DIY 200-Watt Portable Bluetooth Speaker Build – Seeking Feedback and Suggestions on Battery Set-up

Hey everyone,

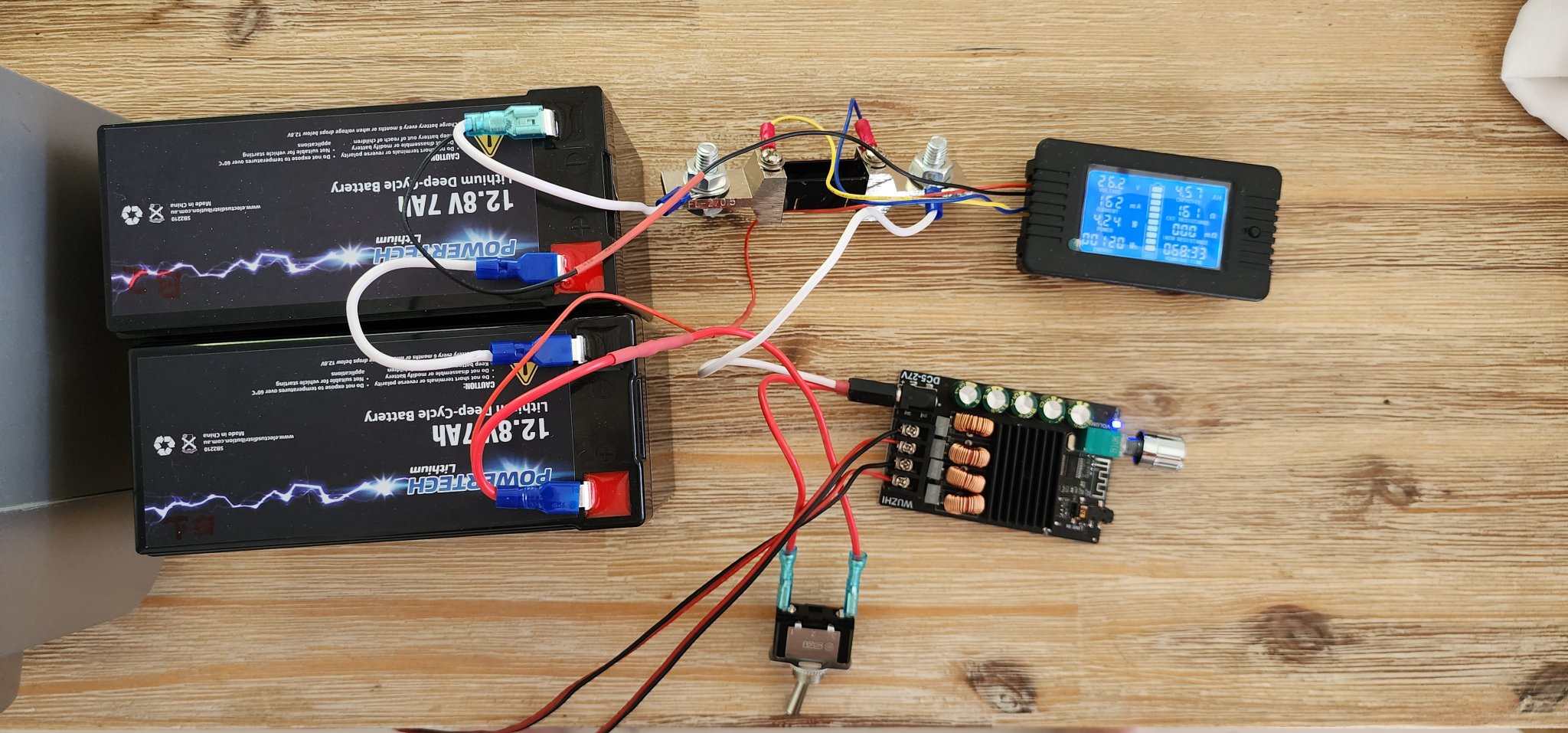

I've just completed a DIY project where I built a 200-Watt portable Bluetooth speaker. I have chosen the components to suit two 100-Watt speakers I had from an old Panasonic unit, with a focus on loudness and battery life. The housing/box for the speakers are quite large, so I knew this would be a ‘not so portable’ set-up.

Here are the components:

· Battery Pack: 2x 12.8V 7Ah lithium deep cycle batteries (configured in series for a total of 25.6V).

· Speakers: A pair of Panasonic sb-ak230 speakers that are 100-Watts each and an impedance of 5 Ohms (speakers are from an old Panasonic unit I had).

· Amplifier: A class D 200W Bluetooth Amplifier Board ‘TPA3116 DAMGOO 100W+100W Audio Amp Board with LC’ that operates between 5V and 28V.

· DC Meter: A 200A 6.5-200V DC Power Battery Meter with External Shunt.

· Off/On Switch: A Narva Off And On Metal Toggle Switch with an Amperage rating 20A at 12V, 10A at 24V.

· Wiring: 15A Twin Core Power Cable.

· Connections: Narva 4mm Clear Electrical Terminal Female Blade Connector

Total Cost: $600 dollars AU. This is very expensive where I could go and buy a great portable bluetooth speaker from the shops or online, that would be louder, more portable and have better sound quality- but I did it as a fun project and to learn as well.

Sound Quality and performance:

This set-up is very loud. I did not expect it to be. As for the sound quality, I think it sounds just as good, if not better, than when it was attached to the Panasonic unit that I bought back in 2005. There is a lot of bass, but it is well balanced and not overpowering. Even near or at max volume, the sound does not distort. Although. the highlight is the battery life. According to my DC meter, I have used 3.42 Ah of the 7Ah the battery pack has. Now this is based on the 2.67 Watts of power that is currently being used while listening to a song, with the volume dial roughly a quarter way out of the max volume. So far, the speakers have been running for 50 hours and 37 minutes. Of course, the running time of the battery pack will vary, and will last a lot less the louder I make it. But so far, a quarter way of the volume is plenty for a small gathering.

The next thing I will need to do is make a housing for the battery pack, amplifier, DC meter, etc, and attach it to the speaker’s housing.

200-Watt portable Bluetooth speaker build information:

I arranged the two 12.8V 7Ah lithium deep cycle batteries in series to meet the voltage requirements to work with the two 100-Watt speakers. So far, I am taking out each individual battery to charge them. The people at Jaycar told me that I would be able to attach a 12v lithium battery charger inp arallel to the batteries which are in series, However, a friend of mine said that I can do this but won’t be able to charge the batteries whilst having the speakers on to play music at the same time. I could buy a 24V lithium charger for this set-up, but they are very expensive.

The next issue I was worried about is that I don’t have a Battery Management System (BMS) for this set-up. The people at Jaycar also said that the 12.8V 7Ah lithium deep cycle batteries have their own built-in BMS and that I wouldn’t need one. After researching online, apparently the built-in BMS in these batteries may not work when they are configured in series.

I am seeking feedback on this build as this is my first project I have done regarding a portable Bluetooth speaker. I understand that some of the components are excessive regarding the power running through the circuit. Here are a few points I'm particularly seeking feedback on:

· Circuit Design: Any suggestions for improving the efficiency or safety of the current circuitry?

· Battery Management: Ideas for charging the batteries while using the speakers at the same time.

· Sound Quality: Recommendations for enhancing audio quality, maybe through equalizer settings or additional components?

I've attached some photos of my setup and would appreciate your insights, critiques, and ideas for further improvements. If you've done something similar or have expertise in electronics and audio systems, your input would be valuable.

Hey everyone,

I've just completed a DIY project where I built a 200-Watt portable Bluetooth speaker. I have chosen the components to suit two 100-Watt speakers I had from an old Panasonic unit, with a focus on loudness and battery life. The housing/box for the speakers are quite large, so I knew this would be a ‘not so portable’ set-up.

Here are the components:

· Battery Pack: 2x 12.8V 7Ah lithium deep cycle batteries (configured in series for a total of 25.6V).

· Speakers: A pair of Panasonic sb-ak230 speakers that are 100-Watts each and an impedance of 5 Ohms (speakers are from an old Panasonic unit I had).

· Amplifier: A class D 200W Bluetooth Amplifier Board ‘TPA3116 DAMGOO 100W+100W Audio Amp Board with LC’ that operates between 5V and 28V.

· DC Meter: A 200A 6.5-200V DC Power Battery Meter with External Shunt.

· Off/On Switch: A Narva Off And On Metal Toggle Switch with an Amperage rating 20A at 12V, 10A at 24V.

· Wiring: 15A Twin Core Power Cable.

· Connections: Narva 4mm Clear Electrical Terminal Female Blade Connector

Total Cost: $600 dollars AU. This is very expensive where I could go and buy a great portable bluetooth speaker from the shops or online, that would be louder, more portable and have better sound quality- but I did it as a fun project and to learn as well.

Sound Quality and performance:

This set-up is very loud. I did not expect it to be. As for the sound quality, I think it sounds just as good, if not better, than when it was attached to the Panasonic unit that I bought back in 2005. There is a lot of bass, but it is well balanced and not overpowering. Even near or at max volume, the sound does not distort. Although. the highlight is the battery life. According to my DC meter, I have used 3.42 Ah of the 7Ah the battery pack has. Now this is based on the 2.67 Watts of power that is currently being used while listening to a song, with the volume dial roughly a quarter way out of the max volume. So far, the speakers have been running for 50 hours and 37 minutes. Of course, the running time of the battery pack will vary, and will last a lot less the louder I make it. But so far, a quarter way of the volume is plenty for a small gathering.

The next thing I will need to do is make a housing for the battery pack, amplifier, DC meter, etc, and attach it to the speaker’s housing.

200-Watt portable Bluetooth speaker build information:

I arranged the two 12.8V 7Ah lithium deep cycle batteries in series to meet the voltage requirements to work with the two 100-Watt speakers. So far, I am taking out each individual battery to charge them. The people at Jaycar told me that I would be able to attach a 12v lithium battery charger inp arallel to the batteries which are in series, However, a friend of mine said that I can do this but won’t be able to charge the batteries whilst having the speakers on to play music at the same time. I could buy a 24V lithium charger for this set-up, but they are very expensive.

The next issue I was worried about is that I don’t have a Battery Management System (BMS) for this set-up. The people at Jaycar also said that the 12.8V 7Ah lithium deep cycle batteries have their own built-in BMS and that I wouldn’t need one. After researching online, apparently the built-in BMS in these batteries may not work when they are configured in series.

I am seeking feedback on this build as this is my first project I have done regarding a portable Bluetooth speaker. I understand that some of the components are excessive regarding the power running through the circuit. Here are a few points I'm particularly seeking feedback on:

· Circuit Design: Any suggestions for improving the efficiency or safety of the current circuitry?

· Battery Management: Ideas for charging the batteries while using the speakers at the same time.

· Sound Quality: Recommendations for enhancing audio quality, maybe through equalizer settings or additional components?

I've attached some photos of my setup and would appreciate your insights, critiques, and ideas for further improvements. If you've done something similar or have expertise in electronics and audio systems, your input would be valuable.

Attachments

Probably you need a proper supply for giving 24V@~10A and a switch for battery/ mains operation.

Strange that you cannot find 24( 29 indeed!) Volt chargers for under $50...I got two from bikes being stolen!

Strange that you cannot find 24( 29 indeed!) Volt chargers for under $50...I got two from bikes being stolen!

About the sound...I'd start from the speakers by removing the plastic cover and see the nude drivers, then rearrange them to make a clean design. You'll need to cut a new baffle onto the old one and cut the circles for drivers. Eventual ducts might be placed later. Drivers must have each the extension of the terminals so they can be arranged without having to have access to the inside of the box.

The drivers might benefit for having T-nuts and the tweeter can be accomodated outside the acoustic box for the woofer, or have a separated chamber, to kill losses and structural deficiency from the start!

Probably you'll find the box without any damping stuff inside, so that's another chapter.

The drivers might benefit for having T-nuts and the tweeter can be accomodated outside the acoustic box for the woofer, or have a separated chamber, to kill losses and structural deficiency from the start!

Probably you'll find the box without any damping stuff inside, so that's another chapter.

Last edited:

About batteries, each battery should be charged and selected individually, then mounted in S/P to obtain the V and A needed. The BMS control each pack of paralleled batteries to let insert into the circuit with constant drain of current, so that it makes safety operation and not let some cells dying from over current (or maybe the opposite?! )...this also during the charge

Hi Picowallspeaker and Mark,

Thank you for your advice. This helped a lot. I will be fixing/implementing what you both said to make this sound better and be more safe.

Thank you for your advice. This helped a lot. I will be fixing/implementing what you both said to make this sound better and be more safe.

100W over several hours... do not drain batteries more than 20% rate, or else accidents like fire will happen, fuse are essential with those things!

So think of a bigger battery.

You do get battery control chips, use those to control a relay, solid state or mechanical, make sure it has huge breaking strength.

And, think of a trolley type speaker frame, makes it easier to handle, the kind used for suit cases.

So think of a bigger battery.

You do get battery control chips, use those to control a relay, solid state or mechanical, make sure it has huge breaking strength.

And, think of a trolley type speaker frame, makes it easier to handle, the kind used for suit cases.

- Home

- Amplifiers

- Power Supplies

- DIY 200-Watt Portable Bluetooth Speaker Build – Seeking Feedback and Suggestions on Battery Set-up.