Over on this thread I made some attempts to do "ultra shallow" waveguides : http://www.diyaudio.com/forums/multi-way/306425-ultra-shallow-waveguides.html

The idea was to put something in my car in the kick panels that was ultra shallow.

Those waveguides had promise, but off-axis response had dips. Can't have your cake and eat it too; if you use geometry trick to narrow the beamwidth, there's a price to pay.

So I thought I'd try making a clone of the Image Dynamics HLCDs. As I understand it, these were designed by Eric from Image Dynamics. I believe Bruce Edgar did some consulting on these too. (They were next door neighbors in California back in the day.)

They're generally the best regarded waveguides for cars. I haven't bought a pair because I like to tinker and DIY.

I have bought a pair from USD, which predates the ID design :

http://www.diyaudio.com/forums/multi-way/151376-homster-how-i-learned-how-fix-horn.html

The idea was to put something in my car in the kick panels that was ultra shallow.

Those waveguides had promise, but off-axis response had dips. Can't have your cake and eat it too; if you use geometry trick to narrow the beamwidth, there's a price to pay.

So I thought I'd try making a clone of the Image Dynamics HLCDs. As I understand it, these were designed by Eric from Image Dynamics. I believe Bruce Edgar did some consulting on these too. (They were next door neighbors in California back in the day.)

They're generally the best regarded waveguides for cars. I haven't bought a pair because I like to tinker and DIY.

I have bought a pair from USD, which predates the ID design :

http://www.diyaudio.com/forums/multi-way/151376-homster-how-i-learned-how-fix-horn.html

The older car audio HLCDs had a cross section that was constant. You can see that in this pic. The challenge with this type of setup is that the frequencies above 4500hz have very very narrow vertical directivity. The vertical beamwidth at 10khz can be as little as five or ten degrees. This is a problem when they horns are mounted at kneecap level

The ID horns have a noticeable diffraction slot. The apparent source of the sound is the edge of the diffraction slot, not the compression driver itself. This is due to the very narrow height of the diffraction slot; basically the wavelength can't expand until it exits the diffraction slot. The net effect is that the ID HLCD should behave a lot like a horizontal ribbon.

I did some measurements on the diffraction slot, and it appears to measure about 70 degrees by zero degrees. It's rotated fifteen degrees off axis.

As detailed here(1), when you're making one of these waveguides you have to be careful about how they're aimed. The reason is because the sound will tend to "hug" one side of the waveguide if you're not careful. This is probably a problem with Smith Horns also, because they're very similar to car audio HLCDs.

The sims from Hornresp show above seem to demonstrated that things will be OK if you pay a lot of attention to the shape of the waveguide at the throat, and if you don't make the waveguide wildly asymmetric. In the pics above, note that I did everything triple-size. That's why Hornresp indicates a frequency of 6000Hz, but the sim is actually 18000Hz.

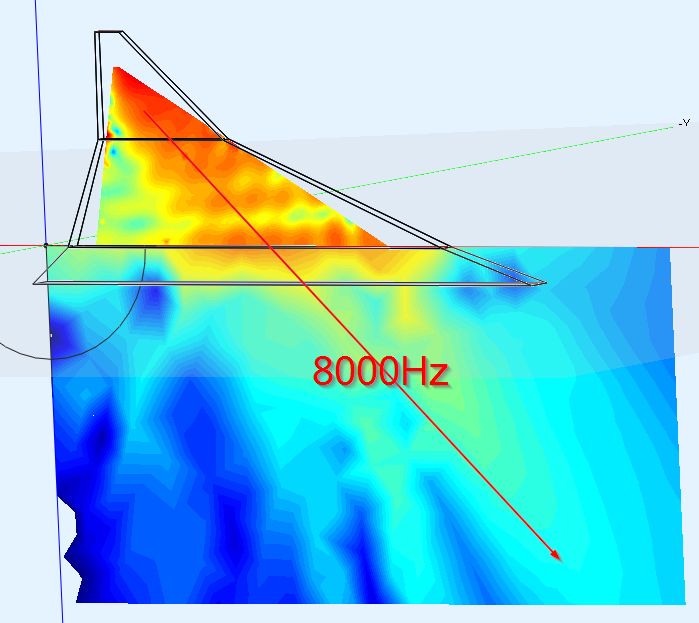

Here's some Abec sims that illustrate what I mean

(1) Car Audio | DiyMobileAudio.com | Car Stereo Forum - View Single Post - Horn Loading a Full Range / It'll End In Tears

Here's the Image Dynamics horn

Here's what I came up with. I made a few changes that I hope will improve performance:

1) there's no reflector. I don't see the advantage of one.

2) The angle on mine is intentionally wider. The reason that I did this is because it's designed for a car that's fairly wide. By making mine wider, I control directivity down below 1000Hz.

3) I'm using an oblate spheroidal curve because I've found that it offers the best polar response

4) The angle of my waveguides is slightly different. The ID waveguides are about 15 degrees off axis, mine are ten. The only reason I made mine ten degrees is because it keeps the width within my target parameters. IE, if I rotated mine another ten degrees, their width would exceed the width I'm aiming for.

Front view. Not a whole lot different than the real deal:

In the side view, you can see the diffraction slot there, basically the idea is to move the 'apparent source' of the loudspeaker to a point that's about halfway down the waveguide throat. (Instead of the compression driver itself.)

I invested an embarassing amount of time smoothing everything out and using bezier curves for EVERYTHING so there isn't a sharp edge to be seen here.

I got a new job and they actually have work to do, so progress on this has been slow

I made the depth quite a bit less, this is designed to widen the vertical coverage angle. Basically the deeper under the dash you go, the smaller the vertical angle is. So I went the other way.

There's also a couple of innovations that I stole from a recent Bose patent:

1) See how the waveguide 'necks down' in the middle? That moves the apparent source of the sound closer to the mouth of the horn. This is designed to improve the vertical polars, it basically makes the horn behave as if the source was in the center of the horn instead of the diaphragm of the compression driver.

2) There's another part that I haven't implemented yet. Coming soon!

I made the depth quite a bit less, this is designed to widen the vertical coverage angle. Basically the deeper under the dash you go, the smaller the vertical angle is. So I went the other way.

There's also a couple of innovations that I stole from a recent Bose patent:

1) See how the waveguide 'necks down' in the middle? That moves the apparent source of the sound closer to the mouth of the horn. This is designed to improve the vertical polars, it basically makes the horn behave as if the source was in the center of the horn instead of the diaphragm of the compression driver.

2) There's another part that I haven't implemented yet. Coming soon!

Revisiting this subject.

As described in post #2, one of the challenges with putting waveguides under the dash of a car is that the high frequencies are aimed at your kneecaps. (Image Dynamics HLCD Clone)

One of the potential solutions is to make the height of the horn very narrow, By doing this, it makes the vertical directivity very wide.

The challenge: How short is too short? Can you go down to 3/4"? 1/4"?

Now that I'm finally half-decent with ABEC I can explore these questions faster. Previously, I just had to build and measure, which meant I accumulated a pile of these:

Here's a model I made in ABEC today. Fairly standard underdash waveguide.

As described in post #2, one of the challenges with putting waveguides under the dash of a car is that the high frequencies are aimed at your kneecaps. (Image Dynamics HLCD Clone)

One of the potential solutions is to make the height of the horn very narrow, By doing this, it makes the vertical directivity very wide.

The challenge: How short is too short? Can you go down to 3/4"? 1/4"?

Now that I'm finally half-decent with ABEC I can explore these questions faster. Previously, I just had to build and measure, which meant I accumulated a pile of these:

Here's a model I made in ABEC today. Fairly standard underdash waveguide.

Here's the response of the waveguide and tweeter. Response is falling, fairly standard for constant directivity waveguides.

Here's the polar response. It's actually quite decent. It's "hottest" fifteen degrees off axis, due to the tilt of the waveguide. Beamwidth is around ninety degrees. One thing that's interesting is that where it's "hottest" wanders a bit; at 3500hz it's hottest at 23 degrees, everywhere else it's hottest at 15 degrees.

Here's what the wavefronts look like. Performance is decent, but lobes begin to appear at 4khz and the beamwidth starts to get progressively narrower beginning at 8khz.

I tried making an ABEC model of something like the Veritas horns, where the center of the horn narrows. That seemed to widen the vertical directivity a little bit. I'm not going to bother posting the results as they were very very similar to the results from post #9.

https://mega.nz/#!NLhD2S5a!Bt-QvgUyZPkxOtJNe-XerNvrheF_SlfVN7_mIfPmBGs

Here's a link to a zip file with:

1) the 123D file for Autodesk 123D or Fusion

2) the STL file for just about any program

3) the step file for gmsh

4) the mesh file for ABEC

5) the project file for ABEC

6) the config files for ABEC

If you want to tinker around with it in ABEC, just unzip the file and open the "project.abec" file in ABEC

Have fun!

Note that it's set at a VERY high resolution : 20khz. You'll probably want to reduce that unless you have six CPUs or more. On my quad core Ryzen it took about four hours to solve.

Here's a link to a zip file with:

1) the 123D file for Autodesk 123D or Fusion

2) the STL file for just about any program

3) the step file for gmsh

4) the mesh file for ABEC

5) the project file for ABEC

6) the config files for ABEC

If you want to tinker around with it in ABEC, just unzip the file and open the "project.abec" file in ABEC

Have fun!

Note that it's set at a VERY high resolution : 20khz. You'll probably want to reduce that unless you have six CPUs or more. On my quad core Ryzen it took about four hours to solve.

I had someone email me about this design, and it looks like it's only one half of a waveguide. You'd have to mirror it to get the other half.

The waveguide isn't really finished.

Here's my thoughts:

I think that conventional waveguides like this perform better:

As I see it, those underdash horns that were sorta popular during the 80s and 90s suffer from massive pattern flip, and they're from an era when amplifier power was limited.

IE, those old schold underdash HLCDs can probably get louder than a modern waveguide, but modern waveguides have superior frequency response and polar response, at the expense of sensitivity.

So...

I would personally recommend using a modern waveguide in a car, not an old school underdash HLCD.

But if anyone is really dying for one, I could make one.

Let me know what the interest level is, and if there's a decent amount of interest I can carve out some time to make one.

The waveguide isn't really finished.

Here's my thoughts:

I think that conventional waveguides like this perform better:

As I see it, those underdash horns that were sorta popular during the 80s and 90s suffer from massive pattern flip, and they're from an era when amplifier power was limited.

IE, those old schold underdash HLCDs can probably get louder than a modern waveguide, but modern waveguides have superior frequency response and polar response, at the expense of sensitivity.

So...

I would personally recommend using a modern waveguide in a car, not an old school underdash HLCD.

But if anyone is really dying for one, I could make one.

Let me know what the interest level is, and if there's a decent amount of interest I can carve out some time to make one.

This article is very interesting. I am starting to do some cad and 3d printing and I would really like to experiment with the designs. It appears that the files are no longer available. Maybe Patrick Bateman could help me out.

Unfortunately, I don't have the files any longer 🙁

I would personally recommend using one of my more recent designs:

https://www.diyaudio.com/community/threads/jbl-m2-for-the-poors.247050/post-7256590

my new stuff is generally better than my old stuff, particularly thanks to @mabat

I would personally recommend using one of my more recent designs:

https://www.diyaudio.com/community/threads/jbl-m2-for-the-poors.247050/post-7256590

my new stuff is generally better than my old stuff, particularly thanks to @mabat

Not quite.So I thought I'd try making a clone of the Image Dynamics HLCDs. As I understand it, these were designed by Eric from Image Dynamics.

Definitely incorrect!I believe Bruce Edgar did some consulting on these too. (They were next door neighbors in California back in the day.)

I'm just repeating what people have told me. I do recall that Image Dynamics and Edgarhorn either shared the same space or were next door to each other, about two decades back. Confirmed here:

http://www.apogeeacoustics.com/oldforum/003627.html

Also here: https://www.audioasylum.com/forums/hug/messages/18/186408.html

Mic Wallace has a long history with Image Dynamics and attests to Bruce Edgar working out of the Image Dynamics shop and helping them to refine their horns here:

https://www.bimmerforums.com/forum/...Jeff-Smith-(CA-amp-E)&p=10147880#post10147880

http://www.apogeeacoustics.com/oldforum/003627.html

Also here: https://www.audioasylum.com/forums/hug/messages/18/186408.html

Mic Wallace has a long history with Image Dynamics and attests to Bruce Edgar working out of the Image Dynamics shop and helping them to refine their horns here:

https://www.bimmerforums.com/forum/...Jeff-Smith-(CA-amp-E)&p=10147880#post10147880

- Home

- Loudspeakers

- Multi-Way

- Image Dynamics HLCD Clone