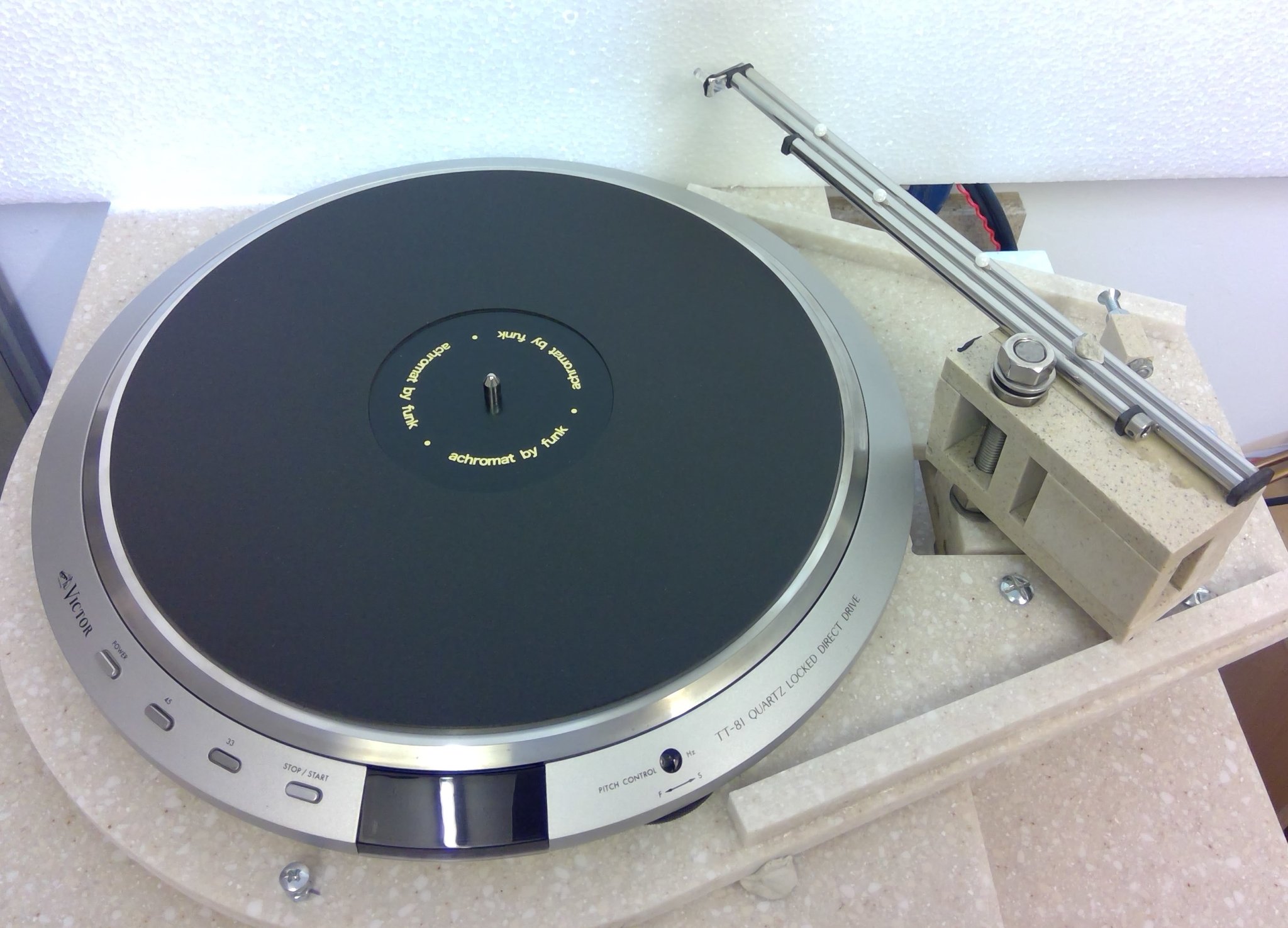

Congrats! It looks nice. However, I am not sure how you make the rear guiding mechanism.I finally did it! It took me some time but I must confess I'm very pleased with the final result. It tracks perfectly tangential, no skating, no worries.

Once again kudos to Mr. Schroeder for his genius idea!

Thanks super10018.

This is how I made it. The iron part was made of about 25 layers of thin tin can iron sheet secured with two component resin adhesive. This way I could give it exactly the shape I carved in the aluminum plate, as resulted from my Excel file.

This is how I made it. The iron part was made of about 25 layers of thin tin can iron sheet secured with two component resin adhesive. This way I could give it exactly the shape I carved in the aluminum plate, as resulted from my Excel file.

Attachments

Hi Consty,Hi Consty,

The rendering looks very good, but to me seems that the vertical dimension it is a bit big and could generate a negative momentum. However, considering the limited space you have in the bottom of the TT, good idea to expand the TA in the upper line.

Hope ur bearing arrive regularly soonest. I may use bearing that I have in the garage while waiting my new ones that I keep just in case.

However I am not a fast guy in doing things.

Rgds

Adelmo

Did you finally use the ceramic bearings? If yes what were the dimension if possible to know.

Tks n rgds

Adelmo

Hi Consty, I took a look at that bearing type on line and they seem to be skateboard type. I would like to consider using something similar on the turn-away of my RTA, and although i have a magnet return stop need something practically zero play, so your first hand experience would be very useful, would you describe them that way please?

M

By the way i currently use a tapered nut in a tapered seat with a rubber spring for pressure to ensure good contact/coupling.

M

By the way i currently use a tapered nut in a tapered seat with a rubber spring for pressure to ensure good contact/coupling.

TksHi Adelmo,

I used 608 ceramic bearings fitted on M8 screw

Best regards,

Consty

I plan to use for my first attempt bearing I have already with following dimension: inner 8mm, outer16mm, height 5mm. But are not ceramic bearing, if the attempt work well I will improve the bearings type getting smaller ones.

Rgds

Adelmo

Last edited:

Hi Mike56,

I'm not sure I understand how do you intend to use the ceramic bearings but the ones I bought on Ebay were the cheapest I could find. So they had a little bit of play. Obviously any bearing will have more or less play, otherwise it would stiffen. But overall they run smooth.

I'm not sure I understand how do you intend to use the ceramic bearings but the ones I bought on Ebay were the cheapest I could find. So they had a little bit of play. Obviously any bearing will have more or less play, otherwise it would stiffen. But overall they run smooth.

Attachments

Consty,

That's an excellent accomplishment - both functional and attractive. I think the inverted arm/bearing carrier and the top mounted magnetic attractor are very good ideas and shouldn't give you any trouble. Congratulations and enjoy your new PTA.

Did you pre-load the bearings? That can make a difference in how well they turn and how quietly.

Adelmo,

I hope the last 20% heals quickly.

DD,

If you're out there, you should be proud of what your nearly-2500-post thread has brought to life over the years. Contrast Consty's with the photo of mine in post 2461.

Doug

That's an excellent accomplishment - both functional and attractive. I think the inverted arm/bearing carrier and the top mounted magnetic attractor are very good ideas and shouldn't give you any trouble. Congratulations and enjoy your new PTA.

Did you pre-load the bearings? That can make a difference in how well they turn and how quietly.

Adelmo,

I hope the last 20% heals quickly.

DD,

If you're out there, you should be proud of what your nearly-2500-post thread has brought to life over the years. Contrast Consty's with the photo of mine in post 2461.

Doug

Consty, i know i am on the wrong specific thread, but the RTA i play around with is, without doubt, correctly oriented to the groove at all times, i.e. 90 degrees whatever the situation or position on the record, warp etc, it's just not Pivoted, however i find your and others work intriguing as well.

Linears and Radials need an arrangement to move the arm away for record loading and more critically back in position both level and radial repeatedly easily and accurately, whilst remaining well coupled through the base to the plinth. my current arrangement turns away OK, but is a bit stiff because of the bearing type. Consequently i might try bearings like yours and pre loaded like Doug suggests should remove play ensure repeatability and coupling with ease of movement. The pic in 2486 shows the arm turned away and you can pick out the post bolt the bearings mount on. As always if i can borrow some experience from others it helps a lot! i am not yet sure exactly how to pre load.........

M

Linears and Radials need an arrangement to move the arm away for record loading and more critically back in position both level and radial repeatedly easily and accurately, whilst remaining well coupled through the base to the plinth. my current arrangement turns away OK, but is a bit stiff because of the bearing type. Consequently i might try bearings like yours and pre loaded like Doug suggests should remove play ensure repeatability and coupling with ease of movement. The pic in 2486 shows the arm turned away and you can pick out the post bolt the bearings mount on. As always if i can borrow some experience from others it helps a lot! i am not yet sure exactly how to pre load.........

M

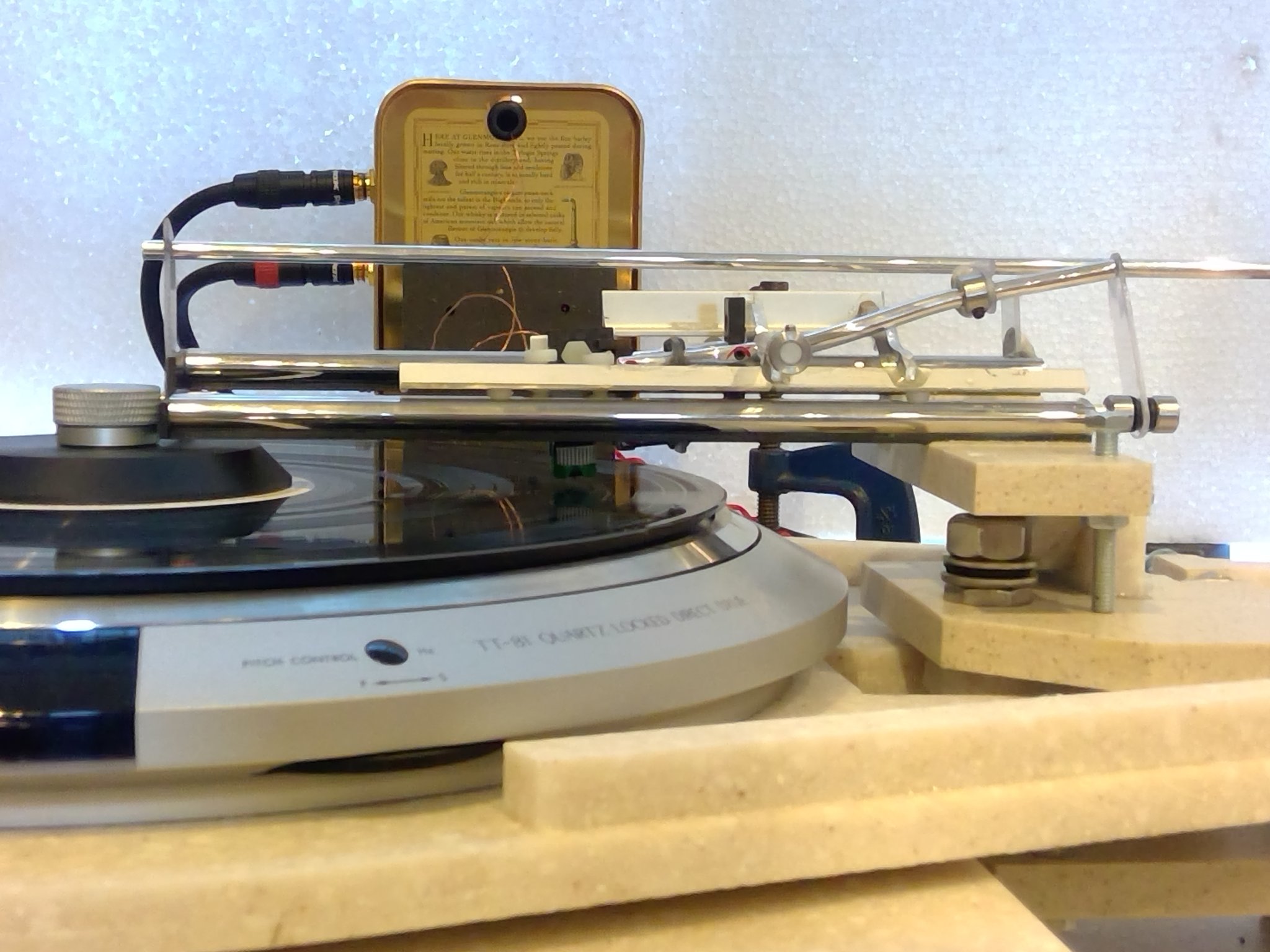

Hi dtut and Mike56,

No, I haven't preloaded the ceramic bearings. This would have increased friction too much. But I used M8 wave washers for securing the two 608 bearings on each pivoting M8 screw.

Mike56, indeed, in your case you can use preloading to achieve both stiffness and ease of movement. Your design looks very familiar to me since I played with a similar design type some time ago. The three white ceramic balls provide the rolling base for the TA, isn't it? The difference between your design and mine is that you make the linear TA base pivot while changing the record, something that allows for a short TA which is very good. I made it fixed in a position similar to the one in your picture and this forced me to use a long TA which was not very good.

The difference between your design and mine is that you make the linear TA base pivot while changing the record, something that allows for a short TA which is very good. I made it fixed in a position similar to the one in your picture and this forced me to use a long TA which was not very good.

No, I haven't preloaded the ceramic bearings. This would have increased friction too much. But I used M8 wave washers for securing the two 608 bearings on each pivoting M8 screw.

Mike56, indeed, in your case you can use preloading to achieve both stiffness and ease of movement. Your design looks very familiar to me since I played with a similar design type some time ago. The three white ceramic balls provide the rolling base for the TA, isn't it?

I do wish to find a better turn away bearing Consty so that's an interesting way to consider, thanks.

Yes, the three ceramic balls are the rollers for the carriage, so it is a non recirculating ball bearing carriage, which should operate with constant contact and no play.

I like the three as it provides for more predictable contact pressures in the transition whereas 4 requires more perfect alignments.

However, when pivoted in, these rails place the stylus on the radial line with the rails directly over it, there is no arm length at all, which is most unusual, so the vertical motion needed to accommodate warp is taken by a paralelogram motion, and the cartridge does not change orientation in warp movement (as a pivoted one does, both short or long) at all whilst remaining tangential to the groove throughout the transition and without skating. There are other compromises of course, but it is sound in these respects.

A pic of the arm in position to play and a video of the separated paralelogram carriage are attached for your interest (or otherwise!) and to add to the explanation.

M

Yes, the three ceramic balls are the rollers for the carriage, so it is a non recirculating ball bearing carriage, which should operate with constant contact and no play.

I like the three as it provides for more predictable contact pressures in the transition whereas 4 requires more perfect alignments.

However, when pivoted in, these rails place the stylus on the radial line with the rails directly over it, there is no arm length at all, which is most unusual, so the vertical motion needed to accommodate warp is taken by a paralelogram motion, and the cartridge does not change orientation in warp movement (as a pivoted one does, both short or long) at all whilst remaining tangential to the groove throughout the transition and without skating. There are other compromises of course, but it is sound in these respects.

A pic of the arm in position to play and a video of the separated paralelogram carriage are attached for your interest (or otherwise!) and to add to the explanation.

M

Attachments

It looks great, congratulations!

How do you adjust VTF? I think you should have a weight somewhere on the oblique aluminum rod extending from the parallelogram.

And another challenge for this design is to make sure that at all times the center of gravity of the carriage stays inside the triangle described by the three ceramic balls

How do you adjust VTF? I think you should have a weight somewhere on the oblique aluminum rod extending from the parallelogram.

And another challenge for this design is to make sure that at all times the center of gravity of the carriage stays inside the triangle described by the three ceramic balls

Absolutely correct on both counts Consty, here in the pic you can see the CW, also how light it needs to be, just 5gms plus the small lift arm, also at different times i use a front weight to ensure the CG stays comfortably in the triangle, in this pic out towards the camera, like many things, once understood, all that's the easy bit, before understood a challenge! Current version doesn't have the front CW. so, it has an ideal geometry in my opinion, measures well, and sounds good to me...........

At the end of the day, that's all that mattersand sounds good to me...........

Tks

I plan to use for my first attempt bearing I have already with following dimension: inner 8mm, outer16mm, height 5mm. But are not ceramic bearing, if the attempt work well I will improve the bearings type getting smaller ones.

Rgds

Adelmo

Hi,

Some small step forward with my clone.

This week end I plan to bond the tip and rear aluminum part to the bamboo arm wand. Also start to make the Supatrac style vertical bearing, in case shall not work I can change to a traditional bearing.

At the present I am checking the pre assembling if all works well before to lock the parts into final assembling.

I keep as last the shape of the magnetic guiding system.

Best regards

Adelmo

Nice construction. I look forward to seeing how this arm develops.

The Supatrac bearing looks very intriguing. I'm a big fan of using spikes for the main bearing element in a tonearm. Whether having the pivot mounted horizontally will be beneficial is the big question. The more conventional vertical orientation will result in a much greater load through the contact point. This should improve coupling but at the expense of friction. 🤔

I'm also a big fan of bamboo. Of all the natural woods used for tonearms I suspect that bamboo would be the clear winner. (I know that bamboo is technically a grass and not wood)

Niffy

The Supatrac bearing looks very intriguing. I'm a big fan of using spikes for the main bearing element in a tonearm. Whether having the pivot mounted horizontally will be beneficial is the big question. The more conventional vertical orientation will result in a much greater load through the contact point. This should improve coupling but at the expense of friction. 🤔

I'm also a big fan of bamboo. Of all the natural woods used for tonearms I suspect that bamboo would be the clear winner. (I know that bamboo is technically a grass and not wood)

Niffy

Hi Niffy,

I made a kind of Supatrac clone and the bearing with single contact point works well. I am still using that TA, but hope I can replace with this one. In fact the horizontal pivot contrast the stylus dragging and works well either with high or low complaint cart. Important the string geometry and the pivot position as well. Also the pivot plane should be below the LP plane, in nay case not above.

In this case I have to use 2 pivots but still in horizontal plane. Shall see if I can balance the TA well later on.

Kuzma is using a similar system for the vertical bearing, but much more precise and more sophisticated execution of course. Also do not use any string, Is not either Horizontal or Vertical, a kind of 45 degree seems. For me is too complex to make like that as I am not using CNC machine but simple tools.

Rgds

Adelmo

I made a kind of Supatrac clone and the bearing with single contact point works well. I am still using that TA, but hope I can replace with this one. In fact the horizontal pivot contrast the stylus dragging and works well either with high or low complaint cart. Important the string geometry and the pivot position as well. Also the pivot plane should be below the LP plane, in nay case not above.

In this case I have to use 2 pivots but still in horizontal plane. Shall see if I can balance the TA well later on.

Kuzma is using a similar system for the vertical bearing, but much more precise and more sophisticated execution of course. Also do not use any string, Is not either Horizontal or Vertical, a kind of 45 degree seems. For me is too complex to make like that as I am not using CNC machine but simple tools.

Rgds

Adelmo

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms