Coverage of assemblage of Lottery amp for my dear Friend, way of paying back for valuable help he gave in some of my endeavors

He's extraordinary busy in last several months, so ......

Amp No. 122, member tunasto here, Vinko at Baby DiyA

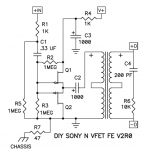

Let's start with schematics - I like when schematics are present

He's extraordinary busy in last several months, so ......

Amp No. 122, member tunasto here, Vinko at Baby DiyA

Let's start with schematics - I like when schematics are present

Attachments

Last edited:

While at schematics, let's cover few things ( I already posted in origin thread about this amp), so let's repeat:

well, I'm always amused studying Papa's schematics, from any imaginable reason .... mistakes being one of them

original, drawing mistake marked, mistake fixed, simple remedy for better AntiBigBadaBoom at speaker out; there is no mistake at Papa's pcb, it is just on drawing

now - last schm - in this moment already tried and proven, results are:

edited delay circ is working flawlessly - no visible move of cone neither at power On nor power Off

only if you are powering it Off reluctantly, slowly operating the switch , there is movement of cone, but slow and gentle - and even that one is not audible

same behavior when leaving power switch ON, and doing power operation with mains cable of switcher - Nada during power On, gentle roll of cone with powering Off

will post plenty of pics and some text, in separate thread

maybe next evening

and yes, really dunno how delay circ operated in original, didn't tried it at all; but I'm used to change Papathings just for sport - hard to make it better, easy to make it in different way

well, I'm always amused studying Papa's schematics, from any imaginable reason .... mistakes being one of them

original, drawing mistake marked, mistake fixed, simple remedy for better AntiBigBadaBoom at speaker out; there is no mistake at Papa's pcb, it is just on drawing

now - last schm - in this moment already tried and proven, results are:

edited delay circ is working flawlessly - no visible move of cone neither at power On nor power Off

only if you are powering it Off reluctantly, slowly operating the switch , there is movement of cone, but slow and gentle - and even that one is not audible

same behavior when leaving power switch ON, and doing power operation with mains cable of switcher - Nada during power On, gentle roll of cone with powering Off

will post plenty of pics and some text, in separate thread

maybe next evening

and yes, really dunno how delay circ operated in original, didn't tried it at all; but I'm used to change Papathings just for sport - hard to make it better, easy to make it in different way

Attachments

OK; thermal issues

some facts:

some facts:

- T bars came in Papa's arrangement, with approx 4mm Dia holes

- TO3 isolator pads are silicone thingies, I don't like those above 15W or so per device; gone for Mica + quality goop

- T bar is having bowed side which is going to meet heatsink; see sketch; some lapping - water-sand paper on thick glass is problem solver

- heatsink is bowed as all extruded heatsink of this profile are bowed; see sketch; no problem when you arrange adequate force with screws - not the case in this case; will rectify that

Attachments

solving thermal issues; see pics, pretty much self-explanatory

whoever did arrange with Modushop guys assembly with M3 screws is not having enough mileage with all things mechanical/thermal; not blaming a guy at all, I know that this wasn't operation made by professionals and outcome is still extraordinary

that's exact reason why I'm posting this, to help Greedy Boyz in proper finishing and to feed my own OCD

fact is -these 4pcs of M3 screws needed to be M4 and additional 2pcs of M4 are necessary

only that way , with lapped T Bar, there is enough squeezing force at disposal to get rid of air gap between T Bar and heatsink

whoever did arrange with Modushop guys assembly with M3 screws is not having enough mileage with all things mechanical/thermal; not blaming a guy at all, I know that this wasn't operation made by professionals and outcome is still extraordinary

that's exact reason why I'm posting this, to help Greedy Boyz in proper finishing and to feed my own OCD

fact is -these 4pcs of M3 screws needed to be M4 and additional 2pcs of M4 are necessary

only that way , with lapped T Bar, there is enough squeezing force at disposal to get rid of air gap between T Bar and heatsink

Attachments

-

2.jpg59.3 KB · Views: 308

2.jpg59.3 KB · Views: 308 -

3.jpg70.5 KB · Views: 307

3.jpg70.5 KB · Views: 307 -

4.jpg59.6 KB · Views: 302

4.jpg59.6 KB · Views: 302 -

5.jpg66 KB · Views: 304

5.jpg66 KB · Views: 304 -

6.jpg67.4 KB · Views: 303

6.jpg67.4 KB · Views: 303 -

6a.jpg74.6 KB · Views: 291

6a.jpg74.6 KB · Views: 291 -

7.jpg35.1 KB · Views: 301

7.jpg35.1 KB · Views: 301 -

8.jpg51.1 KB · Views: 295

8.jpg51.1 KB · Views: 295 -

9.jpg99.5 KB · Views: 295

9.jpg99.5 KB · Views: 295 -

10.jpg27.1 KB · Views: 292

10.jpg27.1 KB · Views: 292 -

11.jpg27.2 KB · Views: 287

11.jpg27.2 KB · Views: 287 -

12.jpg34.7 KB · Views: 281

12.jpg34.7 KB · Views: 281 -

13.jpg59.8 KB · Views: 283

13.jpg59.8 KB · Views: 283 -

15.jpg54.5 KB · Views: 280

15.jpg54.5 KB · Views: 280 -

14.jpg104.6 KB · Views: 304

14.jpg104.6 KB · Views: 304

Still in mechanical realm, sort of

Again post-Pa dealing gone wrong - Pa did arrange 2 pole switch, while hole on back side is for one pole, one pole in kit;

Again no blame from my side ; I did enough mistakes that I know from where they are invoked, rest of life is not enough to learn how to prevent them

I had a bag of proper 2 pole switches

paper masking tape, calipers, files, patience

Again post-Pa dealing gone wrong - Pa did arrange 2 pole switch, while hole on back side is for one pole, one pole in kit;

Again no blame from my side ; I did enough mistakes that I know from where they are invoked, rest of life is not enough to learn how to prevent them

I had a bag of proper 2 pole switches

paper masking tape, calipers, files, patience

Attachments

Still on back side of amp

Mean Well switcher PSU is of good quality, but I don't like flimsiness of DC connector, neither male nor female one

Good ole 5-pin XLR is certainly better; I would like Calt Stecker being on cable, Heiss Stecker being on amp, but didn't had Heiss one ....... anyway , I did stay with original topology - Heiss Stecker on cable

superblingy drill and edge reamer, no need to be overly precise, XLR is covering all

I didn't even hop to my vertical drill, done it with hand-accu one

useful tip for soldering pin-equipped connectors - always mary male one with female one - no bending of pins in plastic, due to heat

Mean Well switcher PSU is of good quality, but I don't like flimsiness of DC connector, neither male nor female one

Good ole 5-pin XLR is certainly better; I would like Calt Stecker being on cable, Heiss Stecker being on amp, but didn't had Heiss one ....... anyway , I did stay with original topology - Heiss Stecker on cable

superblingy drill and edge reamer, no need to be overly precise, XLR is covering all

I didn't even hop to my vertical drill, done it with hand-accu one

useful tip for soldering pin-equipped connectors - always mary male one with female one - no bending of pins in plastic, due to heat

Attachments

Delay circ tweaking

Again, self explanatory

Again, self explanatory

Attachments

-

1.jpg58.3 KB · Views: 287

1.jpg58.3 KB · Views: 287 -

1a.jpg75.5 KB · Views: 276

1a.jpg75.5 KB · Views: 276 -

2.jpg201.6 KB · Views: 263

2.jpg201.6 KB · Views: 263 -

3.jpg140.7 KB · Views: 249

3.jpg140.7 KB · Views: 249 -

4.jpg157.9 KB · Views: 254

4.jpg157.9 KB · Views: 254 -

5.jpg62.5 KB · Views: 251

5.jpg62.5 KB · Views: 251 -

6.jpg123.3 KB · Views: 249

6.jpg123.3 KB · Views: 249 -

7.jpg66.5 KB · Views: 254

7.jpg66.5 KB · Views: 254 -

8.jpg115.8 KB · Views: 260

8.jpg115.8 KB · Views: 260 -

9.jpg189.5 KB · Views: 267

9.jpg189.5 KB · Views: 267 -

9a.jpg190.1 KB · Views: 258

9a.jpg190.1 KB · Views: 258 -

10.jpg156.3 KB · Views: 275

10.jpg156.3 KB · Views: 275 -

11.jpg136.5 KB · Views: 279

11.jpg136.5 KB · Views: 279

Rest of pics

Observe - there are some trick which can make your life easier:

-Cone head temporary screws ( aligning, no scratches round holes)

-align brackets with back side of heatsinks, no warping of back plate in that case

dunno - I did forgot something for sure , but you'll ask; it's not Rocket Science anyway

there are probably few redundant pics, but - hey - web space is cheap nowadays

Observe - there are some trick which can make your life easier:

-Cone head temporary screws ( aligning, no scratches round holes)

-align brackets with back side of heatsinks, no warping of back plate in that case

- headless screws for front plate; how to unscrew and orient bottom to mount washers and nuts and tighten them

- wiring done with one heatsink, bottom and back plate screwed together; then mounting second heatsink, soldering wires, then mounting front

- one or two pads are close to screw nuts; marked on pics; either use plastic washers or metric screws/nuts ( smaller than enclosed ones) or be brave as MZM - I did bend integral star washers, was stubborn to use Papahardware

dunno - I did forgot something for sure , but you'll ask; it's not Rocket Science anyway

there are probably few redundant pics, but - hey - web space is cheap nowadays

Attachments

-

IMG_20220428_165828.jpg82.8 KB · Views: 346

IMG_20220428_165828.jpg82.8 KB · Views: 346 -

IMG_20220428_165908.jpg82.1 KB · Views: 344

IMG_20220428_165908.jpg82.1 KB · Views: 344 -

IMG_20220428_165912.jpg69.4 KB · Views: 318

IMG_20220428_165912.jpg69.4 KB · Views: 318 -

IMG_20220428_170853.jpg61.8 KB · Views: 313

IMG_20220428_170853.jpg61.8 KB · Views: 313 -

IMG_20220428_170901.jpg85.3 KB · Views: 1,153

IMG_20220428_170901.jpg85.3 KB · Views: 1,153 -

IMG_20220428_202849.jpg93.9 KB · Views: 287

IMG_20220428_202849.jpg93.9 KB · Views: 287 -

IMG_20220428_202903.jpg70.4 KB · Views: 289

IMG_20220428_202903.jpg70.4 KB · Views: 289 -

IMG_20220429_215659.jpg43.6 KB · Views: 284

IMG_20220429_215659.jpg43.6 KB · Views: 284 -

IMG_20220429_215709.jpg44.1 KB · Views: 282

IMG_20220429_215709.jpg44.1 KB · Views: 282 -

IMG_20220429_220949.jpg43 KB · Views: 289

IMG_20220429_220949.jpg43 KB · Views: 289 -

IMG_20220429_220956.jpg53.4 KB · Views: 294

IMG_20220429_220956.jpg53.4 KB · Views: 294 -

IMG_20220429_221157.jpg118.3 KB · Views: 308

IMG_20220429_221157.jpg118.3 KB · Views: 308 -

IMG_20220430_180547.jpg78.4 KB · Views: 314

IMG_20220430_180547.jpg78.4 KB · Views: 314 -

IMG_20220504_193529.jpg57.3 KB · Views: 279

IMG_20220504_193529.jpg57.3 KB · Views: 279 -

IMG_20220504_193534.jpg52.4 KB · Views: 347

IMG_20220504_193534.jpg52.4 KB · Views: 347

.........

Attachments

-

IMG_20220504_193539.jpg52.8 KB · Views: 247

IMG_20220504_193539.jpg52.8 KB · Views: 247 -

IMG_20220504_193546.jpg58.8 KB · Views: 233

IMG_20220504_193546.jpg58.8 KB · Views: 233 -

IMG_20220504_193552.jpg93 KB · Views: 242

IMG_20220504_193552.jpg93 KB · Views: 242 -

IMG_20220504_201731.jpg55.1 KB · Views: 246

IMG_20220504_201731.jpg55.1 KB · Views: 246 -

IMG_20220504_202703.jpg80.7 KB · Views: 256

IMG_20220504_202703.jpg80.7 KB · Views: 256 -

IMG_20220504_214131.jpg116.5 KB · Views: 275

IMG_20220504_214131.jpg116.5 KB · Views: 275 -

IMG_20220505_135930.jpg109.1 KB · Views: 283

IMG_20220505_135930.jpg109.1 KB · Views: 283 -

IMG_20220505_135939.jpg92.2 KB · Views: 272

IMG_20220505_135939.jpg92.2 KB · Views: 272 -

IMG_20220505_135942.jpg142.6 KB · Views: 257

IMG_20220505_135942.jpg142.6 KB · Views: 257 -

IMG_20220505_135948.jpg107.8 KB · Views: 267

IMG_20220505_135948.jpg107.8 KB · Views: 267 -

IMG_20220505_135958.jpg92.7 KB · Views: 267

IMG_20220505_135958.jpg92.7 KB · Views: 267 -

IMG_20220505_140003.jpg73.4 KB · Views: 252

IMG_20220505_140003.jpg73.4 KB · Views: 252 -

IMG_20220505_140007.jpg92.7 KB · Views: 243

IMG_20220505_140007.jpg92.7 KB · Views: 243 -

IMG_20220505_140014.jpg81.4 KB · Views: 233

IMG_20220505_140014.jpg81.4 KB · Views: 233 -

IMG_20220505_140031.jpg60.2 KB · Views: 249

IMG_20220505_140031.jpg60.2 KB · Views: 249

...........

Attachments

-

IMG_20220505_140036.jpg54.9 KB · Views: 249

IMG_20220505_140036.jpg54.9 KB · Views: 249 -

IMG_20220505_140041.jpg85.7 KB · Views: 237

IMG_20220505_140041.jpg85.7 KB · Views: 237 -

IMG_20220505_140047.jpg82.9 KB · Views: 233

IMG_20220505_140047.jpg82.9 KB · Views: 233 -

IMG_20220505_140544.jpg85.8 KB · Views: 220

IMG_20220505_140544.jpg85.8 KB · Views: 220 -

IMG_20220505_140547.jpg56.5 KB · Views: 214

IMG_20220505_140547.jpg56.5 KB · Views: 214 -

IMG_20220505_140552.jpg38.6 KB · Views: 236

IMG_20220505_140552.jpg38.6 KB · Views: 236 -

IMG_20220505_153254.jpg117.9 KB · Views: 255

IMG_20220505_153254.jpg117.9 KB · Views: 255 -

IMG_20220505_153259.jpg115 KB · Views: 261

IMG_20220505_153259.jpg115 KB · Views: 261 -

IMG_20220505_153308.jpg65.6 KB · Views: 246

IMG_20220505_153308.jpg65.6 KB · Views: 246 -

IMG_20220505_153311.jpg71.9 KB · Views: 236

IMG_20220505_153311.jpg71.9 KB · Views: 236 -

IMG_20220506_112259.jpg41.9 KB · Views: 224

IMG_20220506_112259.jpg41.9 KB · Views: 224 -

IMG_20220506_112303.jpg62.2 KB · Views: 226

IMG_20220506_112303.jpg62.2 KB · Views: 226 -

IMG_20220506_112859.jpg58.4 KB · Views: 243

IMG_20220506_112859.jpg58.4 KB · Views: 243 -

IMG_20220506_112911.jpg48.7 KB · Views: 239

IMG_20220506_112911.jpg48.7 KB · Views: 239 -

IMG_20220506_112903.jpg62.5 KB · Views: 258

IMG_20220506_112903.jpg62.5 KB · Views: 258

.........

Attachments

-

IMG_20220506_114519.jpg120.8 KB · Views: 309

IMG_20220506_114519.jpg120.8 KB · Views: 309 -

IMG_20220506_114742.jpg101.2 KB · Views: 264

IMG_20220506_114742.jpg101.2 KB · Views: 264 -

IMG_20220506_114756.jpg44.8 KB · Views: 238

IMG_20220506_114756.jpg44.8 KB · Views: 238 -

IMG_20220506_120359.jpg110.3 KB · Views: 232

IMG_20220506_120359.jpg110.3 KB · Views: 232 -

IMG_20220506_120421.jpg46.9 KB · Views: 249

IMG_20220506_120421.jpg46.9 KB · Views: 249 -

IMG_20220506_121146.jpg99.3 KB · Views: 271

IMG_20220506_121146.jpg99.3 KB · Views: 271 -

IMG_20220506_121201.jpg110.4 KB · Views: 269

IMG_20220506_121201.jpg110.4 KB · Views: 269 -

IMG_20220506_121836.jpg100.8 KB · Views: 246

IMG_20220506_121836.jpg100.8 KB · Views: 246 -

IMG_20220506_121840.jpg105.7 KB · Views: 250

IMG_20220506_121840.jpg105.7 KB · Views: 250 -

IMG_20220506_121947.jpg121.1 KB · Views: 252

IMG_20220506_121947.jpg121.1 KB · Views: 252 -

IMG_20220506_130345.jpg62.5 KB · Views: 252

IMG_20220506_130345.jpg62.5 KB · Views: 252 -

IMG_20220506_130351.jpg37 KB · Views: 256

IMG_20220506_130351.jpg37 KB · Views: 256 -

IMG_20220506_130404.jpg83.5 KB · Views: 243

IMG_20220506_130404.jpg83.5 KB · Views: 243 -

IMG_20220506_130408.jpg52.3 KB · Views: 267

IMG_20220506_130408.jpg52.3 KB · Views: 267 -

IMG_20220506_130502.jpg131.8 KB · Views: 298

IMG_20220506_130502.jpg131.8 KB · Views: 298

Facts

-PSU 36Vdc

-Iq one channel 1A76, second channel 1A8; was thinking to alter that to 1A6 by the Book, but who cares - more the merrier

-Output node set by the Book - to 14Vdc

-Ambient Temp 20degC

-VFet Case 66degC

-Mos Case 59degC

-T Bar Temp at exact mid between two TO3 50degC

-Heatsink Temp at outer side, between fins, exactly between M4 Allen head screws 44degC

-1R5 at channel pcbs 99degC (Papa is FAB, no clearance)

-3R3 at PSU pcb (ZM is Chicken, 2mm clearance) 88degC

-JFets 44degC

-Switcher case , placed on edge at bench 37degC

-no noise, no hum

-It sings; forgot to take a picture

-PSU 36Vdc

-Iq one channel 1A76, second channel 1A8; was thinking to alter that to 1A6 by the Book, but who cares - more the merrier

-Output node set by the Book - to 14Vdc

-Ambient Temp 20degC

-VFet Case 66degC

-Mos Case 59degC

-T Bar Temp at exact mid between two TO3 50degC

-Heatsink Temp at outer side, between fins, exactly between M4 Allen head screws 44degC

-1R5 at channel pcbs 99degC (Papa is FAB, no clearance)

-3R3 at PSU pcb (ZM is Chicken, 2mm clearance) 88degC

-JFets 44degC

-Switcher case , placed on edge at bench 37degC

-no noise, no hum

-It sings; forgot to take a picture

few more details I forgot:

- ZM is Chicken - 20K multiturn trimpot instead of enclosed 25K FABPa model

-washer + split washer everywhere

-heatshrinking wire ends leads to nicer look; it also increase your Zen

-toss enclosed crimping connectors in trash bin; solder everything; it also increase your Zen

-soldering of sensitive plastic parts - crank station to max, do it fast and efficient - funny but lesser melting of plastic that way

-enclosed nice dome head screws - while M3, having 'Merican Allen key head - who invented that shizo thing - ZM Is not having 'Merican Allen wrenches in appropriate quality, so I can't tighten them properly ..... anyway - stainless steel headless screws and nuts are much better for T Bar tightening ..... even if inadequate

-drilling of 4.2mm holes for additional M4 Allen key screws- sorta mid of T Bar length, use calipers to b precise enough to situate them exactly in between the heatsink fins; drill heatsink first, then mark through these holes points on T Bars

-dissipation of mosfet is 1A8*(14V-(1A8*0R75))=22W77

-dissipation of VFet is (36V-(1R1*1A8)-14V)*1A8=36W04

-summ dissipation per channel , including PSU, is 1A8 x36V=64W8

go figure - 128W of heat for 2x10Wrms

aaaaaaalmost SIT-2 Territory

- ZM is Chicken - 20K multiturn trimpot instead of enclosed 25K FABPa model

-washer + split washer everywhere

-heatshrinking wire ends leads to nicer look; it also increase your Zen

-toss enclosed crimping connectors in trash bin; solder everything; it also increase your Zen

-soldering of sensitive plastic parts - crank station to max, do it fast and efficient - funny but lesser melting of plastic that way

-enclosed nice dome head screws - while M3, having 'Merican Allen key head - who invented that shizo thing - ZM Is not having 'Merican Allen wrenches in appropriate quality, so I can't tighten them properly ..... anyway - stainless steel headless screws and nuts are much better for T Bar tightening ..... even if inadequate

-drilling of 4.2mm holes for additional M4 Allen key screws- sorta mid of T Bar length, use calipers to b precise enough to situate them exactly in between the heatsink fins; drill heatsink first, then mark through these holes points on T Bars

-dissipation of mosfet is 1A8*(14V-(1A8*0R75))=22W77

-dissipation of VFet is (36V-(1R1*1A8)-14V)*1A8=36W04

-summ dissipation per channel , including PSU, is 1A8 x36V=64W8

go figure - 128W of heat for 2x10Wrms

aaaaaaalmost SIT-2 Territory

Last edited:

Those are some excellent mechanical upgrades to the chassis. I may have to disassemble mine to do something similar..

- Home

- Amplifiers

- Pass Labs

- Lottery DIY Sony VFET pt 2 (N-Channel) - assembly by Mighty ZM