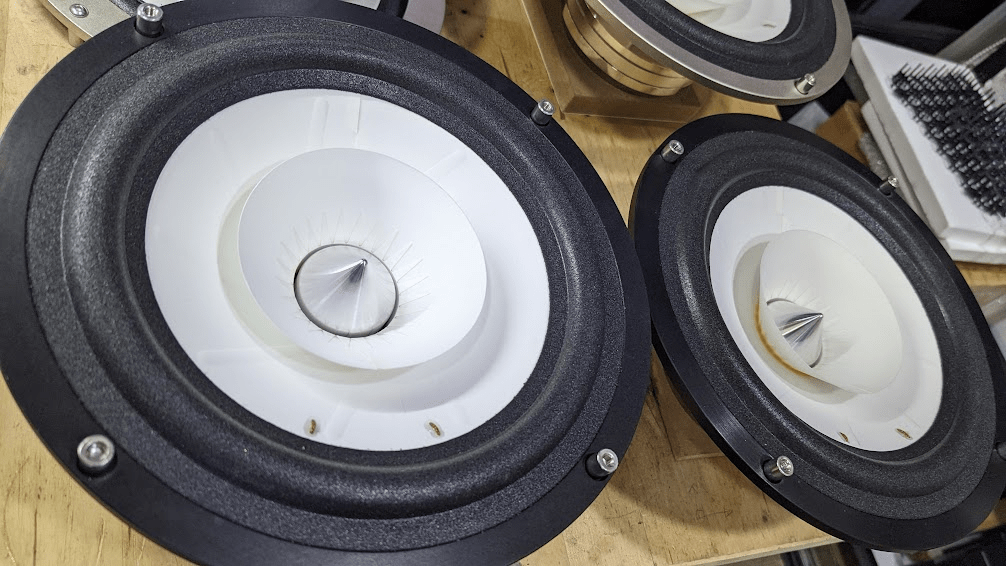

One more thing. A fellow Lowther owner suggested cutting the edge of the whizzer on my DX4 drivers to unfurl the reverse roll (to make the whizzer straight), based on his claims that the high frequencies sound better. After some careful consideration, I did so and I also thought that the high frequencies improved. When I ordered the DX65 drives I ordered them without the reverse roll.

I have non folder whizzer cone but that was used in my own fullrange design, I don't find that much difference once the paper weight is 110gsm or below for the whizzer cone.

Last edited:

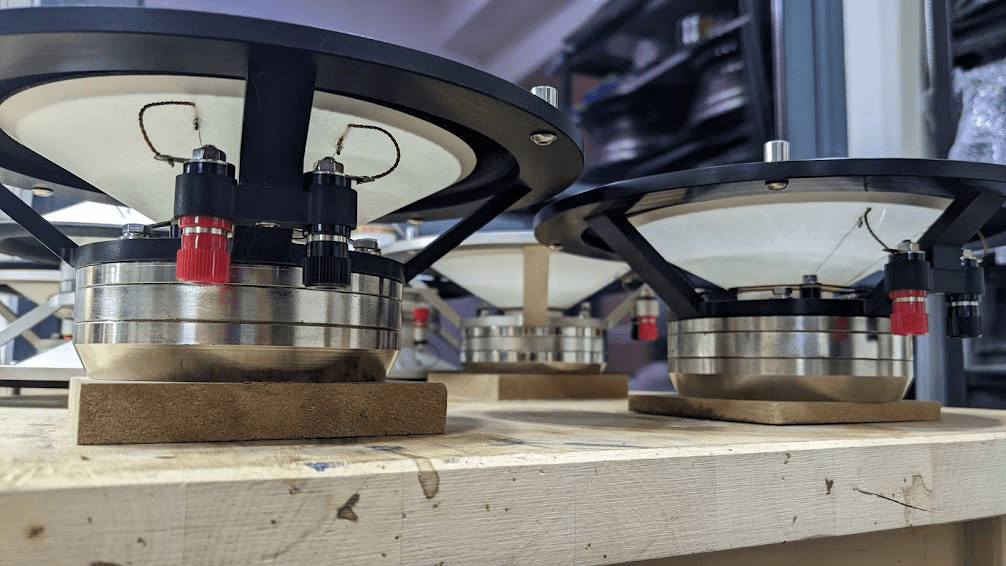

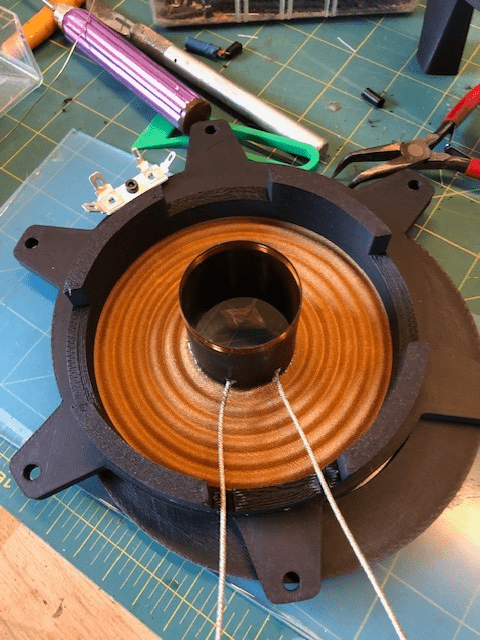

My personal design is much different from Lowther, with the voice coil slightly smaller and taller former.

All made with Japanese washi hemp/kozo paper. It has a very good dynamic responses compare to Lowther.

All made with Japanese washi hemp/kozo paper. It has a very good dynamic responses compare to Lowther.

Last edited:

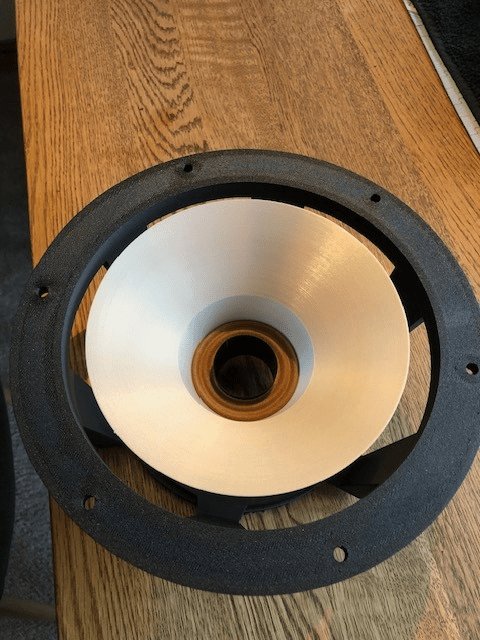

Repairing a coil on an existing Lowther cone without damaging the former is probably near-impossible, Have you contacted Lowther to find out how much it costs for a new cone? Since the new cone would likely look different than the old one, it would probably makes sense to purchase two new cones. The cones come mounted on the baskets, and you just need to attach your existing magnets.

If you do get new cones, they require extensive break-in.

Retsel

If you do get new cones, they require extensive break-in.

Retsel

Great work and good specs. Appreciate the structured cone design bringing more stiffness without more weight.

Very thin whizzer cones made from plastic could be an alternative. Or putting very thin aluminum foil from the goldsmith on cone and whizzer.

Did that in year 2000 with a Fostex FE208 sigma.

Here some Fotos.

https://www.diyaudio.com/community/threads/how-to-make-a-loudspeaker-sandwich-cone.402917/

Very thin whizzer cones made from plastic could be an alternative. Or putting very thin aluminum foil from the goldsmith on cone and whizzer.

Did that in year 2000 with a Fostex FE208 sigma.

Here some Fotos.

https://www.diyaudio.com/community/threads/how-to-make-a-loudspeaker-sandwich-cone.402917/

There is someone in the Lowther Facebook group planning to do that, he boughta pair of my voice coil with intention to cut and remove the old one from the cone, and replace with the new ones.Repairing a coil on an existing Lowther cone without damaging the former is probably near-impossible, Have you contacted Lowther to find out how much it costs for a new cone? Since the new cone would likely look different than the old one, it would probably makes sense to purchase two new cones. The cones come mounted on the baskets, and you just need to attach your existing magnets.

If you do get new cones, they require extensive break-in.

Retsel

Not a simple work and takes lots of patience and time

Wow... So happy to have found this post @ghemml. I have been climbing up this ladder for a while without any idea what I am doing.

I have a pair of Tannoy speakers I am very fond of and took up the challenge to repair them after I stupidly blew them by accident.

In the process I had to work out a way of replacing the spiders too as they got damaged in the deconstruction process. I 3D printed mine which I'm happy to say are a little like the ones you have made. I will post pictures in due course.

I have a pair of Tannoy speakers I am very fond of and took up the challenge to repair them after I stupidly blew them by accident.

In the process I had to work out a way of replacing the spiders too as they got damaged in the deconstruction process. I 3D printed mine which I'm happy to say are a little like the ones you have made. I will post pictures in due course.

@BruceH

If you are interested using 3D printing for Loudspeaker, you can look at Frank Jensen's creation

https://www.facebook.com/frank.jensen.5891004

https://www.facebook.com/groups/lowthermodificationsupportgroup/permalink/1483408992211151/

If you are interested using 3D printing for Loudspeaker, you can look at Frank Jensen's creation

https://www.facebook.com/frank.jensen.5891004

https://www.facebook.com/groups/lowthermodificationsupportgroup/permalink/1483408992211151/

Amazing restoration work!One more thing to try is applying different coatings, and particularly the enABLe treatment developed by Bud Purvine. If you look around the web, you will see some forum posts about that.

Retsel

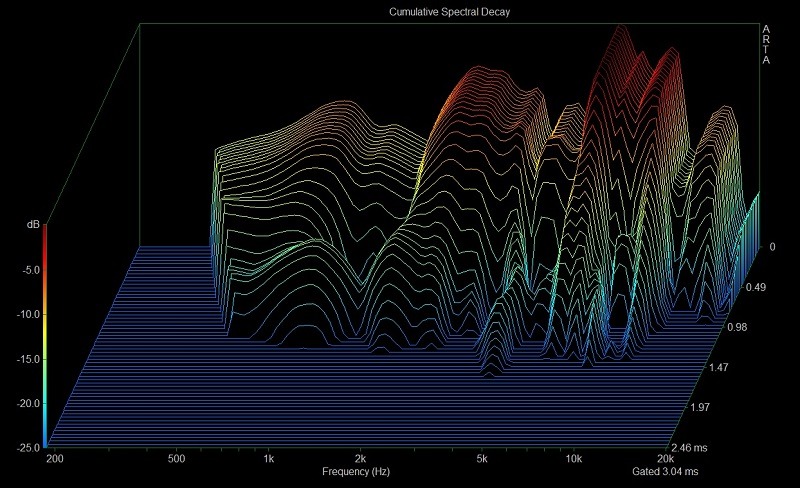

I have experimented with EnABL treatments on factory DX3 and DX4 cones - reported on the EnABL thread. The best solution to the whizzer shout (without cutting) was to use several layers of latex treatment on the back (or inside) of the outer whizzer roll. I have also experimented with different phase plug shapes using different 3D printed variations and also found that best results came with the pointed shape shown in the photos in post #22 above. Mine were slightly more elliptical... I have also used adhesive wool felt on the back-side reflective metal surfaces (particularly the magnet) and noticed slightly better clarity.

Frank

DSP can do a lot to correct the sound without adding weight. I have lots of experience to adjust the sound of fullrange with the help of measurements and final listening time with music and real instruments which were recorded and are then played in the listening room at the same time with the record playing.

FIR could maybe help for the turning phase of backloaded horns at approximately 200hz.

Did anyone try FIR compensation?

FIR could maybe help for the turning phase of backloaded horns at approximately 200hz.

Did anyone try FIR compensation?

Real instruments which were recorded diy is the best medicine against changes in listening mood/bad days where you think your system does not sound right.

You then learn all sounds identical you just have a bad day

You then learn all sounds identical you just have a bad day

This is merely an opinion - not supported by direct experimental observation. I believe the the lapped radial joint on the Lowther cones, with its increase in mass and stiffness, is a significant source of problematic resonance on the cone surface. The EnABL process aims to reduce any such surface resonances. The DX3 and DX4 cones that I have treated require that the entire cone surface is covered, which is aggressive compared to other drivers’ requirements. The result, however, is an obvious improvement in their “neutrality”. I have wondered what the amazing Lowther motors could achieve with a pressed (non-jointed) cone.

I found that the 16 ohm variety of DX4 did not have the 2000 hz peak (shout), although that does not mean that the frequency response is completely flat. When I accidently destroyed the former on one of my DX4 cones, I opted for the 16 ohm DX65 cones since I am using the Lowthers in front waveguides which does not need the larger cone size (I am only reproducing above 500 hz). According to Jon ver Halen (see quote below), Lowther applies a coating of shellac and the most recent owner applies more of it which likely improves the sound overall. Based on my findings, the straight edge whizzer (at least in waveguides) has a better sounding treble, so when I ordered the DX65 cones, I had Lowther make the whizzer straight edge.

Jon ver Halen:

"Lowther have been coated with shellac forever. I have a 1940's PM2A that has a heavy coating on it. During the last owners reign of terror, cones were put into a bath of shellac and allowed to soak. We could ask for longer soak times to get a darker color, which Nelson Pass thought improved the sound.

The prior coating was thin. Not sure if that was the shellac used or the process. And it would certainly affect the sound. I suspect that the thicker coating will require a longer and more aggressive break-in. The break-in is the result of the paper fibers becoming more flexible at the cone-to-former interface, and allowing flexure at certain frequencies. The heavier coating will require more force/longer time to break down. My favorite method was to turn the speakers on medium loud (so you have to raise your voice slightly to talk over the music. Around 82-85 db if you have a dB meter) and let them play music, out of phase, with the cones facing each other. This largely cancels the sound around them, but it is still not a pleasant experience. Put them in the garage for 30-40 hours to play away, then see what they are like. Use music, not test tones. The variety of frequencies are required."

Jon ver Halen:

"Lowther have been coated with shellac forever. I have a 1940's PM2A that has a heavy coating on it. During the last owners reign of terror, cones were put into a bath of shellac and allowed to soak. We could ask for longer soak times to get a darker color, which Nelson Pass thought improved the sound.

The prior coating was thin. Not sure if that was the shellac used or the process. And it would certainly affect the sound. I suspect that the thicker coating will require a longer and more aggressive break-in. The break-in is the result of the paper fibers becoming more flexible at the cone-to-former interface, and allowing flexure at certain frequencies. The heavier coating will require more force/longer time to break down. My favorite method was to turn the speakers on medium loud (so you have to raise your voice slightly to talk over the music. Around 82-85 db if you have a dB meter) and let them play music, out of phase, with the cones facing each other. This largely cancels the sound around them, but it is still not a pleasant experience. Put them in the garage for 30-40 hours to play away, then see what they are like. Use music, not test tones. The variety of frequencies are required."

- Home

- Loudspeakers

- Full Range

- Lowther DX4 rebuild