I've been designing ~450-500VDC linear power supplies on pcbs that also contain the rectifiers/filters for heater taps and switches. It occurred to me that layout should not be just about crosstalk/noise but also to avoid arcing or unintentional shorts. It looks like there is some general guidance from IPC-2221, but it is very restrictive.

I've been using the calculator here: https://www.smps.us/pcbtracespacing.html

You can see that for a 500VDC trace, you should have 2.5mm to 3mm spacing. That's quite a lot of spacing. Is this a practice that others here employ? What else can I do for safety on powersupplies?

Also, if anyone has found connecters with >2.5mm between the pins, that would be useful.

I've been using the calculator here: https://www.smps.us/pcbtracespacing.html

You can see that for a 500VDC trace, you should have 2.5mm to 3mm spacing. That's quite a lot of spacing. Is this a practice that others here employ? What else can I do for safety on powersupplies?

Also, if anyone has found connecters with >2.5mm between the pins, that would be useful.

There are connectors with 3.96mm (.15inch I think) spacing, from for instance Phoenix Contact or Würth.

I am using those up to 2.2kV in my direct drive amp.

I haven't used more than 3 or 4mm spacing and have not seen any arcing.

It is important though to clean your board well after soldering with flux remover and/or isopropyl alcohol.

Jan

I am using those up to 2.2kV in my direct drive amp.

I haven't used more than 3 or 4mm spacing and have not seen any arcing.

It is important though to clean your board well after soldering with flux remover and/or isopropyl alcohol.

Jan

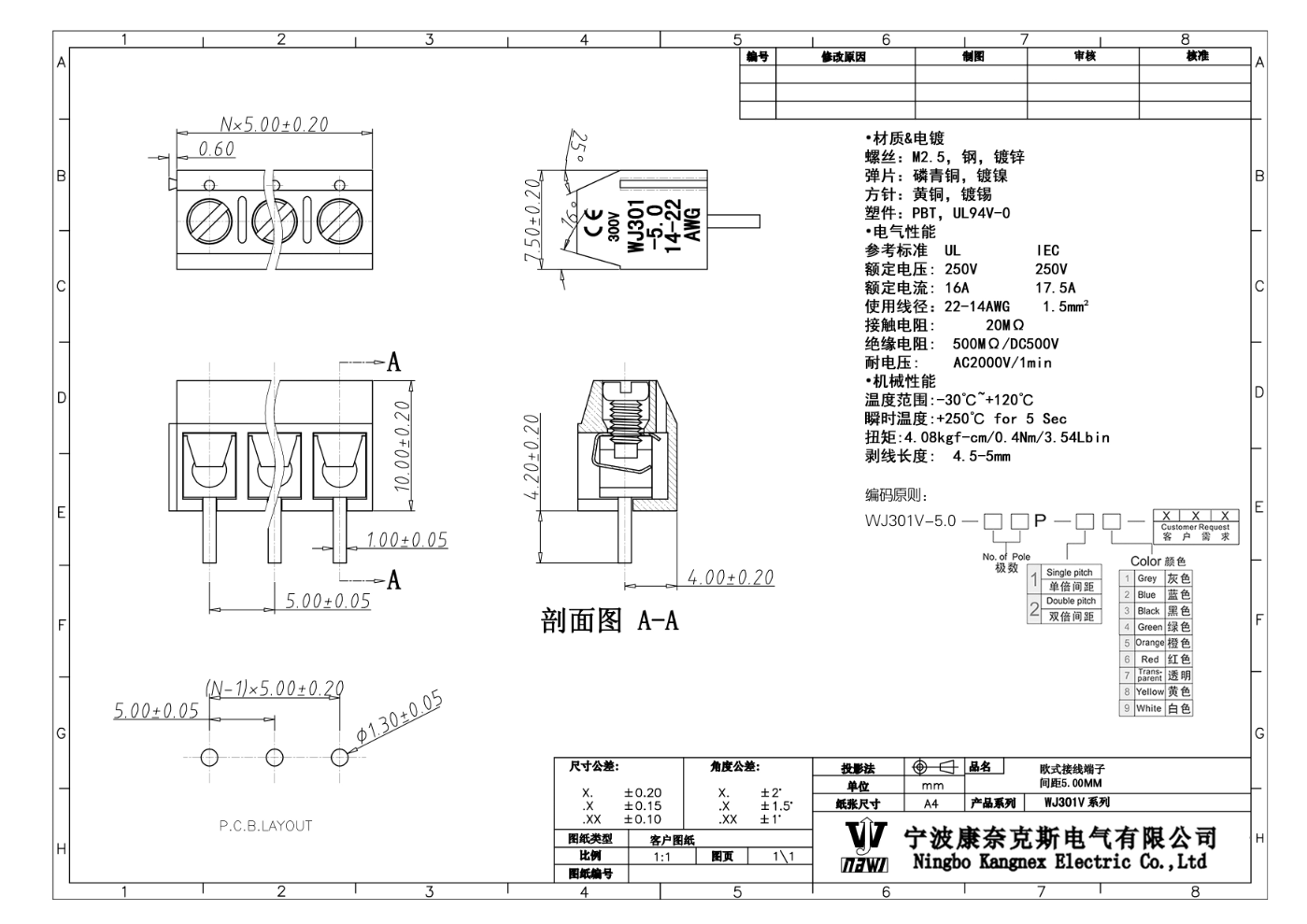

I use these standard 5mm spacing connectors with 700VDC (low current) and never had an arc over.

I use no clean flux (and don't clean it).

I use no clean flux (and don't clean it).

You have a part number by chance? Searching through mouser has been unreliable for this.There are connectors with 3.96mm (.15inch I think) spacing, from for instance Phoenix Contact or Würth.

I am using those up to 2.2kV in my direct drive amp.

I haven't used more than 3 or 4mm spacing and have not seen any arcing.

It is important though to clean your board well after soldering with flux remover and/or isopropyl alcohol.

Jan

I'm currently using a molex two pin connector good for 18 gauge wire but its pin spacing is about 1.5mm.

edit: just searching mouser by pin pitch revealed a lot of options

Last edited:

Just read this but 4 mm is not enough officially for 2.2 kV. 4 mm is enough for 500V DC. It may work for a while but it won't be up to code and it may eventually lead to fireworks when things get dirty/dusty. My advice with DC is not to take chances by saving a few Euro.

Use at least connectors with one position without contact (so empty) just to make sure things stay safe. Phoenix has these.

Use at least connectors with one position without contact (so empty) just to make sure things stay safe. Phoenix has these.

A link to the ones I'm using: https://lcsc.com/product-detail/Screw-terminal_Ningbo-Kangnex-Elec-WJ301V-5-0-2P_C8475.htmlYou have a part number by chance? Searching through mouser has been unreliable for this.

I'm currently using a molex two pin connector good for 18 gauge wire but its pin spacing is about 1.5mm.

edit: just searching mouser by pin pitch revealed a lot of options

"open" types are not better than closed types (so those with plastic all around wire openings) for higher voltage use. Stuff is made to withstand a certain voltage. Instead of cheap one could look to stuff made for the voltage that will be there.

They´re norms like the IEC60950.

Please look at the connectors datasheets.

I´ll use something from Würth.

https://www.we-online.com/catalog/en/em/connectors/terminal_blocks

But check first distributor availability.

JP

Please look at the connectors datasheets.

I´ll use something from Würth.

https://www.we-online.com/catalog/en/em/connectors/terminal_blocks

But check first distributor availability.

JP

Question...Lets say the trace spacing on a HV should be 3mm, does this spacing also apply to the spacing through the board? For example if making a two sided board for a 900V power supply filter chain and you have ground plane copper on both sides and the board is the standard 1.65mm thick... Do you have to concern yourself with HV traces running on the opposite side which fly over the ground plane on the opposite side? Or should I double up all HV traces to both sides so the ground planes are always 3mm away be it across or through the board? If this is the case then you can't do any crossovers because the board itself is 1.65mm and the spec calls for 3mm. Basically does the 3mm only apply to the air dielectric or to the board too?

FR4 is isolator, 10kV/mm if I recall.Question...Lets say the trace spacing on a HV should be 3mm, does this spacing also apply to the spacing through the board? For example if making a two sided board for a 900V power supply filter chain and you have ground plane copper on both sides and the board is the standard 1.65mm thick... Do you have to concern yourself with HV traces running on the opposite side which fly over the ground plane on the opposite side? Or should I double up all HV traces to both sides so the ground planes are always 3mm away be it across or through the board? If this is the case then you can't do any crossovers because the board itself is 1.65mm and the spec calls for 3mm. Basically does the 3mm only apply to the air dielectric or to the board too?

JP

Looked this up and apparently it is 10 kV for 20 mils so 0.5 mm which IMHO can't be any safe. Regulations and norms seem to be changing in time with one dominant nation at the controls. Of course the curse of continues change, required certifications, jargon and the need to keep up by non free obtainable papers is included. Now I am used to high voltage high power stuff and when I see this I really doubt if the numbers are safe. If you have ever witnessed creepage and HV (which is above 1500V) leaking through +10 mm thick glass reinforced plastics you would never accept 0.5 mm for 10 kV 🙂 I admit this is AC, not audio, not electronics and with creepy high current possible but still...

We used to keep 4 mm minimum clearance for 230V AC mains voltage but that was then when things needed to be safe, durable and BS free so we kept to 5mm. Maybe it is good to apply old fashioned design techniques and keep higher voltage traces not running exactly at the opposite side and also keep more than the minimum clearance as clearance is free. Why would one keep to the minimum? To find out why it is the minimum?

We used to keep 4 mm minimum clearance for 230V AC mains voltage but that was then when things needed to be safe, durable and BS free so we kept to 5mm. Maybe it is good to apply old fashioned design techniques and keep higher voltage traces not running exactly at the opposite side and also keep more than the minimum clearance as clearance is free. Why would one keep to the minimum? To find out why it is the minimum?

Last edited:

This thread is missing and confusing an important distinction. There are 2 specifications - Creepage and Clearance. The first is the physical path length and the second is the straight line air gap for an arc. The attached snip from UL shows the spec UL840. The voltage referenced 320 for example based on the peak of 220Vac etc. My fear is that people are seriously under estimating the safe distances.

Attachments

Problem is that it is a specialism to know things exactly/correctly in this area and this point in time even for professionals. Second the now dominant emphasis on "minimum" so low cost. Adhere to "minimum" and when stuff fails in dirty/dusty environments one can state the the device has been designed to meet minimum requirements so all is good.

With recent power electronics one can see this. It does not take long to have PCB traces covered with attracted dust/debri and this is not a good combination with higher voltages and minimum clearance/creepage. I was witness in a case where high energy power supply PCBs had white stuff covering the high current PCB traces in nearly all of those devices. In a number of these devices this was combined with a dark powdery stuff being in a spotted pattern. Weird. It went to the power MOSFETs and caused shorts and irreparable failure not only to the PSU but also to the load..... Of course the blame had to go somewhere so this became nasty.

With recent power electronics one can see this. It does not take long to have PCB traces covered with attracted dust/debri and this is not a good combination with higher voltages and minimum clearance/creepage. I was witness in a case where high energy power supply PCBs had white stuff covering the high current PCB traces in nearly all of those devices. In a number of these devices this was combined with a dark powdery stuff being in a spotted pattern. Weird. It went to the power MOSFETs and caused shorts and irreparable failure not only to the PSU but also to the load..... Of course the blame had to go somewhere so this became nasty.

Last edited:

As I know, creepage distance is equal to clearance distance, to make it simple.

Sorry, in German:

https://www.weidmueller.de/de/produ...nd_steckverbinder/luft_und_kriechstrecken.jsp

JP

Sorry, in German:

https://www.weidmueller.de/de/produ...nd_steckverbinder/luft_und_kriechstrecken.jsp

JP

IEC 60065 is for audio related, IEC 60950 is telecom related, and then there are every now and then some amendments, but usually it's not big difference between the standards.

Those figures given in the link suggesting 2,5-3 mm seems wrong to me for someone who have been working long ago with IEC 60950, it's too small clearance and creepage distance for something like 500 V.

Some things that decides clearance and creepage distance are input voltage, insulation, material group, pollution degree, overvoltage category, altitude.... and even if there's logically no immediate arc-over risk on a fresh circuit just put into use, the standards are taking into account long term effects, such as pollution degree in particular that will affect the distance and as dust particles sets on the PCB and adding in humidity it starts to get charred from ionization and by time it becomes conductive and causing an arc.

Unfortunately those standards are not for free so one can only try to dig up bits and pieces from internet.

Adding some general info links for whom it may interest.

https://www.elektormagazine.com/news/pcb-clearance-and-creepage-distances-1

https://www.elektormagazine.com/news/pcb-clearance-and-creepage-distances-criteria

https://www.elektormagazine.com/news/pcb-clearance-and-creepage-distances-part-3

Those figures given in the link suggesting 2,5-3 mm seems wrong to me for someone who have been working long ago with IEC 60950, it's too small clearance and creepage distance for something like 500 V.

Some things that decides clearance and creepage distance are input voltage, insulation, material group, pollution degree, overvoltage category, altitude.... and even if there's logically no immediate arc-over risk on a fresh circuit just put into use, the standards are taking into account long term effects, such as pollution degree in particular that will affect the distance and as dust particles sets on the PCB and adding in humidity it starts to get charred from ionization and by time it becomes conductive and causing an arc.

Unfortunately those standards are not for free so one can only try to dig up bits and pieces from internet.

Adding some general info links for whom it may interest.

https://www.elektormagazine.com/news/pcb-clearance-and-creepage-distances-1

https://www.elektormagazine.com/news/pcb-clearance-and-creepage-distances-criteria

https://www.elektormagazine.com/news/pcb-clearance-and-creepage-distances-part-3

Now imagine being a hobbyist working with higher than 1 kV tube gear and having and willing to find a way to do things right.

Never forget the time that I was shown a very high DC voltage open frame tube amplifier with bare wires/cabling (sounds best....), bees wax filled caps etc. in a cupboard of a normal home with small children and pets. No PE either of course.

Never forget the time that I was shown a very high DC voltage open frame tube amplifier with bare wires/cabling (sounds best....), bees wax filled caps etc. in a cupboard of a normal home with small children and pets. No PE either of course.

The "one hand in the pocket" helps. Between many questionable habits this good habit is thankfully done by many.

Did look around a little bit further and found out that since December 20th, 2020, there's a new standard called IEC (EN, UL, etc) 62368 [Audio/video, information and communication technology equipment - Part 1: Safety requirements] replacing both IEC 60065 and IEC 60950 and hereafter becoming just one standard, there is still an ongoing transitional period and the dates depends on which region in the world, but for new designs the new standard should be adopted.

More info here:

https://www.ul.com/insights/transition-iec-62368-1-iec-60950-1-and-iec-60065

https://web.archive.org/web/20220000000000*/https://webstore.iec.ch/publication/27412

Here some further good information what the transition implies:

https://ptitest.com/what-happens-when-iec-60950-1-is-withdrawn/

https://web.archive.org/web/2022000...m/what-happens-when-iec-60950-1-is-withdrawn/

The new IEC 62368 standard can be bought here at the current price of CHF 380.- (currently on par in € and $ values).

https://webstore.iec.ch/publication/27412

Further link trivia:

https://www.tuvsud.com/en-us/-/medi...e-books/tuvsud-iec-62368-1-white-paper_v1.pdf

More info here:

https://www.ul.com/insights/transition-iec-62368-1-iec-60950-1-and-iec-60065

https://web.archive.org/web/20220000000000*/https://webstore.iec.ch/publication/27412

Here some further good information what the transition implies:

https://ptitest.com/what-happens-when-iec-60950-1-is-withdrawn/

https://web.archive.org/web/2022000...m/what-happens-when-iec-60950-1-is-withdrawn/

The new IEC 62368 standard can be bought here at the current price of CHF 380.- (currently on par in € and $ values).

https://webstore.iec.ch/publication/27412

Further link trivia:

https://www.tuvsud.com/en-us/-/medi...e-books/tuvsud-iec-62368-1-white-paper_v1.pdf

Last edited:

So the "global safety science leader" (as they call themselves) charges 380 Euro if you want to learn/know their forced new standard? I think that is a little bizarre. Can't help to think that overhead, bureaucracy and forthcoming self created power are only growing to too great heights. Suppose you want to develop a commercial device and what will be on your path. The silly thing is that companies can certify ther own produced stuff which is outright crazy.

If one would be of the cautious type one would almost think someone somewhere has a benefit from this....

If one would be of the cautious type one would almost think someone somewhere has a benefit from this....

Last edited:

- Home

- Amplifiers

- Power Supplies

- High voltage pcb safety guidelines & trace spacing