The plan is for midbass Cabs of 100-120L and subwoofer Cabs of 220L

I'm going for the lowest weight as possible so I'd like to use 1/2" BB. With good bracing do you see any issues with my plan? Noise, panel resonance etc?

I'm going for the lowest weight as possible so I'd like to use 1/2" BB. With good bracing do you see any issues with my plan? Noise, panel resonance etc?

Last edited by a moderator:

It might be possible, but you will need very well designed reinforcements and stiffening.

As an alternative to 1/2" BB, you might want to consider 3/4" popular core plywood. BB is quite dense, and cabinet grade popular core is fairly light weight. I suspect that 1/2" BB and 3/4" popular core are about the same weight per square foot.

j.

As an alternative to 1/2" BB, you might want to consider 3/4" popular core plywood. BB is quite dense, and cabinet grade popular core is fairly light weight. I suspect that 1/2" BB and 3/4" popular core are about the same weight per square foot.

j.

Member

Joined 2009

Paid Member

You will want to stiffen it up so resonances are pushed up above the operating frequency of the subwoofer. When I built my subwoofer I stiffened the box considerably by gluing strips of ply edge-on along the inside surfaces of the box.

You can kind of see in the drawing in the first post: https://www.diyaudio.com/community/threads/altair-sub-2x-trio8s.140069/

You can kind of see in the drawing in the first post: https://www.diyaudio.com/community/threads/altair-sub-2x-trio8s.140069/

I'm going for the lowest weight as possible so I'd like to use 1/2" BB. With good bracing do you see any issues with my plan?

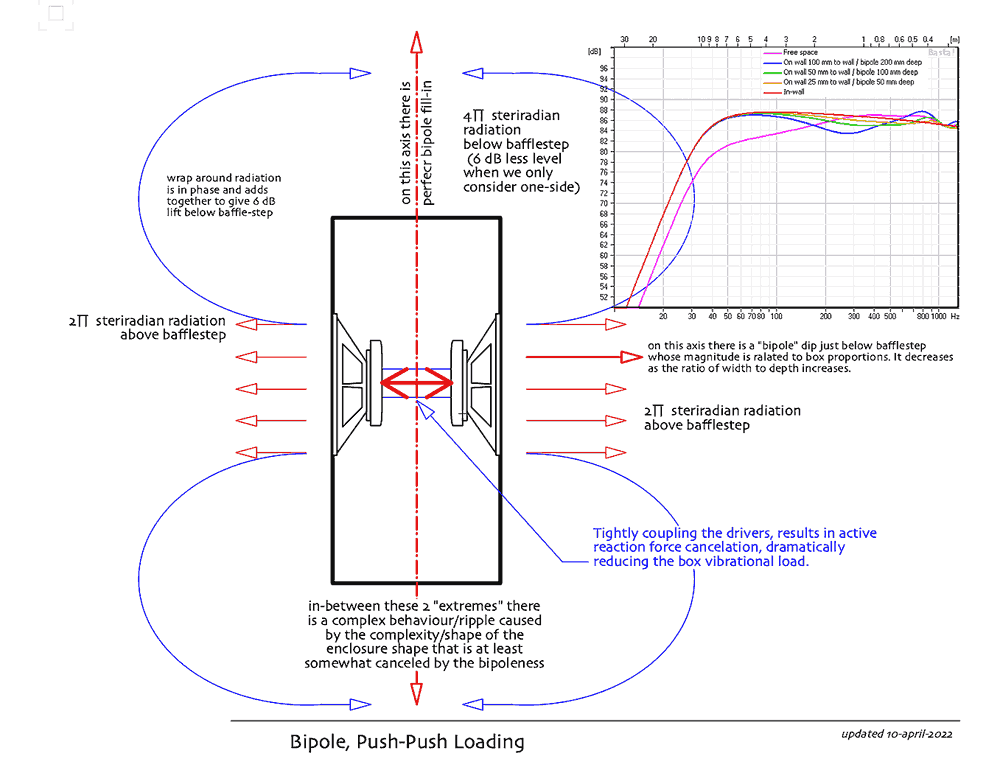

It will work. Clever design required, and if you have 2 bass drivers, push-push is worth considering as that deals with most of the vibrational energy actively making for a need of a less robust cabinet.

dave

I have had the thought to try 1/4 bracing, since bracing is directional you can get rid of a lot of material by using thinner for bracing. Try it out! You can make L bracing with 1/4 and get rid of some weight and some flex, thats what they do in I beams in construction.

Great help, many thanks!

Dave has got me thinking about push push. I did follow many of the Push-pull and isobaric threads and I remember Dave mentioning the advantages of Push-Push. I'm interested in learning more and could still go that route as subs are not purchased yet but modelled for a Dayton Sub.. I have all of the drivers for the main tower which is being designed as sealed Qtc 0.5 and ported QB3 with a plate on the rear that can mount over the port opening to close it. It will be used as sealed with a sealed sub but would like to demo the main tower as ported independently. The dimensions are internal. wall thickness to be added.

I'll read up below. What is the sensitivity loss from Push-Push? Keeping sensitivity high as possible is of importance

System will be used in and active system with 6 channels of class A 50w. Mid to tweeter crossed passively.

https://www.diyaudio.com/community/threads/push-push-bass-design.287842/

Dave has got me thinking about push push. I did follow many of the Push-pull and isobaric threads and I remember Dave mentioning the advantages of Push-Push. I'm interested in learning more and could still go that route as subs are not purchased yet but modelled for a Dayton Sub.. I have all of the drivers for the main tower which is being designed as sealed Qtc 0.5 and ported QB3 with a plate on the rear that can mount over the port opening to close it. It will be used as sealed with a sealed sub but would like to demo the main tower as ported independently. The dimensions are internal. wall thickness to be added.

I'll read up below. What is the sensitivity loss from Push-Push? Keeping sensitivity high as possible is of importance

System will be used in and active system with 6 channels of class A 50w. Mid to tweeter crossed passively.

https://www.diyaudio.com/community/threads/push-push-bass-design.287842/

Attachments

What is the sensitivity loss from Push-Push?

No acoutic losses.

The only thing different is that the physical arrangement of the drivers so that the reactive force of each driver is actively cancelled by the reaction force of the other.

The only thing you are doing is removing a very significant amount of reaction energy from ever entering the box.

At these frequencies the speaker is omnidirectional, in theory it mtters not where the driver is (in practice you have to worry about walls, floors couches etc.

I made this a long time ago, but have updated it. While searching for my original expot found a drwing the is essentially Nelson's SLAPS.

dave

Thanks Dave! I'll study post 9 for awhile.

So if I was planning on 200L with a particular sub , it would now require 400L or remain at 200L?

So if I was planning on 200L with a particular sub , it would now require 400L or remain at 200L?

1/2" is fine with good bracing as others have said. I use window pane braces spaced at irregular intervals to help break up resonances. You might consider adding 1X2 stick bracing between windows.

1/2" is fine with good bracing as others have said. I use window pane braces spaced at irregular intervals to help break up resonances.

THose break this general guideline: The subpanels created by a brace should have higher aspect ratio than the panel they are bracing and the subpanels should not be equivalent.

In that box it means that your brace need to run vertically, and they should not be equallt spaced.

Even more critical given the use of MDF>

dave

So if I was planning on 200L with a particular sub , it would now require 400L or remain at 200L?

2 drivers require twice the volume as one does.

dave

3 - 4 inch wide Masonite (tempered if you can find it) strips on edge, glued into shallow slots cut with a router can have a surprising improvement. But like a lot of efforts to improve rigidity, getting a good result can be hit or miss, without a good bit of advanced math (way above my pay grade) -- or even more experience.

Cheers

Cheers

In the USA and Canada, if you buy grade A/A or A/B hardwood veneer plywood (i.e. interior cabinet grade), the core veneers are almost always popular. I have recently purchased several sheets of red-oak plywood, cherry plywood, and maple plywood. In every case, the outer veneer was cosmetically pretty good (but not excellent), and the core was light weight popular. It is much less dense than marine plywood (all layers douglas fir) or baltic birch (all layers birch).

These speakers will be 4 feet from rear wall. For this this system Im leaning towards a single woofer facing forward next to each tower. I have a plan for a different system where Push Push might be a good choice.

If push push removes vibrational energy, reducing/removing box radiation, then box radiation is more audibly colouring than I thought.

Will look at bracing plan and other sheet materials. Cost and weight might not be a concern anymore.

If push push removes vibrational energy, reducing/removing box radiation, then box radiation is more audibly colouring than I thought.

Will look at bracing plan and other sheet materials. Cost and weight might not be a concern anymore.

I'm going with 1/2" MDF and Plywood front, back and braces!

Regarding Push-Push or Push-Pull, I'm very interested in knowing what is changed to reduce unwanted radiation!

I measured and listened to a bass cabinet with 3 16 ohm woofers in parallel. At one point I had accidentally wired one woofers reverse polarity. The acoustic measurement was of course -6db or more from the correct polarity but with same bass extension and roll off. I immediately noticed an improvement in bass control and definition.

Is it reduced box radiation or internal damping? I'm keen on making a push-push speaker but what does the science show us. Post 5 states panel vibrational energy reduction, but I keep thinking about discussions that state box radiation is not that audible.

🙂

Regarding Push-Push or Push-Pull, I'm very interested in knowing what is changed to reduce unwanted radiation!

I measured and listened to a bass cabinet with 3 16 ohm woofers in parallel. At one point I had accidentally wired one woofers reverse polarity. The acoustic measurement was of course -6db or more from the correct polarity but with same bass extension and roll off. I immediately noticed an improvement in bass control and definition.

Is it reduced box radiation or internal damping? I'm keen on making a push-push speaker but what does the science show us. Post 5 states panel vibrational energy reduction, but I keep thinking about discussions that state box radiation is not that audible.

🙂

Regarding Push-Push or Push-Pull, I'm very interested in knowing what is changed to reduce unwanted radiation!

One simply ensures that the meachanical motion of the drivers are in opposite directions and the drivers are tightly coupled together so that the reacive forces cancel each other. It is much easier to do this with push-psuh, and if you are using decent woofers you loose nothing with push-push. Push-pull wil reduce second order distortion at the expense of the 3rd. if the woofer has poor enuff symmetry that the loss of the 2nd overrides the gain in 3rd then one is a winner. But they also tend to be uglier. So i tend to use good woofers push-push. Easiest to do with even numbers of woofers but it has been done with 3 (Martin Logan and the i have some sketches).

dave

Last edited:

- Home

- Loudspeakers

- Multi-Way

- 1/2 inch Baltic Birch for Bass Cabinets?