Hi all, time for my bi-annual post 🙂

I have been using the darlington rangemaster design for years in a Tony Iommi style boost pedal. I am noticing that maybe once a year or every other year I have to replace the MP44 soviet made germanium cans for seemingly no reason. As far as I know Tony never had to have the rangemaster serviced in the 10 years he used it, I am wondering if his was built better then mine or the cans were just swapped for silicon.

I understand germanium REALLY hates temp swings, I remember a long time ago I saw a circuit using a diode between the emitter and base (I think) with both the transistor and diode attached to a heatsink so the diode will thermally compensate for the bias but I forgot what that is called.

Is there a way to make this circuit more stable?

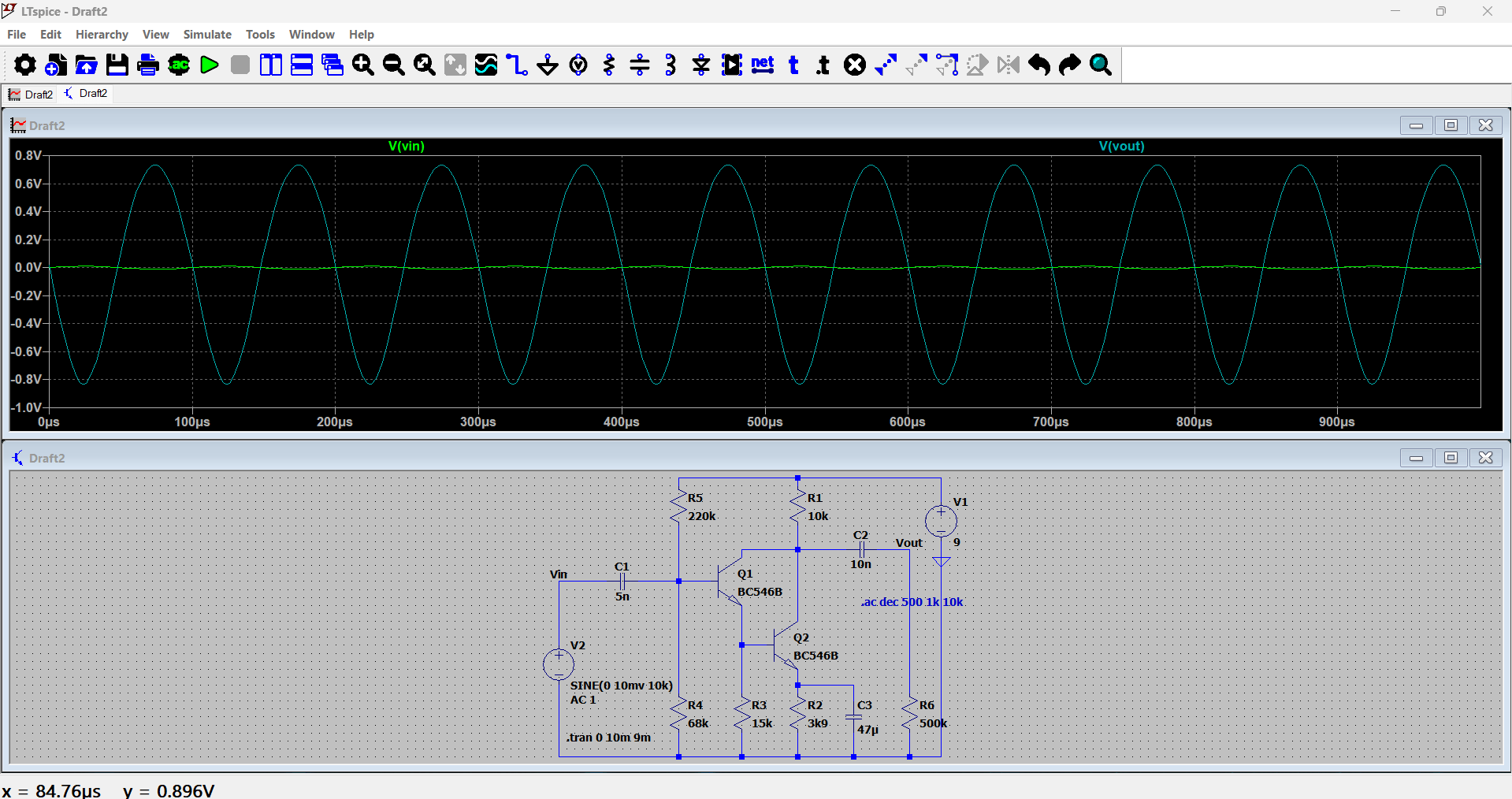

Here is the circuit (Ignore the way I bungled up the 10k) I replaced the volume pot with a 10k resistor since I always run it dimed anyways.

Any advice greatly appreciated.

I have been using the darlington rangemaster design for years in a Tony Iommi style boost pedal. I am noticing that maybe once a year or every other year I have to replace the MP44 soviet made germanium cans for seemingly no reason. As far as I know Tony never had to have the rangemaster serviced in the 10 years he used it, I am wondering if his was built better then mine or the cans were just swapped for silicon.

I understand germanium REALLY hates temp swings, I remember a long time ago I saw a circuit using a diode between the emitter and base (I think) with both the transistor and diode attached to a heatsink so the diode will thermally compensate for the bias but I forgot what that is called.

Is there a way to make this circuit more stable?

Here is the circuit (Ignore the way I bungled up the 10k) I replaced the volume pot with a 10k resistor since I always run it dimed anyways.

Any advice greatly appreciated.

Attachments

The resistor values are so high and the supply voltage so low that there is no realistic way for the transistor to fail operationally. That said a possible failure mode could be transient voltage spikes on either the input or output connections that are causing damage. Adding a series resistor at the input and output might help with that possibility.

I would add a small silicon diode, 1N4148 or so, with its cathode connected to the base of the first transistor and its anode to ground, to ensure that negative voltage peaks at the input don't damage the base-emitter junction of the first transistor. I don't know if base-emitter breakthrough is an issue for old germanium transistors, but it certainly is for modern silicon ones.

Mooly, realistically that is a very good idea, however gain is not something I am willing to sacrifice 😛

Marcel, That is a very good idea and along the lines of what I was thinking. If I have a failure in the future I will definitely try to determine if it is the first transistor or both, as that is a very good theory.

Marcel, That is a very good idea and along the lines of what I was thinking. If I have a failure in the future I will definitely try to determine if it is the first transistor or both, as that is a very good theory.

I was thinking something like a 1k at the input and output which would have minimal impact. the output resistor rerally depends on what you feed this into but given the low value coupling caps the impedances all around must be very high.

This is the standard circuit biased for silicon:

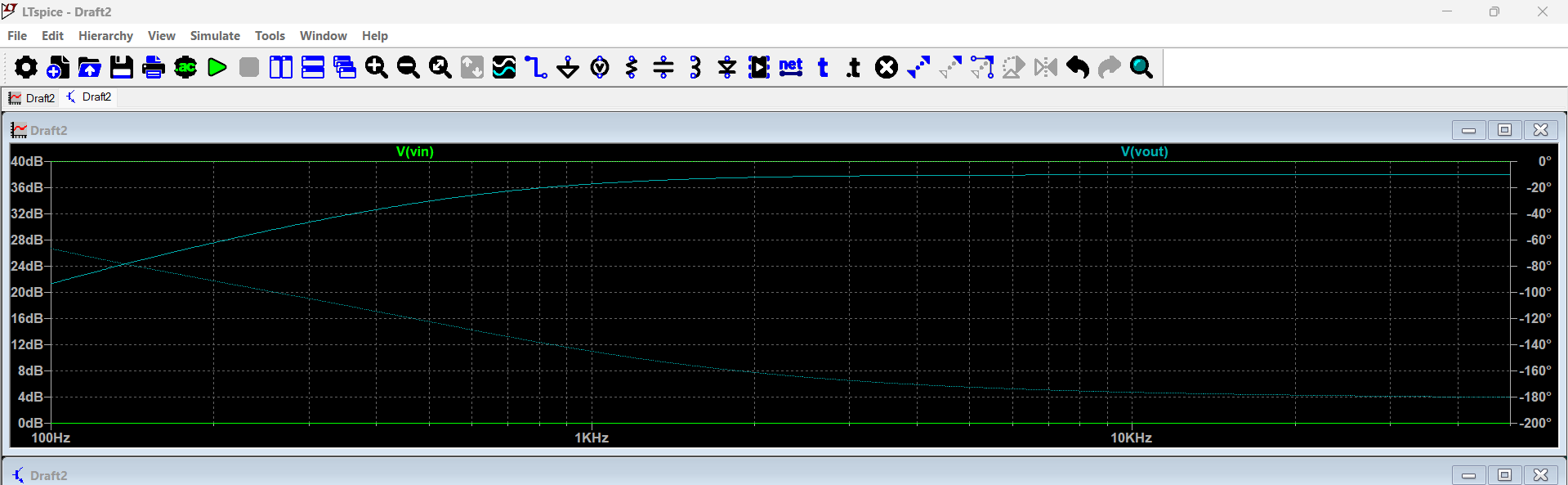

And the gain is about 38db:

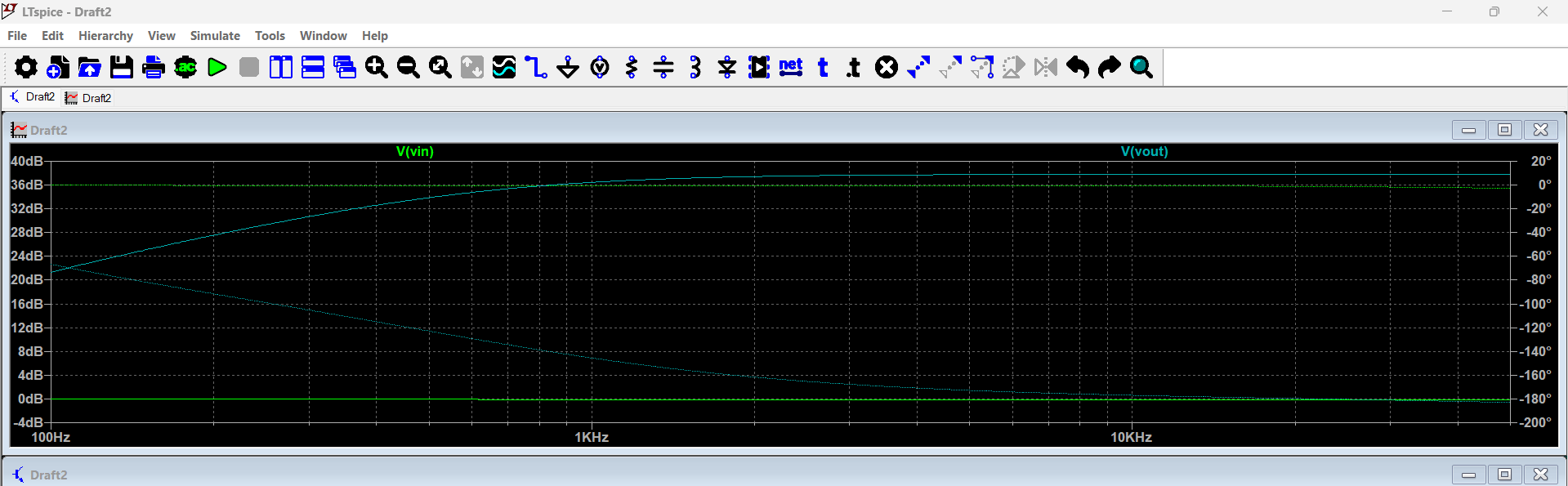

And with a 1k at the input gain is 37.8db:

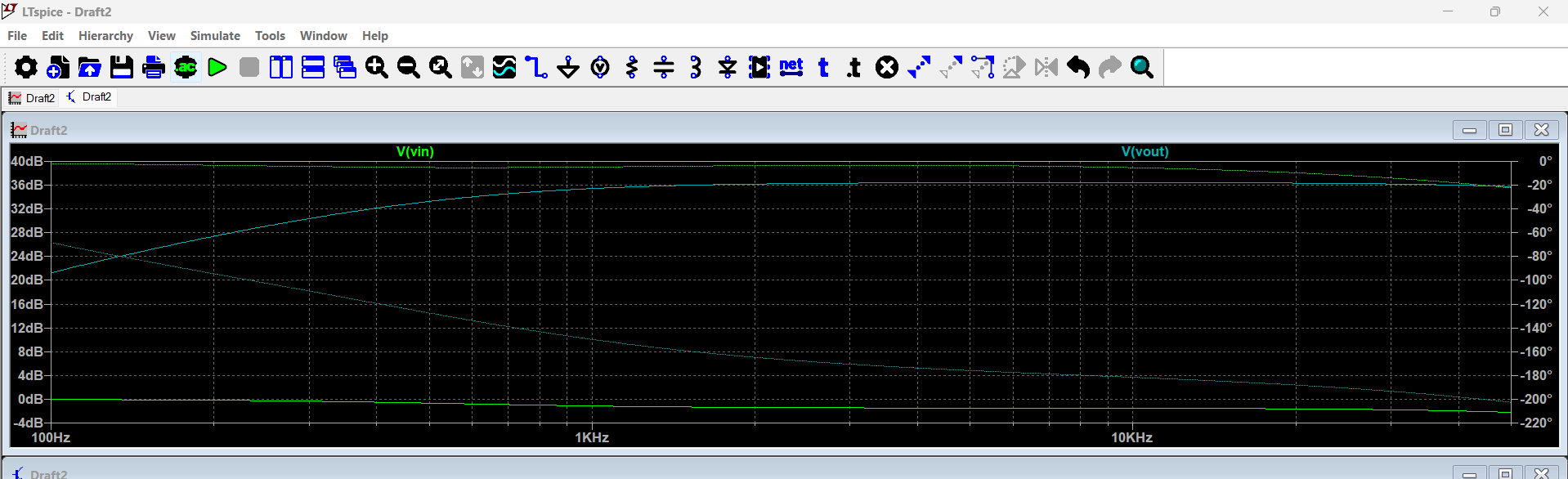

And a 10k at the input is still over 36db gain:

This is the standard circuit biased for silicon:

And the gain is about 38db:

And with a 1k at the input gain is 37.8db:

And a 10k at the input is still over 36db gain:

Attachments

Resistor isolation and diode clamping are both good suggestions.

I'm not sure if transistors have a shelf life, but germanium transistors have to be at least 50 years old. Plus if the seal is breached or the manufacturing process is substandard, they'll have a high rate of failure. Soviet manufactured in the 1960s or 1970s and the quality control is -????

You might try replacing one or both transistors with silicon. I don't know if it will sound the same, but it's worth a try.

"Overdriving" them is not an issue. As long as you're inside the SOA all is kosher.

I'm not sure if transistors have a shelf life, but germanium transistors have to be at least 50 years old. Plus if the seal is breached or the manufacturing process is substandard, they'll have a high rate of failure. Soviet manufactured in the 1960s or 1970s and the quality control is -????

You might try replacing one or both transistors with silicon. I don't know if it will sound the same, but it's worth a try.

"Overdriving" them is not an issue. As long as you're inside the SOA all is kosher.

Regarding shelf life, I know some old European germanium transistor types have tin whisker issues, no idea if the same applies to USSR types.

I built lots of clones of the Vox Tone Bender / Dallas Arbiter Fuzz Face back around 1968 - 1970. I used transistors scavenged from transistor radios and other low buck Japanese consumer electronics. I found two things that fry germanium devices, heat and voltage. Most of the transistors lifted from a device that ran from a 9 volt battery would work on 12 volts, but few survived much more than that.

Even those big fat TO-36 doorknobs that are found on the back of many early 60's car radios have a very low tolerance for overvoltage. I used them for small "booster" amps as a kid. I found that most would eat 3 X 6 volt lantern batteries, but few would survive 4. My trusty DIY test power supply back then was a big Lionel train transformer feeding a big selenium rectifier stack from a car battery charger and a couple of big fat caps.

Even those big fat TO-36 doorknobs that are found on the back of many early 60's car radios have a very low tolerance for overvoltage. I used them for small "booster" amps as a kid. I found that most would eat 3 X 6 volt lantern batteries, but few would survive 4. My trusty DIY test power supply back then was a big Lionel train transformer feeding a big selenium rectifier stack from a car battery charger and a couple of big fat caps.

I built the same kind of booster in high school just because I had all the parts. I also scavenged parts from old electronics and built stuff.

I ran it off an 18 volt transformer power supply. It never burned up. It worked pretty good.

I ran it off an 18 volt transformer power supply. It never burned up. It worked pretty good.

Here is the first Tone Bender clone I ever made. I built this one to see if the schematic that I had traced from a Vox Tone Bender was correct. When tracing the original I ran across a cap labeled 103. At the time (1968) I assumed 103 pF since I had never seen a cap labeled 103 before. I also used sockets for the transistors to test them all for best "tone." The later versions used "Bud" style boxes from the local Lafayette Radio Electronics store. Some even had relay switching.

Attachments

Your capacitor was only off by a factor of 100. Of course you know now that 103 = 10,000 pF.

I always measure caps labeled “xx0”. 100 could be 10 pF or 100. I’ve seen dog-bone silver micas and ceramic discs labeled both ways. At least if the value ends in “1” and has 3 digits it is a multiplier.

I always measure caps labeled “xx0”. 100 could be 10 pF or 100. I’ve seen dog-bone silver micas and ceramic discs labeled both ways. At least if the value ends in “1” and has 3 digits it is a multiplier.

I dissected the original Vox Tone Bender in 1968. most of my DIY parts were obtained by showing up at the local trash dump with a bag full of tools and a "take out box." At that time the only diagnostic device I had was an Eico VTVM that I had assembled from a kit. Measuring caps was far beyond me. Big electrolytics were tested and sorted by how big of a spark they made. Small caps were "try it and see what happens." Many of the little ones were rated in MMFDs (Micro-Micro Farads). Somewhere in my youth the term MMFD was changed to pF. My guess would be in the early 60's or late 50's. Some of the stuff in that landfill had been there for a long long time. There is a high density housing development there now.

I changed the caps and some of the resistors in that box at least once. Some a few times. They were changed whenever I found a box or bag of like parts to test. Back in the 60's there were several electronic surplus shops in the Miami area. Even the "Eagle Army - Navy store had an isle of oddball electronics surplus and an "All vacuum tubes are $1" shelf. The tubes were "Thoro Test" branded GE's, and yes, they sometimes had 6L6GC's until I came in. I think Lafayette wanted about $5 for them.

I changed the caps and some of the resistors in that box at least once. Some a few times. They were changed whenever I found a box or bag of like parts to test. Back in the 60's there were several electronic surplus shops in the Miami area. Even the "Eagle Army - Navy store had an isle of oddball electronics surplus and an "All vacuum tubes are $1" shelf. The tubes were "Thoro Test" branded GE's, and yes, they sometimes had 6L6GC's until I came in. I think Lafayette wanted about $5 for them.

Very unusual to see npn germanium small signal transistors. Only npn germanium was AC127 and some ASYxx

"switching" transistors in some "computer modules" (from the time before integrated circuits) where about all i ever saw.

Are those transistors ment to be npn germanium?

"switching" transistors in some "computer modules" (from the time before integrated circuits) where about all i ever saw.

Are those transistors ment to be npn germanium?

Last edited:

Adding the 1N4148 and.or series resistors may be a good idea, but I just have the impression that a significant percentage of germanium transistors WILL fail regardless of the circuit. In the 80s I had a (1960s) Farfisa organ that had a bad transistor in one of the dividers. Not knowing any better (that it's important to the sound), I replaced it with a silicon transistor. I currently have a Vox Jaguar that also has a bad transistor in a divider, I haven't gotten around to look for germanium transistors. Nowadays I wonder what percentage of them are fake or just no good. Maybe I could find a 1960s transistor radio ...

An organ uses 15 volts (at least the Vox, I think Farfisa was lower) from the power supply, and each transistor surely has a lot more current in the "on" state than do the transistors in a battery-powered distortion box, but then I've read so much about electrically leaky germaniums and such, I'd rather not have to mess with them.

An organ uses 15 volts (at least the Vox, I think Farfisa was lower) from the power supply, and each transistor surely has a lot more current in the "on" state than do the transistors in a battery-powered distortion box, but then I've read so much about electrically leaky germaniums and such, I'd rather not have to mess with them.

True, Ge transistors are in general not as reliable as modern silicon ones. Some are going to be NFG just sitting in storage for decades. But if you run them into breakdown you’ll get a failure for sure so you do what you can to avoid that. And have spares on hand if you value the equipment.

I‘m always on the lookout for bargain Ge’s. I’m not paying $20 for one, especially considering the likelihood of failure/duds.

I‘m always on the lookout for bargain Ge’s. I’m not paying $20 for one, especially considering the likelihood of failure/duds.

Can't say i have ever heard of reoccurring germanium transistor failures in a rangemaster. Only thing i can think of is...

1. you are using a power supply and spikes are killing it

2. transistor is getting too hot during soldering and damage is occurring

3. Russian transistors are junk.

Can not find any info on mp44 transistors? I have hundreds of russian trannys but not that number, i take that as a typo? Where are you located at?

1. you are using a power supply and spikes are killing it

2. transistor is getting too hot during soldering and damage is occurring

3. Russian transistors are junk.

Can not find any info on mp44 transistors? I have hundreds of russian trannys but not that number, i take that as a typo? Where are you located at?

As a child I assembled a Heathkit transistor radio and the instructions were clear that you should put a "heat sink" (like long-nose pliers with rubber band holding it on the lead) on each leg while soldering it, between the transistor body and the PCB. They might even have been silicon transistors, but I wouldn't doubt they figured it's better to use use a heat sink on every transistor rather than trust people to make the distinction between germanium and silicon.2. transistor is getting too hot during soldering and damage is occurring

It was easy to convert painted glassenvelope transistors into photosensitive transitors by scratching the protecting paint off.

First transistor i ever bougth, a OC70, payd a weeks (+45h)salary for it, but prices dropped quickly, some years later i could get a handfull for the same price

First transistor i ever bougth, a OC70, payd a weeks (+45h)salary for it, but prices dropped quickly, some years later i could get a handfull for the same price

Last edited:

- Home

- Live Sound

- Instruments and Amps

- Reliability of germanium transistors when overdriven