I'm having trouble finding a supplier that has the correctly magnetized flexible magnetic strip. All I can find are multi pole and no single pole. Anybody know of a reliable supplier for this material in the USA?

Thx, Brent

Thx, Brent

Some neodymium-based ones here. They're not cheap though. If you're doing a small experiment, might get you through.

https://www.mcmaster.com/magnets/conformable-magnets-for-irregular-surfaces/

"Through thickness" is the typical term for the magnetization you're looking for. Here are a couple flexible magnet suppliers that say they can provide it, but I don't know what kind of volumes are required. I didn't search exhaustively, so there may be someone else out there that stocks it.

https://www.rochestermagnet.com/flexible-magnets/flexible-magnetic-strip

https://www.adamsmagnetic.com/flexible-magnets/flexible-strip/

https://www.mcmaster.com/magnets/conformable-magnets-for-irregular-surfaces/

"Through thickness" is the typical term for the magnetization you're looking for. Here are a couple flexible magnet suppliers that say they can provide it, but I don't know what kind of volumes are required. I didn't search exhaustively, so there may be someone else out there that stocks it.

https://www.rochestermagnet.com/flexible-magnets/flexible-magnetic-strip

https://www.adamsmagnetic.com/flexible-magnets/flexible-strip/

I contacted Rochester and they can do it for $1.00/foot plus shipping. Adams says they don't normally do retail stuff but could do it for $.65/foot.

Neo magnets...yikes! I'm too cheap to pay for those. There must be a cheaper solution. I bought 25 feet of the wrong stuff at hobby lobby for $6.

The search continues.

Thx for the links though.

Brent

Neo magnets...yikes! I'm too cheap to pay for those. There must be a cheaper solution. I bought 25 feet of the wrong stuff at hobby lobby for $6.

The search continues.

Thx for the links though.

Brent

I looked at the fridge gaskets and it will be more expensive by the time I get 150 feet of it. Most of it is also isotropic magnetized with multiple poles along its surface. Do you have a link to something that would work?

Brent

Brent

I guess yes, those are magnetized (duh!!) BUT multipolar, meaning they are magnetized in bands across their width, alternating poles every few inches.Here the parts shops sell by length, so much per foot.

Good to hold to thin steel plate (such as fridge doors, metallic announcement panels, office filing cabinets, etc.) so that is the preferred way and most commonly available but I guess Gooey wants it magnetized all in the same direction for some personal project.

Probably Audio related? 😉

@Gooey1 : IF so, remember those are very weak magnets, barely holding their own (light) weight against a fridge door or something.

Only practical "Audio" use I ever saw for them is in some Bass Guitar pickups, which used a loosely wound coil around a strip of so called "magnetic rubber" , just glorified fridge magnetic gasket material, and even so, a popular Mod was to remove it and place a rectangular bar of Alnico or ferrite bar instead, which increased pickup output big time.

But hey, experimenting is King.

Didn I mention it´s also FUN???

And every Magnepan planar driverOnly practical "Audio" use I ever saw for them is in some Bass Guitar pickups, which used a loosely wound coil around a strip of so called "magnetic rubber"

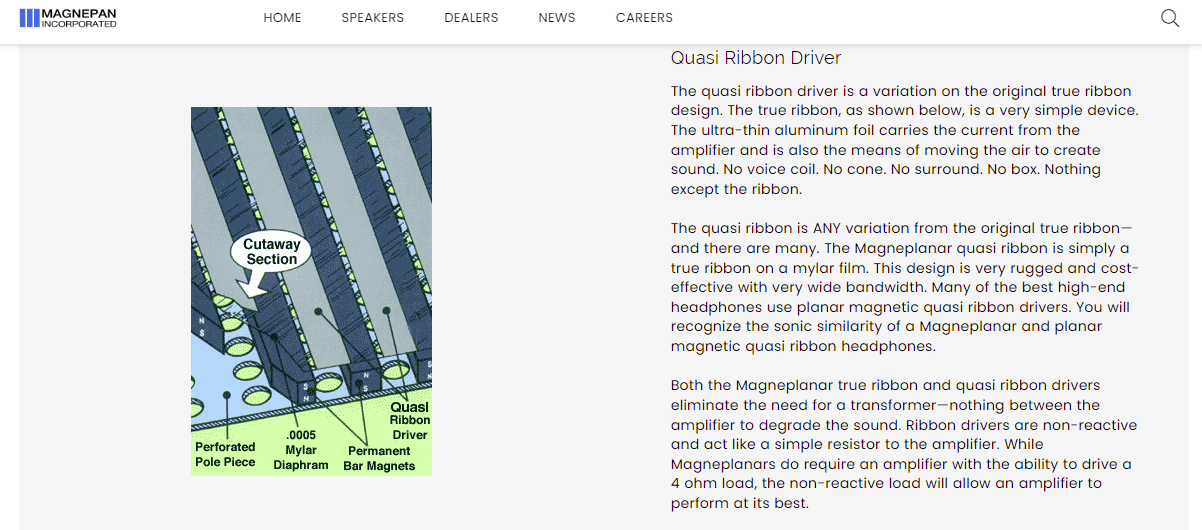

https://en.wikipedia.org/wiki/Magnepan

All Magnepan speakers are based on flexible ferrite magnet strips (like refrigerator magnets), 0.060" (1.5 mm) thick, typically cut to either 1/4" (6 mm) wide (mid-bass) or 1/8" (3 mm) wide (tweeters) and more or less the length of the speaker. The magnets are glued to a piece of custom perforated 20-gauge (1 mm) steel sheet. The steel supports the magnets and also completes the magnetic circuit on the back of the magnets, resulting in about a 25% stronger magnetic field in front of the magnets.

Well I'm not having any luck finding flexible magnets in the configuration I want. Maybe I don't quite understand the design. (most likely)

What type of flexible magnet material do I really need to get started learning about these speakers. The suppliers I contacted acted like I was from mars.

Brent

What type of flexible magnet material do I really need to get started learning about these speakers. The suppliers I contacted acted like I was from mars.

Brent

I asked you earlier what was your use.

You should have been clear in your request, and quest.

Why you need to act like a secretive old person is beyond me...though all the old people act as if their stuff is top secret.

Read up on planar speakers, someone somewhere might have made their own.

More difficult to make than regular speakers.

You should have been clear in your request, and quest.

Why you need to act like a secretive old person is beyond me...though all the old people act as if their stuff is top secret.

Read up on planar speakers, someone somewhere might have made their own.

More difficult to make than regular speakers.

I think you do understand the design basics; it's just not the common configuration for flexible magnets. The cheapest ones will always be whatever is a commodity. In this case, that's multi-pole units likely coming out of China.

For American made/magnetized ones in the configuration you want, it's natural to have to pay more than the commodity price you had in your head from your Hobby Lobby experience.

Here are some basics of Magnepan's method.

https://magnepan.com/pages/about-us

This link takes you to the spot in a Magnepan tour where they show the perforated metal and the magnets

What are you actually trying to accomplish? Do you want to build one set of large speakers? One small test speaker? Do you want to build something that doesn't exist or are you trying to build your own Magnepan but cheaper? There are other ways to make a planar speaker, but the best path will depend on your intentions.

For American made/magnetized ones in the configuration you want, it's natural to have to pay more than the commodity price you had in your head from your Hobby Lobby experience.

Here are some basics of Magnepan's method.

https://magnepan.com/pages/about-us

This link takes you to the spot in a Magnepan tour where they show the perforated metal and the magnets

What are you actually trying to accomplish? Do you want to build one set of large speakers? One small test speaker? Do you want to build something that doesn't exist or are you trying to build your own Magnepan but cheaper? There are other ways to make a planar speaker, but the best path will depend on your intentions.

Yes I just want to start playing around with these speakers. I plan to just start out building a set of mid sized set to see if I can get something to experiment with and learn about planar speakers. I don't thoroughly understand the design but I learn best by trying it and most of the time ruining some stuff but having fun doing it. I'm finding that gathering the materials is a challenge in itself.

Thx for the help.

Brent

Thx for the help.

Brent

For anyone looking for this material it is available from Rochester magnets in New York. You have to look in their store under "Science Projects" to find the conventionally magnetized flexible strip. Sort of expensive but it's magnetized correctly for these speakers.

https://www.rochestermagnet.com/shop/science-projects/120-x-0-500-x-100-plain-mc-detail

Brent

https://www.rochestermagnet.com/shop/science-projects/120-x-0-500-x-100-plain-mc-detail

Brent

If you don't have any experience with planars in general, I'd start off with something small. A 6" by 6" speaker is plenty to deal with in the beginning. Until you understand the basics, going larger than that just adds cost, complexity, and build time, and you don't learn much more for all the effort. Once you aren't making basic mistakes anymore, scaling things up makes more sense.

If resistance is too low on the small panel to drive practically, you can add external resistors to bring it up to 4 ohms.

If resistance is too low on the small panel to drive practically, you can add external resistors to bring it up to 4 ohms.

Are you sure about the magnets there? As @JMFahey says. the type used in refrigerator doors are very weak. Circa 1986 I built my first Magnepan clone with fridge door magnets. Yes, it worked and sounded nice, but it was super inefficient. In fact the wires went up in smoke trying to get decent volume from it. The magnets need to be strong.And every Magnepan planar driver

As shown in the video above at time 3:21, Magnepan is still using flexible magnets for their planars. I obviously don't know the exact composition over time. Their US patent 4,210,786 discusses using magnets of different strengths together, but I don't know if this this was ever done in practice.

https://www.stereophile.com/interviews/103winey/index.html

"Winey: At 3M, I happened to be working on an application that involved laminating tape to flexible magnets. I must have been sitting there, thinking about the project as well as my electrostatic project. I looked up and saw some perforated ceiling tiles, and the light bulb went on. It's as simple as that."

https://patents.google.com/patent/US3674946A/

"The flexible sheet magnet 34 is formed of any suitable material, but it has been found that a plastic rubber bonded barium ferrite magnetic material known by its trademark Plastiform sold by Minnesota Mining & Manufacturing Company of St. Paul, Minn., has proven to be satisfactory."

https://www.stereophile.com/interviews/103winey/index.html

"Winey: At 3M, I happened to be working on an application that involved laminating tape to flexible magnets. I must have been sitting there, thinking about the project as well as my electrostatic project. I looked up and saw some perforated ceiling tiles, and the light bulb went on. It's as simple as that."

https://patents.google.com/patent/US3674946A/

"The flexible sheet magnet 34 is formed of any suitable material, but it has been found that a plastic rubber bonded barium ferrite magnetic material known by its trademark Plastiform sold by Minnesota Mining & Manufacturing Company of St. Paul, Minn., has proven to be satisfactory."

Flexible magnets are made out of ferrite dust and some binder, plastic or rubber, and guess proportions depend on application.

Still guessing: cheap publicity type magnets must have "just enough" ferrite % and not more, purely on $$$ reasons, while special use ones (such as in Magneplanars, Guitar pickups and some electric motors) must definitely have "as much as they can take" without becoming easy to crack by flexing.

Couldn´t find any relevant datasheet yet.

In their Magnetic Materials books, Philips shows many types, including "plastic magnets", meant for "serious" uses, and the best type approached about half the remaining magnetism of Ferroxdure, not bad at all.

Not flexible though.

Still guessing: cheap publicity type magnets must have "just enough" ferrite % and not more, purely on $$$ reasons, while special use ones (such as in Magneplanars, Guitar pickups and some electric motors) must definitely have "as much as they can take" without becoming easy to crack by flexing.

Couldn´t find any relevant datasheet yet.

In their Magnetic Materials books, Philips shows many types, including "plastic magnets", meant for "serious" uses, and the best type approached about half the remaining magnetism of Ferroxdure, not bad at all.

Not flexible though.

Last edited:

I read the magnapan patent papers where they refer to the 3M magnet material specifically 3M 1316 and 1317. The data sheets are available from 3M and they are described to have "multiple poles n and s along it's length". I was a little thrown off by this magnetic configuration as from what I have read it needed to be north on one surface and south on the other. It does seem quite strong at 16oz per sq inch. Being a complete newbie to this I was not sure what I needed. I also could not find the 3M material anyway so I went with the magnetic config I hve been reading about on these forums. I guess I will find out how well, or not, the stuff I ordered will work. Thanks for the great information,

https://www.freepatentsonline.com/3919499.html

https://multimedia.3m.com/mws/media/82986O/1316-magnetic-tape-data-sheet.pdf

Brent

https://www.freepatentsonline.com/3919499.html

https://multimedia.3m.com/mws/media/82986O/1316-magnetic-tape-data-sheet.pdf

Brent

- Home

- Loudspeakers

- Planars & Exotics

- Flexible magnetic strip