Doug, I've seen better the last photo:- this way we have a rope on rope friction avoided with the two concentric pulleys (its crucial to have this way, to have a hor, coincident point control. Which is better? Tests to do with the proto

ciao carlo

ciao carlo

I would like to touch the hobgoblin one more time.

Not all PLT arms are same.

If a PLT arm has no offset angle, there is no skating force.

I have done some experiments years ago, but I am not going to hijack this thread. I can start a new thread if some of you are interested.

Not all PLT arms are same.

If a PLT arm has no offset angle, there is no skating force.

I have done some experiments years ago, but I am not going to hijack this thread. I can start a new thread if some of you are interested.

3 themes

Please share your finding here, Jim. This is pertinent to the discussion and Carlo's arm has no offset angle so I'm sure he would like to read about it too.

It was my fault for stoking the skating force debate with alighiszem (post#1305). I was simply questioning if the Klaudio tonearm has skating force even though it track across the record in a straight line while NOT being a parallel tracker. (I'm still not convinced it has zero skating force.) Personally, my interest is in line with Doug's in coming up with clever geometric designs so don't let skating force hinder your imagination.

===============================================

Anyway, let me reiterate the THREE simple themes of this thread. I say themes not rules because we shouldn't be so strict on these things. While no topic is off limit and I'm certainly at time guilty of going off topic, it's probably best to leave the discussion to other threads that are worthy of the topics.

1) NO AIRBEARING

2) NO PARALLEL TRACKERS

3) NO SERVO

1 & 2 are similar and Jim's excellent thread has already covered the airbearing designs and vynuhl.addict has his extensive mechanical linear arm thread. I'm sure there is or will be a servo arm thread out there. There will be exceptions such as designs that cross into those categories in some hybridization (eg, Klaudio, Reed 5T, etc...) so feel free to discuss here too. Other than that, we can talk about anything.

If a PLT arm has no offset angle, there is no skating force.

I have done some experiments years ago, but I am not going to hijack this thread. I can start a new thread if some of you are interested.

Please share your finding here, Jim. This is pertinent to the discussion and Carlo's arm has no offset angle so I'm sure he would like to read about it too.

It was my fault for stoking the skating force debate with alighiszem (post#1305). I was simply questioning if the Klaudio tonearm has skating force even though it track across the record in a straight line while NOT being a parallel tracker. (I'm still not convinced it has zero skating force.) Personally, my interest is in line with Doug's in coming up with clever geometric designs so don't let skating force hinder your imagination.

===============================================

Anyway, let me reiterate the THREE simple themes of this thread. I say themes not rules because we shouldn't be so strict on these things. While no topic is off limit and I'm certainly at time guilty of going off topic, it's probably best to leave the discussion to other threads that are worthy of the topics.

1) NO AIRBEARING

2) NO PARALLEL TRACKERS

3) NO SERVO

1 & 2 are similar and Jim's excellent thread has already covered the airbearing designs and vynuhl.addict has his extensive mechanical linear arm thread. I'm sure there is or will be a servo arm thread out there. There will be exceptions such as designs that cross into those categories in some hybridization (eg, Klaudio, Reed 5T, etc...) so feel free to discuss here too. Other than that, we can talk about anything.

Hi all.

I would disagree with Jim's theory that if you have no offset you have no skating force. I believe that if you have a pivot you will have skating. In Carlos arm pulling the arm forwards puts a sideways pressure between the string and the rear bearing that inevitably leads to skating, even though there is no offset

A couple of years ago I carried out an in-depth investigation into all aspects that would effect lateral tracking angle errors created for a variety of pivoted and linear tracking tonearms.

Unfortunately I have never got round to expanding this investigation to include pivoted tangential arms. The main reason I have not done so is the amount of work involved. To be fair and balanced I would have to analyse several different types of arm. Part of the analysis involves calculating the effective mass for each arm. For variable length arms, such as those using the Thales or Birch geometries, where you have a combination of rotation and translation this becomes quite involved. That problem pails in comparison to working out bearing friction (I used actual measurements for my investigation)

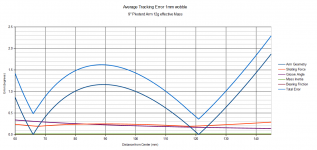

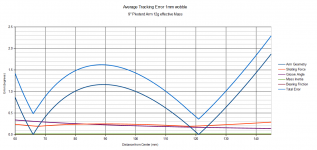

Below is a graph showing the lateral tracking error for a typical 9"arm. The arm is modelled using a cartridge with a compliance of 22um/mN (as this is the cartridge I am currently using). The effective mass, inc cartridge, is 12g. The record used for the model has a moderately highly eccentricity that would cause the arm to move back and forth by 1mm . The level of tracking error shown is the average amount that you would expect to see for a single rotation of the record at that distance from the spindle. The peek amount will be higher but I found the average more informative.

By far the greatest contribution to LTA error is arm geometry. The contributions from the groove angle and antiskate are similar. Remember that if the record was perfectly concentric the groove angle would go away but the antiskate would be unaffected. The contributions from bearing friction and mass-inertia are insignificant but are included as they become more significant with other arm designs.

If I were to model an arm such as Carlo's what differences would we expect to see?

Hopefully the error due to geometry would be eradicated.

The error due to groove angle would remain the same.

I think that the level of antiskate error would be roughly the same. It may be possible to fine tune the amount of antiskate to vary depending upon the arms position. If so the skate error would reduce by a small amount.

As the arm both rotates and extends the effective mass will be higher than a purely pivoted design. If there is no play in the system the amount of tracking error due to mass-inertia would probably be in the range of 0.05-0.1°. If there is significant play in the system then eccentricity may be entirely accommodated by rotation alone. In this case the tracking error due to mass-inertia would be insignificant but you would have about 0.2° of error due to arm rotation. I did include bearing play in my investigation but didn't include it in the graph for pivoted arms as it doesn't really effect this type of arm. It can however be significant in mechanical linear tracking arms that use low grade ball race bearings.

I think that the make or break aspect for Carlo's arm is going to be bearing friction. Hopefully you can keep this as low as possible. If friction is too high you could easily end up with worse lateral tracking errors than for a conventional pivoted arm. If I may I'll throw a couple of ideas into the mix as to how friction can be minimized. As part of the development for my passive linear tracking tonearm, don't worry I won't take us off topic, I heavily researched bearings. Rather than using ball race bearings I ended up using pin bearings. The jewelled bearings that I am currently using have less than a fifth the friction of a standard grade ball race bearing. Before I used the jewelled bearings I was using home made pin bearings made from sewing pins and m3 grub screws. These have only a third the friction of the standard grade bearings and half that of top grade bearings. Judging by the build quality of the test pieces you've posted these are well within your ability to make, and they're much cheaper than high grade ball race bearings. Another advantage to this type of bearing is that they don't chatter. For the string try dental floss. Tease out a couple of strands and use these. They are strong and very flexible. (This string can also be used for the string in falling weight antiskate mechanisms.) If you know anyone who does archery try and score some fast-flight bow string, it's even better than dental floss.

Without having more information on bearing friction and the amount of play within the system it is difficult to estimate what the tracking error will be. Hopefully it will be significantly lower than the pivoted arm.

I hope this is helpful/informative

Niffy

I would disagree with Jim's theory that if you have no offset you have no skating force. I believe that if you have a pivot you will have skating. In Carlos arm pulling the arm forwards puts a sideways pressure between the string and the rear bearing that inevitably leads to skating, even though there is no offset

A couple of years ago I carried out an in-depth investigation into all aspects that would effect lateral tracking angle errors created for a variety of pivoted and linear tracking tonearms.

Unfortunately I have never got round to expanding this investigation to include pivoted tangential arms. The main reason I have not done so is the amount of work involved. To be fair and balanced I would have to analyse several different types of arm. Part of the analysis involves calculating the effective mass for each arm. For variable length arms, such as those using the Thales or Birch geometries, where you have a combination of rotation and translation this becomes quite involved. That problem pails in comparison to working out bearing friction (I used actual measurements for my investigation)

Below is a graph showing the lateral tracking error for a typical 9"arm. The arm is modelled using a cartridge with a compliance of 22um/mN (as this is the cartridge I am currently using). The effective mass, inc cartridge, is 12g. The record used for the model has a moderately highly eccentricity that would cause the arm to move back and forth by 1mm . The level of tracking error shown is the average amount that you would expect to see for a single rotation of the record at that distance from the spindle. The peek amount will be higher but I found the average more informative.

By far the greatest contribution to LTA error is arm geometry. The contributions from the groove angle and antiskate are similar. Remember that if the record was perfectly concentric the groove angle would go away but the antiskate would be unaffected. The contributions from bearing friction and mass-inertia are insignificant but are included as they become more significant with other arm designs.

If I were to model an arm such as Carlo's what differences would we expect to see?

Hopefully the error due to geometry would be eradicated.

The error due to groove angle would remain the same.

I think that the level of antiskate error would be roughly the same. It may be possible to fine tune the amount of antiskate to vary depending upon the arms position. If so the skate error would reduce by a small amount.

As the arm both rotates and extends the effective mass will be higher than a purely pivoted design. If there is no play in the system the amount of tracking error due to mass-inertia would probably be in the range of 0.05-0.1°. If there is significant play in the system then eccentricity may be entirely accommodated by rotation alone. In this case the tracking error due to mass-inertia would be insignificant but you would have about 0.2° of error due to arm rotation. I did include bearing play in my investigation but didn't include it in the graph for pivoted arms as it doesn't really effect this type of arm. It can however be significant in mechanical linear tracking arms that use low grade ball race bearings.

I think that the make or break aspect for Carlo's arm is going to be bearing friction. Hopefully you can keep this as low as possible. If friction is too high you could easily end up with worse lateral tracking errors than for a conventional pivoted arm. If I may I'll throw a couple of ideas into the mix as to how friction can be minimized. As part of the development for my passive linear tracking tonearm, don't worry I won't take us off topic, I heavily researched bearings. Rather than using ball race bearings I ended up using pin bearings. The jewelled bearings that I am currently using have less than a fifth the friction of a standard grade ball race bearing. Before I used the jewelled bearings I was using home made pin bearings made from sewing pins and m3 grub screws. These have only a third the friction of the standard grade bearings and half that of top grade bearings. Judging by the build quality of the test pieces you've posted these are well within your ability to make, and they're much cheaper than high grade ball race bearings. Another advantage to this type of bearing is that they don't chatter. For the string try dental floss. Tease out a couple of strands and use these. They are strong and very flexible. (This string can also be used for the string in falling weight antiskate mechanisms.) If you know anyone who does archery try and score some fast-flight bow string, it's even better than dental floss.

Without having more information on bearing friction and the amount of play within the system it is difficult to estimate what the tracking error will be. Hopefully it will be significantly lower than the pivoted arm.

I hope this is helpful/informative

Niffy

If tracking angle errors are resolved via geometry and as you state groove angle and skate results in cumulative errors, would the error not be vanishingly small?

Is skate force direct prepositional to offset? What are the differences between 0° and 90°?

Should be very easy to model or mock that up.

Is skate force direct prepositional to offset? What are the differences between 0° and 90°?

Should be very easy to model or mock that up.

Four years ago, I did some experiments and tried to see the relationship between overhang and skating force. Here are the test results.

I used VPI table with VPI arm. VPI had no anti skating device. I also pulled signal wires out to tape it on the top of the arm base in order to avoid possible side force generated by the wires. A cartridge was mounted on the arm tube behind the center spindle in stead of on head shell. I named the distance between center of spindle and stylus as underhang which is in opposite of overhang. The cantilever was set so it was parallel to the center line of the arm tube. VTF was set as 1.8 g as normally it should be. On the table, I used a single side of LP. Its blank side faced up.

First, I set the underhang 1 cm. Please see the video.

1cm in out - YouTube

I dropped the needle as normally playing a record. You can see from the video. The cartridge moved toward to the center but it stopped at inner part of record. It became stationary. The cartridge didn’t move side ways any more although the table kept running. I lifted the arm and dropped it just on the edge of the center label. The arm started to move outwards. It stopped and kept stationary at same spot as the arm moved inwards. This indicates that at this particular spot, there was no skating force generated by moving table. The cantilever is tangential to the groove.

Then, I set the underhang at 2 cm and did same thing as above.

2cm in out - YouTube

You can see that the stationary spot moved to the middle of record. It means that the groove which was tangential to cantilever changed because the underhang had been changed. It was the groove in middle of the record. It indicated that the groove tangential to cantilever was different one now. I did same thing to drop the needle from inner part of record. You can see the arm moved from inner part of record towards outer part of record.

Finally, I set the underhang 4.5 cm which is almost maximum underhang I could do because the cartridge would drop off the record.

4 5cm in out - YouTube

From the video, you can see the arm moved fast towards the edge of the record. Then, it stopped on the outer edge of the record.

Here I use a graphic to summary what I found.

Red area indicates inward skating. Arm will move towards center of record. Green area indicates outward skating. Arm will move towards edge of record. Blue line is edge of both green area and red area. On the blue line, cantilever is tangential to the groove. Arm will be stationary without moving side ways. Therefore, there are no skating force if the stylus locates on the blue line. The force of skating increases when the stylus moves away from the blue line. So, as long as the arm meets two conditions, there is no skating force.

1. No offset angle.

2. Cantilever tangential to groove.

Carlo’s arm has no offset angle and its cantilever is suppose to be tangential to groove. Therefore, his arm doesn’t skate.

I used VPI table with VPI arm. VPI had no anti skating device. I also pulled signal wires out to tape it on the top of the arm base in order to avoid possible side force generated by the wires. A cartridge was mounted on the arm tube behind the center spindle in stead of on head shell. I named the distance between center of spindle and stylus as underhang which is in opposite of overhang. The cantilever was set so it was parallel to the center line of the arm tube. VTF was set as 1.8 g as normally it should be. On the table, I used a single side of LP. Its blank side faced up.

First, I set the underhang 1 cm. Please see the video.

1cm in out - YouTube

I dropped the needle as normally playing a record. You can see from the video. The cartridge moved toward to the center but it stopped at inner part of record. It became stationary. The cartridge didn’t move side ways any more although the table kept running. I lifted the arm and dropped it just on the edge of the center label. The arm started to move outwards. It stopped and kept stationary at same spot as the arm moved inwards. This indicates that at this particular spot, there was no skating force generated by moving table. The cantilever is tangential to the groove.

Then, I set the underhang at 2 cm and did same thing as above.

2cm in out - YouTube

You can see that the stationary spot moved to the middle of record. It means that the groove which was tangential to cantilever changed because the underhang had been changed. It was the groove in middle of the record. It indicated that the groove tangential to cantilever was different one now. I did same thing to drop the needle from inner part of record. You can see the arm moved from inner part of record towards outer part of record.

Finally, I set the underhang 4.5 cm which is almost maximum underhang I could do because the cartridge would drop off the record.

4 5cm in out - YouTube

From the video, you can see the arm moved fast towards the edge of the record. Then, it stopped on the outer edge of the record.

Here I use a graphic to summary what I found.

Red area indicates inward skating. Arm will move towards center of record. Green area indicates outward skating. Arm will move towards edge of record. Blue line is edge of both green area and red area. On the blue line, cantilever is tangential to the groove. Arm will be stationary without moving side ways. Therefore, there are no skating force if the stylus locates on the blue line. The force of skating increases when the stylus moves away from the blue line. So, as long as the arm meets two conditions, there is no skating force.

1. No offset angle.

2. Cantilever tangential to groove.

Carlo’s arm has no offset angle and its cantilever is suppose to be tangential to groove. Therefore, his arm doesn’t skate.

Last edited:

Beautifully done experiment. Sometimes it makes more sense, than just doing complicated maths, those anyway should be followed by experiment. So, if in Carlo's arm stylus will follow blue curve, it will not skate.Brilliant.

This thread is a champion! Congratulations to Directdriver, as you started it.

This thread is a champion! Congratulations to Directdriver, as you started it.

Last edited:

That blue line is an arc of an ellipse.

...isn't that why one of the designs discussed here relies on changing the effective length of the tonearm?

Had it been an arc of a circle, I would presume no need for variable length.

Build it... and it will skate.

Well-presented experiment. Everything you say is true - for the case of an arm with a fixed pivot. Carlo’s arm does not have a fixed pivot. To assume that the observed behavior of the fixed pivot arm in your experiment can be assigned to Carlo’s ‘two string slider’ leads you, and others, to the wrong conclusion. Yes, the stylus axis does pass through the pivot point, but there are additional forces applied by the string and pulley system.

It will skate. Build it and see.

Ray K

Red area indicates inward skating. Arm will move towards center of record. Green area indicates outward skating. Arm will move towards edge of record. Blue line is edge of both green area and red area. On the blue line, cantilever is tangential to the groove. Arm will be stationary without moving side ways. Therefore, there are no skating force if the stylus locates on the blue line. The force of skating increases when the stylus moves away from the blue line. So, as long as the arm meets two conditions, there is no skating force.

1. No offset angle.

2. Cantilever tangential to groove.

Carlo’s arm has no offset angle and its cantilever is suppose to be tangential to groove. Therefore, his arm doesn’t skate.

Well-presented experiment. Everything you say is true - for the case of an arm with a fixed pivot. Carlo’s arm does not have a fixed pivot. To assume that the observed behavior of the fixed pivot arm in your experiment can be assigned to Carlo’s ‘two string slider’ leads you, and others, to the wrong conclusion. Yes, the stylus axis does pass through the pivot point, but there are additional forces applied by the string and pulley system.

It will skate. Build it and see.

Ray K

Attachments

Hi 2wice,

With a conventional pivoted tonearm with the pivot at a fixed location the skating force is calculated as:

Sin (offset angle-geometric tracking error) x stylus drag.

As longer arms have smaller offset and less geometric error they produce less tracking error.

Stylus drag varies with tracking force, stylus profile, vinyl composition, record speed and groove modulation. Generally the coefficient of friction between a stylus and record varies from 0.3 for an unmodulated groove to 0.6 for one that is heavily modulated. Some stylus profiles do lead to higher coefficients of friction but the variation is not much greater. Whilst playing any single record the only major variation is groove modulation. As an aside, it is not a good idea to set antiskate using a blank record. You will set antiskate to be correct for an unmodulated groove. As soon as you have modulation the antiskate will be too low.

My calculations set antiskate to an average to give the lowest skating error. For a 9" arm the average tracking error due to the antiskate not perfectly balancing skating is about 0.25°, which is not massive in itself and is probably not much above the limit of what is audible.

Remember I am talking about the difference between the skating force and the antiskate force. If you were to not use an antiskate mechanism the errors would be massively higher.

It is possible to make an antiskate mechanism that accounts for the slight variation due to tracking angle. This will slightly reduce lateral tracking error. This figure is calculated for a relatively high compliance cartridge. The error with a lower compliance cartridge will tend to be less though this will depend upon how high the tracking force is.

With a tangential arm with variable offset the skating force is calculated as:

Sin (offset) x stylus drag.

Again, is is possible to compensate for the variation in offset to give a variable antiskate.

Hi Jim,

Nice experiment. The results are exactly as theory would suggest. There is however a marked difference between your experiment and Carlo's design. In your example the pivot point and arm length are both fixed and you get only a single point where there is no skating. You have to physically change the length of the arm to change the zero skating point. In Carlo's design the length of the arm varies and is determined by the angle of the arm. Have a look at Carlo's diagram, look at the middle diagram on the left.

The stylus drag pulls the arm in line with the pivot to the left. The arm is prevented from moving to the left by the red string. This puts the red string into tension. The level of tension in the string is equal to the stylus drag. The level of tension is equal at all points along its length. Where the string passes around the rear bearing it turns through roughly 90°. The rear of the arm will be pushed sideways with a force of approximately equal to the stylus drag. The level of skating will be equal to stylus drag divided by the ratio of the lengths of the front section of the arm to the rear section. As the arm tracks across the record this ratio increases. Therefore the level of skating will decrease as the arm moves towards the centre of the record.

Niffy

With a conventional pivoted tonearm with the pivot at a fixed location the skating force is calculated as:

Sin (offset angle-geometric tracking error) x stylus drag.

As longer arms have smaller offset and less geometric error they produce less tracking error.

Stylus drag varies with tracking force, stylus profile, vinyl composition, record speed and groove modulation. Generally the coefficient of friction between a stylus and record varies from 0.3 for an unmodulated groove to 0.6 for one that is heavily modulated. Some stylus profiles do lead to higher coefficients of friction but the variation is not much greater. Whilst playing any single record the only major variation is groove modulation. As an aside, it is not a good idea to set antiskate using a blank record. You will set antiskate to be correct for an unmodulated groove. As soon as you have modulation the antiskate will be too low.

My calculations set antiskate to an average to give the lowest skating error. For a 9" arm the average tracking error due to the antiskate not perfectly balancing skating is about 0.25°, which is not massive in itself and is probably not much above the limit of what is audible.

Remember I am talking about the difference between the skating force and the antiskate force. If you were to not use an antiskate mechanism the errors would be massively higher.

It is possible to make an antiskate mechanism that accounts for the slight variation due to tracking angle. This will slightly reduce lateral tracking error. This figure is calculated for a relatively high compliance cartridge. The error with a lower compliance cartridge will tend to be less though this will depend upon how high the tracking force is.

With a tangential arm with variable offset the skating force is calculated as:

Sin (offset) x stylus drag.

Again, is is possible to compensate for the variation in offset to give a variable antiskate.

Hi Jim,

Nice experiment. The results are exactly as theory would suggest. There is however a marked difference between your experiment and Carlo's design. In your example the pivot point and arm length are both fixed and you get only a single point where there is no skating. You have to physically change the length of the arm to change the zero skating point. In Carlo's design the length of the arm varies and is determined by the angle of the arm. Have a look at Carlo's diagram, look at the middle diagram on the left.

The stylus drag pulls the arm in line with the pivot to the left. The arm is prevented from moving to the left by the red string. This puts the red string into tension. The level of tension in the string is equal to the stylus drag. The level of tension is equal at all points along its length. Where the string passes around the rear bearing it turns through roughly 90°. The rear of the arm will be pushed sideways with a force of approximately equal to the stylus drag. The level of skating will be equal to stylus drag divided by the ratio of the lengths of the front section of the arm to the rear section. As the arm tracks across the record this ratio increases. Therefore the level of skating will decrease as the arm moves towards the centre of the record.

Niffy

Carlo’s arm does not have a fixed pivot.

Just to make sure I understand - assuming a design can be implemented to:

1. Retain a fixed pivot point, and,

2. Allow for variable length to follow an eclipse arc...

...there should be no skating?

Sin(0°) = 0

0*(drag force) = 0

Looks right to me. ;p

This does give me an idea to more closely simulate modulated grooves while still keeping the possibility of drift.

I wonder if it is possible to chemically etch a blank disc to roughness that will simulate ~3000hz.

0*(drag force) = 0

Looks right to me. ;p

This does give me an idea to more closely simulate modulated grooves while still keeping the possibility of drift.

I wonder if it is possible to chemically etch a blank disc to roughness that will simulate ~3000hz.

Ray and Niffy,

I don’t think the pivot on his arm changes. Please see his drawing. In his design, there are two pivots. P( yellow dot), horizontal pivot is the real pivot. The other one, vertical pivot, is for vertical movements only. Although vertical pivot moves back and forth following a straight line, but it doesn’t change the geometry at all. What changes in his designs is effective length only. Let us assume an arm geometry is R.W. Birch’s. Its pivot changes. But it doesn’t matter, as long as the arm has no offset angle and its cantilever is tangential to groove. There will be no skating force. Carlo uses a term, under-hang errors in his design. If such errors exist, it will cause cantilever not to be tangential to groove. So, there will be slight skating force. So it doesn’t satisfy my two conditions for nonexistence of skating. This why I said before that his design was SUPPOSE to have no tracking errors. In reality, his arm may have some tracking errors due to the existence of his under-hang errors. In other words, in some areas, the cantilever is not tangential to groove.

I don’t care how complicate the driving mechanism is. For all the tangential pivot arms, if the stylus sees different behavior of a tangential pivot from regular pivot, there will be problems. All the tangential pivot should act as regular pivot from the view of stylus. Or at least, the behavior of a tangential pivot should be as close to regular pivot as possible. Otherwise, in my opinion, such arm is not up to a high-fidelity level yet.

In Ray’s drawing, there is a side force to act upon the stylus. It is not good. It means the designs is not perfect or making of arm is not as accurate as it should be. In reality, groove is a spiral, so it will produce some pulling force. But it is not skating force as we are talking about here. From the mechanism of the arm, it doesn't produce skating force.

Jim

I don’t think the pivot on his arm changes. Please see his drawing. In his design, there are two pivots. P( yellow dot), horizontal pivot is the real pivot. The other one, vertical pivot, is for vertical movements only. Although vertical pivot moves back and forth following a straight line, but it doesn’t change the geometry at all. What changes in his designs is effective length only. Let us assume an arm geometry is R.W. Birch’s. Its pivot changes. But it doesn’t matter, as long as the arm has no offset angle and its cantilever is tangential to groove. There will be no skating force. Carlo uses a term, under-hang errors in his design. If such errors exist, it will cause cantilever not to be tangential to groove. So, there will be slight skating force. So it doesn’t satisfy my two conditions for nonexistence of skating. This why I said before that his design was SUPPOSE to have no tracking errors. In reality, his arm may have some tracking errors due to the existence of his under-hang errors. In other words, in some areas, the cantilever is not tangential to groove.

I don’t care how complicate the driving mechanism is. For all the tangential pivot arms, if the stylus sees different behavior of a tangential pivot from regular pivot, there will be problems. All the tangential pivot should act as regular pivot from the view of stylus. Or at least, the behavior of a tangential pivot should be as close to regular pivot as possible. Otherwise, in my opinion, such arm is not up to a high-fidelity level yet.

In Ray’s drawing, there is a side force to act upon the stylus. It is not good. It means the designs is not perfect or making of arm is not as accurate as it should be. In reality, groove is a spiral, so it will produce some pulling force. But it is not skating force as we are talking about here. From the mechanism of the arm, it doesn't produce skating force.

Jim

Attachments

Last edited:

Ray and Niffy,

... It means the designs is not perfect or making of arm is not as accurate as it should be. In reality, groove is a spiral, so it will produce some pulling force. But it is not skating force as we are talking about here. From the mechanism of the arm, it doesn't produce skating force.

Jim

Make the design as perfect as you like, this arm will still still skate. Don't know how to make you see what you're missing.

Ray K

2wice,

Yup, there's that ellipse arc again. Good catch. I believe it's also in Carlo's most recent drawings and that it showed up in the model I built. I hope that's true because it means Carlo's "gadget" is seriously tangent.

Super10018,

The "under hang errors" in Carlo's drawing may be the result of forcing the Birch geometry where it's not really appropriate. Back two or three hundred posts, Jonathan Carr found tracking errors in the Birch geometry. If the track across the LP for Carlo's arm is the correct ellipse arc, those errors may well disappear.

Yup, there's that ellipse arc again. Good catch. I believe it's also in Carlo's most recent drawings and that it showed up in the model I built. I hope that's true because it means Carlo's "gadget" is seriously tangent.

Super10018,

The "under hang errors" in Carlo's drawing may be the result of forcing the Birch geometry where it's not really appropriate. Back two or three hundred posts, Jonathan Carr found tracking errors in the Birch geometry. If the track across the LP for Carlo's arm is the correct ellipse arc, those errors may well disappear.

Last edited:

Do current highend pivoted quasi linear or 90 degree tangential tonearm incorporate antiskate in them ? Why they included or not included antiskate would be worth investigating.

Regards.

Regards.

Thank you all for these deep analysis, and thank you Super10018: your description is perfect! Evidently my English and my graph are not so clear, because I have said these things since the post with the first idea of this arm.

Geometry - Everything I've tried is to make a damn Thales with the horizontal pivot exactly and steadily where the good old Thales wanted. Seems absurd but there is no one around, maybe is too silly. Since this arm (which is a catheter and not a radius) must have a variable length, it is inevitable that it will have a variable vertical pivot. Are you worried about it? I'm more worried by the CG shifts of the counterweights.

Guiding - to perform this geometry, we need the force for the elongation: Various incarnations of Birch arms rely directly on the stylus drag (what happens during instant variations?) mine uses indirectly what moves quite all the arms of the world, the side force from the spiral groove, with a force multiplied through a 4: 1 leverarm.

Skating: now I'm convinced that here comes not only from the "arm problems" but even from geometry - alighiszem post has spurred me to look for it. Doug "string test" confirms that, my mockup without bearings, instead, made me wrongly think the opposite. However skate is hopefully far less than others for both the direction and the 1:4 disadvantage you get (said this too)

Underhang: my guiding gadget derives from the difference of the length of the catheter and that of the radius during tracking. Graphically it seems a linear function that I tried to get in that way. On the mock up I found an error of + - 1,5mm, that never gave me any problems. Prototype wil have a rear pulleys fine tuning to select the best nullpoint.

Now I leave you to the debate on skating, sometimes unfruitful, but always exciting. I'm searching a linear bearing solution that avoids issues I know. I'm desperate, I even looked at the "Rolamite"...

ciao carlo

Niffy thanks, but... dental floss? for my arms just Dyneema 1999 - mixed, not stirred....

Geometry - Everything I've tried is to make a damn Thales with the horizontal pivot exactly and steadily where the good old Thales wanted. Seems absurd but there is no one around, maybe is too silly. Since this arm (which is a catheter and not a radius) must have a variable length, it is inevitable that it will have a variable vertical pivot. Are you worried about it? I'm more worried by the CG shifts of the counterweights.

Guiding - to perform this geometry, we need the force for the elongation: Various incarnations of Birch arms rely directly on the stylus drag (what happens during instant variations?) mine uses indirectly what moves quite all the arms of the world, the side force from the spiral groove, with a force multiplied through a 4: 1 leverarm.

Skating: now I'm convinced that here comes not only from the "arm problems" but even from geometry - alighiszem post has spurred me to look for it. Doug "string test" confirms that, my mockup without bearings, instead, made me wrongly think the opposite. However skate is hopefully far less than others for both the direction and the 1:4 disadvantage you get (said this too)

Underhang: my guiding gadget derives from the difference of the length of the catheter and that of the radius during tracking. Graphically it seems a linear function that I tried to get in that way. On the mock up I found an error of + - 1,5mm, that never gave me any problems. Prototype wil have a rear pulleys fine tuning to select the best nullpoint.

Now I leave you to the debate on skating, sometimes unfruitful, but always exciting. I'm searching a linear bearing solution that avoids issues I know. I'm desperate, I even looked at the "Rolamite"...

ciao carlo

Niffy thanks, but... dental floss? for my arms just Dyneema 1999 - mixed, not stirred....

Last edited:

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms