Glad we can help Paul. We were all beginners at some stage. X helped me so much when I started off with diy. Please ask if you are unsure.

Ask as much as needed, measure three times, solder once.

Here are Mouser numbers for

LED blue : 630-HLMP-LB65-RU0DD

LED green : 645-521-8133F

R LED : 603-RC0805FR-0715KL

Here is a nice knob I used on my PCA from RS Components: 777-7312

Keep us posted.

Edit: LED green : 645-521-8133F is better (dome vs oval)

Ask as much as needed, measure three times, solder once.

Here are Mouser numbers for

LED blue : 630-HLMP-LB65-RU0DD

LED green : 645-521-8133F

R LED : 603-RC0805FR-0715KL

Here is a nice knob I used on my PCA from RS Components: 777-7312

Keep us posted.

Edit: LED green : 645-521-8133F is better (dome vs oval)

Last edited:

Thanks for the tips, Twocents.

Bazabing,

67 or maybe I meant 68ohms. Within 5% of nominal value is fine but they should be matched left and right to 1%.

The Bourns pot works well too.

The LED is any old 3mm dia through hole part in any color you like. White is nice actually.

Bazabing,

67 or maybe I meant 68ohms. Within 5% of nominal value is fine but they should be matched left and right to 1%.

The Bourns pot works well too.

The LED is any old 3mm dia through hole part in any color you like. White is nice actually.

Thank you both for your help. It's going to be my first attempt with surface mount so it will be interesting!

The one last question I wanted to ask (for the time being ) was regarding batteries.

) was regarding batteries.

I have seen rechargeable batteries from Amazon which seem almost too good to be true at 1300mAh, especially as they are quite cheap.

https://www.amazon.co.uk/dp/B09QHTX...1-2-dc1129fb-c8d4-4aec-832b-0226c0abeddd&th=1

Will these be ok or am I better of going for a more normal 200mAh RS branded battery?

The one last question I wanted to ask (for the time being

I have seen rechargeable batteries from Amazon which seem almost too good to be true at 1300mAh, especially as they are quite cheap.

https://www.amazon.co.uk/dp/B09QHTX...1-2-dc1129fb-c8d4-4aec-832b-0226c0abeddd&th=1

Will these be ok or am I better of going for a more normal 200mAh RS branded battery?

Those ratings can be misleading. It might be 1200mAhr for the base 3.6v S1 cell. With a DCDC boost converter to 9v that’s probably about a 3x reduction in mAhr or closer to 400mAhr which is ok.

This EBL brand is what I have used and you get about 3hrs a pair.

Note well, when using rechargeable batteries, they have a safety shutdown circuit that prevents high current in rush when first turning on. You need to click the on/off the off switch 2-3 times in quick succession to slowly charge the caps and then it will stay on. Or else the battery shuts down thinking it’s short to prevent fire.

On regular non rechargeable batteries it works fine without the clicking.

This EBL brand is what I have used and you get about 3hrs a pair.

Note well, when using rechargeable batteries, they have a safety shutdown circuit that prevents high current in rush when first turning on. You need to click the on/off the off switch 2-3 times in quick succession to slowly charge the caps and then it will stay on. Or else the battery shuts down thinking it’s short to prevent fire.

On regular non rechargeable batteries it works fine without the clicking.

FYI, I just ordered three of these: https://www.lcsc.com/product-detail...iometers_ALPSALPINE-RK0971221Z05_C336003.html

They're from China, so we'll see if they are genuine. Cheap though.

They're from China, so we'll see if they are genuine. Cheap though.

Hi Forum Members,C2_1 Output cap 3.5mm pitch, 8 dia (390uF 20v Panasonic OSCON 20SEPF390M) or Nichicon AK 470uF if you can fit it Edit: I highly recommend a 1000uF 16v OSCON here for low impedance phones.

C2_2 Output cap 5mm pitch, up to 9mm wide (Wima 1uF MKS2C041001F00KSSD) Edit: I highly recommend a second 1000uF 16v OSCON here, if you have 30ohm or lower phones, and place Wima on SMT side.

I am procuring parts to build this neat little HPA. I am not sure about the number of CAPS required for C2_1 and C2_2 despite obvious efforts to make it clear.

I will be using my HPA for low-impedance phones mostly, so will need to add the OSCON CAPS.

For C2_1 do I add the 1000uF 16v OSCON in addition to the 390 uF 20v Panasonic? Also, for C2_2 it seems clear that I need the 1000 uF 16v OSCON in addition to the the Wima 1uF. Is that right?

If I am correct that would be 2 CAPS for C2_1 and 2 CAPS for C2_2. Thanks in advance for any clarification anyone can offer me.

Respectfully,

Dave M.

Hey team,

Newbie question. I am used to testing each and every resistor, cap, and diode when working with through-hole components. Is it customary to test SMD's prior to placement? How? They seem far too small to get reliable readings. Sorry for such a basic question but I'm a perfectionist and want to get it right.

Thanks everyone. Dave M.

Newbie question. I am used to testing each and every resistor, cap, and diode when working with through-hole components. Is it customary to test SMD's prior to placement? How? They seem far too small to get reliable readings. Sorry for such a basic question but I'm a perfectionist and want to get it right.

Thanks everyone. Dave M.

You can test SMT resistors and some capacitors with the sharp probe tip of a DMM. Place part on bench and use the points of the probes to touch the exposed metallic ends like a tweezer.

The resistors usually are marked with the value. On 0805 size they are direct value and you can read them. Like 680R or 273 (27k) etc. on 0603 they are sometimes a hex code and you need to look them up. You can be sure if you test one, the rest in the tape strip are the same as they were made at the same time same batch.

Capacitors are usually not marked. The 100nF 50v X7R ones are large enough a value to measure. Little 15pF caps etc are too small to measure.

You can also use these tweezer probes to connect to your DMM if you do this all the time:

https://a.aliexpress.com/_mNKzdMS

Or this one has built in meter:

https://a.aliexpress.com/_mOJUyPG

But, I would just go by the markings on the resistors and check only if you are in doubt or need to verify tolerance for a critical part.

The resistors usually are marked with the value. On 0805 size they are direct value and you can read them. Like 680R or 273 (27k) etc. on 0603 they are sometimes a hex code and you need to look them up. You can be sure if you test one, the rest in the tape strip are the same as they were made at the same time same batch.

Capacitors are usually not marked. The 100nF 50v X7R ones are large enough a value to measure. Little 15pF caps etc are too small to measure.

You can also use these tweezer probes to connect to your DMM if you do this all the time:

https://a.aliexpress.com/_mNKzdMS

Or this one has built in meter:

https://a.aliexpress.com/_mOJUyPG

But, I would just go by the markings on the resistors and check only if you are in doubt or need to verify tolerance for a critical part.

Hi Forum members,

Thought I would liven this thread up a bit with a progress report on my Pocket Class A HPA efforts. Oh my gosh those 0805 package resistors are a challenge to place for this old guy!

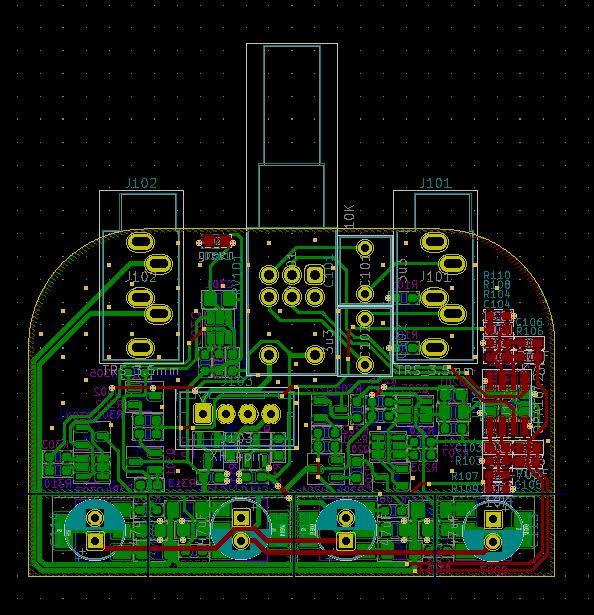

Given the number of SMT devices involved, I decided to try a new process. Up until now, I have been soldering them with an iron. I have a hot air wand but really haven't had much luck getting that technique right. This time I borrowed a technique from another member using a variac and an LED reflow hotplate. I monitored the temp with an IR thermometer as I went.

I'm pretty happy with the outcome, given it was my first attempt. C4A and C5A are pretty close to touching. I may need to use hot air to adjust their clearance. Obviously, I won't know for sure until I get to testing (and listening) but for small pcb's I think I could replicate this process. Cheers!

Dave M.

Thought I would liven this thread up a bit with a progress report on my Pocket Class A HPA efforts. Oh my gosh those 0805 package resistors are a challenge to place for this old guy!

Given the number of SMT devices involved, I decided to try a new process. Up until now, I have been soldering them with an iron. I have a hot air wand but really haven't had much luck getting that technique right. This time I borrowed a technique from another member using a variac and an LED reflow hotplate. I monitored the temp with an IR thermometer as I went.

I'm pretty happy with the outcome, given it was my first attempt. C4A and C5A are pretty close to touching. I may need to use hot air to adjust their clearance. Obviously, I won't know for sure until I get to testing (and listening) but for small pcb's I think I could replicate this process. Cheers!

Dave M.

Attachments

Looks great! Very good idea to use the little LED reflow heat pad. I have seen similar things for disassembling iphone screens etc.

Your parts look neat and well placed. The solder looks a bit thick still - usually you want a concave fillet - the you know it has fully wetted. Not high enough heat or it long enough duration maybe the cause.

Best is to use the thermal pad on bottom and touch up the top side with the hot air pencil. Heat from above and bottom will make it look really clean.

I have been eyeing this one for occasional use:

https://a.aliexpress.com/_mtgfIRU

For lab use maybe a bigger full-featured one like this is better:

https://a.aliexpress.com/_mL1B0om

Your parts look neat and well placed. The solder looks a bit thick still - usually you want a concave fillet - the you know it has fully wetted. Not high enough heat or it long enough duration maybe the cause.

Best is to use the thermal pad on bottom and touch up the top side with the hot air pencil. Heat from above and bottom will make it look really clean.

I have been eyeing this one for occasional use:

https://a.aliexpress.com/_mtgfIRU

For lab use maybe a bigger full-featured one like this is better:

https://a.aliexpress.com/_mL1B0om

Thanks for the feedback X. I may break out my heat pencil and try reflowing it again. That would also give me a chance to adjust the two capacitors that got close to each other.

I was a bit concerned about overheating the parts, especially the actives. Maybe I was playing it a little too safe. Practice makes perfect I guess.

I was a bit concerned about overheating the parts, especially the actives. Maybe I was playing it a little too safe. Practice makes perfect I guess.

When reflowing, you only need to apply a little less than melt temp like 150C to 170C on the bottom. The parts can sit there indefinitely without damage. Then use the hot air pencil to locally melt parts of interest and it only applies high heat above melt temp for short time until you move on. Generally, I use 350C hot air to melt the tops but I move on after about 10 seconds to allow parts to fully wet. The parts probably never get hotter than 225C for low temp solder. Practice on a junk board with some resistors to get the hang of things. The parts are quite rugged and I have yet to destroy one from excessive heat.

A new idea for a Class AB Pocket Diamond Buffer (PDB) headphone amp is in the works. OPA1642 voltage gain stage and 9 actives per channel discrete emitter follower output stage. More info here:

https://www.diyaudio.com/community/...buffer-pdb-headphone-amp.401404/#post-7404743

Diamond buffer is discussed here:

https://www.diyaudio.com/community/threads/jhoflands-diamond-buffer.401231/#post-7403622

All in the same Altoids tin package with two 9v batteries for +/-9v rails.

https://www.diyaudio.com/community/...buffer-pdb-headphone-amp.401404/#post-7404743

Diamond buffer is discussed here:

https://www.diyaudio.com/community/threads/jhoflands-diamond-buffer.401231/#post-7403622

All in the same Altoids tin package with two 9v batteries for +/-9v rails.

I was about to start my build and then, once I went through all my parts labelling them, realised I didn't have the Wima caps.

The 2.2uF Wima's are readily available but the 1uF are out of stock at all the usual UK suppliers. Would a Vishay cap (BFC237011105) be ok as a replacement?

The 2.2uF Wima's are readily available but the 1uF are out of stock at all the usual UK suppliers. Would a Vishay cap (BFC237011105) be ok as a replacement?

I also noticed that post 2,189 showed one side of the low impedance version (which is what I am about to attempt).

Would it be possible to post a picture of the other side of the board?

I am still very new to this, so it's always useful to have a quick visual reference to make sure I am on the right track.

Thanks

paul

Would it be possible to post a picture of the other side of the board?

I am still very new to this, so it's always useful to have a quick visual reference to make sure I am on the right track.

Thanks

paul

- Home

- Group Buys

- xrk971 Pocket Class A Headamp GB