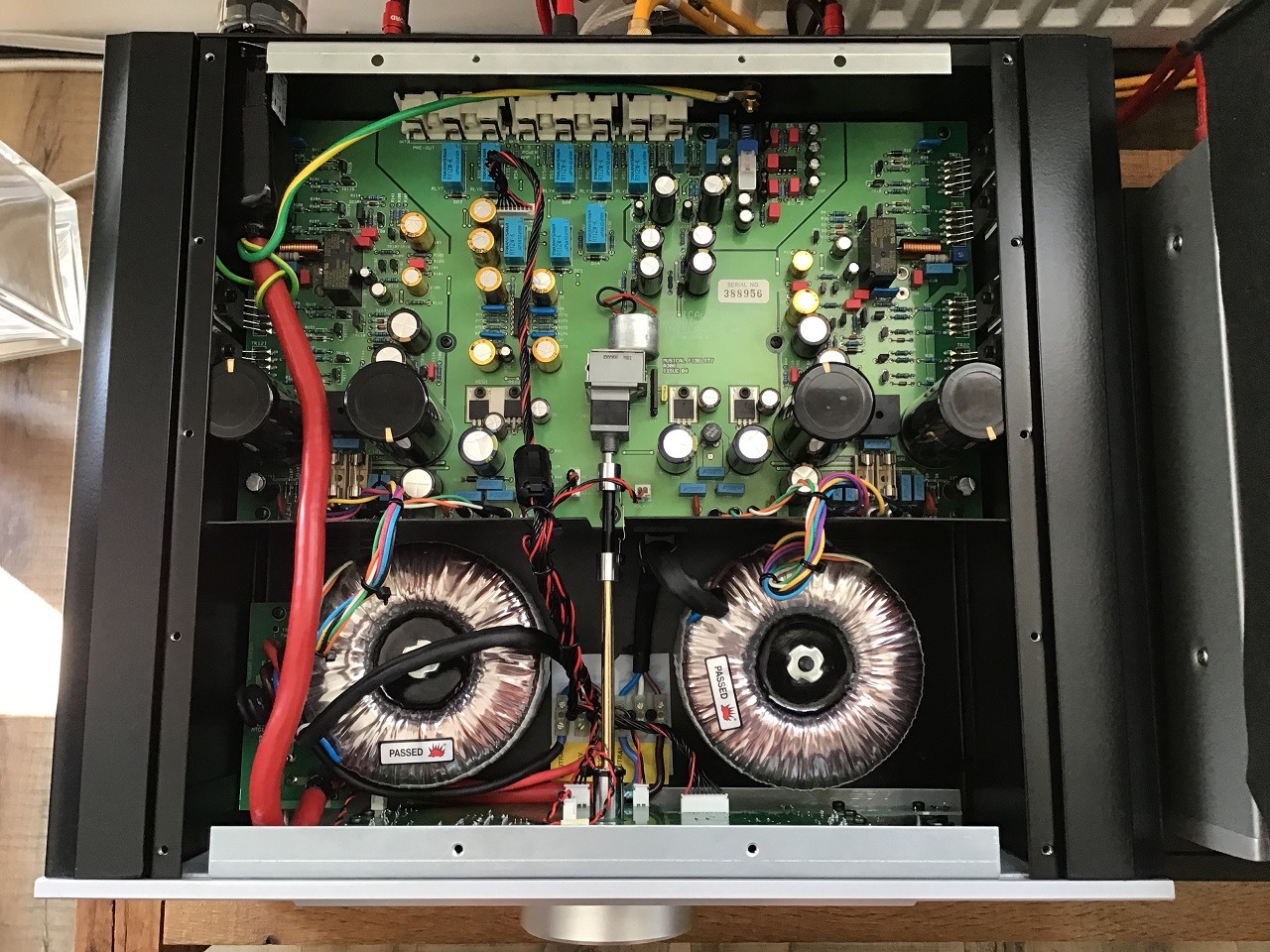

I have been using Musical Fidelity A308CR power amplifier and preamp that I have been using with Totem Hawk speakers for quite some time now. The build date is stamped in 2003, they are both officially 20 years old to date! Everything works great and looks good internally but considering the age, I'd like to give them a refresh and replace the 20 year old capacitors and upgrade a few internal bits as well. I also have modified a Musical fidelity x10v3 tube buffer with an upgrade kit by guy named "Rockgrotto" who supplies modifications for these units (basic soldering, and removal of the old tubes + caps) but that is the extent of my abilities with basic knowledge. So I am open to any suggestions you guys have and what you would change internally in these amplifiers.

Btw, feel free to criticize as well if you don't like the amplifier design - please explain why though! I am aware that Musical Fidelity tends to use fairly basic/average components in their designs (Jamicon caps) and the wiring seems fairly substandard, amongst others. I however look at that as a positive - these amps sound pretty darn good as is (and were the top of the range at the time from Musical Fidelity) so updating/replacing the weak stuff with caps from the likes of Nichicon and adding thicker internal wiring could only make it something special (or at least that's my logic!)

Below are pictures of the a308cr power amplifier for now, as that is what I want to tackle first. So far I am looking at replacing the 8 Jamicon 10000uf 80v caps with Nichicon 10000uf 100v caps (LKG2A103MKZ) and all remaining smaller caps with similar ratings by Nichicon. There are also 14 Metallized Polypropylene Film Capacitors that I would like to update and I'm open to suggestions on that (Wima? Siemens MKV?). Kimber TCX for the main board to binding posts, while using Kimber TCSS for the signal path wiring. I may also consider changing out all the diodes for something better quality as well, but again, I'm open to what you guys think. It has also come to my attention that the amp should be biased properly, but I don't have the equipment to do this - is this necessary? Thank you all in advance!

Btw, feel free to criticize as well if you don't like the amplifier design - please explain why though! I am aware that Musical Fidelity tends to use fairly basic/average components in their designs (Jamicon caps) and the wiring seems fairly substandard, amongst others. I however look at that as a positive - these amps sound pretty darn good as is (and were the top of the range at the time from Musical Fidelity) so updating/replacing the weak stuff with caps from the likes of Nichicon and adding thicker internal wiring could only make it something special (or at least that's my logic!)

Below are pictures of the a308cr power amplifier for now, as that is what I want to tackle first. So far I am looking at replacing the 8 Jamicon 10000uf 80v caps with Nichicon 10000uf 100v caps (LKG2A103MKZ) and all remaining smaller caps with similar ratings by Nichicon. There are also 14 Metallized Polypropylene Film Capacitors that I would like to update and I'm open to suggestions on that (Wima? Siemens MKV?). Kimber TCX for the main board to binding posts, while using Kimber TCSS for the signal path wiring. I may also consider changing out all the diodes for something better quality as well, but again, I'm open to what you guys think. It has also come to my attention that the amp should be biased properly, but I don't have the equipment to do this - is this necessary? Thank you all in advance!

Hi - i recapped my A220 after it blew it’s rectifier bridge due to the caps shorting/excess ripple.

I used CDE for the main caps. The old jamicon 10,000uF have quoted ripple of 5.4A at 50Hz, the CDE i used had a ripple quoted as 6.4A hence the selection. Just check the lead pin width to ensure they fit the pad spacing.

I recapped the signal path by replacing the 10uF electrolytics with WIMA MKP4 10uF. Note there is a large size difference.

I used panasonic organics (low ESR) for the pre amp power supply - note that the derating for 50Hz is drastic. The caps derate from 4000mA to 400mA ripple. My pre section PSU has an ESR of 5mOhm 🙂

I replaced my phono stage electrolytics with Panasonic (although an option for nicicon muse es here) or WIMA. However this is less used.

I had a few discoloured resistors I replaced with CPF higher wattage.

So basically I used CDE for the large electrolytics, panasonic for the smaller electrolytics, WIMA for the film replacements (these will not fit without some wiring).

Why not panasonic film caps? Well I tried them and they were dark and not good sounding compared to the WIMAs.

I also replaced the IEC socket with a schaffner mains filter combined socket - literally a small metalwork adjustment and the same plastic boot fits! Why not have noise reduction at the AC inlet before it hits the torroids?

Lastly - be very very careful with the PCB tracks when removing the caps. The MF cook an egg philosophy means the PCBs are very delicate and the tracks/padscan lift/break very easily.

I’m toying with a OPA replacement.

I used CDE for the main caps. The old jamicon 10,000uF have quoted ripple of 5.4A at 50Hz, the CDE i used had a ripple quoted as 6.4A hence the selection. Just check the lead pin width to ensure they fit the pad spacing.

I recapped the signal path by replacing the 10uF electrolytics with WIMA MKP4 10uF. Note there is a large size difference.

I used panasonic organics (low ESR) for the pre amp power supply - note that the derating for 50Hz is drastic. The caps derate from 4000mA to 400mA ripple. My pre section PSU has an ESR of 5mOhm 🙂

I replaced my phono stage electrolytics with Panasonic (although an option for nicicon muse es here) or WIMA. However this is less used.

I had a few discoloured resistors I replaced with CPF higher wattage.

So basically I used CDE for the large electrolytics, panasonic for the smaller electrolytics, WIMA for the film replacements (these will not fit without some wiring).

Why not panasonic film caps? Well I tried them and they were dark and not good sounding compared to the WIMAs.

I also replaced the IEC socket with a schaffner mains filter combined socket - literally a small metalwork adjustment and the same plastic boot fits! Why not have noise reduction at the AC inlet before it hits the torroids?

Lastly - be very very careful with the PCB tracks when removing the caps. The MF cook an egg philosophy means the PCBs are very delicate and the tracks/padscan lift/break very easily.

I’m toying with a OPA replacement.

Last edited:

I've no reason to criticise this model but I think its worth a cautionary note about tinkering with the output power transistors, the associated power supplies, components and connections. The reason being that MF deployed their favourite Sanken Darlington transistors (SAP15) on masse here and in many other models in the range, during that period. That's fine but they're fragile beasts and their internal emitter resistor commonly failed, rendering the transistor useless. This was a very common fault with MF and others who fitted these advanced types of Darlington transistor. Take care in how you handle this beast, those semis are not common types.

I noted your point about the biasing.

From experience of rebiasing my A220, the bias pots get baked by the heat and the turn to change is very very sensitive. I managed to get the channels biased closer together. You will need something that will allow you to see the wave form - I used a sound card at the time to generate a 1KHz and a 10Khz sine wave at a known peak-to-peak input (using the scope), then used the scope to check the signal output into a pair of 8ohm 100W planar resistors (the A220 is only 50W/ch) as I use 8ohm speakers.

The A220 doesn't have anything between the output transistors (BUZ900/901) and the speaker terminals so I assume this has no output protection either (thus to Ian's point - be careful with the output transistors).

From experience of rebiasing my A220, the bias pots get baked by the heat and the turn to change is very very sensitive. I managed to get the channels biased closer together. You will need something that will allow you to see the wave form - I used a sound card at the time to generate a 1KHz and a 10Khz sine wave at a known peak-to-peak input (using the scope), then used the scope to check the signal output into a pair of 8ohm 100W planar resistors (the A220 is only 50W/ch) as I use 8ohm speakers.

The A220 doesn't have anything between the output transistors (BUZ900/901) and the speaker terminals so I assume this has no output protection either (thus to Ian's point - be careful with the output transistors).

Nickkuk, thanks for the info and advice on watching out for the delicate pads from heat. The entire bulky aluminum case is the heatsink and heat wasn't too much a concern; it is noteworthy that things could get brittle and delicate - especially over 20 years. I've also noticed that some of the caps seem to have been glued on first to make for easier soldering from the factory. Just another issue to take care of when wiggling the large caps off the board.

Ian Finch, youre giving me slight anxiety and possibly foreshadowing with the old saying "If it ain't broke, don't fix it!". So are you saying even if I change the caps to the same spec, it could affect the SAP15 transistors? I planned on making things pretty much the same spec but with updated components and even same length wiring (albeit, with slightly thicker gauge and using copper vs. what seems to be aluminum). I also wanted to raise the original 80v caps to 100v as the costs are negligible and I am not hindered by the size increase.

As a side note, I recently found out that RussAndrews modifies these amps - here's a picture for reference. It seems he does something very similar to what I had planned....

Ian Finch, youre giving me slight anxiety and possibly foreshadowing with the old saying "If it ain't broke, don't fix it!". So are you saying even if I change the caps to the same spec, it could affect the SAP15 transistors? I planned on making things pretty much the same spec but with updated components and even same length wiring (albeit, with slightly thicker gauge and using copper vs. what seems to be aluminum). I also wanted to raise the original 80v caps to 100v as the costs are negligible and I am not hindered by the size increase.

As a side note, I recently found out that RussAndrews modifies these amps - here's a picture for reference. It seems he does something very similar to what I had planned....

The glue under the caps is because the caps will sing under load.

It looks like to access the underside of the board you’ll been to detach all the output devices from the HS. You’ll want new thermal pads if you do that. I used phase change compound pads. Any changes become a risk.

It’a worth giving the sink a bit of a smoothing with emery paper to ensure there’s no burrs that will prevent the devices sitting flat.

I see he has put copper shielding around the caps (i assume they’re grounded.

It’s quite involved process.

It looks like to access the underside of the board you’ll been to detach all the output devices from the HS. You’ll want new thermal pads if you do that. I used phase change compound pads. Any changes become a risk.

It’a worth giving the sink a bit of a smoothing with emery paper to ensure there’s no burrs that will prevent the devices sitting flat.

I see he has put copper shielding around the caps (i assume they’re grounded.

It’s quite involved process.

Last edited:

Hi,

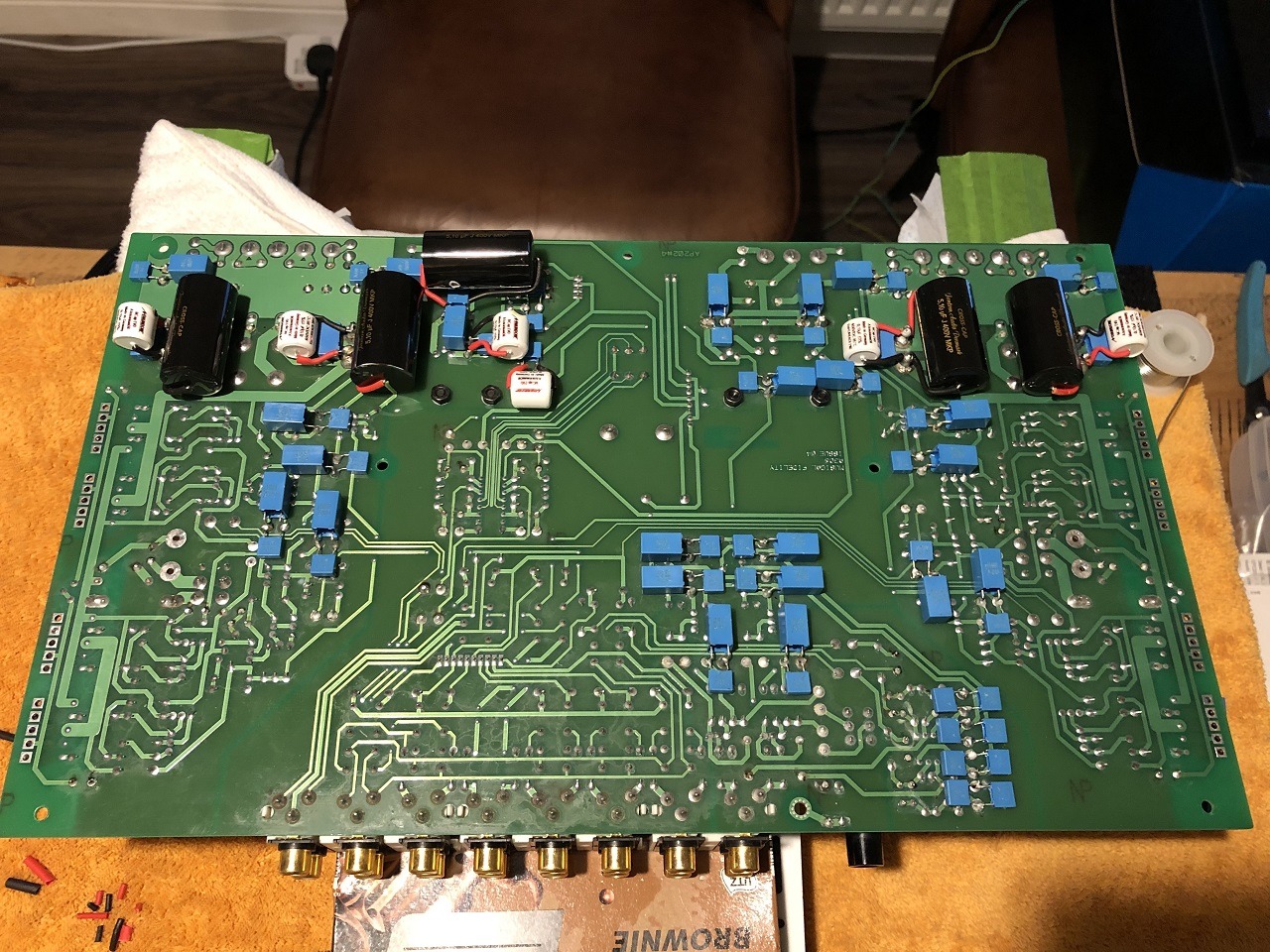

I have a MF A308 that I have extensively modified over the last year or so, including very comprehensive re-cap.

There is a lot of commonality in the overall design, albeit the A308 lacks the choke regulation of the A308cr. Your A308cr is very highly regarded.

Fortunately the PCB's used in the A308 series are very high quality double sided fibreglass boards that were produced and loaded in the UK, so you won't have the same concerns as NickKUK has working on his A220. Incidentally, the gentleman that ran the company that made and loaded the boards is on this forum, search should turn up his posts - they make for useful background reading. One thing I would highly recommend is a vacuum desoldering station if you are going to replace more than a handful of components, otherwise the large copper grounds will sink heat very rapidly and make component removal very difficult and time consuming. The one I purchased was relatively inexpensive and has proven invaluable.

Agree with NcikKUK on fitting a filtered AC inlet. I used Schurter, although I expect they are very similar design. Mouser is an excellent source for components (you may already have your own preferred source), they are listed here.

I also replaced the very cheap internal mains lead and would recommend you do so while you have the amp dismantled. I used screened Belden 19364 – 83803 Combined Design:

I'll take another internals photo as things have changed considerably.

The designer, Tim de Paravicini, gives quite an in depth presentation on the design of the PSU here, well worth a look.

I'll post more background references for you as I also had a good look at what others were doing while planning.

I have a full BoM in excel format if that's of use.

Manuals are hard to come by for MF. I used the A300 manual from hifiengine. It may be useful in some areas.

As Ian and Nick mentioned you will need to unbolt the Allegro Sanken SAP(15P/N?) Darlingtons from the heatsink in order to remove the board. Nothing to be overly concerned about so long as you are careful. Once they are unbolted, remove the Allen bolts from the headsinks and then the heatsinks themselves allows enough flex to remove the board from the chassis. Mains leads and mains input to toroids also need to be disconnected from the chocolate blocks, you won't need to desolder the secondaries this way.

One question on the Nichicons you mentioned is the lead spacing. They are listed as 18mm - does that match the Jamicons? Mine were 10mm.

I carefully cut the adhesive with a stanley knife to remove the Jamicons. As mentioned they should be secured.

After 20+years, one had begun to leak and another rattled, although values were still reasonable.

Don't overlook bypassing the cap's, it is worthwhile:

I used TDK EPCOS, Mundorf Mcap EVO & Jantzen Cross Cap for bypass.

Wima in the signal path.

Choose replacements for the non-polar 10uF carefully - this significantly improved clarity and detail.

Replace the cheap PVC speaker output cables.

I see the inputs are screened, but I'd seriously consider re-routing those away from the chokes and power supply areas of the board and I'd screen the back of the input PCB.

The results are very worthwhile. It will honestly surprise you just how good the amp will sound once the full potential is realised.

I have a MF A308 that I have extensively modified over the last year or so, including very comprehensive re-cap.

There is a lot of commonality in the overall design, albeit the A308 lacks the choke regulation of the A308cr. Your A308cr is very highly regarded.

Fortunately the PCB's used in the A308 series are very high quality double sided fibreglass boards that were produced and loaded in the UK, so you won't have the same concerns as NickKUK has working on his A220. Incidentally, the gentleman that ran the company that made and loaded the boards is on this forum, search should turn up his posts - they make for useful background reading. One thing I would highly recommend is a vacuum desoldering station if you are going to replace more than a handful of components, otherwise the large copper grounds will sink heat very rapidly and make component removal very difficult and time consuming. The one I purchased was relatively inexpensive and has proven invaluable.

Agree with NcikKUK on fitting a filtered AC inlet. I used Schurter, although I expect they are very similar design. Mouser is an excellent source for components (you may already have your own preferred source), they are listed here.

I also replaced the very cheap internal mains lead and would recommend you do so while you have the amp dismantled. I used screened Belden 19364 – 83803 Combined Design:

I'll take another internals photo as things have changed considerably.

The designer, Tim de Paravicini, gives quite an in depth presentation on the design of the PSU here, well worth a look.

I'll post more background references for you as I also had a good look at what others were doing while planning.

I have a full BoM in excel format if that's of use.

Manuals are hard to come by for MF. I used the A300 manual from hifiengine. It may be useful in some areas.

As Ian and Nick mentioned you will need to unbolt the Allegro Sanken SAP(15P/N?) Darlingtons from the heatsink in order to remove the board. Nothing to be overly concerned about so long as you are careful. Once they are unbolted, remove the Allen bolts from the headsinks and then the heatsinks themselves allows enough flex to remove the board from the chassis. Mains leads and mains input to toroids also need to be disconnected from the chocolate blocks, you won't need to desolder the secondaries this way.

One question on the Nichicons you mentioned is the lead spacing. They are listed as 18mm - does that match the Jamicons? Mine were 10mm.

I carefully cut the adhesive with a stanley knife to remove the Jamicons. As mentioned they should be secured.

After 20+years, one had begun to leak and another rattled, although values were still reasonable.

Don't overlook bypassing the cap's, it is worthwhile:

I used TDK EPCOS, Mundorf Mcap EVO & Jantzen Cross Cap for bypass.

Wima in the signal path.

Choose replacements for the non-polar 10uF carefully - this significantly improved clarity and detail.

Replace the cheap PVC speaker output cables.

I see the inputs are screened, but I'd seriously consider re-routing those away from the chokes and power supply areas of the board and I'd screen the back of the input PCB.

The results are very worthwhile. It will honestly surprise you just how good the amp will sound once the full potential is realised.

For thermal pad replacements Keratherm Red 86/82 are recommended should you elect to do so and available from this forum shop, albeit if you are outside the US shipping and import duty adds to the cost.

As mentioned, I replaced the cheap PVC clad speaker output wires and also the thin brass jumpers that are used as attachment points to the binding posts:

I wouldn't say it was necessary, but I did also replace the binding posts with WBT-0710 Cu mC:

More importantly, don't overlook the mains lead - again I replaced it with screened Belden 19364 – 83803 Combined Design, shielded with Flexo® Anti-Stat - 9.53mm - Black (CNN0.38BK). Furutech FI-11 N1(R) IEC Connector and MK Toughplug - Silver Plated - Black.

Returning to capacitors,

If there is space beneath the board I would highly recommend Nichicon UFW 2200uF or greater direct to the collector of each output transistor.

I adopted this from a recommendation for Naim amplifiers and it results in a significant improvement in low end authority. Images here.

- Electrolytic power supply decoupling caps are low ESR Panasonic FM/FC/NHG, Elna Silmic II RFS or Nichicon Muse KZ, bypassed with Epcos MKP

- Non-polar coupling caps are Audio Note Kaisei NON-POLAR PET, bypassed with Epcos MKP. Not cheap, but very good. I haven't tried Wima MKP's although I've seen several recommendations.

Some additional references for reading on MF upgrades:

https://audiokarma.org/forums/index.php?threads/musical-fidelity-owners-thread.692782/page-2

Musical Fidelity A5 Amplifier dynamic performance test and circuit (take some of the comments with a grain of salt)

Future plans for my A308 are to replace the W04 bridge rectifiers with discrete Vishay VS-E5PH3012L-N3 fast recovery rectifiers and introduce a Pi filter (again, A308 is not choke regulated) to further improve smoothing as per Nelson Pass reference designs.

Last couple of recommendations, high quality solder, e.g. Audio Note 6% Silver Solder and deflux the PCBs when you are done.

Solder picks are very useful for component removal as most component legs are bent over.

As mentioned, I replaced the cheap PVC clad speaker output wires and also the thin brass jumpers that are used as attachment points to the binding posts:

I wouldn't say it was necessary, but I did also replace the binding posts with WBT-0710 Cu mC:

More importantly, don't overlook the mains lead - again I replaced it with screened Belden 19364 – 83803 Combined Design, shielded with Flexo® Anti-Stat - 9.53mm - Black (CNN0.38BK). Furutech FI-11 N1(R) IEC Connector and MK Toughplug - Silver Plated - Black.

Returning to capacitors,

- the polypropylene film bypass and snubber capacitors were replaced with TDK EPCOS metal film. They are inexpensive so I replaced all of them, EPCOS B32521E6104J

- smoothing caps 10000uF Jamicon LP replaced with Mundorf Mlytic AG 22000uF, bypassed with Jantzen Audio 5% 5.1uF EPCOS B32521E6104J 0.1uF and Mundorf MCap EVO Oil 5% 0.01uF

If there is space beneath the board I would highly recommend Nichicon UFW 2200uF or greater direct to the collector of each output transistor.

I adopted this from a recommendation for Naim amplifiers and it results in a significant improvement in low end authority. Images here.

- Electrolytic power supply decoupling caps are low ESR Panasonic FM/FC/NHG, Elna Silmic II RFS or Nichicon Muse KZ, bypassed with Epcos MKP

- Non-polar coupling caps are Audio Note Kaisei NON-POLAR PET, bypassed with Epcos MKP. Not cheap, but very good. I haven't tried Wima MKP's although I've seen several recommendations.

Some additional references for reading on MF upgrades:

https://audiokarma.org/forums/index.php?threads/musical-fidelity-owners-thread.692782/page-2

Musical Fidelity A5 Amplifier dynamic performance test and circuit (take some of the comments with a grain of salt)

Future plans for my A308 are to replace the W04 bridge rectifiers with discrete Vishay VS-E5PH3012L-N3 fast recovery rectifiers and introduce a Pi filter (again, A308 is not choke regulated) to further improve smoothing as per Nelson Pass reference designs.

Last couple of recommendations, high quality solder, e.g. Audio Note 6% Silver Solder and deflux the PCBs when you are done.

Solder picks are very useful for component removal as most component legs are bent over.

Not really - my point was just that these transistors are easily damaged and and the original line is long obsolete - now replaced by STDO3 which requires the additional resistor. Mostly, the SAP15 semis offered online are just fakes whilst the originals are virtually unobtainium at reasonable prices. Octopart shows a price of US$27-39 ea. from only one bona fide supplier. For DIYs in particular, its too easy to damage these transistors whist testing and tinkering with experimental mods and it's far better to eliminate risks by not taking them - particularly with replacement semis, circuit modifications, test gear quality and procedures.Ian Finch, youre giving me slight anxiety and possibly foreshadowing with the old saying "If it ain't broke, don't fix it!". So are you saying even if I change the caps to the same spec, it could affect the SAP15 transistors?

Protegimus, thank you for taking the time and effort into putting that treasure trove of information you’ve provided! I have also owned the a308 Integrated and I agree, they are similar but there are distinct audio differences in comparing the A308cr power and preamps – in particular, I have noticed the high’s were immediately more ‘distinct’ with a different quality when I switched between the amps.

In regards to all of your suggestions, I will certainly keep everything in mind and I have gone through quite a few hours worth of reading re-evaluating what work should be done (and consequently, what work I feel comfortable with doing myself).

First of all, of particular concern is not having schematics or workshop manuals for these amplifiers. This leads me to complications with what particular values to use for any use of bypassing caps and biasing the amp. Thanks to your link for technical data on the SAP15P, that does seem to give a general idea where values should be but is still a bit of an unknown and risky business for someone like me to be fooling around with. I also don’t have the specialized equipment aside from your standard multimeter.

In regard to bypassing caps: I am very surprised that you bypassed ALL of your caps on the board of your a308 and not just the 4 main large caps. That is one hell of a lot of work! Sadly, I think this area of tinkering is beyond my abilities at the moment. Especially since I had overlooked the simple task of lead spacing on the capacitor replacements(!). You are correct that the Jamicons are 10mm spacing so I am debating whether I will go for the Kemet (ALC10S1104DL) or Nichicon (LLS1K103MELC) which are both 10,000uf and 80v. These caps are reasonably priced for what I can source here in Canada and provide top level specifications all things relative to others. Any insight on which would be a better choice?

Another surprise is that you said you went to Mundorf 22000uF? That’s a huge increase from 10,000uF… have you encountered any issues with this? I was under the impression that this is generally something you should only increase ever so slightly if wanted. The voltage increase would be more of a standard practice to increase without much ill effect but I have decided to keep things simple and match things fairly to OEM specification (and yes, I am aware the Kemet capacitors I am looking at are taller by a quite a bit (80mm vs 50mm) but they will fit just fine)

Here is a link to what Russ Andrews does on his site (as was referenced before) to his modified a308cr services: https://www.russandrews.com/us/musical-fidelity-a308cr-power-amp-upgrade/. I think for simplicity sake and what I have read thus far in regards to bypassing caps, I may forego doing this for now – but more reading is needed on my part in understanding what this accomplishes and what I can expect in result. If you look in the link above, he uses rather small bypass caps on what seems to be the 8 main capacitors with Kimberkap 018 +-10% 600v caps. How would this compare versus what you have done?

I’ll have to open up the a308cr preamp next and see what sort of fun I’m in for on that end of things next and then the wallet draining procedure can commence!

In regards to all of your suggestions, I will certainly keep everything in mind and I have gone through quite a few hours worth of reading re-evaluating what work should be done (and consequently, what work I feel comfortable with doing myself).

First of all, of particular concern is not having schematics or workshop manuals for these amplifiers. This leads me to complications with what particular values to use for any use of bypassing caps and biasing the amp. Thanks to your link for technical data on the SAP15P, that does seem to give a general idea where values should be but is still a bit of an unknown and risky business for someone like me to be fooling around with. I also don’t have the specialized equipment aside from your standard multimeter.

In regard to bypassing caps: I am very surprised that you bypassed ALL of your caps on the board of your a308 and not just the 4 main large caps. That is one hell of a lot of work! Sadly, I think this area of tinkering is beyond my abilities at the moment. Especially since I had overlooked the simple task of lead spacing on the capacitor replacements(!). You are correct that the Jamicons are 10mm spacing so I am debating whether I will go for the Kemet (ALC10S1104DL) or Nichicon (LLS1K103MELC) which are both 10,000uf and 80v. These caps are reasonably priced for what I can source here in Canada and provide top level specifications all things relative to others. Any insight on which would be a better choice?

Another surprise is that you said you went to Mundorf 22000uF? That’s a huge increase from 10,000uF… have you encountered any issues with this? I was under the impression that this is generally something you should only increase ever so slightly if wanted. The voltage increase would be more of a standard practice to increase without much ill effect but I have decided to keep things simple and match things fairly to OEM specification (and yes, I am aware the Kemet capacitors I am looking at are taller by a quite a bit (80mm vs 50mm) but they will fit just fine)

Here is a link to what Russ Andrews does on his site (as was referenced before) to his modified a308cr services: https://www.russandrews.com/us/musical-fidelity-a308cr-power-amp-upgrade/. I think for simplicity sake and what I have read thus far in regards to bypassing caps, I may forego doing this for now – but more reading is needed on my part in understanding what this accomplishes and what I can expect in result. If you look in the link above, he uses rather small bypass caps on what seems to be the 8 main capacitors with Kimberkap 018 +-10% 600v caps. How would this compare versus what you have done?

I’ll have to open up the a308cr preamp next and see what sort of fun I’m in for on that end of things next and then the wallet draining procedure can commence!

Protegimus, thank you for taking the time and effort into putting that treasure trove of information you’ve provided! I have also owned the a308 Integrated and I agree, they are similar but there are distinct audio differences in comparing the A308cr power and preamps – in particular, I have noticed the high’s were immediately more ‘distinct’ with a different quality when I switched between the amps.

In regards to all of your suggestions, I will certainly keep everything in mind and I have gone through quite a few hours worth of reading re-evaluating what work should be done (and consequently, what work I feel comfortable with doing myself).

First of all, of particular concern is not having schematics or workshop manuals for these amplifiers. This leads me to complications with what particular values to use for any use of bypassing caps and biasing the amp. Thanks to your link for technical data on the SAP15P, that does seem to give a general idea where values should be but is still a bit of an unknown and risky business for someone like me to be fooling around with. I also don’t have the specialized equipment aside from your standard multimeter.

In regard to bypassing caps: I am very surprised that you bypassed ALL of your caps on the board of your a308 and not just the 4 main large caps. That is one hell of a lot of work! Sadly, I think this area of tinkering is beyond my abilities at the moment. Especially since I had overlooked the simple task of lead spacing on the capacitor replacements(!). You are correct that the Jamicons are 10mm spacing so I am debating whether I will go for the Kemet (ALC10S1104DL) or Nichicon (LLS1K103MELC) which are both 10,000uf and 80v. These caps are reasonably priced for what I can source here in Canada and provide top level specifications all things relative to others. Any insight on which would be a better choice?

Another surprise is that you said you went to Mundorf 22000uF? That’s a huge increase from 10,000uF… have you encountered any issues with this? I was under the impression that this is generally something you should only increase ever so slightly if wanted. The voltage increase would be more of a standard practice to increase without much ill effect but I have decided to keep things simple and match things fairly to OEM specification (and yes, I am aware the Kemet capacitors I am looking at are taller by a quite a bit (80mm vs 50mm) but they will fit just fine)

Here is a link to what Russ Andrews does on his site (as was referenced before) to his modified a308cr services: https://www.russandrews.com/us/musical-fidelity-a308cr-power-amp-upgrade/. I think for simplicity sake and what I have read thus far in regards to bypassing caps, I may forego doing this for now – but more reading is needed on my part in understanding what this accomplishes and what I can expect in result. If you look in the link above, he uses rather small bypass caps on what seems to be the 8 main capacitors with Kimberkap 018 +-10% 600v caps. How would this compare versus what you have done?

I’ll have to open up the a308cr preamp next and see what sort of fun I’m in for on that end of things next and then the wallet draining procedure can commence!

You are welcome.

Schematics - the A300 manual will be helpful as a starting point. Despite the obvious differences these A3 series amps are all iterations of a similar basic theme.

I studied numerous MF (and other) designs and elements commonly appear across widely differing designs. NickKUK has an excellent thread on the A220 that utilises a very similar pre-amp stage. He also has LTSpice skills that he used to create a schematic of his own circuitry. Again worth looking at, lot's to learn!

No harm in simply drawing the relevant circuits out as a starting point.

Once you learn some of the fundamentals, it's only the application that changes and you quickly begin to understand and analyse in depth areas of interest.

Bypassing caps - likely due to cost saving MF were often guilty of omitting bypass capacitors where they are recommended in manufacturer application notes.

Appreciate that there are diminishing returns, but quite a few factors come into play:

- amp (and components) was designed more than 20 years ago. EMF landscape has completely changed in that time, mobile phones, wi-fi, SMPS, etc.

- other high end manufacturers often include them in their designs

- the required components are very inexpensive

- anecdotal evidence from the success of others and my own experience

- values:- I used very similar values to those used in the Russ Andrews upgrades (I used his recommendations for research too!)

It is a fair amount of work, but easily achievable. Took me three or four days to complete and I'm very methodical.

You will need a high wattage soldering iron (90W recommended) with fine tip due to the large PCB traces/ground planes sinking heat.

PSU smoothing capacitors - looking at the vendor spec sheets for the KEMET and Nichikons you've proposed, personally I'd go with the KEMETs as you've confirmed they fit.

- purpose designed for audio

- excellent ripple current rating (odd it is not listed in the KEMET datasheet)

- good ESR (not listed for the Nichikon)

- long lifetime

- cost similar

- Noted the Nichikon has significantly lower leakage current, that may well be a trade-off due to optimised construction of the KEMET for audio.

- derating - yes if you can improve through higher temp and voltage rating definitely do so. Be aware of ripple derating from the datasheets if data available, but with quality of components you're considering, not an issue

Regarding the Mundorf 22000uF, zero issues. The amps use PTCs for soft start, so no concerns with inrush current, etc.

As I mentioned the A308 doesn't have the excellent choke regulated PSU of the A308cr; simply linear unregulated supplies, so major benefits to be gained here. Have a look at Nelson Pass designs for more information on this.

Biasing - the datasheet does provide the necessary data, MF implementation is pretty much verbatim.

Without necessary equipment (again refer to NickKUK's A220 thread, great insight there) I'd leave adjustment alone unless you plan to change components other than caps in the output stages. You can safely measure the current values if confident though.

In terms of approach, I'd recommend

mains cabling (internal and power cable),

mains filter

PSU smoothing (including the smaller electrolytics once you've identified suitable values and purpose)

metallized polypropylene film capacitors used as snubbers, etc.

Non-polar coupling caps are a must

Something that will make the task manageable and less prone to mistakes is to make up your own Bill of Materials for your project.

I photographed and measured every component of interest then made up a spreadsheet to document them and list chosen replacements.

Quite time consuming, but very worthwhile as you are learning about the circuitry as you work through amp.

Small correction, in-rush current limiters are NTCs mounted on the small power switch PCB bottom left in your first photo (same PCB for A308 int and A308cr).

The PTCs are used in each of the low voltage secondary connections.

Nichicon 🙂

Couple more points intended to be included in recommendations for approach,

replace the cheap PVC clad speaker wires

improve the connections to the binding posts (I used some nice Mundorf copper ring terminals I had from another project)

Not intending to spam your thread with my stuff, but thought it might be useful to show current upgrade status as above images are from a fair few months ago.

Changes are discrete +-15V regulators with heatsink, discrete op-amps & solid tantalum reservoir capacitors. Dry carbon/Wurth Elektronik EMI shield between mains section and PCB and also for the RCAs.

Four layer carbon is 99% effective EMI screen.

Damping mounts for the toroidal transformers (fashioned from self-adhesive bitumen speaker cabinet damping pads) and chassis top, with additional EMI shielding for cabling, relays, etc. from TitanRF Faraday tape/sheet:

Hope the details are valuable for your mods!

Not only around the caps, but also around the toroidal transformers:

I won't speculate on effectiveness, however I've seen the copper shielding on capacitors in a few photo's of (older) high end amps?

Anyone have more details on effectiveness?

The PTCs are used in each of the low voltage secondary connections.

Nichicon 🙂

Couple more points intended to be included in recommendations for approach,

replace the cheap PVC clad speaker wires

improve the connections to the binding posts (I used some nice Mundorf copper ring terminals I had from another project)

Not intending to spam your thread with my stuff, but thought it might be useful to show current upgrade status as above images are from a fair few months ago.

Changes are discrete +-15V regulators with heatsink, discrete op-amps & solid tantalum reservoir capacitors. Dry carbon/Wurth Elektronik EMI shield between mains section and PCB and also for the RCAs.

Four layer carbon is 99% effective EMI screen.

Damping mounts for the toroidal transformers (fashioned from self-adhesive bitumen speaker cabinet damping pads) and chassis top, with additional EMI shielding for cabling, relays, etc. from TitanRF Faraday tape/sheet:

Hope the details are valuable for your mods!

Hi Nick, hope you are well....

I see he has put copper shielding around the caps (i assume they’re grounded.

...

Not only around the caps, but also around the toroidal transformers:

I won't speculate on effectiveness, however I've seen the copper shielding on capacitors in a few photo's of (older) high end amps?

Anyone have more details on effectiveness?

That carbon fiber shielding is really neat - you really went to town on that amplifier and it's giving me plenty of idea's! I can actually address the copper tape shielding around the caps via this thread: https://www.diyaudio.com/community/threads/copper-foil-around-electrolytic-capacitors.64748/

It does actually work! But it is negligible... interesting as to why nonetheless. Much better to ground the shielding if you're going through with that apparently.

It does actually work! But it is negligible... interesting as to why nonetheless. Much better to ground the shielding if you're going through with that apparently.

The carbon fibre you will want to ensure you have a good bond with the earthing (possibly need to abrade some of the epoxy for that). An alternative is use double copper claded PCB sheets, mark and cut but with the benefit that they can be soldered (again a large soldering iron required) to ensure a good bonding between any sides.

The A220 differs in it uses the heatsink itself as a shield between the transformer and the amp. As the heatsink is bolted onto the chassis, it acts like a bonding to protective earth.

Also the A220 suffers in a design decision that the signal path goes around 3 sides of the amp. Shortening that, bypassing the manual selector switch improved the sound quality (yours has relays so it won't suffer the same). However the old ALPS volume pot could also be replaced for a stereo stepped attenuator which the A220 doesn't have the space for. The design of the A220 volume interacts with both sides of the two opamps (IIRC it's on the feedback) so it's not a simple feed the signal through the volume pot to attenuate. In the end I decided against going all out to modify all the components because I bought the amp after auditioning both the Cyrus and the Audiolab 8000 at the time.. The audiolab was crystal clear to the A220's a little less but I found both far better than the Cyrus which turned me of Cyrus gear for life.

As an aside I am considering replacing the A220's opamp (MC33079P quad opamp) with a OPA1644 (a modern quad opamp) with local ceramics+film for decoupling the power on the pins of the 1644 on the TSOP to DIP adaptor for kicks and giggles. However my attention is turning to the CDP which I'm eyeing up changing the DAC.

If you do start changing components - I would recommend saving your speakers by using a pair of Ohmite LPR series planar resistors (mine are 8ohm 100W) to act as dummy loads. Any oops means only destroying the amp rather than your speakers too.

I also would agree with making changes incrementally as discussed above. It's very easy to desire to make changes that are justified mentally (confirmation bias), so take each step and measure before+after (this is where a good audio analyser helps). It also prevents you from making things worse without realising it.

The A220 differs in it uses the heatsink itself as a shield between the transformer and the amp. As the heatsink is bolted onto the chassis, it acts like a bonding to protective earth.

Also the A220 suffers in a design decision that the signal path goes around 3 sides of the amp. Shortening that, bypassing the manual selector switch improved the sound quality (yours has relays so it won't suffer the same). However the old ALPS volume pot could also be replaced for a stereo stepped attenuator which the A220 doesn't have the space for. The design of the A220 volume interacts with both sides of the two opamps (IIRC it's on the feedback) so it's not a simple feed the signal through the volume pot to attenuate. In the end I decided against going all out to modify all the components because I bought the amp after auditioning both the Cyrus and the Audiolab 8000 at the time.. The audiolab was crystal clear to the A220's a little less but I found both far better than the Cyrus which turned me of Cyrus gear for life.

As an aside I am considering replacing the A220's opamp (MC33079P quad opamp) with a OPA1644 (a modern quad opamp) with local ceramics+film for decoupling the power on the pins of the 1644 on the TSOP to DIP adaptor for kicks and giggles. However my attention is turning to the CDP which I'm eyeing up changing the DAC.

If you do start changing components - I would recommend saving your speakers by using a pair of Ohmite LPR series planar resistors (mine are 8ohm 100W) to act as dummy loads. Any oops means only destroying the amp rather than your speakers too.

I also would agree with making changes incrementally as discussed above. It's very easy to desire to make changes that are justified mentally (confirmation bias), so take each step and measure before+after (this is where a good audio analyser helps). It also prevents you from making things worse without realising it.

Last edited:

Quick question Protegimus: you said you replaced your film caps with Epcos B32521E6104J. The a308cr has "104J 250v" film caps throughout while your replacement you mentioned is rated 400v - I assume your a308 and my a308cr basically use the same parts. Is the voltage disparity an issue or am I doing things incorrectly? (btw, I tried contacting you via facebook for such simple questions to no avail). I'm just about to place a big order with Mouser as I begin this project - I opened up the a308cr power amp to take a closer look at things and it seems pretty much all of my PSU caps are bulging at the top. Needless to say I'm excited to hear the differences given that the amp sounds good as is with outdated, average, bulging caps! lol

Thanks again NickKUK for all the info! I wish had more time, budget, patience, and expertise to make the measurements and changes accordingly. I think a basic spec-for-spec full capacitor replacement and re-wiring with higher quality cable throughout, including the mains, is as good as it's going to get at this time but should also yield significant gains based on what I've been reading so far. I feel bypassing caps and changing other components are beyond my understanding and expertise at the moment and should give me a good start before digging in further. This also plays into your suggestion of making changes incrementally which I completely agree with. If all goes smoothly, I'll move on to the a308cr preamp that I have with similar changes

Thanks again NickKUK for all the info! I wish had more time, budget, patience, and expertise to make the measurements and changes accordingly. I think a basic spec-for-spec full capacitor replacement and re-wiring with higher quality cable throughout, including the mains, is as good as it's going to get at this time but should also yield significant gains based on what I've been reading so far. I feel bypassing caps and changing other components are beyond my understanding and expertise at the moment and should give me a good start before digging in further. This also plays into your suggestion of making changes incrementally which I completely agree with. If all goes smoothly, I'll move on to the a308cr preamp that I have with similar changes

Last edited:

One last note - I noticed that you and Russ Andrews' mod replaced the orange ceramic cap with "471J" with film caps. This is located right by the adjusting pot on both left and right channels. Why was this done and what did you replace it with? It seems Russ Andrews replaced it with a WIMA film cap given the signature red colored capacitor but left the other ceramics in place and I'm not sure what model or spec it was replaced with...

So the orange is a ceramic cap. The brown-datk red is a film cap. Those were the original looking caps for the A220 however i could never identify their manufacturer.

Panasonic make similar looking brown film caps but they wre marked with an M in a circle. I found the panasonic caps on the signal path of the A220 to not sound as good as wima (but insert your voice wn preference here).

Without the schematic i can’t say more because I don’t know the purpose.

The voltage difference in caps (going up in voltage rating is ok) can return benefits in sound but careful of lead size changes.

A 0.22uF 630V wima fkp1 is larger than a 100V MKP4 10uF. The build/type of cap also differs. Hence you need to understand the purpose, why the values csj be increased (or not - if it changes signal filtering the wrong way).

Panasonic make similar looking brown film caps but they wre marked with an M in a circle. I found the panasonic caps on the signal path of the A220 to not sound as good as wima (but insert your voice wn preference here).

Without the schematic i can’t say more because I don’t know the purpose.

The voltage difference in caps (going up in voltage rating is ok) can return benefits in sound but careful of lead size changes.

A 0.22uF 630V wima fkp1 is larger than a 100V MKP4 10uF. The build/type of cap also differs. Hence you need to understand the purpose, why the values csj be increased (or not - if it changes signal filtering the wrong way).

Hi,

C17 and C117 471J 470pF 5% tolerance +20year old low quality ceramics replaced with WIMA FKP2-470/100/2.5T 470pf 2.5% tolerance. Purpose is RF filter caps direct across the speaker outputs, reduce any antenna pickup/emission from the speaker cables!

For analogue bypass/decoupling the polypropylene/metal film WIMA and TDK EPCOS are selected due to their superior characteristics, less susceptibility to microphonics, low cost and preferred audio performance.

Lead spacing is drop in replacement. Do you want a copy of my BoM? As I mentioned there are a significant number of common components especially in the output stages.

Nick has already answered on voltage rating (thanks Nick!). Higher voltage rating cap's often provide improved characteristics (see voltage derating). Always double check the data sheet rating as many suppliers list DC and AC ratings interchangeably and they are not!

With respect to the ceramics the metal film package are only slightly larger in footprint 7.2 x 4.5 x 6.5mm l x w x h with 5mm lead spacing.

My only comment here is to add the bypass caps for the main PSU replacements during installation.

Reason - for the large caps the solder lands are massive (especially the ground planes) so you will need to use a powerful iron/gun to apply heat for minimal period to avoid damaging your expensive new reservoirs! You don't want to do this again.

Bypassing lowers ESR, offers improved pulse rise time to meet transient demand and values are chosen to optimise reactance for filtering higher frequency noise (Xc = 1/2πfC).

You are welcome to add me on fb (Musical Fidelity group?). It would be nice to keep all the information here in one place for others reference (intend to collate my own posts into a A308 int thread for the same reason at some point!).

[edit]

Additional notes for disassembly

Good luck & why not save and share your mouser project so that we can offer any recommendations before you spend your hard earned$ 🙂

C17 and C117 471J 470pF 5% tolerance +20year old low quality ceramics replaced with WIMA FKP2-470/100/2.5T 470pf 2.5% tolerance. Purpose is RF filter caps direct across the speaker outputs, reduce any antenna pickup/emission from the speaker cables!

For analogue bypass/decoupling the polypropylene/metal film WIMA and TDK EPCOS are selected due to their superior characteristics, less susceptibility to microphonics, low cost and preferred audio performance.

Lead spacing is drop in replacement. Do you want a copy of my BoM? As I mentioned there are a significant number of common components especially in the output stages.

One last note - I noticed that you and Russ Andrews' mod replaced the orange ceramic cap with "471J" with film caps. This is located right by the adjusting pot on both left and right channels. Why was this done and what did you replace it with? It seems Russ Andrews replaced it with a WIMA film cap given the signature red colored capacitor but left the other ceramics in place and I'm not sure what model or spec it was replaced with...

Nick has already answered on voltage rating (thanks Nick!). Higher voltage rating cap's often provide improved characteristics (see voltage derating). Always double check the data sheet rating as many suppliers list DC and AC ratings interchangeably and they are not!

With respect to the ceramics the metal film package are only slightly larger in footprint 7.2 x 4.5 x 6.5mm l x w x h with 5mm lead spacing.

Quick question Protegimus: you said you replaced your film caps with Epcos B32521E6104J. The a308cr has "104J 250v" film caps throughout while your replacement you mentioned is rated 400v - I assume your a308 and my a308cr basically use the same parts. Is the voltage disparity an issue or am I doing things incorrectly? (btw, I tried contacting you via facebook for such simple questions to no avail). I'm just about to place a big order with Mouser as I begin this project - I opened up the a308cr power amp to take a closer look at things and it seems pretty much all of my PSU caps are bulging at the top. Needless to say I'm excited to hear the differences given that the amp sounds good as is with outdated, average, bulging caps! lol

Thanks again NickKUK for all the info! I wish had more time, budget, patience, and expertise to make the measurements and changes accordingly. I think a basic spec-for-spec full capacitor replacement and re-wiring with higher quality cable throughout, including the mains, is as good as it's going to get at this time but should also yield significant gains based on what I've been reading so far. I feel bypassing caps and changing other components are beyond my understanding and expertise at the moment and should give me a good start before digging in further. This also plays into your suggestion of making changes incrementally which I completely agree with. If all goes smoothly, I'll move on to the a308cr preamp that I have with similar changes

My only comment here is to add the bypass caps for the main PSU replacements during installation.

Reason - for the large caps the solder lands are massive (especially the ground planes) so you will need to use a powerful iron/gun to apply heat for minimal period to avoid damaging your expensive new reservoirs! You don't want to do this again.

Bypassing lowers ESR, offers improved pulse rise time to meet transient demand and values are chosen to optimise reactance for filtering higher frequency noise (Xc = 1/2πfC).

You are welcome to add me on fb (Musical Fidelity group?). It would be nice to keep all the information here in one place for others reference (intend to collate my own posts into a A308 int thread for the same reason at some point!).

[edit]

Additional notes for disassembly

- looks like the bridge rectifiers are bolted to the base of the chassis for heatsink

- the washers on the (phillips head on the A308cr) screws for the Sanken Darlington output transistors are separate. I used a tiny drop of superglue to attach them to the head and make them captive, makes assembly easier!

Good luck & why not save and share your mouser project so that we can offer any recommendations before you spend your hard earned$ 🙂

Last edited:

Good luck & why not save and share your mouser project so that we can offer any recommendations before you spend your hard earned$ 🙂

I would certainly recommend this. A different set of eyes over a BOM is worth it's weight in gold. Especially when you're spending a considerable amount.

I would also think about solder, flux and cleaning. Desoldering can be done in a number of ways - suckers, braid and even cutting the pins of the old component to make the removal of the remaining wire easier and less chance of damaging the pads.

If this is your first time soldering or desoldering (there's an art to this too) you may want to get a small DIY kit to simply solder then desolder and resolder the parts (the kit it disposable but the experience will be live on).

Incidentally I decided to add the replacement OPA to yesterdays mouser purchase (separate project).. so I'll have the top off the A220 again 😀

Probably one of the most important questions - do you have a multimeter? If you want to splash for a decent one I can recommend the Brymen 869s but the other Brymen are decent. I have a couple of other <£30 multimeters and they worked with less resolution.

One observation - the jamicons didn't have a blow open pressure release at the top of the can, and the plastic simply domes so there's no real indication other than the leak at the bottom - the lack of a pressure release is another sign of lack of quality. I took one of mine apart to see why it was rattling! This is why @Protegimus started to see the leak at the bottom. First sign of a cap problem I had was the fuse blew and the bridge rectifier was damaged.

Last edited:

Alright guys, thanks for your patience with me and I really appreciate having you look over everything before purchasing. I've attached the BOM as a .pdf. What is not included is the bypass caps yet and wire replacements of which I will source at a local shop (probably Kimber TCSS for signal leads and Kimber TCX for high current leads) plus internal power cabling using Belden 19364 – 83803 as recommended. The AC mains on this unit does use a filter capacitor already so I may just leave it at that (numbers listed on the cartridge are 220n x2 and 275v ~ SH) and I already have a thick external mains lead that I use.

Protegimus, you have convinced me to at least solder on some bypass caps to the 8 main capacitors. Given the Kemet slit capacitors that I chose, what would be an appropriate bypass capacitor to use? I have heard of the 1% rule... but this area is completely foreign to me.

Just for reference, I do have a Etepon WH5000A multimeter and a nice 100w soldering iron with high silver solder, flux, solder pump etc. I have experience working on replacing all the caps and tubes on a Musical Fidelity X10v3 tube buffer that I enjoy using in my system and that turned out well. I was also aware that increasing voltage can lead to gains, but I was not aware that film caps originally rated at 250v can be replaced with caps rated at 400v - something about going so widely different from OEM spec had me thinking I was misinterpreting something.

Other things that I plan on doing: Taking the 4 fuses and giving the contact tips a very light sanding with something like 600 grit sandpaper on the ends and then coating with dielectric grease given the 20+ years of oxidation. I also plan to install some very simple heatsinks on the total of 4 JE350/JE340 transistors given what I saw happen on the MF X10v3 - literal burn marks from cooking the PCB due to the heat output (and yes, I measured the transistors and they were all still within spec and working)

Protegimus, you have convinced me to at least solder on some bypass caps to the 8 main capacitors. Given the Kemet slit capacitors that I chose, what would be an appropriate bypass capacitor to use? I have heard of the 1% rule... but this area is completely foreign to me.

Just for reference, I do have a Etepon WH5000A multimeter and a nice 100w soldering iron with high silver solder, flux, solder pump etc. I have experience working on replacing all the caps and tubes on a Musical Fidelity X10v3 tube buffer that I enjoy using in my system and that turned out well. I was also aware that increasing voltage can lead to gains, but I was not aware that film caps originally rated at 250v can be replaced with caps rated at 400v - something about going so widely different from OEM spec had me thinking I was misinterpreting something.

Other things that I plan on doing: Taking the 4 fuses and giving the contact tips a very light sanding with something like 600 grit sandpaper on the ends and then coating with dielectric grease given the 20+ years of oxidation. I also plan to install some very simple heatsinks on the total of 4 JE350/JE340 transistors given what I saw happen on the MF X10v3 - literal burn marks from cooking the PCB due to the heat output (and yes, I measured the transistors and they were all still within spec and working)

Attachments

Last edited:

- Home

- Amplifiers

- Solid State

- Musical Fidelity A308CR Power Amplifier Recap Suggestions