture that might be needed.

I have gone back and resoldered each solder joint several times, making sure that they look as good as I could make them with the right amount of solder and not having them be cold. I used the reccommended 60/40 solder.

I have a rather long thread still open on the Bottlehead forum with some pictures, but even though the kind people over there tried suggesting some things, nothing has worked.

I have spent so many hours trying to fix this amp and I really miss listening to it, so if anyone has any idea on things to try I would greatly appreciate the advice. Please help me out.

But looking at your pictures, this one is not correct.

The resistor lead should wrap around the tube pin before being tied to the next pin. The first joint is "fluxy" while the other joint is "lack of solder sweat" from not letting the solder melt and bond.

Bottlehead.. I guess if you don't know where to start. All of these they got out of tube application guides. This one was in one of the RCA ones published sometime in the late 30s-40s

Hello. This is my first post here.

I have seen a number of helpful threads and thought I would give this a try to fix the issue I am having with my Bottlehead Crack tube amp.

Since a couple of months now I have been trying to fix a horrible noise that my amp is having, making it unusable.

The amp had worked fine for around 3 months, but then one night I heard a loud crackling noise in the right driver.

I do not believe the cold solder joint is the root cause of your problem. That being said, you could do a slightly better job with soldering.

It is either a faulty valve, a bad valve socket, or a sound coupling capacitor (or other capacitor... like power supply rails' decoupling) issue.

Sometimes the transformers start to be winding-to-winding layer conductive, due to high voltage / slight mechanical bump... that damages the lacquer finish. This kind of issue manifests itself once the transformer heats up.

You said you replaced valves and wiggled the sockets... I'd look at the sockets very closely. The valve pins need to be completely clean; each valve socket needs to grab the valve pin tight.

Monitoring all the plate currents (insert 1 ohm / 10W resistors) with digital storage voltmeters (oscilloscopes) may reveal/narrow down the root cause.

Any chance you could post the overall photos of that thing? Detailed, well-lit in-focus photos would help a lot Also, can you sketch the circuit?? I'd like to know the location of all capacitors... Also, sometimes carbon-film resistors can develop a "hot-spot" - kind of issue... do you see any discolouration on any resistor?

Good luck.

FIrst off, thank you for the suggestions. I appreciate it.

I have uploaded some close up pictures here.

I had thought that it might be the socket pins not making good contact, but even after cleaning them and lightly tightening them up nothing changed.

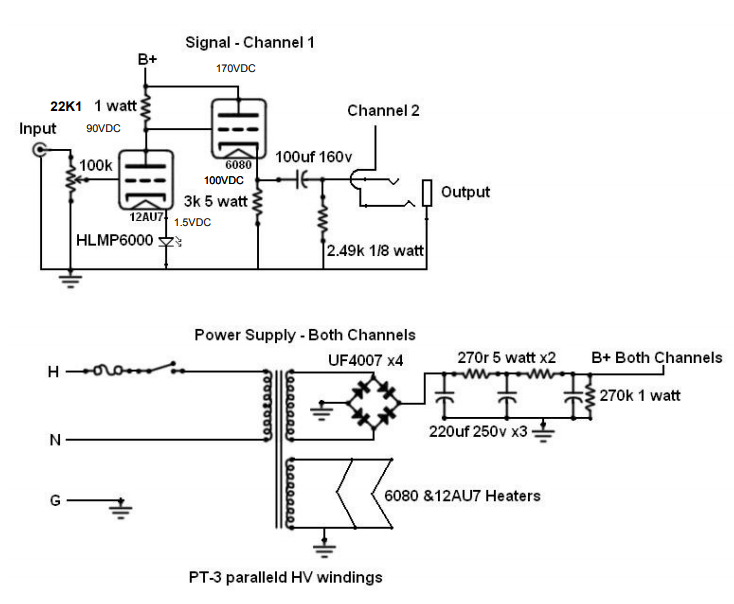

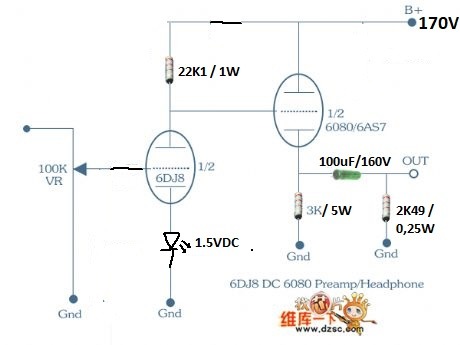

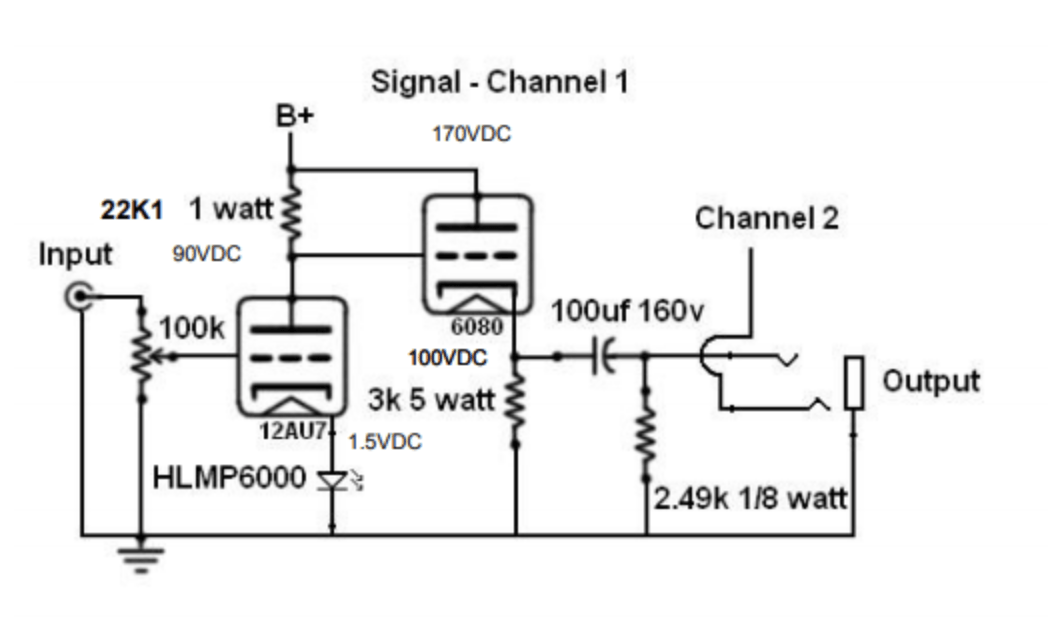

I'm not sure I would be allowed to share the circuit scheme that's in the manual, but if you google search it you can find this, which looks to be the same. If I'm not mistaken the "Channel one" sketch should be the right channel, which is the one that's giving me issues.

I have uploaded some close up pictures here.

I had thought that it might be the socket pins not making good contact, but even after cleaning them and lightly tightening them up nothing changed.

I'm not sure I would be allowed to share the circuit scheme that's in the manual, but if you google search it you can find this, which looks to be the same. If I'm not mistaken the "Channel one" sketch should be the right channel, which is the one that's giving me issues.

I think your control might be dirty and since it doesn't have a wiper bias resistor, when the wiper connection lifts the tube bias would go crazy.

But as far as that circuit:

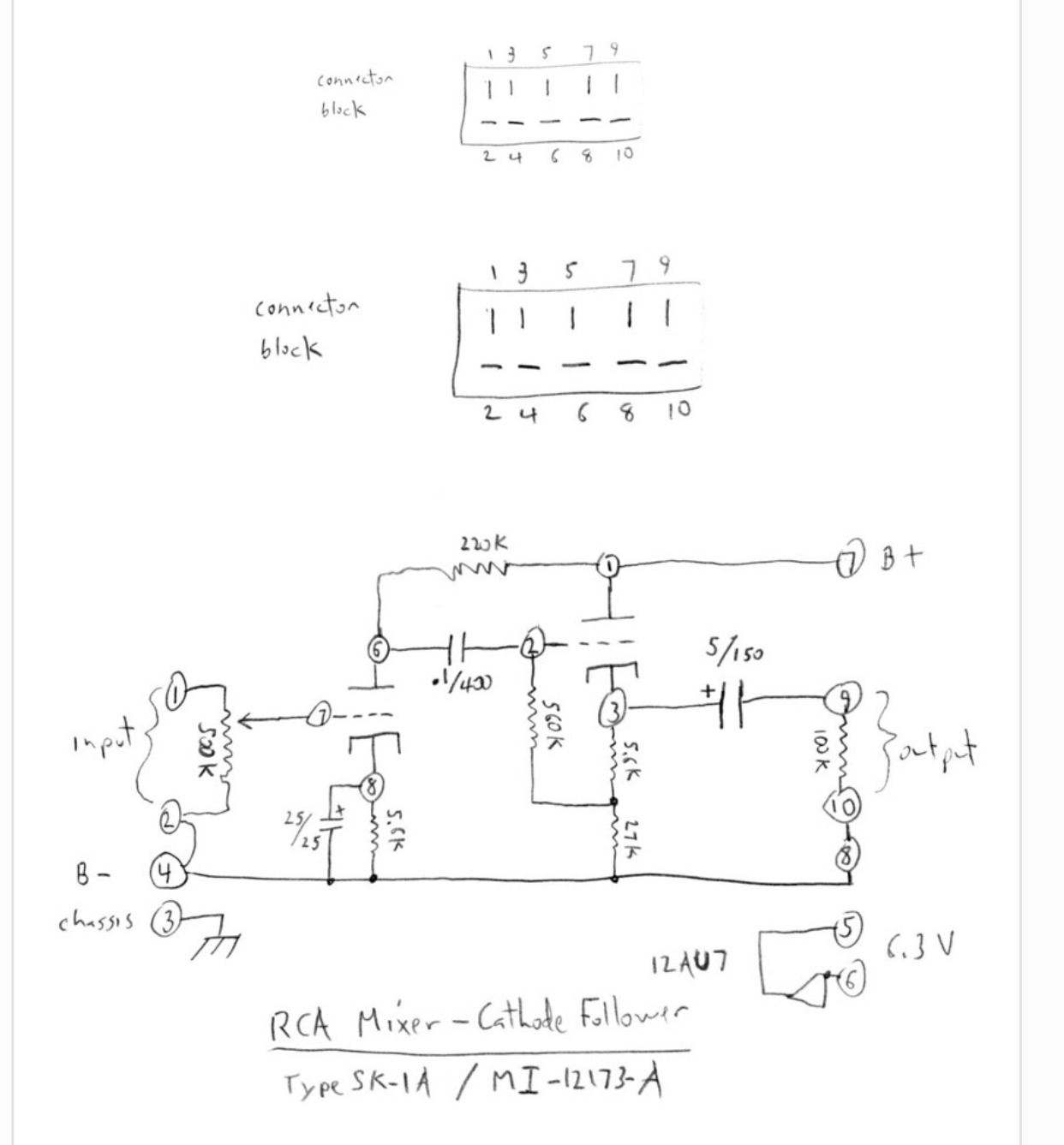

That is a variant of a Rainbow module from a 1950s mixer.Headphone or buss out. A lot of people have done it over the years. Its obvious that they would be into selling "upgrade options" because its not really complete or finely engineered.

This is a MI-12173-A. The only difference is using one section of a 6as7 as the cathode follower.

The bottom one is the most correct. There should be a 1M from wiper to gnd to prevent pot noise. Since the tube otherwise relies on the pot for bias, any time the wipe gets interrupted, the bias would go haywire on that tube. The grid stop is somewhat absent, but it has to be sized correctly depending on the input in the device before this is dc coupled. That is why some people have success, others would have issues with this circuit because its not quite universal and capacitor coupled from the previous stage would be the only one that wouldn't upset the operation of the circuit. The bottom circuit runs the tube plate at a little bit more reasonable voltage, and the 33 ohm gridstop would be the minimum that it would need to stabilize with a 8200 ohm resistor on the cathode.

The crackhead uses LEDs there, which would force a constant bias state, but this would cause extra sensitivity on the grid. To find the right size of gridstop, you would take a 1M potentiometer and wire it as a variable resistor and inset it at the first tube where the 33 ohm resistor is in the bottom schematic.Connect the source, and adjust for the best noise floor. If you don't drop the plate voltage on the 1st tube to about 50% of the 6AS7, a 470 ohm grid stop should be used.

When selecting gridstops and cathode resistors, you should use ones that offeres no to low insertion loss, and low thermal ppm to keep the hiss down to a minimum. I use Mills/Dale/Vishay resistors. Which I would do Mills mra5 on cathodes and the grid stops

of course, what you see out there when you search

But as far as that circuit:

That is a variant of a Rainbow module from a 1950s mixer.Headphone or buss out. A lot of people have done it over the years. Its obvious that they would be into selling "upgrade options" because its not really complete or finely engineered.

This is a MI-12173-A. The only difference is using one section of a 6as7 as the cathode follower.

The bottom one is the most correct. There should be a 1M from wiper to gnd to prevent pot noise. Since the tube otherwise relies on the pot for bias, any time the wipe gets interrupted, the bias would go haywire on that tube. The grid stop is somewhat absent, but it has to be sized correctly depending on the input in the device before this is dc coupled. That is why some people have success, others would have issues with this circuit because its not quite universal and capacitor coupled from the previous stage would be the only one that wouldn't upset the operation of the circuit. The bottom circuit runs the tube plate at a little bit more reasonable voltage, and the 33 ohm gridstop would be the minimum that it would need to stabilize with a 8200 ohm resistor on the cathode.

The crackhead uses LEDs there, which would force a constant bias state, but this would cause extra sensitivity on the grid. To find the right size of gridstop, you would take a 1M potentiometer and wire it as a variable resistor and inset it at the first tube where the 33 ohm resistor is in the bottom schematic.Connect the source, and adjust for the best noise floor. If you don't drop the plate voltage on the 1st tube to about 50% of the 6AS7, a 470 ohm grid stop should be used.

When selecting gridstops and cathode resistors, you should use ones that offeres no to low insertion loss, and low thermal ppm to keep the hiss down to a minimum. I use Mills/Dale/Vishay resistors. Which I would do Mills mra5 on cathodes and the grid stops

of course, what you see out there when you search

These kind of noise issues can drive you crazy. I know all too well from experience. But the advantage you have is that this is a very simple circuit and you have already ruled out the tubes themselves as the problem. And it occurs only in one channel. That rules out the power supply.

I don't own a Crack, but if this is the signal circuit for one channel

then the problem has to be one or more connections above on the right channel side. The fact that the problem originally responded to wiggling the 6080 tube suggests the problem might well be a questionable solder connection somewhere in its vicinity--not necessarily soldered to the octal socket but a connection down or upstream from it. That the noise is now constant suggests that what once was a questionable solder connection has become an outright bad connection.

The chopstick test ought to work. Have you probed with a chopstick each and every one of the connections in the above schematic? Any of those connections could be the culprit. Be careful with the solder joints that connect the LED because its leads are very fragile.

The last resort would be to desolder and remove all the components on the right channel side of the signal chain, remove the leftover solder on the terminals and socket pins (a vacuum pump device would be easiest for this), and carefully reinstall everything, doing your utmost best with each solder connection. I'd recommend buying a replacement HLMP600 since reusing a fragile LED can be dicey. They're cheap; you'll spend more on shipping than on the LED itself. You might also buy a new 100K potentiometer. It's possible you've got bad contact in the wiper of the pot you got with the kit. Make sure you get an audio taper pot, not a linear one. They're inexpensive as well. Bottlehead usually provides Alpha pots in their kits. They're OK quality, but I'd spend a few dollars more and get a CTS or Bourns pot.

I don't own a Crack, but if this is the signal circuit for one channel

then the problem has to be one or more connections above on the right channel side. The fact that the problem originally responded to wiggling the 6080 tube suggests the problem might well be a questionable solder connection somewhere in its vicinity--not necessarily soldered to the octal socket but a connection down or upstream from it. That the noise is now constant suggests that what once was a questionable solder connection has become an outright bad connection.

The chopstick test ought to work. Have you probed with a chopstick each and every one of the connections in the above schematic? Any of those connections could be the culprit. Be careful with the solder joints that connect the LED because its leads are very fragile.

The last resort would be to desolder and remove all the components on the right channel side of the signal chain, remove the leftover solder on the terminals and socket pins (a vacuum pump device would be easiest for this), and carefully reinstall everything, doing your utmost best with each solder connection. I'd recommend buying a replacement HLMP600 since reusing a fragile LED can be dicey. They're cheap; you'll spend more on shipping than on the LED itself. You might also buy a new 100K potentiometer. It's possible you've got bad contact in the wiper of the pot you got with the kit. Make sure you get an audio taper pot, not a linear one. They're inexpensive as well. Bottlehead usually provides Alpha pots in their kits. They're OK quality, but I'd spend a few dollars more and get a CTS or Bourns pot.

I really appreciate everyone's ideas and suggestions, so thank you.

This is my first DIY project ever, and the experience has been as rewarding (when my amp worked) as equally mortifying, when putting so many hours into it I haven't found a solution yet.

I'll get back to working on it as soon as I have some time and I'll update you on any new developments.

This is my first DIY project ever, and the experience has been as rewarding (when my amp worked) as equally mortifying, when putting so many hours into it I haven't found a solution yet.

I'll get back to working on it as soon as I have some time and I'll update you on any new developments.

His kits are basically 'learning kits' that you would learn the basics, and how to work the kinks out in a circuit. I'm more surprised that there is enough 6as7 tubes still going around to be put in a kit. 6080 tubes yes, but those are the power regulator tube versions that some are ok, but some of them will arc internally after been used for a while. That is why ruling the potentiometer out by substituting it or putting it on the wiper was one of the tests.I really appreciate everyone's ideas and suggestions, so thank you.

This is my first DIY project ever, and the experience has been as rewarding (when my amp worked) as equally mortifying, when putting so many hours into it I haven't found a solution yet.

I'll get back to working on it as soon as I have some time and I'll update you on any new developments.

My first kit (years and years ago) was the simplest guitar amplifier that Chris Hurley's AX84.com project offered. As I recall, one of the documents on the AX84 website guaranteed something like "hours of frustration with your new guitar amp kit." Cheeky but true. There's a pretty steep learning curve at first. But once you debug your first build, it's hard not to seek out more.I really appreciate everyone's ideas and suggestions, so thank you.

This is my first DIY project ever, and the experience has been as rewarding (when my amp worked) as equally mortifying, when putting so many hours into it I haven't found a solution yet.

I'll get back to working on it as soon as I have some time and I'll update you on any new developments.

Last edited:

Temporarily putting a 1M resistor from the wiper to gnd will eliminate the potentiometer if it is the problem.

This is why I asked for schematics and photos.

@Cowwe

Set the bias with a pot, then remove the pot... and insert a resistor. DC current running through the graphite-viper contact junction is asking for trouble. I would use either a rheostat-type potentiometer, or the correct resistor value.

A good way to check would be to sniff the potentiometer after the amp warms up.... you'll probably notice the typical graphite burning smell...

Good luck.

I really appreciate everyone's ideas and suggestions, so thank you.

This is my first DIY project ever, and the experience has been as rewarding (when my amp worked) as equally mortifying, when putting so many hours into it I haven't found a solution yet.

I'll get back to working on it as soon as I have some time and I'll update you on any new developments.

So, how did you go? Are there any updates to share with us?

Sorry for the lack of updates!

I was intending to get working on the amp last weekend, but I got myself bedridden with a bad flu and wasn't able to do anything but sleeping for a while..

Thankfully I will have time off work during the holidays so I'll definitely be updating this thread starting next week!

I was intending to get working on the amp last weekend, but I got myself bedridden with a bad flu and wasn't able to do anything but sleeping for a while..

Thankfully I will have time off work during the holidays so I'll definitely be updating this thread starting next week!

I finally have an update: me going insane.So, how did you go? Are there any updates to share with us?

In my initial post I had avoided mentioning that around a month ago I had brought my amp to a repairman some 15 kilometers away from me, since I had ran out of ideas on how to fix my issue. What came out of it was that the man couldn't hear, nor find anything wrong with the amp, except when I turned it on again at my house the noise was as present as ever. I assumed that could mean two things: either I had gotten scammed out of a few bucks and the repairman hand't even turned my amp on, or there might have been the slight chance that some contact moved while travelling by car.

Fast forward to last week, I have gone back to check each contact in the signal path to the right channel, completely resoldering the most sturdy parts (I avoided tempering with the led connections too much, aside from testing with chopsticks) and of course nothing changed in the slightest.

I decided to bring the amp to a different, well regarded repairman 40 minutes away from here that specializes in tubes. After several hours of testing, once again, there are zero noises coming from the amp, and there doesn't seem to be anything wrong with it (aside from a couple parts not being the preferable choice). We have tested with my tubes and power chord and with different ones to no avail. Zero issues.

I bring the amp back home and the noise is there. I bring it to my brother's house (5km away) and it's still there.

I have tried every wall outlet of my house and I have turned off every electronic device I have around and nothing changed.

I am at a serious loss. Whenever I bring my kit over to a professional it works perfectly. I bring it back and it's unusable.

I'm sorry to hear that your crack is noisy. Happens to all of us sometimes...

Sorry, I had to

On a more serious note. Perhaps it's not an issue with the crack? Have you checked with other sources/headphones?

What I would do, if I were you, is to switch parts of the circuits left to right and the other way. Eg.: Left driver tube connected to right output tube etc. That should help you narrow down the issue to a couple of elements at a time.

Sorry, I had to

On a more serious note. Perhaps it's not an issue with the crack? Have you checked with other sources/headphones?

What I would do, if I were you, is to switch parts of the circuits left to right and the other way. Eg.: Left driver tube connected to right output tube etc. That should help you narrow down the issue to a couple of elements at a time.

I have started thinking that it might not be an issue with the amp itself, yeah. I have tested different headphones and cables, different sources (even with no source connected at all, the noise is there), different power cords, different tubes (I can't switch right and left around since the crack only uses one input and one output tube for both channels). I have tried different wall outlets, removed other electric devices, moved to a different house. Nothing changes.

The only moments the noise disappeared were the two times that I brought it over to a professional to have a look at it. If I believed in the occult I would think I'm actually cursed.

I am one step away from walking around town with my amp and asking random people if I can plug it to their outlets to test.

The only moments the noise disappeared were the two times that I brought it over to a professional to have a look at it. If I believed in the occult I would think I'm actually cursed.

I am one step away from walking around town with my amp and asking random people if I can plug it to their outlets to test.

- Home

- Amplifiers

- Headphone Systems

- Noisy Bottlehead Crack