That also counts for all nice things. BTW I would sell it ASAP. Terrible excess in many parameters that I for sure don't need.

I have yet to hear/read a useful explanation why to do already inefficient things the absolute most inefficient way with all the then necessary silly things like fans and water cooling and for what purpose. Is there a difference in 1 kW and 40W class A power when running the speakers at moderate levels? One could argue that the 40W device without fans and water cooling is better suited for the job with less drawbacks.

So time consuming very precise designing at one hand for totally non fitting requirements at the other hand even introducing new challenges like added noise (with the new necessity to do it as silent as possible) and now possible water leakage 🙂

I have yet to hear/read a useful explanation why to do already inefficient things the absolute most inefficient way with all the then necessary silly things like fans and water cooling and for what purpose. Is there a difference in 1 kW and 40W class A power when running the speakers at moderate levels? One could argue that the 40W device without fans and water cooling is better suited for the job with less drawbacks.

So time consuming very precise designing at one hand for totally non fitting requirements at the other hand even introducing new challenges like added noise (with the new necessity to do it as silent as possible) and now possible water leakage 🙂

Last edited:

"So a kiloWatt... for what?"

120W fully differential Class A Monoblocks, each dissipating 500W. 1kW for a stereo pair.

Natural convection, with additional water cooling manifolds built-in for hot summer..

First DIY project from 2006.

Cheers,

Patrick

120W fully differential Class A Monoblocks, each dissipating 500W. 1kW for a stereo pair.

Natural convection, with additional water cooling manifolds built-in for hot summer..

First DIY project from 2006.

Cheers,

Patrick

For hobby.

PS The one below is not mine. Way above my budget.

PS The one below is not mine. Way above my budget.

Attachments

Last edited:

That also counts for all nice things. BTW I would sell it ASAP. Terrible excess in many parameters that I for sure don't need.

I have yet to hear/read a useful explanation why to do already inefficient things the absolute most inefficient way with all the then necessary silly things like fans and water cooling and for what purpose. Is there a difference in 1 kW and 40W class A power when running the speakers at moderate levels? One could argue that the 40W device without fans and water cooling is better suited for the job with less drawbacks.

So time consuming very precise designing at one hand for totally non fitting requirements at the other hand even introducing new challenges like added noise (with the new necessity to do it as silent as possible) and now possible water leakage 🙂

... just imagine those guys who listen to 1000W class D amps.... all that power and they still have to pay for the heating. That's what I call waste...

It is NOT about class A versus D etc. It is plain mediocre engineering to design/build a 1 kW dissipating amplifier for a required few Watts output power AND self inflict the necessity to use noise making fans and/or water cooling while all this was possible more effective/efficient within class A with clever designing thereby not needing fans/water cooling. In other words: the habit to build a way too high output power amplifier with the already least efficient construction technique is not the most clever of choices. Scaling down would facilitate passively cooled class A amplifiers that are cheaper to build, smaller, lighter, less heat generating, less power consuming, 100% silent while having the exact same required power for the loudspeakers and required sound level. If I would need cooling fans let alone water cooling and then hear the added noise of the fans and pumps between playing back tracks I would feel like a donkey 🙂

Detail: class D will only consume that 1 kW when one turns it fully open which will never happen. So those guys will not waste much and they will also not pay for the heating by their amplifier. Simple, the reasoning was flawed to begin with.

Detail: class D will only consume that 1 kW when one turns it fully open which will never happen. So those guys will not waste much and they will also not pay for the heating by their amplifier. Simple, the reasoning was flawed to begin with.

Last edited:

I like the simplistic approach and sound of a 2-gain-stage, single-ended pure class-A amplifier. To me, this approach gives the best results and reasonable heat dissipation in my listening room - I have no issue at all with that dissipated heat - around 200W at 4A of quiescent current.

Even my DAC runs its output stage in pure class-A-mode and dissipates 50-60W of heat at all times.... and it is the best sounding DAC I heard.

After searching for more than 3 decades.... I found and settled on a particular class-A design. From my tubes' days, a single-ended topology was a must. Driven by my reasoning and beliefs, I wanted the least amount of gain stages required for an amplifier that also provides some but not too much gain and a differential input. It is also extremely stable and DC coupled. So, I searched, listened and found... Aleph J. Ingenious simplistic beauty. Its harmonic distortion spectrum can also be fairly easily tuned to suit any need/preference. The exact opposite of what you call plain mediocre engineering.

Re fans: the fans I use inside my amp are silent; I can not tell if they are running when they are on... it's not that my amp needs them in its 5U chassis - I just choose to have an option to turn the fans on if I want to. I am not sure why you constantly keep saying the fans are noisy? Not all fans are - check post #39.

Please share with us what you prefer and use in your system.

Even my DAC runs its output stage in pure class-A-mode and dissipates 50-60W of heat at all times.... and it is the best sounding DAC I heard.

After searching for more than 3 decades.... I found and settled on a particular class-A design. From my tubes' days, a single-ended topology was a must. Driven by my reasoning and beliefs, I wanted the least amount of gain stages required for an amplifier that also provides some but not too much gain and a differential input. It is also extremely stable and DC coupled. So, I searched, listened and found... Aleph J. Ingenious simplistic beauty. Its harmonic distortion spectrum can also be fairly easily tuned to suit any need/preference. The exact opposite of what you call plain mediocre engineering.

Re fans: the fans I use inside my amp are silent; I can not tell if they are running when they are on... it's not that my amp needs them in its 5U chassis - I just choose to have an option to turn the fans on if I want to. I am not sure why you constantly keep saying the fans are noisy? Not all fans are - check post #39.

Please share with us what you prefer and use in your system.

If you read carefully you would have read that I work with forced cooled devices on a daily basis and I will never allow that in a living room. Any fan, so even the best, makes more noise than passive cooling. It is not me constantly saying they make noise, it is the fans that constantly make noise (and attract dust/dirt and will fail in time). Just like no cap is the best cap, no SMPS is the best SMPS -> no fan is the best fan and coincidentally also the most silent solution (WIN-WIN big time) so we go for that as we like the devices to reproduce music and not that they make music themselves.

You misread my comment about mediocre engineering (reread post #66 please) or take it out of context for some reason but I am fine with that 🙂 It is a bit like designing a house for a single person with 8 bath rooms and only 1 being used and still the need to maintain and clean them all 8.

You misread my comment about mediocre engineering (reread post #66 please) or take it out of context for some reason but I am fine with that 🙂 It is a bit like designing a house for a single person with 8 bath rooms and only 1 being used and still the need to maintain and clean them all 8.

Last edited:

all my amps have a Noctua fan. With a help of my friend I made a digital control board where the fan comes on after a temp threshold has been reached and then the temp is maintained. If there was no LED indicator I would not have known that the fan came on (I have to lean and look through the heatsink to see if the fan is spinning or try to feel air moving with my hand). the board does trouble detection and shuts the amp down if the amp is to overheat, if either the temp sensor or the fan fails. A big advantage (to me) of having active cooling is a faster warm up to the best sounding amp state than with the passive cooling. Then you piggy back off of the fan control board and add soft start and speaker protection function and you have an all round winner.

https://www.diyaudio.com/community/threads/burning-amp-ba-3b-balanced.201281/page-29#post-4794952

https://www.diyaudio.com/community/threads/burning-amp-ba-3b-balanced.201281/page-29#post-4794952

Jean-Paul, I blame Nelson for perverting the course of history, seducing and leading us astray and needing to squeeze every drop of available class A from every single circuit. It really should not be legal to waste this much heat, and pointing fans on amps is not engineering. But I'm not stopping until the G-men are at the door....

That might be sooner than you realize.Jean-Paul, ... But I'm not stopping until the G-men are at the door....

I finalized my fan cooling of my SIT3X in a diyAudio Store 300mm 4U chassis and it looks good and works very well. Here are some pictures:

Attachments

Didn't some tube amp company make some rather low powered OTL amps

in the 70's that needed a pump and compressor. I think the amps might only

weigh 50 lbs or so but the pump and compressor weighed 250lbs or more.

in the 70's that needed a pump and compressor. I think the amps might only

weigh 50 lbs or so but the pump and compressor weighed 250lbs or more.

Yes it was sold to soon-to-be single men I recall.Didn't some tube amp company make some rather low powered OTL amps

in the 70's that needed a pump and compressor. I think the amps might only

weigh 50 lbs or so but the pump and compressor weighed 250lbs or more.

Well done. I like the airflow baffle engineering. In which direction are your fans blowing (I guess in)?I finalized my fan cooling of my SIT3X in a diyAudio Store 300mm 4U chassis and it looks good and works very well. Here are some pictures:

I was musing about a forced air hifi rack in ZM’s babysitter thread: https://www.diyaudio.com/community/threads/babysitter-for-papas-koan.186554/post-7042342 ☺️

Ihquam, nice airflow design. I have also been toying with bottom up through the heatsink type of solution but I still have an oven inside. (Amp is LuDEF) Would be nice to have your feedback on 1)how much cooler things run and 2) how noisy is it? Thanks for sharing.I finalized my fan cooling of my SIT3X in a diyAudio Store 300mm 4U chassis and it looks good and works very well. Here are some pictures:

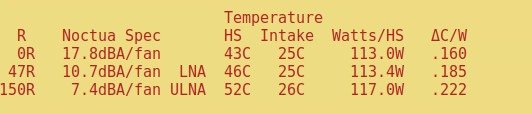

Here are temperature measurements for the setup on post #73 https://www.diyaudio.com/community/threads/forced-cooling-a-class-a-amp.385221/post-7044446 for three different fan speeds. I did not make measurements for the amplifier with no fans since that would require totally rebiasing the amplifier to a much lower overall power dissipation.

Temperature

R Noctua Spec HS Intake Watts/HS ΔC/W

0R 17.8dBA/fan 43C 25C 113.0W .160

47R 10.7dBA/fan LNA 46C 25C 113.4W .185

150R 7.4dBA/fan ULNA 52C 26C 117.0W .222

diyAudio Store DISSIPANTE 4U 300mm chassis

Two Noctua NF-S12A FLX fans

Each fan has resistor R in series with 12VDC supply.

Total power to amplifier: 120VAC 2.34A = 280VA (140VA/ch)

Temperature

R Noctua Spec HS Intake Watts/HS ΔC/W

0R 17.8dBA/fan 43C 25C 113.0W .160

47R 10.7dBA/fan LNA 46C 25C 113.4W .185

150R 7.4dBA/fan ULNA 52C 26C 117.0W .222

Attachments

Last edited:

- Home

- Amplifiers

- Pass Labs

- Forced cooling a class A amp