Take your average 1,4" inch compression driver and put it in an undersized horn, you'll still typically get a natural rolloff at about 500-600 Hz.

Other than the horn losing pattern control this low, is there any other reason not to make use of this extension in a home setting with a brick-wall high pass filter at say ~400 Hz?

Other than the horn losing pattern control this low, is there any other reason not to make use of this extension in a home setting with a brick-wall high pass filter at say ~400 Hz?

Last edited:

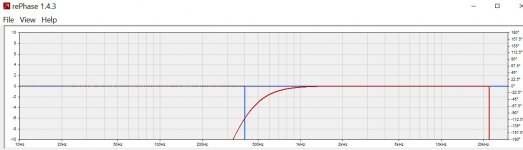

Stay aware that steep high pass corners can greatly increase loading at the corner, relative to conventional order xovers.

The red trace is a LR 24 dB/oct, which by nature is -6dB at 400Hz xover.

Blue is a 400Hz brick wall.

The brick wall's 6dB higher level allows double the voltage and excursion at the 400Hz knee.....(compared to the LR24)

The red trace is a LR 24 dB/oct, which by nature is -6dB at 400Hz xover.

Blue is a 400Hz brick wall.

The brick wall's 6dB higher level allows double the voltage and excursion at the 400Hz knee.....(compared to the LR24)

In listening terms compression drivers on short horns sound "Blatty" to me when driven hard.(Beak up?) Before reaching that point they tend to sound too direct, like I"m hearing the driver and not the music. A deeper horn give me the sound of the recording, not the speaker. Just my personal observations. Distortion is likely the cause of what I heard.

Stay aware that steep high pass corners can greatly increase loading at the corner, relative to conventional order xovers.

The red trace is a LR 24 dB/oct, which by nature is -6dB at 400Hz xover.

Blue is a 400Hz brick wall.

The brick wall's 6dB higher level allows double the voltage and excursion at the 400Hz knee.....(compared to the LR24)

View attachment 979375

My thought was to utilise the driver rolloff for ~LR24 (acoustic) at 500-600 Hz.

Then do a steep DSP filter somewhere below that for driver protection.

Smaller the horn in the terms of loading the closer you are to the sound of a waveguide excluding dispersion

If the compression driver sounds decent without a horn, it would definitely sound good with one, and much better with a filter. However, it may necessary to exercise some caution while trying this, in order to avoid damage.

Example (from 3:45): PA-DE99 Tweeter P-audio,made in Thailand.bound to Batasan Q.C. - YouTube

Example (from 3:45): PA-DE99 Tweeter P-audio,made in Thailand.bound to Batasan Q.C. - YouTube

Last edited:

My thought was to utilise the driver rolloff for ~LR24 (acoustic) at 500-600 Hz.

Then do a steep DSP filter somewhere below that for driver protection.

Gotcha.

How far down will you need the CD to sum? If to say to -12dB, like in LR 24 graph posted above, the brick wall would need to move down to about 300Hz.

My take is once 12dB down, the CD probable doesn't need any more protection than the LR24 continues to give on its own, going lower..

So i think it comes back to the knee area.

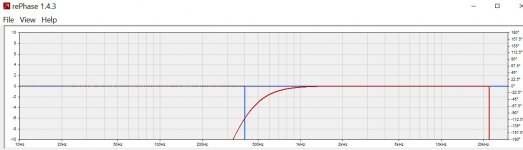

I've decided a linear-phase LR 48 dB/oct is a good compromise for taking a CD low and not banging the knee area too hard.

Here's a LR48 at 400 Hz against a LR24,

Gotcha.

How far down will you need the CD to sum? If to say to -12dB, like in LR 24 graph posted above, the brick wall would need to move down to about 300Hz.

My take is once 12dB down, the CD probable doesn't need any more protection than the LR24 continues to give on its own, going lower..

So i think it comes back to the knee area.

I've decided a linear-phase LR 48 dB/oct is a good compromise for taking a CD low and not banging the knee area too hard.

Here's a LR48 at 400 Hz against a LR24,

View attachment 979448

Goal is to take the CD down as far as possible. Whether it be LR or some other topology.

The general rule is to cross 1 octave above horn cutoff.

But I reckon this is purely for maintaining dispersion? (HD shouldn't be an issue for home use)

Taking the driver below horn cutoff should help mate with a smaller woofer however, where both will have wide dispersion characteristics. But you hardly ever see horns and CD's being crossed at the natural low-end driver rolloff.

Smaller the horn in the terms of loading the closer you are to the sound of a waveguide excluding dispersion

What would "the sound of a waveguide excluding dispersion" be like? 🙂

In listening terms compression drivers on short horns sound "Blatty" to me when driven hard.(Beak up?) Before reaching that point they tend to sound too direct, like I"m hearing the driver and not the music. A deeper horn give me the sound of the recording, not the speaker. Just my personal observations. Distortion is likely the cause of what I heard.

Like this lol....not speaking from personal experience but I've interviewed many people in my thread on various topics, and recall some describing the sound of compression drivers in a waveguide just like Pano has said above....

A horn is also a waveguide and a waveguide is not horn....loading is the main characteristic that separates the two...so the less (higher) loading, the more you are leaning towards it just being a waveguide

"Distortion is likely the cause of what I hear" - due to higher excursion is my prediction.

Like this lol....not speaking from personal experience but I've interviewed many people in my thread on various topics, and recall some describing the sound of compression drivers in a waveguide just like Pano has said above....

A horn is also a waveguide and a waveguide is not horn....loading is the main characteristic that separates the two...so the less (higher) loading, the more you are leaning towards it just being a waveguide

"Distortion is likely the cause of what I hear" - due to higher excursion is my prediction.

Hmm, interesting. It's kind of the opposite of what I'm used to reading. Shallow constant directivity waveguides seem to be generally preferred over deep horns.

Here's an example of Faital HF142 in LTH142 using the natural rolloff of the driver for a LR4@630 Hz with a LR6 DSP filter at 400 Hz for protection:

Good idea, bad idea?

Attachments

A horn is also a waveguide and a waveguide is not horn....loading is the main characteristic that separates the two...so the less (higher) loading, the more you are leaning towards it just being a waveguide

"Distortion is likely the cause of what I hear" - due to higher excursion is my prediction.

Right, all horns load via narrowing directivity and compression horns via added variable directivity, i.e. slower expansion based on its frequency, flare factor.

True if not properly designed, i.e. my [4] octave 'rule' for sizing WGs.

Last edited:

Hmm, interesting. It's kind of the opposite of what I'm used to reading. Shallow constant directivity waveguides seem to be generally preferred over deep horns.

Here's an example of Faital HF142 in LTH142 using the natural rolloff of the driver for a LR4@630 Hz with a LR6 DSP filter at 400 Hz for protection:

Good idea, bad idea?

Just try it. But the drivers xyz positions are bot 0/0/0. Could you check this? Otherwise you will not get correct results. Generally, if both drivers are aligned to the fron the HF part must become negative with respect to the woofer for longer horns like LTH142.

The sound of a diaphragm hammering the phase plug, not pleasant in any way.Goal is to take the CD down as far as possible. Whether it be LR or some other topology.

The general rule is to cross 1 octave above horn cutoff.

But I reckon this is purely for maintaining dispersion? (HD shouldn't be an issue for home use)

What would "the sound of a waveguide excluding dispersion" be like? 🙂

You'll know it when you hear it! If using aluminum or beryllium diaphragms, won't take too long before you hear the "sounds of silence"

Crossing an octave above Fc has everything to do with excursion (and decent sound quality), little to do with dispersion.

Just try it. But the drivers xyz positions are bot 0/0/0. Could you check this? Otherwise you will not get correct results. Generally, if both drivers are aligned to the fron the HF part must become negative with respect to the woofer for longer horns like LTH142.

This isn't a serious simulation, just a something quick to illustrate the point 🙂

The sound of a diaphragm hammering the phase plug, not pleasant in any way.

You'll know it when you hear it! If using aluminum or beryllium diaphragms, won't take too long before you hear the "sounds of silence"

Crossing an octave above Fc has everything to do with excursion (and decent sound quality), little to do with dispersion.

I just can't imagine excursion being an issue at home listening levels. I've ran full-range test sweeps (by accident) through a DE250 before at pretty loud levels with no audible distortion, and much less the diaphragm slamming the phase plug. At least with an L-pad in place flattening the resonance peaks (which I had on the DE250). But that's just my own experience.

Last edited:

Defo,I just can't imagine excursion being an issue at home listening levels. I've ran full-range test sweeps (by accident) through a DE250 before at pretty loud levels with no audible distortion, and much less the diaphragm slamming the phase plug. At least with an L-pad in place flattening the resonance peaks (which I had on the DE250). But that's just my own experience.

At 400 Hz, a wide angle (90 degree) "waveguide" or "undersized horn" will provide very little gain, the output level would be little more than that of a similar size cone driver with similar excursion.

Most HF compression drivers have little more than 0.5mm distance between the diaphragm and phase plug, few have more than 0.8mm.

The DE250 has a 1.7" (44mm) diameter diaphragm, at 400 Hz it should do about 87dB before the diaphragm hits the phase plug, a 3" could do about 97dB (peak) at one meter.

Polyimide diaphragms (like in the DE 250) won't sound as bad as metal when they hit the phase plug- kind of like the difference between substituting a Frisbee for a cymbal 😉.

If the drivers don't ever exceed that level, no problem.

Just for the experience, play a 400 Hz tone through the horn/driver at a "pretty loud level", then add in a 1kHz tone, tell us what you think of the 1400 & 1800 Hz tones you hear in addition.

Art

Attachments

Defo,

At 400 Hz, a wide angle (90 degree) "waveguide" or "undersized horn" will provide very little gain, the output level would be little more than that of a similar size cone driver with similar excursion.

Most HF compression drivers have little more than 0.5mm distance between the diaphragm and phase plug, few have more than 0.8mm.

The DE250 has a 1.7" (44mm) diameter diaphragm, at 400 Hz it should do about 87dB before the diaphragm hits the phase plug, a 3" could do about 97dB (peak) at one meter.

Polyimide diaphragms (like in the DE 250) won't sound as bad as metal when they hit the phase plug- kind of like the difference between substituting a Frisbee for a cymbal 😉.

If the drivers don't ever exceed that level, no problem.

Just for the experience, play a 400 Hz tone through the horn/driver at a "pretty loud level", then add in a 1kHz tone, tell us what you think of the 1400 & 1800 Hz tones you hear in addition.

Art

Great info, thanks!

Take a look at this Faital HF142 + LTH142 combo I simulated earlier:

Test Bench: FaitalPRO HF142 Compression Driver Coupled with LTH142 60degx50deg Horn | audioXpress

97 db at 400 Hz would mean 109 db at 600 Hz (12 db higher in level), so that should work out fine one would think?

Regarding playing a 400 Hz tone then a 1 kHz tone; is it intermodulation distortion you're aiming at here? Or something unique to horns?

When CDs are used below the horn loading frequency, the excursion rises a lot. Excursion rises the distortion and if the VC leaves the pole plate, the excursion causes an explosion of distortion because of the underhung construction of practically every an dall CDs.

The whole problem simmers down to what dispersion, which dispersion (/control) and which spl is needed.

The whole problem simmers down to what dispersion, which dispersion (/control) and which spl is needed.

Are you sure.. horn loading is not so much about holding the diaphragm back, as it is about radiation resistance.

Greetings all,

for the moron(s) like yours truly, what does the term "undersized horn" mean?

Kindest regards,

M

for the moron(s) like yours truly, what does the term "undersized horn" mean?

Kindest regards,

M

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Compression drivers in undersized horns