The CL08FR project uses only one parameter: the speed of sound in air 341 m/sec. Universal because it is suitable for all types of 8 cm (3") full-range drivers.

The driver is mounted in a compression chamber with an internal volume of about one liter, positioned one meter above the floor.

The frontal emission is direct.

The mddTL rear acoustic load is different from other multiple resonance systems because the emissions are also multiple. The emissions are also coherent, delayed and at progressive heights. They recreate a virtual 3D sound image, it is not the same image as the original event but I prefer it to a point source.

The succession of delays at the listening point, from 4.5 to 9 milliseconds, optimizes the interaction with the room for the anti-Haas effect. The multiple and delayed emissions together with the reflections of the walls prevent a single sound from being interpreted as two distinct sounds, decreasing listening fatigue.

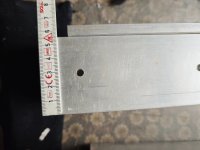

The mddTL rear acoustic load has eight constant-section waveguides, the total internal surface is similar to the surface of the driver cone, a very good 3FE25 from Faital-Pro. The length series is: 1570, 1712, 1867, 2036, 2221, 2422, 2641, 2880 mm.

With the simplified formula for calculating resonances in transmission lines for waveguides open on one side and closed on the driver side we obtain:

(341/L/4) 54.3 49.8 45.7 41.9 38.4 35.2 32.3 29.6 Hz

The volume of air inside the compression chamber also activates the resonances for waveguides open on both sides:

(341/L/2) 108.6 99.6 91.3 83.7 76.8 70.4 64.6 59.2 Hz

(341/L/2*2) 217.2 199.1 182.6 167.4 153.5 140.8 129.1 118.4 Hz

(341/L/2*3) 325.7 298.7 273.9 251.2 230.3 211.2 193.7 177.6 Hz.

The resonances are distributed evenly over the first octaves so the mddTL acoustic load is neutral with respect to the characteristics of the driver and the listening environment.

In the impedance graph, the first resonance c/L/4 is noted at about 30 Hz, it was expected at 29 Hz. Between 60 Hz and 300 Hz, the c/L/2 resonances are visible. In particular, the resonances between 100 and 200 Hz are highlighted.

The peaks can be easily eliminated by inserting a foam cube at the end of each waveguide, the graph becomes regular. At listening level, I did not detect any differences.

When measuring the frequency response with the microphone positioned near the output of the longest waveguide, the peaks of the response to the c/L/2 resonances can be seen: 60, 120, 180, 240, 300, 360, 420, 480, 540 and 600 Hz.

By placing the frequency responses of all the waveguides side by side, a complex graph is obtained in which the series of resonances distributed uniformly in the lowest octaves can be identified.

The REW program can calculate the average of the eight responses that compensate each other, the average is regular between 100 Hz and 1 KHz.

The frequency response measured at the listening point is good above 100 Hz, below this frequency the room resonance modes are highlighted.

The step response is good with a problem related to an oscillation at about 11 KHz typical of the 3FE25 driver, it does not create any problems if the speakers are oriented parallel and not towards the listener.

Thanks for your attention.

link

https://www.claudiogandolfi.it

https://www.claudiogandolfi.it/cl08fr.html