Don't Give Up!!!

Gabriel,

Please don't give up...

Perhaps consider building one of the smaller Alephs in the same chassis... Your design looks very nice...

I've recently had the experience of listening to an Aleph 0s (stereo) through a pair of Apogee Stages. We hooked it up not expecting much because it was only rated at 40 watts.... We were blown away to say the least!!!

My point is simply that you may be very surprised at what this design is capable of driving... Do you really need 100 watts per channel?

Rather than send it "to the closet" why not choose a particular model that is more closely suited to your chassis design???

On the other hand, take a chance and build exactly what you propose. The experiment will allow you to learn exactly what works properly and what doesn't. Through this you will learn what to do differently the next time... It may end up costing $$$ though for the lesson...

The comments from all of us are simply in the interest of wanting you to succeed and for you be very happy with the outcome...

Again, don't be discouraged!!!

Best Regards,

Steve

Gabriel,

Please don't give up...

Perhaps consider building one of the smaller Alephs in the same chassis... Your design looks very nice...

I've recently had the experience of listening to an Aleph 0s (stereo) through a pair of Apogee Stages. We hooked it up not expecting much because it was only rated at 40 watts.... We were blown away to say the least!!!

My point is simply that you may be very surprised at what this design is capable of driving... Do you really need 100 watts per channel?

Rather than send it "to the closet" why not choose a particular model that is more closely suited to your chassis design???

On the other hand, take a chance and build exactly what you propose. The experiment will allow you to learn exactly what works properly and what doesn't. Through this you will learn what to do differently the next time... It may end up costing $$$ though for the lesson...

The comments from all of us are simply in the interest of wanting you to succeed and for you be very happy with the outcome...

Again, don't be discouraged!!!

Best Regards,

Steve

Gabster....

My Aleph 2s have 1000VA each and they're as small as you should go. As a reference - Nelson says: "1500VA" for an Aleph 2 is what you really want. My amps appear to be fine... but. It's not ideal.

But. For an Aleph 4, you would be fine with either 2x 625VA or a single 1500VA, for the 2 channels as you said. I think you're good to go.

W.

My Aleph 2s have 1000VA each and they're as small as you should go. As a reference - Nelson says: "1500VA" for an Aleph 2 is what you really want. My amps appear to be fine... but. It's not ideal.

But. For an Aleph 4, you would be fine with either 2x 625VA or a single 1500VA, for the 2 channels as you said. I think you're good to go.

W.

You don'T really need to buy already made heatsink. You can build it yourself using aluminum sheet or you can go at your local electronic repair shop. Some of them stock piece of electronic they where not able to repair or didn't repair. In those they are a lot of old audio amp whit massive heatsink.

And if your unluky with the repair shop building an heatsink is not that hard.(If you can build amp you can surly build heatsink.) One thing is that you make it larger than wath should be needed in order to get a good safety margin.

And if your unluky with the repair shop building an heatsink is not that hard.(If you can build amp you can surly build heatsink.) One thing is that you make it larger than wath should be needed in order to get a good safety margin.

JBL, as you say I don't think I'll go for new heatsinks since they'll need some reshaping (outside heatsink won't be square). I'll just wait until I find something used and interesting.

Wayne, I guess the most simple solution will be to build an Aleph4 in two boxes.

BTW, what is the difference between these two amps? They are delivering the same output power and schematics are pretty much the same...

Apogee, good advice, but I'll try everything I can to get those 100W amps. However, building an Aleph0 is also part of my projects as it would be more flexible.

Thanks folks, you're really bringing great support to my project.

ciao,

Gabriel

Wayne, I guess the most simple solution will be to build an Aleph4 in two boxes.

BTW, what is the difference between these two amps? They are delivering the same output power and schematics are pretty much the same...

Apogee, good advice, but I'll try everything I can to get those 100W amps. However, building an Aleph0 is also part of my projects as it would be more flexible.

Thanks folks, you're really bringing great support to my project.

ciao,

Gabriel

As extreme as it gets

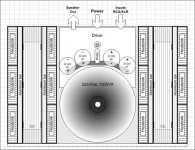

Well, I don't seem to be able to get that Aleph 2 out of my head.

I have rethought every millimeter of that amp to have that 1500VA transformer fiited.

I have added a section of heatsink above X6 boards. This way I get 240in² of heatsink surface which is very close to WaneyS' 260in². I just hope that my good heat distribution and a massive covers (top and bottom) venting will make heat acceptable (I'm very confident ). As Mr. Pass say, the worst that could happen is that it will run hotter, one think that I don't really mind.

). As Mr. Pass say, the worst that could happen is that it will run hotter, one think that I don't really mind.

ciao folks,

Gabriel

Well, I don't seem to be able to get that Aleph 2 out of my head.

I have rethought every millimeter of that amp to have that 1500VA transformer fiited.

I have added a section of heatsink above X6 boards. This way I get 240in² of heatsink surface which is very close to WaneyS' 260in². I just hope that my good heat distribution and a massive covers (top and bottom) venting will make heat acceptable (I'm very confident

ciao folks,

Gabriel

Attachments

Transistor mounting to Heatsink(s)

It looks like you are using aluminium bar to mount the MOSFETs to and using that to spread heat across the row of heatsinks.

This would result in reduced heat transfer as you are introducing another thermal interface into the equation - better to mount each MOSFET directly to the heatsink as this will reduce the junction temperatures of the devices - Each thermal interface is most likely going to cost you about 1 degree Celcius/w.

Copper would be better than aluminium at spreading the heat, but it's still far from ideal and will also cost you loss of efficiency.

Hope this helps

It looks like you are using aluminium bar to mount the MOSFETs to and using that to spread heat across the row of heatsinks.

This would result in reduced heat transfer as you are introducing another thermal interface into the equation - better to mount each MOSFET directly to the heatsink as this will reduce the junction temperatures of the devices - Each thermal interface is most likely going to cost you about 1 degree Celcius/w.

Copper would be better than aluminium at spreading the heat, but it's still far from ideal and will also cost you loss of efficiency.

Hope this helps

The aluminium bar is used in case I have one heatsink per MOSFET because the chassis wouldn't be rigid enough otherwise. However, adding the bar would decrease the heat transfer but could add heat absorption...is this relevant?

The best would be to find full length heatsink with enough base thickness to bolt bottom and cover...

ciao,

Gabriel

The best would be to find full length heatsink with enough base thickness to bolt bottom and cover...

ciao,

Gabriel

Popular little thread, this

A couple of general comments first. I am concerned with the desire of many would-be-Aleph builders to try to build the higher power versions.

The vast majority of our listening is <10W, unless you are one of these poor/silly folk who have grossly inefficient speakers. OK, 100W sounds much "sexier" and more "impressive" but in real terms most of us do not need the extra power. In fact, I was quite happy with my old A40!

I chose to build the A-4 because of chance toroid acquisition ..... not because I thought I needed it! Several have commented that my PS is a little small for the A-4 and they are correct. The toroids are way too hot for a commercial amp and their longevity is under constant suspicion.

Likewise, I have the compromise of 3-FETs per bank, so the junction temps will be higher than if I had used the recommended 6-FETs. Then my heatsink is less than optimal, given the idle temperature is about 68C. Again ..... longevity lives under a cloud !!!

Please remember, most of this hardware was bought surplus ... so there was no logical selection in the design

I am currently building a replacement for this amp. It will be an Aleph5 (actually, it may well have the Volks front-end) as a stereo monoblock. Case format not dissimilar from Wayne's "masterpieces" ......

My honest advice, if you are near the limit in heat and hardware, just build an A-5. Unless you are in a position where you will not cry if "smoke signals" appear.

cheers, mark

PS: my amp still sounds great ..... many hundreds of hours of service ..... hot, damn hot !!!

A couple of general comments first. I am concerned with the desire of many would-be-Aleph builders to try to build the higher power versions.

Please remember dB is a log scale and going from a 60W Aleph5 to 100W will gain you slightly less than 3dB ...... but this move will cost a lot in terms of heat and required hardware.We hooked it up not expecting much because it was only rated at 40 watts.... We were blown away to say the least!!!

The vast majority of our listening is <10W, unless you are one of these poor/silly folk who have grossly inefficient speakers. OK, 100W sounds much "sexier" and more "impressive" but in real terms most of us do not need the extra power. In fact, I was quite happy with my old A40!

I chose to build the A-4 because of chance toroid acquisition ..... not because I thought I needed it! Several have commented that my PS is a little small for the A-4 and they are correct. The toroids are way too hot for a commercial amp and their longevity is under constant suspicion.

Likewise, I have the compromise of 3-FETs per bank, so the junction temps will be higher than if I had used the recommended 6-FETs. Then my heatsink is less than optimal, given the idle temperature is about 68C. Again ..... longevity lives under a cloud !!!

Please remember, most of this hardware was bought surplus ... so there was no logical selection in the design

I am currently building a replacement for this amp. It will be an Aleph5 (actually, it may well have the Volks front-end) as a stereo monoblock. Case format not dissimilar from Wayne's "masterpieces" ......

My honest advice, if you are near the limit in heat and hardware, just build an A-5. Unless you are in a position where you will not cry if "smoke signals" appear.

cheers, mark

PS: my amp still sounds great ..... many hundreds of hours of service ..... hot, damn hot !!!

Hi, I think a good analogy would be a comparison with cars. All makers offer various engines for each of their models. Often the difference between the less and the most powerful version can reach 100 HP. Since no one (should) use his car for racing, a 260 HP car should be useless. However, one day or another we all fell like hitting the gas and fell the incredible acceleration.

In audio, I like to have the same oppotunity: getting the most possible; Listening to music louder than I should be or having the possibily to do so.

Now, why does people don't get a 260 HP car?

1) Because they are reasonable.

2) They can't afford it.

So why do I want a 100W class A amplifier?

1) I'm not reasonable.

2) I can afford it.

Furthermore, a 100W amp is a good asset and the power it can deliver will be highly appreciated when it will be required. Even if it is true that the majority of my listening is made at a lower level, I believe it is important to build the amplifier than will give me the best flexibily. After all, I'm still young and parties still keep an important place in my life!

Please don't flame me for this, I said what I think and I'm sure I'm not the only one.

regards,

Gabriel

In audio, I like to have the same oppotunity: getting the most possible; Listening to music louder than I should be or having the possibily to do so.

Now, why does people don't get a 260 HP car?

1) Because they are reasonable.

2) They can't afford it.

So why do I want a 100W class A amplifier?

1) I'm not reasonable.

2) I can afford it.

Furthermore, a 100W amp is a good asset and the power it can deliver will be highly appreciated when it will be required. Even if it is true that the majority of my listening is made at a lower level, I believe it is important to build the amplifier than will give me the best flexibily. After all, I'm still young and parties still keep an important place in my life!

Please don't flame me for this, I said what I think and I'm sure I'm not the only one.

regards,

Gabriel

Ok, it sounds like you're going for the 100w no matter what!

Go for it!!!! I can relate...

A couple of thoughts on your revised design...

a) Rather than mounting the fets to the aluminum bar that you show, why not instead run a piece of 20mm square stock as "rails" along the top and bottom edges of the heatsinks with heatsink compound between. Your drawing would look the same but the bar wouldn't be one big piece...but instead two smaller ones... This would allow the rigidity that you're looking for as well as solid mounting for the heatsinks themselves. It would also allow for mounting the fets directly to the heatsinks themselves - this would be much more thermally efficient...

b) Suggest using 6 - 10mm plate for the bottom (and perhaps top) of the amps. This would make the amps much more ridged as well as increase the thermal sinking...use heatsink compound between the above mentioned "rails" and the tops and bottoms of the cases... Attach the "rails" to the chassis in several places along their lengths to create good thermal transition...

c) Be sure to design your venting in the tops and bottoms for lots of airflow... I figure you've already taken this into account but I figured that I'd mention it anyway...

d) Based on your drawing, it looks to me like you still have a bit of available space between the heatsinks. What about locating or fabricating heatsinks with deeper fins? This should improve the dissipation factor a bit...

Just a few ideas...

Best Regards,

Steve

Go for it!!!! I can relate...

A couple of thoughts on your revised design...

a) Rather than mounting the fets to the aluminum bar that you show, why not instead run a piece of 20mm square stock as "rails" along the top and bottom edges of the heatsinks with heatsink compound between. Your drawing would look the same but the bar wouldn't be one big piece...but instead two smaller ones... This would allow the rigidity that you're looking for as well as solid mounting for the heatsinks themselves. It would also allow for mounting the fets directly to the heatsinks themselves - this would be much more thermally efficient...

b) Suggest using 6 - 10mm plate for the bottom (and perhaps top) of the amps. This would make the amps much more ridged as well as increase the thermal sinking...use heatsink compound between the above mentioned "rails" and the tops and bottoms of the cases... Attach the "rails" to the chassis in several places along their lengths to create good thermal transition...

c) Be sure to design your venting in the tops and bottoms for lots of airflow... I figure you've already taken this into account but I figured that I'd mention it anyway...

d) Based on your drawing, it looks to me like you still have a bit of available space between the heatsinks. What about locating or fabricating heatsinks with deeper fins? This should improve the dissipation factor a bit...

Just a few ideas...

Best Regards,

Steve

Well .... I really don't mind what you do, but this is actually a terrible analogy and reinforces my concern about many not undertanding the nature of the dB scale and how it relates to an amplifiers W-RMS rating.I think a good analogy would be a comparison with cars. All makers offer various engines for each of their models. Often the difference between the less and the most powerful version can reach 100 HP. Since no one (should) use his car for racing, a 260 HP car should be useless.

A difference between cars of 100HP will be dramatic. You will accelerate at "break-neck" speeds in the more powerful car. The top speed may be 50-100mph greater. The more powerful car will invariably have better suspension and breaks, etc., etc. That is, to drive them at any speed, will be a vastly different experience.

Now lets come back to our beloved Alephs ..... the only difference will be about 2.5dB ..... ie. you might get 108 versus 106 dB. The "character" of the amplifier will be essentially the same. Their "acceleration" will be the same, their "cornering" will be the same ..... and so on.

In a "blinded" listening test, I suspect you would never be able to tell me relaibly which was which.

cheers, mark

PS: Good luck with the project and enjoy .... I really do mean this

PPS: Grey et al., yes I do appreciate their are small differences between the Alephs in terms of relative biasing etc. ..... but as some-one who spent his youth in turbo-charged Porsches I couldn't let this analogy slip through

Mark, my analogy was not pointing to the fact that the difference is not noticeable, but that it is not mandatory (Please don't make me sound like I cannot make the difference between a car or another...I would never trade my Audi for any of those same priced american cars. However a '98 Porsche Turbo would be considered  ).

).

Maybe I've been misunderstood but what I really wanted to say is that when you care about it, each HP or watt counts...and if you can afford it, then it is obvious that you should go for it. I understand what you're saying: that a 100W aleph will not sound better (even if someone was pointing that Mr. Pass say that the Aleph 2 sounds better), that it will not give an unbelievable output power increase. I know what a dB SPL is, please believe me.

thanks for carrying about my project,

Gabriel

Maybe I've been misunderstood but what I really wanted to say is that when you care about it, each HP or watt counts...and if you can afford it, then it is obvious that you should go for it. I understand what you're saying: that a 100W aleph will not sound better (even if someone was pointing that Mr. Pass say that the Aleph 2 sounds better), that it will not give an unbelievable output power increase. I know what a dB SPL is, please believe me.

thanks for carrying about my project,

Gabriel

I've just glanced through this thread, and perhaps I missed something...but if the intent is to build a pair of Aleph 2s, then a 1500VA transformer is not necessary. You can easily use a 600VA (Plitron has, I believe, 625VA) or 750VA, if you want a little more elbow room. I use 1kVA transformers on my Aleph 2s without the least bit of trouble, and regard that as excessive; purely for sonic (as opposed to thermal or electrical) reasons.

As regards wattage, Mark is quite correct. I tend to go for more power for two reasons: One--my drivers are only so-so in efficiency, being somewhere in the mid 80s dB-wise. Two, I really, really hate the sound of clipping, and am always astonished when I go to hear someone's system, hear obvious clipping and they're grinning like a madman, saying,"Doesn't it sound great?" Well, frankly, no. For starters, turn the damned thing down so that the amplifiers can breathe a bit. One of the first comments by people who listen to larger amps is that they sound more 'dynamic' and reproduce the peaks 'without strain.' Well, <i>duh!</i>

Just had this experience yesterday afternoon, in fact. The guy reportedly has $40,000 in his listening room alone. (12" thick walls, various sound treatments, etc. etc. etc.) He's sitting there telling me how great his system is. And, in all fairness, it's pretty good. But he's playing it too loud, and it's clipping, and he doesn't seem to notice. The same old story. I could say more, but I think I'll reserve some of the juicy parts for the 'listening' thread I keep threatening to write.

More power costs more money and creates more heat. But it makes a difference. Horn folks are in better shape here, since even small amps are shown to better advantage, but for those of us who chose (for any number of reasons) not to use horns, power is a good thing to have, even if you don't play particularly loud.

Grey

As regards wattage, Mark is quite correct. I tend to go for more power for two reasons: One--my drivers are only so-so in efficiency, being somewhere in the mid 80s dB-wise. Two, I really, really hate the sound of clipping, and am always astonished when I go to hear someone's system, hear obvious clipping and they're grinning like a madman, saying,"Doesn't it sound great?" Well, frankly, no. For starters, turn the damned thing down so that the amplifiers can breathe a bit. One of the first comments by people who listen to larger amps is that they sound more 'dynamic' and reproduce the peaks 'without strain.' Well, <i>duh!</i>

Just had this experience yesterday afternoon, in fact. The guy reportedly has $40,000 in his listening room alone. (12" thick walls, various sound treatments, etc. etc. etc.) He's sitting there telling me how great his system is. And, in all fairness, it's pretty good. But he's playing it too loud, and it's clipping, and he doesn't seem to notice. The same old story. I could say more, but I think I'll reserve some of the juicy parts for the 'listening' thread I keep threatening to write.

More power costs more money and creates more heat. But it makes a difference. Horn folks are in better shape here, since even small amps are shown to better advantage, but for those of us who chose (for any number of reasons) not to use horns, power is a good thing to have, even if you don't play particularly loud.

Grey

Actually I meant to comment on this bit before. Someone correct me, but my "rule-of-thumb" for transformer VA rating is at least 2x the constant current draw for the amplifier.

The Aleph 2 dissipates a little over 300W/channel, so 600VA would be acceptable and as Grey suggests 750VA would be fine.

I don't disagree with Grey's comments on power/clipping either .... simply, if you do have relatively inefficient speakers and like it LOUD, then you are better off in the X600 territory than going from 60 to 100W.

If you want an Aleph, go for 1.2 monoblocks ..... "some like it hot"

Even the great man sacrificed pure Class A to go into the higher power 'X' realms ...... didn't matter because for 99% of the amps use they are in class A mode anyways.

cheers, mark

The Aleph 2 dissipates a little over 300W/channel, so 600VA would be acceptable and as Grey suggests 750VA would be fine.

I don't disagree with Grey's comments on power/clipping either .... simply, if you do have relatively inefficient speakers and like it LOUD, then you are better off in the X600 territory than going from 60 to 100W.

If you want an Aleph, go for 1.2 monoblocks ..... "some like it hot"

Even the great man sacrificed pure Class A to go into the higher power 'X' realms ...... didn't matter because for 99% of the amps use they are in class A mode anyways.

cheers, mark

I guess I overdid it...

I just picked up 2 custom made 1000VA transformers for my pair of Aleph 2. They are pretty heavy.. 15lb each.

I was pretty sure that I recall Nelson stating 1000VA is the minimum.

--

Brian

gte619j@prism.gatech.edu

I just picked up 2 custom made 1000VA transformers for my pair of Aleph 2. They are pretty heavy.. 15lb each.

I was pretty sure that I recall Nelson stating 1000VA is the minimum.

--

Brian

gte619j@prism.gatech.edu

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- The perfect heatsink