I am looking to get some supplies to mount chips to heatsinks for a few projects, and am starting to read about thermal pastes and compounds to interface between devices and heatsinks and wonder if there was a consensus as to which was the best method of approach?

Living in the sticks, my parts will need to be ordered online, so I have some option, but would rather not spend a butt load on shipping from 3 different places for stuff.

It would seem there are differences between pastes, and am flying blind. I have a mica piece to insulate my LM4780. Do all sinks need them if they are not insulated?

Then I have seen people suggest foregoing the paste and mica and going with something like a Sil-Pad 400... where does a guy start? Any help would be appreciated. Thanks in advance.

Living in the sticks, my parts will need to be ordered online, so I have some option, but would rather not spend a butt load on shipping from 3 different places for stuff.

It would seem there are differences between pastes, and am flying blind. I have a mica piece to insulate my LM4780. Do all sinks need them if they are not insulated?

Then I have seen people suggest foregoing the paste and mica and going with something like a Sil-Pad 400... where does a guy start? Any help would be appreciated. Thanks in advance.

Silicone Pads are the best and less messy. Most pastes are similar. Go for the one with the best thermal conductivity like Dow Corning DC4. The reason paste is used is to fill any air gap which increases thermal conductivity. Silicone Pads are soft and mould nicely to the space between the component and the heatsink.

NEVER fit a component without a pad or heatsink mica and paste. Even if the same potential as the heatsink. Air gaps reduce the thermal conductivity.

NEVER fit a component without a pad or heatsink mica and paste. Even if the same potential as the heatsink. Air gaps reduce the thermal conductivity.

One aspect of silicone pads is in manufacturing and "no mess" construction.

Be cautious asking for consensus on a forum. 🙂 You will get opinions and facts.

For most of my construction I use silicone pads for the no-mess feature.

From the LM4780 data sheet:

"(1) The NDM0027A is a non-isolated package. The package's metal back, and any heat sink to which it is mounted are connected to the Vpotential when using only thermal compound. If a mica washer is used in addition to thermal compound, θCS (case to sink) is increased, but the heat sink will be electrically isolated from V-."

So you could mount it directly for the best thermal connection but would have to isolate the entire heat sink from ground. Not really recommended but possible.

Thermal compound fills in the small gaps that occur when two "flat" surfaces get mounted together. I do not use mica without some.

edit: did not see JonSnell Electronic post: slow typing on my part 🙂

Be cautious asking for consensus on a forum. 🙂 You will get opinions and facts.

For most of my construction I use silicone pads for the no-mess feature.

From the LM4780 data sheet:

"(1) The NDM0027A is a non-isolated package. The package's metal back, and any heat sink to which it is mounted are connected to the Vpotential when using only thermal compound. If a mica washer is used in addition to thermal compound, θCS (case to sink) is increased, but the heat sink will be electrically isolated from V-."

So you could mount it directly for the best thermal connection but would have to isolate the entire heat sink from ground. Not really recommended but possible.

Thermal compound fills in the small gaps that occur when two "flat" surfaces get mounted together. I do not use mica without some.

edit: did not see JonSnell Electronic post: slow typing on my part 🙂

Last edited:

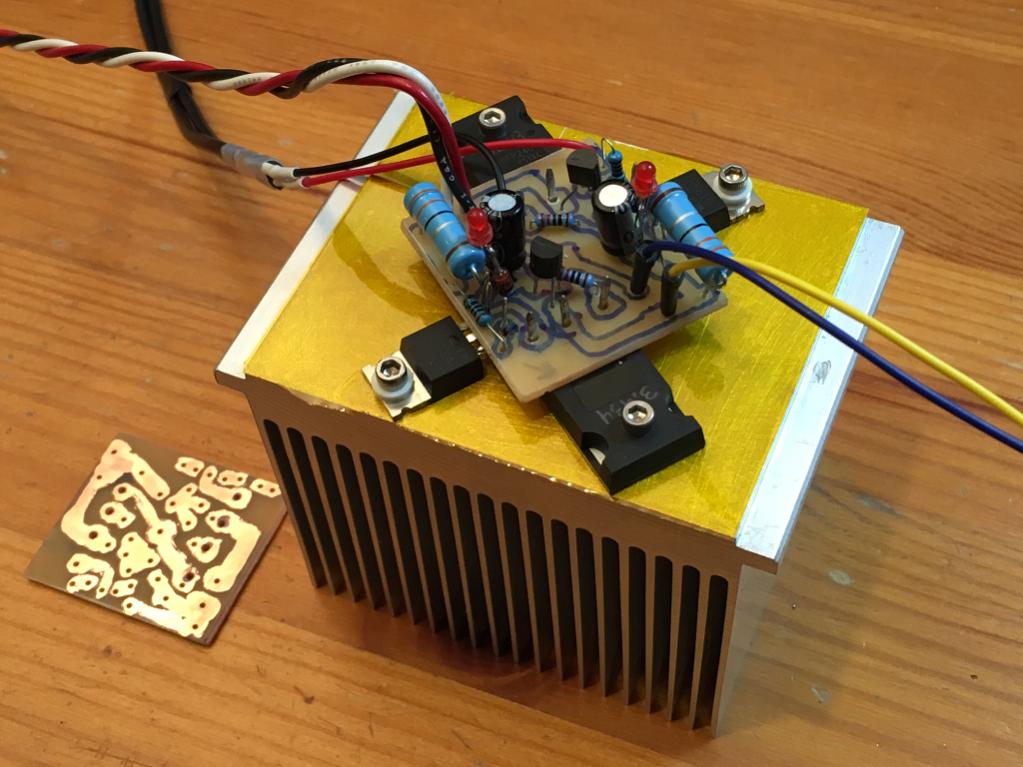

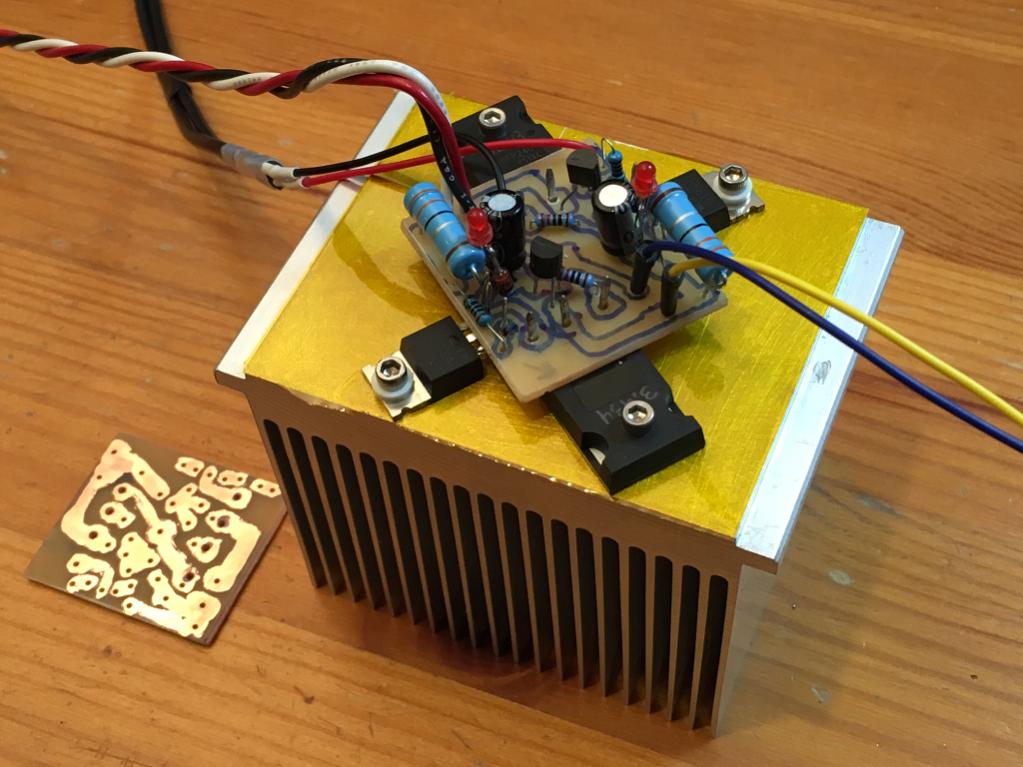

First off: The fins of the heat sink need to be vertical for best heat removal.

Inside an enclosed cabinet they need not be black (it's black all-over already).

I use only Sil-Pad 400 type (with good success for 20 years) insulators. No messy grease required. E

Inside an enclosed cabinet they need not be black (it's black all-over already).

I use only Sil-Pad 400 type (with good success for 20 years) insulators. No messy grease required. E

Do the silicone pads in lieu of paste and mica also insulate? Or is the mica and grease recommended if I don't plan to isolate the sink from ground?

I have been using Kapton tape, no grease ever since I ran out of silicone pads. Seems to work well. Probably not as good heat transfer as with grease. But nothing has blown up yet 🙂

for DIY & hobbyists don't overlook the 'shelf life' of the insulation systems you pick. sil-pads and such, maybe 2-3 years they'll de-laminate and crumble. The white grease and mica can be reused ad infinite. OEM like the sil-pads for sure, but hobbyists may need to re-order them every other time they re- build work on their stuff. A small tube of white grease will last a life time literally.

One dangerous dirty lil' secret is run no insulator just grease. So what, its live heat-sink put a sign on it and keep the lid on. The heat sink will be half the size and hotter for same Tj (junction temp ) use insulation bushing to mount the heat sink. I know at least one pro OEM change their whole amplifier topology to get the collectors at ground level so no insulation required at all.

One dangerous dirty lil' secret is run no insulator just grease. So what, its live heat-sink put a sign on it and keep the lid on. The heat sink will be half the size and hotter for same Tj (junction temp ) use insulation bushing to mount the heat sink. I know at least one pro OEM change their whole amplifier topology to get the collectors at ground level so no insulation required at all.

Last edited:

I have to disagree with Infinia. I have been using Sil-Pads for over 20 years on 15A/230VAC circuits without failures, including reuse of the pad after service. E

SHELF LIFE ask your Bergquist Rep or look in the catalogs it's in there. ~ 1 year for many line items. I've personally had to throw out all my samples from them, maybe they might have a special improved design out of the thousand or so parts they OFFER . I'm sure its a big no-no to reuse them after they phase change. even if you could scrape them off in one piece.

OK, let me prove it. I'll mail out #10 envelopes to the first 10 who pm me with sheets samples of leftover 400 Sil-Pad product I bought 15 years ago. Please note: I have no connection to Berquist, other than as a former customer! E

If going with grease, Arctic silver used to be a favorite of computer over-clockers. They have the same needs for mounting a cpu to a heatsink.

Why use grease/pads? Because a "metal to metal contact" hits only on the high points of the "flat" metal. It is really 99% air. Micro-polishing may give 97% air.

(This does bring out the first point of device to sink physics- be sure your sink is FLAT! (Maybe check your device also.))

If we can't get metal-to-metal, can we do better than air in the gap? Grease is much worse than metal but much better than air. Grease filled with zinc-oxide (sunburn cream filler) is even better. There's stuff which claims Silver content.

Do you even need grease? If you are working with large devices on small heatsinks, grease is pointless. If it runs just-hot, OK. If it runs too hot, get a bigger sink! Your bottleneck is sink-to-air, not device-to-sink.

But a Pentium CPU has 60 Watts heat in a contact patch hardly bigger than a TO3 (and we rarely run one TO3 to 60W). We use big sinks, with fans, but space inside a PC is limited so we is always on a ragged edge. Here grease may be essential.

When you get to big-enough sinks, you are then limited by contact quality. You simply "must" grease a transistor-- this is a Rite Of Passage for all electronic tinkerers. Not too much, but certainly no skips. You literally want just enough grease to fill the micro-raggedness of the metal surfaces. A wee bit will ooze under the screw. If you get a lot of ooze, you used too much. No ooze suggests too little. And the stuff ALWAYS gets all over your fingers and tools.

Which is why pads are good. I didn't know their endurance was questionable, interesting.

If at all possible, ask if you can spread your total heat over MANY devices. This will reduce the total pounds of Aluminum you need in your sink because heat doesn't spread well over many inches even in thick extrusions. Modern transistor prices make a many-device power section far more affordable than the old days. You find commercial amplifiers running long rows of devices at 20W per device on quite light extrusions.

Of course using LM4780 you don't have this option. But remember that LM4780 is aimed at MASS-production products. The larger ones will be greased but they won't obsess about the type of grease, certainly no Silver. (They do however have a magic wand that sucks generic sink-grease out of 55 gallon drum and puts the Exact Right amount on each spot.)

(This does bring out the first point of device to sink physics- be sure your sink is FLAT! (Maybe check your device also.))

If we can't get metal-to-metal, can we do better than air in the gap? Grease is much worse than metal but much better than air. Grease filled with zinc-oxide (sunburn cream filler) is even better. There's stuff which claims Silver content.

Do you even need grease? If you are working with large devices on small heatsinks, grease is pointless. If it runs just-hot, OK. If it runs too hot, get a bigger sink! Your bottleneck is sink-to-air, not device-to-sink.

But a Pentium CPU has 60 Watts heat in a contact patch hardly bigger than a TO3 (and we rarely run one TO3 to 60W). We use big sinks, with fans, but space inside a PC is limited so we is always on a ragged edge. Here grease may be essential.

When you get to big-enough sinks, you are then limited by contact quality. You simply "must" grease a transistor-- this is a Rite Of Passage for all electronic tinkerers. Not too much, but certainly no skips. You literally want just enough grease to fill the micro-raggedness of the metal surfaces. A wee bit will ooze under the screw. If you get a lot of ooze, you used too much. No ooze suggests too little. And the stuff ALWAYS gets all over your fingers and tools.

Which is why pads are good. I didn't know their endurance was questionable, interesting.

If at all possible, ask if you can spread your total heat over MANY devices. This will reduce the total pounds of Aluminum you need in your sink because heat doesn't spread well over many inches even in thick extrusions. Modern transistor prices make a many-device power section far more affordable than the old days. You find commercial amplifiers running long rows of devices at 20W per device on quite light extrusions.

Of course using LM4780 you don't have this option. But remember that LM4780 is aimed at MASS-production products. The larger ones will be greased but they won't obsess about the type of grease, certainly no Silver. (They do however have a magic wand that sucks generic sink-grease out of 55 gallon drum and puts the Exact Right amount on each spot.)

If going with grease, Arctic silver used to be a favorite of computer over-clockers. They have the same needs for mounting a cpu to a heatsink.

I used Artic Silver in my first amp build since I had a tube laying around from my overclocking days. It didn't last long before the first output transistor died.

Again, I say Kapton tape works wonders. Doesn't degrade with time (perhaps one of the most durable plastics ever, interesting how even the glue they use on the tape doesn't seem to go bad either).

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Heatsinks - What is the best way to mount?