If I could only have two meters, probably would be the Owon HDS242s scope/DMM/functiongen and the Fluke 115. If only 1 meter, the Fluke 115.

Lately, I have found the handheld scope to be indispensable for debugging and characterization.

If I needed something that’s accurate and super portable, it’s the Fluke 101. I usually take that when I travel to a job site for consulting/trouble shooting. The 101 is also very affordable. For many DIYA amp builds, sometimes two or three DMM’s are needed for initial setup.

Lately, I have found the handheld scope to be indispensable for debugging and characterization.

If I needed something that’s accurate and super portable, it’s the Fluke 101. I usually take that when I travel to a job site for consulting/trouble shooting. The 101 is also very affordable. For many DIYA amp builds, sometimes two or three DMM’s are needed for initial setup.

Last edited:

Nice looking amp! Love the meters on black case.

Fluke 115 looks like a great meter. I think my Fluke also had inductance but maybe I am wrong about that, pretty handy when matching or winding them which I have done a few times. I think I am going to search to see if they make one that does.

I just looked at the Fluke 289, $$$$, ouch!

I think I will just look for a good used LCR meter instead.

Rick

Fluke 115 looks like a great meter. I think my Fluke also had inductance but maybe I am wrong about that, pretty handy when matching or winding them which I have done a few times. I think I am going to search to see if they make one that does.

I just looked at the Fluke 289, $$$$, ouch!

I think I will just look for a good used LCR meter instead.

Rick

Last edited:

Thanks for trying it out. It’s a great subwoofer - not many at this price point with a toroidal trafo, discrete class AB amp, and 5-way banana binding posts. Plus the sound is super with a high aspect ratio slot vent - it uses surface viscous drag for low turbulence. Can you confirm that the typos on back panel are fixed?

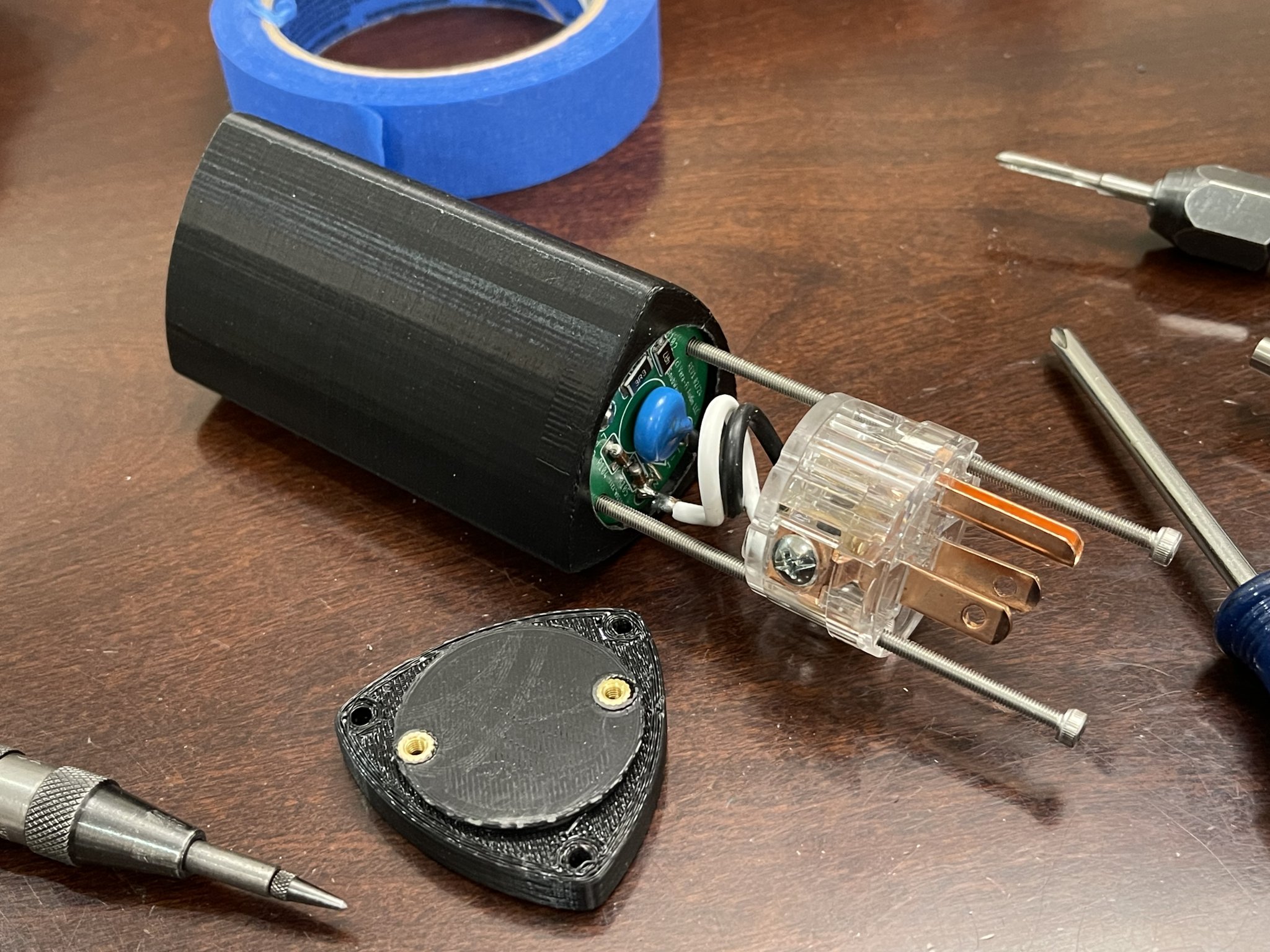

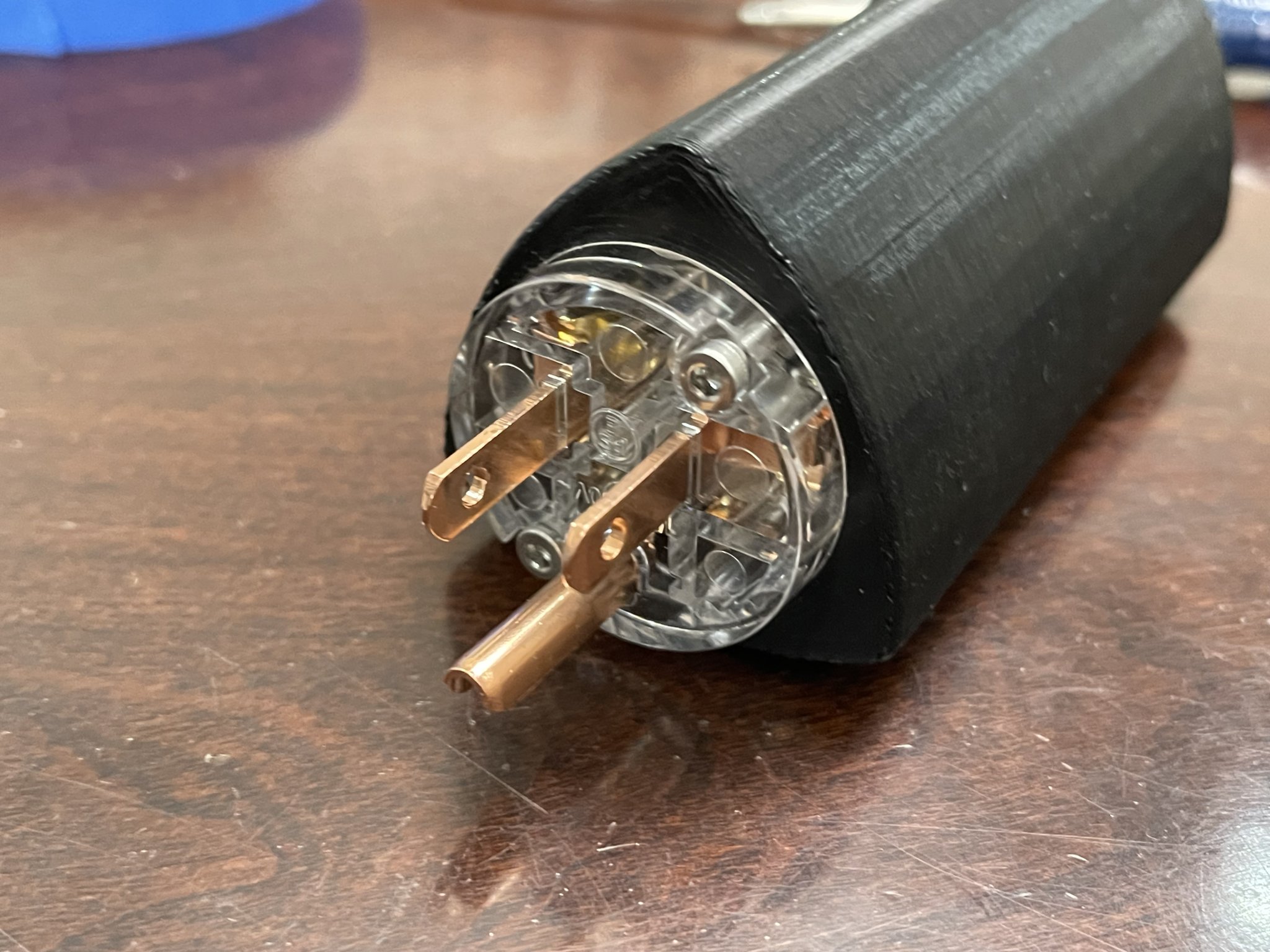

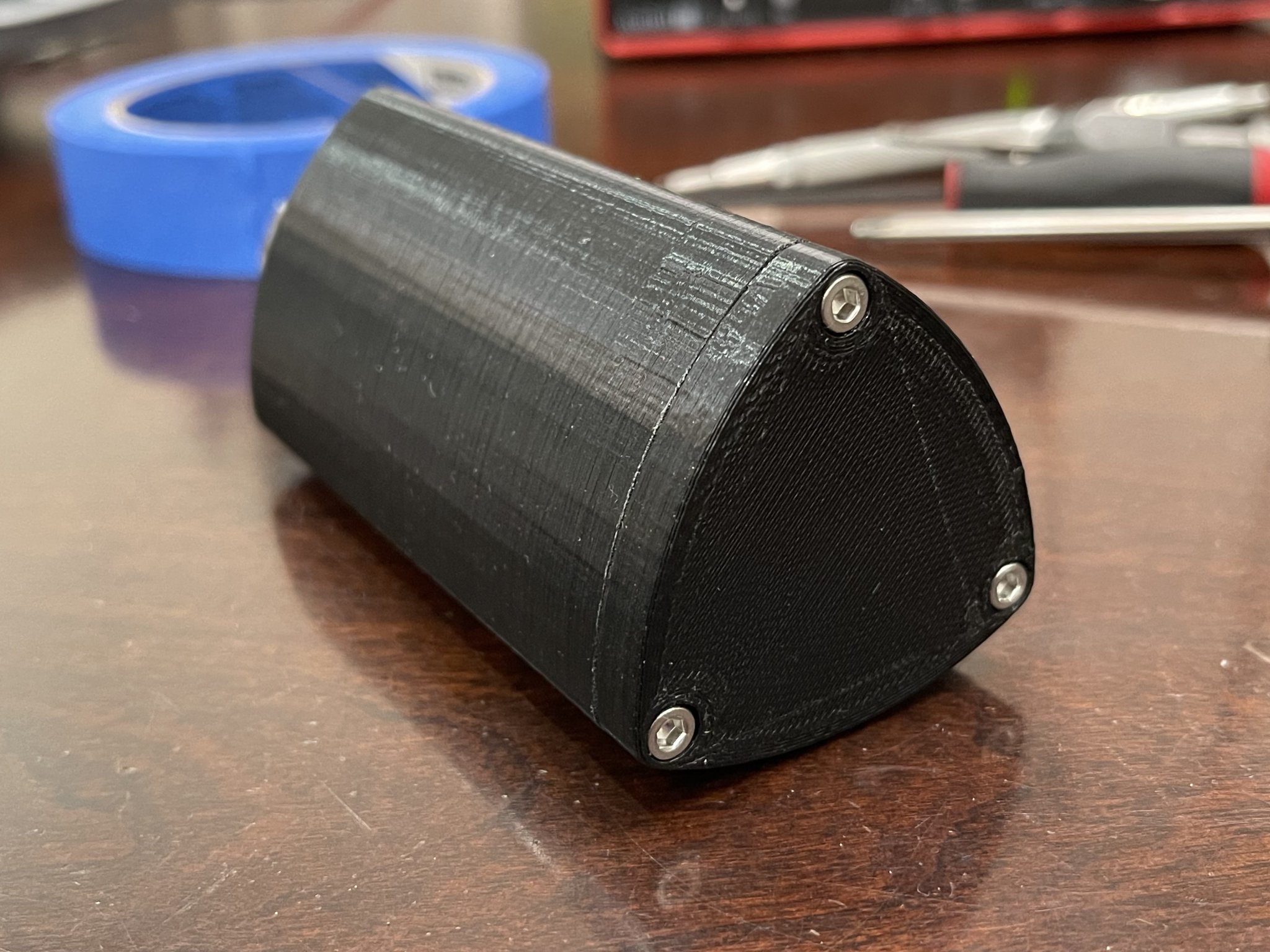

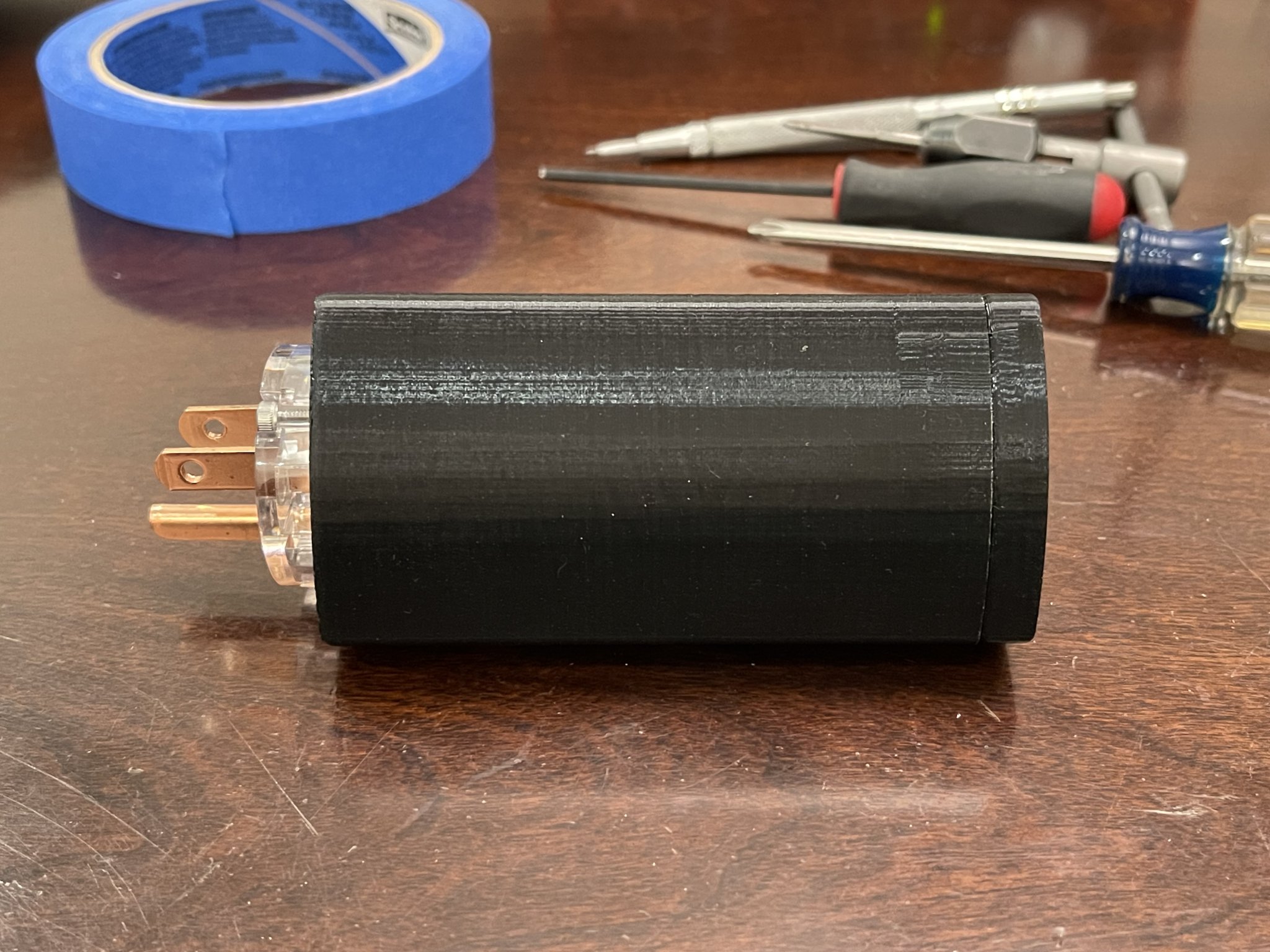

On the bench is test fitting the SnubWay to a new Viborg plug base. Super quality in clear acrylic and solid pure copper terminals. For the 3D printed prototype I am using brass M3 threaded inserts whereas on final it will be CNC aluminum with tapped holes.

The fit is perfect as the 100mm long M3 hex socket cap screw goes through all three PCB assemblies and hits the threaded inserts on the lid. In the metal production unit we will have insulating liner between the circuit board and the Wankel shell. There will be a small vampire stub connected to ground touching the shell from the base.

The fit is perfect as the 100mm long M3 hex socket cap screw goes through all three PCB assemblies and hits the threaded inserts on the lid. In the metal production unit we will have insulating liner between the circuit board and the Wankel shell. There will be a small vampire stub connected to ground touching the shell from the base.

On the bench tonight is a personal one of a kind monitor I am building as a treat to myself. I bought these Fostex NX6A woofers 3 years ago for a blowout deal ($15ea). I have a spare early prototype cabinet with cutouts already made for some other driver that we never used. The cabinets are really nice immaculate rosewood veneer. I have some Dayton AMT2-4 tweeters sitting around. I think these will go well together. I need to make an adapter ring for the tweeter on the 3D printer. I need to get some binding post cups for the precut rectangular hole in the back. Box is 10.4L internal volume. Off to SolidWorks now for the ring adapter. The woofer is not flush mounted and sits about 5mm proud. I think I am going to make the tweeter come out by equivalent amount as well with an angled slope adapter.

I’m thinking crossover will be at 3.5kHz. Reflex box tune circa 60Hz.

I’m thinking crossover will be at 3.5kHz. Reflex box tune circa 60Hz.

It’s supposed to reduce suspension distortion. The shape in the cone reduces breakup modes I think. We will see. I just dug up the old DATS data. Vas is 8.5L and Fs is 57Hz. Qts is 0.46 so this is perfect for a 10.4L box tuned to 55Hz I think. This will capture the kick drum bass nicely.

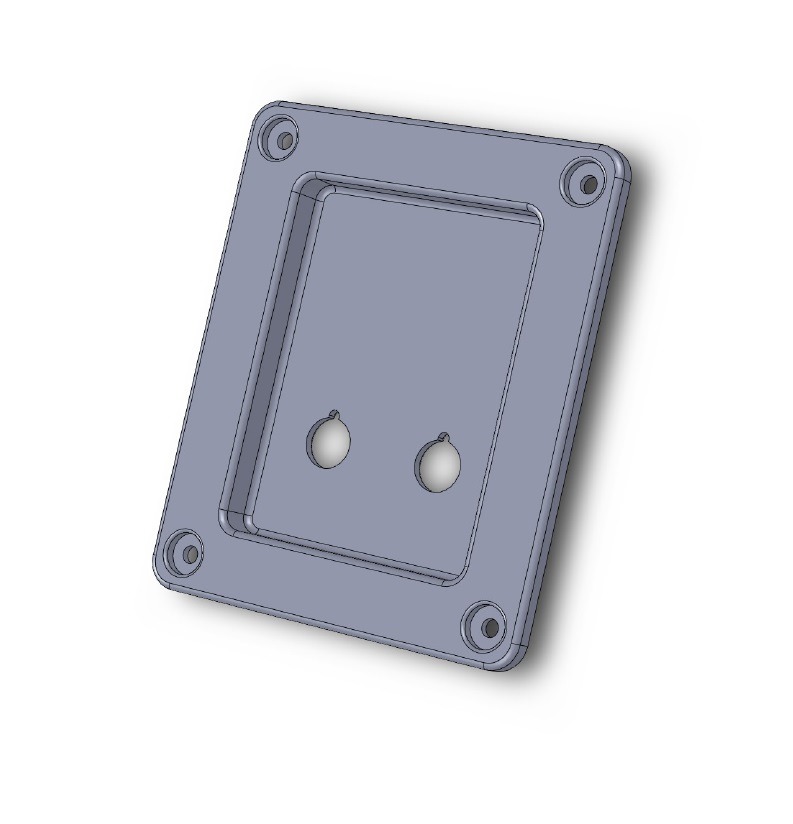

Model for binding post cup is done and now go to get print of tweeter adapter from printer and start new job for the binding post cup.

Print turned out well:

You may be wondering why I did not make the tweeter flush. The existing cutout is too large and the 4 screws miss the wood sort of. The adapter plate will attach to the baffle with glue and has to have some thickness for the tweeter screws.

Print turned out well:

You may be wondering why I did not make the tweeter flush. The existing cutout is too large and the 4 screws miss the wood sort of. The adapter plate will attach to the baffle with glue and has to have some thickness for the tweeter screws.

Last edited:

If you have it, it’s great but very expensive. There are free CAD programs and also yearly subscription of Fusion 360 is a lot less. Watch YT videos. They are great for learning. JLCPCB will do 3D prints for reasonable prices nowadays. They have laser UV SLA which makes nice smooth prints with higher resolution. They can also do metal 3D (pricey though - still less than a single job CNC).I need to learn how to use SW, such a great skill for projects like this.