One of my latest rework on a pair of Lowther DX4. The cone, voice coil, damper(Spider) are all custom made by me.

Voice coil wire: Copper Clad Aluminum (0.13mm x 27 turns)

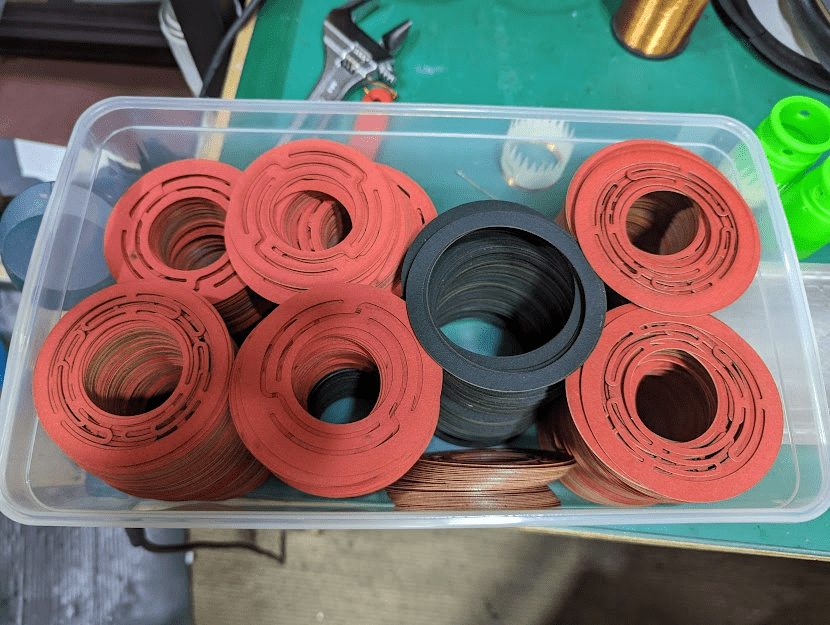

Damper: 0.5mm thick Insulation Paper

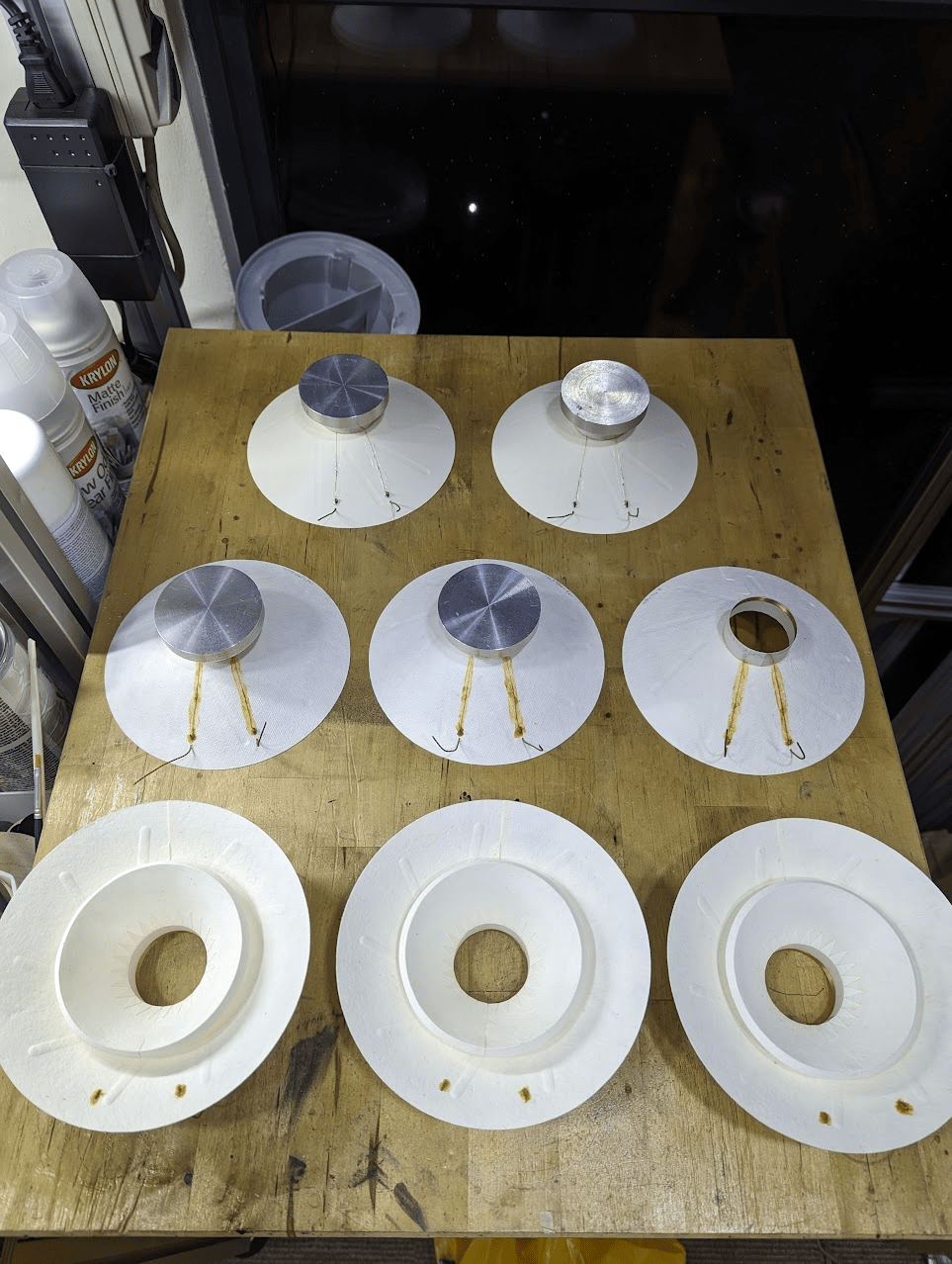

Main Cone: 160gsm Mulberry paper from Thailand

Whizzer Cone: 125gsm Mulberry paper from Thailand

Voice coil wire: Copper Clad Aluminum (0.13mm x 27 turns)

Damper: 0.5mm thick Insulation Paper

Main Cone: 160gsm Mulberry paper from Thailand

Whizzer Cone: 125gsm Mulberry paper from Thailand

- f(s)= 35.02 Hz

- R(e)= 7.446 Ohms

- Z(max)= 129.8 Ohms

- Q(ms)= 8.616

- Q(es)= 0.5242

- Q(ts)= 0.4942

- V(as)= 83.33 liters (2.943 cubic feet)

- L(e)= 0.3574 mH

- n(0)= 0.6512 %

- SPL= 90.24 1W/1m

- M(ms)= 14.07 grams

- C(ms)= 1.468 mm/N

- BL= 6.631

- K(r)= 4.875

- X(r)= 0.04851

- K(i)= 0.01231

- X(i)= 0.4455

Attachments

-

PXL_20221013_155126044.jpg245.5 KB · Views: 407

PXL_20221013_155126044.jpg245.5 KB · Views: 407 -

PXL_20221013_155135352.jpg360.2 KB · Views: 346

PXL_20221013_155135352.jpg360.2 KB · Views: 346 -

PXL_20221013_155150721.jpg266.4 KB · Views: 397

PXL_20221013_155150721.jpg266.4 KB · Views: 397 -

PXL_20221028_131703151.jpg346.5 KB · Views: 358

PXL_20221028_131703151.jpg346.5 KB · Views: 358 -

PXL_20221102_124334386.jpg451.8 KB · Views: 376

PXL_20221102_124334386.jpg451.8 KB · Views: 376 -

PXL_20221103_153404744.jpg370.1 KB · Views: 381

PXL_20221103_153404744.jpg370.1 KB · Views: 381 -

PXL_20220708_133827555.jpg401.4 KB · Views: 372

PXL_20220708_133827555.jpg401.4 KB · Views: 372

Last edited:

The basket(Frame) was sand down and resprayed.

Attachments

-

PXL_20221113_154928509.jpg473.8 KB · Views: 272

PXL_20221113_154928509.jpg473.8 KB · Views: 272 -

PXL_20221113_154916567.jpg487.8 KB · Views: 279

PXL_20221113_154916567.jpg487.8 KB · Views: 279 -

PXL_20221008_161214961.jpg374.8 KB · Views: 294

PXL_20221008_161214961.jpg374.8 KB · Views: 294 -

PXL_20221012_143119871.jpg417.3 KB · Views: 273

PXL_20221012_143119871.jpg417.3 KB · Views: 273 -

PXL_20221109_135751695.jpg488.3 KB · Views: 270

PXL_20221109_135751695.jpg488.3 KB · Views: 270 -

PXL_20221014_041704776.jpg445 KB · Views: 268

PXL_20221014_041704776.jpg445 KB · Views: 268 -

PXL_20221014_041648529.jpg379.7 KB · Views: 242

PXL_20221014_041648529.jpg379.7 KB · Views: 242

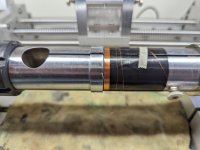

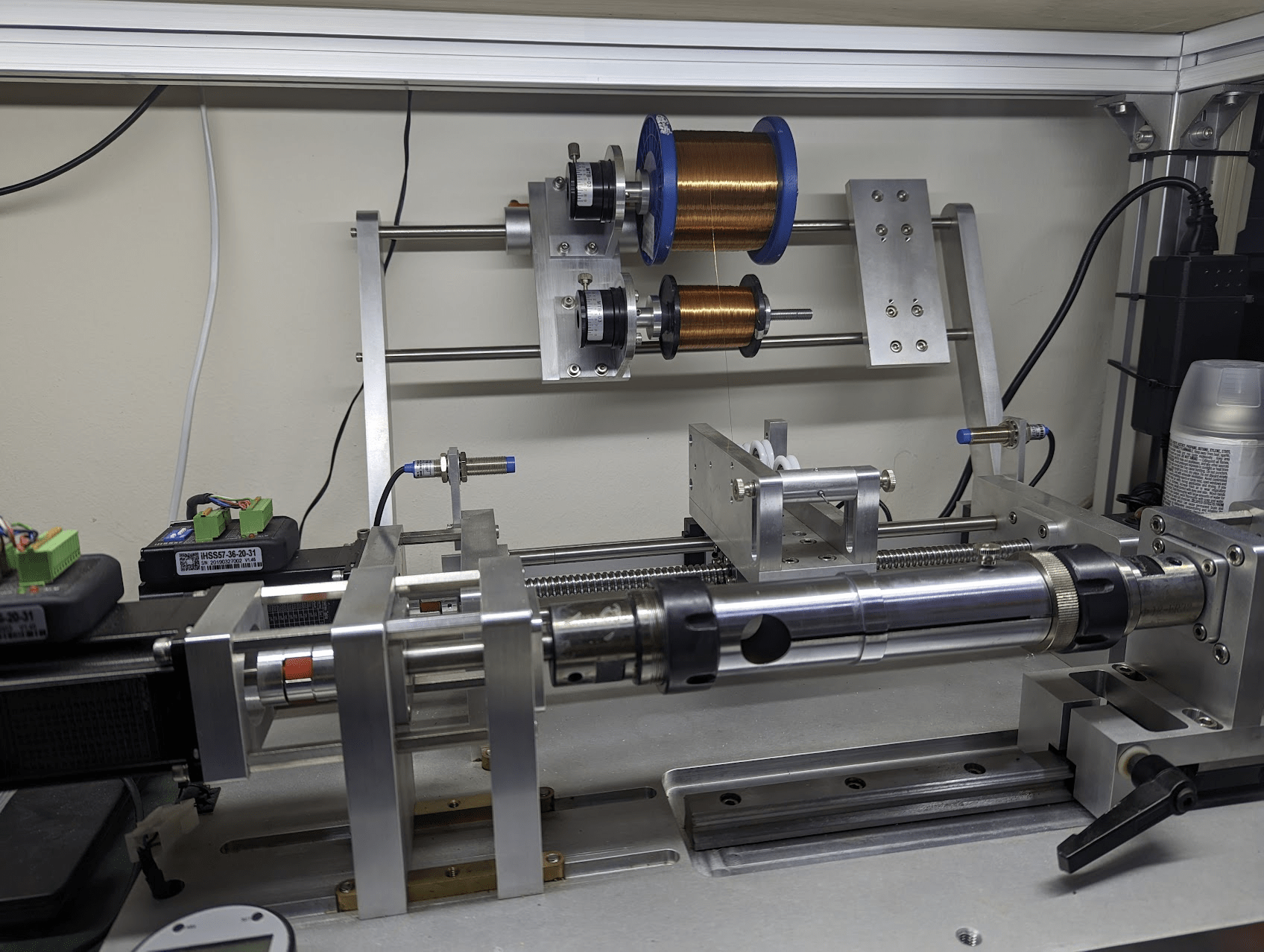

The method of Voice coil winding I used for inner winding. A teflon sleeving to prevent the winding get misaligned from rubbing on the bobbin.

The bobbin is a specially made with a tail end insert. When the tail end is remove, the bobbin can be collapsed slightly to allow the winding to be released.

The bobbin is a specially made with a tail end insert. When the tail end is remove, the bobbin can be collapsed slightly to allow the winding to be released.

Attachments

EX4 Restoration and custom cone rebuild

Attachments

Lowther Voice Coil:

- 0.13mm diameter CCA Wire

- 27 Turns

- Former Height 16.5mm

- Inner Diameter 38.3mm

I have a pair of DX3 sitting in boxes right now.

Nothing wrong with them.

I had wanted to try PM6A, but never seem to be in the right place at the right time.

I had also fantasized about rebuilding the DX3 with some exotic cones and phenolic spiders as field coils.

I’m always amazed when I see people doing stuff like this themselves.

Nothing wrong with them.

I had wanted to try PM6A, but never seem to be in the right place at the right time.

I had also fantasized about rebuilding the DX3 with some exotic cones and phenolic spiders as field coils.

I’m always amazed when I see people doing stuff like this themselves.

I have quite a few designs for the spider using phenolic and Vulcanized Fibre paper.

Hi,Lowther Voice Coil:

Building Lowther recone kit for overseas customers.

- 0.13mm diameter CCA Wire

- 27 Turns

- Former Height 16.5mm

- Inner Diameter 38.3mm

It might be a silly question, but where do you see the advantages of having the coil inside the former instead of outside?

However, great work as usual!

All the best

Mattes

It mainly for assemble of the cone where the voice coil is attached to the whizzer cone 1st then the main cone. So the winding will not cause any blockage.

It is much difficult to make inner winding compared to outer winding. Also the inner winding is to match the design from the original lowther

It is much difficult to make inner winding compared to outer winding. Also the inner winding is to match the design from the original lowther

I believe the Lowther DX4 is about 11 grams, so this heavier cone would explain the higher Q and lower Fs. The Lowther 8 ohm aluminum voice coil DX4 has the 2 khz peak- the "famous" shout (at least it used to), I suspect that this driver with a different cone would have a very different frequency response. It would be interesting to see the frequency response of this driver. I noticed that this driver has a very high compliance, higher than Lowther's which I believe is high to begin with. It would be interesting to also see the impulse respone of your driver.

My cones weighs about 6.0g to 6.4g without surround and damper(spider). The average paper weight for Lowther is around 160 to 165gsm.

Lowther shout is mainly due to overly thick whizzer cone, so what I did was reduce the whizzer cone paper to around 90gsm to 100gsm. Will update shortly on the measurements again.

Lowther shout is mainly due to overly thick whizzer cone, so what I did was reduce the whizzer cone paper to around 90gsm to 100gsm. Will update shortly on the measurements again.

I am sure that the thickness of the whizzer cone is a factor. I also observed that the 16 ohm version did not have the 2000 hz peak (thus, the weight of the voice coil is also a fac tor), but it seems that it had peaks elsewhere. I think that it is a challenge designing these drivers to be efficient and have a flat frequency response. I am impressed with what you are doing.

I purchased a set of surrounds and spiders from Zenwood Audio for my DX4s which had finally rotted out. I think that their replacement surrounds/spiders sounded really, really good - probably better than Lowther's. So playing around with different surround and spider materials is worthwhile - one more variable though.

I adapted a plastic light bulb socket I purchased at a local hardware store to fit where the diffuser would go, and I screwed in different light bulb shapes to try different diffusers. The diffuser affects the frequency response and is particularly useful to reduce beaming.

I had DX4s, but I screwed up a former on one of the DX4s, so I purchased DX65 cones from Lowther and I am using those in front waveguides.

One more thing to try is applying different coatings, and particularly the enABLe treatment developed by Bud Purvine. If you look around the web, you will see some forum posts about that.

Retsel

I purchased a set of surrounds and spiders from Zenwood Audio for my DX4s which had finally rotted out. I think that their replacement surrounds/spiders sounded really, really good - probably better than Lowther's. So playing around with different surround and spider materials is worthwhile - one more variable though.

I adapted a plastic light bulb socket I purchased at a local hardware store to fit where the diffuser would go, and I screwed in different light bulb shapes to try different diffusers. The diffuser affects the frequency response and is particularly useful to reduce beaming.

I had DX4s, but I screwed up a former on one of the DX4s, so I purchased DX65 cones from Lowther and I am using those in front waveguides.

One more thing to try is applying different coatings, and particularly the enABLe treatment developed by Bud Purvine. If you look around the web, you will see some forum posts about that.

Retsel

Hi,It mainly for assemble of the cone where the voice coil is attached to the whizzer cone 1st then the main cone. So the winding will not cause any blockage.

It is much difficult to make inner winding compared to outer winding. Also the inner winding is to match the design from the original lowther

Thanks a lot for the explanation.

All the best

Mattes

- Home

- Loudspeakers

- Full Range

- Lowther DX4 rebuild