If the board can sustain the inrush current, superb! (I don't like double boards either) My thought was simplistic: Never underestimate Mark, so if bigger buggers can't be on the board, then they maybe aren't supposed to be onboard (by design)...rather not build one delay board per channel though I have considered this.

@RickRay "to boldly go where …"

Attachments

Assuming that there is space in chassis and sufficient clearance to avoid EM pickup by signal wires, then I would do two boards for my own design.

Divides load between two boards, thereby reducing any concerns with copper trace handling and current limits, adapting and placing oversized current limiters, and arguably makes dual mono PS construction and troubleshooting easier. But I will admit these are simply preferences snd not hard limits requiring use of two boards; plus there is extra cost if boards, parts , and the space need (as mentioned above). In 4U Deluxe chassis, this may preclude use of double boards.

Divides load between two boards, thereby reducing any concerns with copper trace handling and current limits, adapting and placing oversized current limiters, and arguably makes dual mono PS construction and troubleshooting easier. But I will admit these are simply preferences snd not hard limits requiring use of two boards; plus there is extra cost if boards, parts , and the space need (as mentioned above). In 4U Deluxe chassis, this may preclude use of double boards.

I am not sure why there is the concern about copper traces.

My impression is that this circuit reduces high inrush current. Increasing the size of the CL is surely just going to slow the rate at which it heats up, therefore maintaining more modest `charge up' currents for longer. Using a 2Sec time delay and a big CL should enable a higher value of charge to be put into the smoothing capacitors while maintaining realistic values for current.

I can appreciate there is some question of how one solders the welding rod legs to the board without lifting the tracks -so going for two in series may be more realistic from a practical standpoint.

Maybe I'm missing something here.

My impression is that this circuit reduces high inrush current. Increasing the size of the CL is surely just going to slow the rate at which it heats up, therefore maintaining more modest `charge up' currents for longer. Using a 2Sec time delay and a big CL should enable a higher value of charge to be put into the smoothing capacitors while maintaining realistic values for current.

I can appreciate there is some question of how one solders the welding rod legs to the board without lifting the tracks -so going for two in series may be more realistic from a practical standpoint.

Maybe I'm missing something here.

A simplified procedure to calculate an approximate value for the peak inrush current, could look like this:

Plug in the numbers for your design and voila! You get a conservative over-estimate of peak inrush current. In reality the current will be smaller because those other resistances in the mains circuit aren't zero.

The mains current obeys Ohm's Law, even at turn-on: current = voltage / resistance. Voltage in this case is Vmains (115VAC or 230VAC) and resistance is the total of all the series circuit elements.

Making the ultra conservative assumption that the transformer core is fully saturated at the instant of turn-on, its resistance is reduced to R_primary_copper. Then

Total Resistance Seen By Mains = MainsFuseR + (IEC RFI suppressor R) + (R of chassis wiring) + (Trafo_primary_copper_R) + (ICL_resistance_when_cold)

Now, making another conservative assumption, let's pretend that all terms in the above summation are ZERO microhms, except (ICL_resistance_when_cold). We pretend all other resistances are negligibly small compared to the ICL cold resistance.

Ohm's Law tells us: current = voltage / resistance and in this case: Inrush_current <= Vmains / (ICL_resistance_when_cold)

Plug in the numbers for your design and voila! You get a conservative over-estimate of peak inrush current. In reality the current will be smaller because those other resistances in the mains circuit aren't zero.

assuming transient music is short lived and will not cause overheating we're talking about the sum of bias/idle currents... I think it's a couple of amps so should be OK

but you have all sorts of interesting amps in your signature... so in your experience is that accurate?

but you have all sorts of interesting amps in your signature... so in your experience is that accurate?

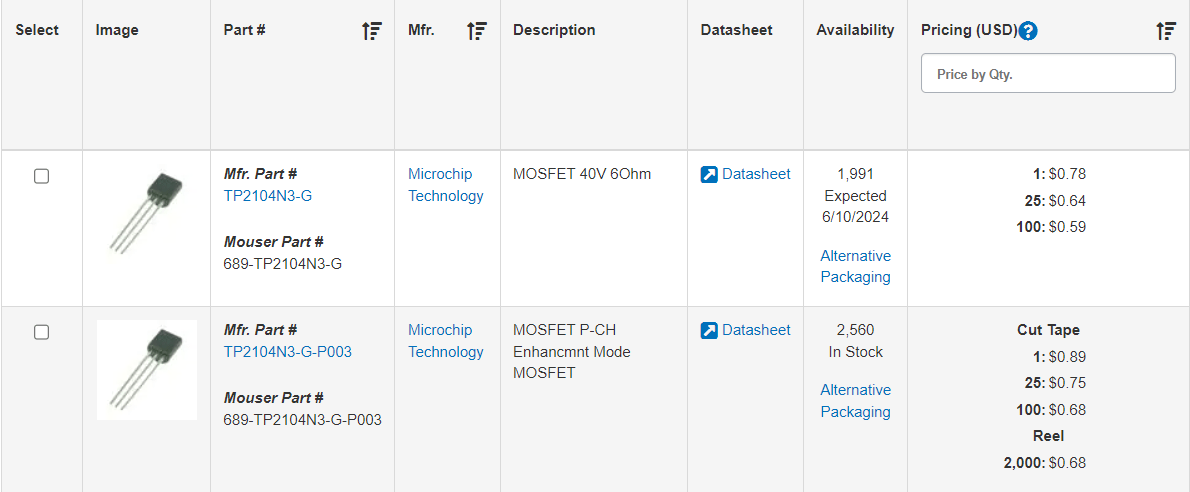

Just bought parts for a build. Currently Mouser (as usual) is out of some of the resistors, but those are fairly easy to find replacements for. I had to head out to Digikey to find the 40V 6 Ohm MOSFETs (Q1 Q2 Q3) , though. A typical day in the life of a DIY builder, I guess.

LOL. We might be on different pages! I do appreciate your help, though!

Here is what I see in pfarrell's cart from the first page of the thread:

https://www.mouser.com/ProductDetail/689-TP2104N3-G

You can still purchase this product for backorder.

On Order: 1,991

Here is what I see in pfarrell's cart from the first page of the thread:

https://www.mouser.com/ProductDetail/689-TP2104N3-G

Availability

Stock: 0

Notify me when product is in stock.You can still purchase this product for backorder.

On Order: 1,991

Expected 10-Jun-24

So sorry, I should have posted more specifics. Here is what I'm seeing.

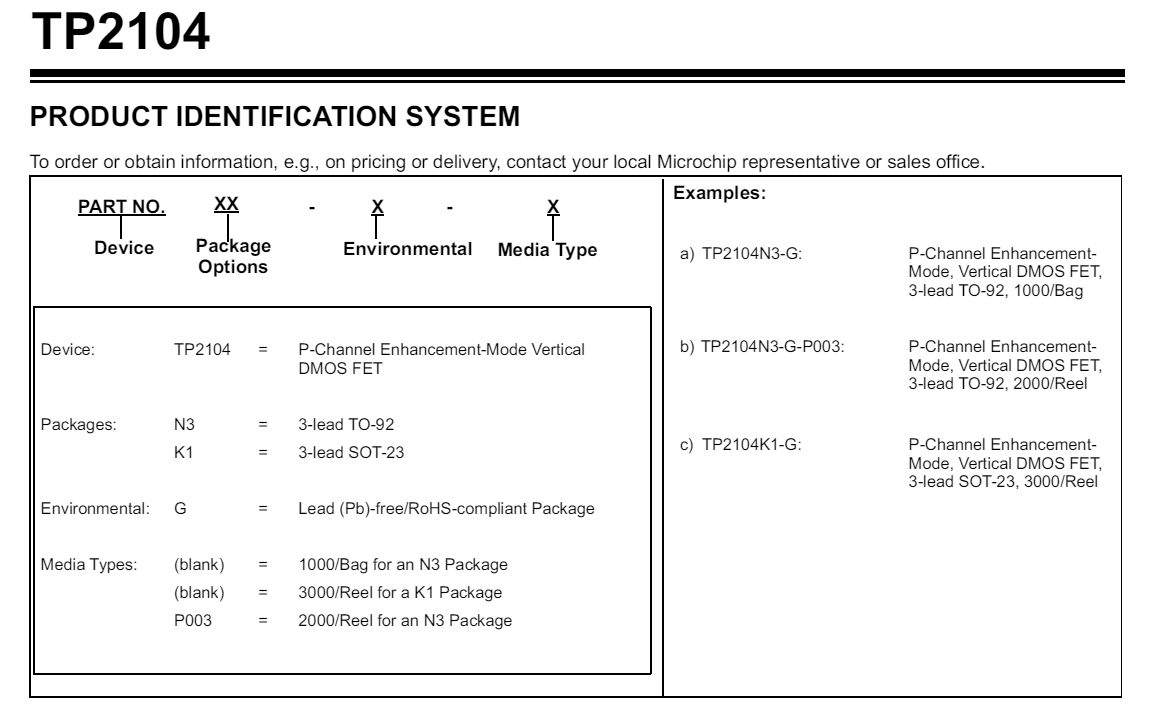

Granted, I had to go to another provider to get the datasheet to download, but with a VERY brief scan... with my untrained eye... here is what I saw in the data sheet for "P003". Right side, comparing example a to example b.

https://ww1.microchip.com/downloads...de-Vertical-DMOS-FET-Data-Sheet-20005958A.pdf

Again... I am TOTALLY not the guy to try and choose substitute parts. If it were just for me... I'd take the risk. Advising others... I'm not there yet.

Granted, I had to go to another provider to get the datasheet to download, but with a VERY brief scan... with my untrained eye... here is what I saw in the data sheet for "P003". Right side, comparing example a to example b.

https://ww1.microchip.com/downloads...de-Vertical-DMOS-FET-Data-Sheet-20005958A.pdf

Again... I am TOTALLY not the guy to try and choose substitute parts. If it were just for me... I'd take the risk. Advising others... I'm not there yet.

The only difference is that the ones with P003 in the part number are shipped to you on a paper tape that can be wound onto a reel, with the ones without P003 are shipped to you as loose individual TO-92's in a plastic bag. For the circuits used in this PCB, either one will be perfect. Buy what's cheapest or buy what's most easily available or buy what you find sexy.

buy what you find sexy.

I can only imagine "custom color" versions in the future... blue transistors to match your blue-mask PC board... LOL

No worries, IAIMH. I actually went for the exact part outside of Mouser, but you and Mark did teach me that the other part would have been available. As always, the education (of me) was worth your combined efforts. Many thanks.

You took care to get the correct ICL (115V/230V) I hope? (When I used pfarrells BOM/mouser cart, I did not and had to invent a new project to have it embedded in the shopping cart)…

Also, Mark often recommended us to use octoparts.com to hunt down parts…

(And I once went with red resistors to match the red PCB, but couldn’t go much further because the other parts (trimpots, capacitors etc.) are what they are, anything but red, 😂)

Also, Mark often recommended us to use octoparts.com to hunt down parts…

(And I once went with red resistors to match the red PCB, but couldn’t go much further because the other parts (trimpots, capacitors etc.) are what they are, anything but red, 😂)

Yes, I did get a 115V ICL, thanks.

Well, paint the whole thing at that point! I know, I know...good job, bhjazz: propose adding something that will increase the heat...

Maybe build up the circuit, mount it upside down and paint the backside? Like this (not my work):

I once went with red resistors to match the red PCB, but couldn’t go much further because the other parts (trimpots, capacitors etc.) are anything but red

Well, paint the whole thing at that point! I know, I know...good job, bhjazz: propose adding something that will increase the heat...

Maybe build up the circuit, mount it upside down and paint the backside? Like this (not my work):

haha. fun idea to paint a board. Me, I wouldn't do skulls, and if anything, I'd rather go a more poetic route:

(from tidal)

or one of these: https://www.wopc.co.uk/japan/sanyo-ukiyo-e

(from tidal)

or one of these: https://www.wopc.co.uk/japan/sanyo-ukiyo-e

This PCB will work just fine as a push-on, push-off switch for the AC mains. Even when the audio gear doesn't really need soft start. Soft start definitely won't hurt a Designed-It-Yourself outboard linear power supply for an ACP+.

Soft start won't really help either. Which means: you're paying a lot of money and burning up a lot of PCB real estate, for components that you don't actually need. If that offends your inner Scotsman (or inner Dutchman (shout-out to Jan Didden!)), you could consider building a different board that has push-on, push-off mains switching, but omits soft start.

One candidate is Rod Elliott's project 166, as mentioned in the very first post of this Forum thread. No money "wasted" on a gigantic 125 Joule, 32 mm diameter, Inrush Current Limiter component made by Ametherm. No money "wasted" on a triac, optoisolator, and heatsink. Perhaps this may appeal to you on the grounds of efficiency and elegance.

I have no idea whether Rod or anyone else offers finished PCBs for sale, or Gerbers for download.

I'm quoting Mark's entire post from 2021-07-18 because there's lots of good info here for me to chew on. I'm building a BA2018 preamp and had decided to use the H9KPXG for power switching. I now mostly understand why this is overkill for a BA2018, and the mention of it taking up real estate and some dollars is spot on. I really just need the low-power front-panel switching. I do remember, though, my Theta Casanova preamp which had an elegant delay once the front panel power button was touched. I can only suspect if that unit had soft-start. Likely.

I looked into Rod Elliott's Project 166 and have dispatched email to him since boards for that project do not appear in his store. I'll follow-up with what I find.

I also looked into the AMB ε24, but honestly like the rather finite list of parts for the H9KPXG instead. The ε24 has some posts in their forum listing some buzzing with the SSR, and I'd rather not troubleshoot which SSR works or does not work with my particular build. I think I'll have enough to do once I get power to my build on day one. I'll keep the ε24 on my radar, though, as I've built some of his projects before and really enjoy them. (my list of todo projects includes the AMB σ78 and σ79 ultra low noise voltage regulators. These will drop into my CK²III headphone amp that I build years ago and remains in rotation on my desk!)

Okay. Enough rambling. Solder on, gents!

- Home

- Amplifiers

- Power Supplies

- PCB: low voltage On-Off switch drives AC mains relay \ includes soft start .. H9KPXG