I'm embarking on updating (but not necessarily upgrading) the passive XO network on my Matrix 802 series 3 speakers and could use some guidance.

I've seen prior posts about doing this, namely:

http://www.diyaudio.com/forums/multi-way/268700-b-w-matrix-802-s3-crossover-refresh.html

-and-

B&W crossover rebuild

I am also aware of North Creek's "full monty" and "basic" crossovers for them:

B&W Matrix Crossovers

However, I am looking to keep the original inductors and resistors and replace just the caps. The Bennic MKP caps will be replaced with like MKP caps (prolly Mundorfs), while the electrolytics will be replaced with like electrolytics (also prolly Mundorphs).

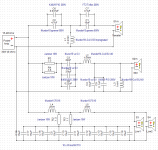

Here's the OEM schematic from one of the above sites:

C1 - Bennic PMT polypropylene (4.7uF, 160V)

C2 - Bennic PMT polypropylene (10uF, 160V)

C3 - Bennic bipolar electrolytic (26uF, 70V, 5%)

C4 - Bennic bipolar electrolytic (10uF, 70V, 5%)

C5 - Bennic bipolar electrolytic (150uF, 70V, 5%)

R1 - Bennic wirewound in cement (3.3ohms, 7W)

R2 - Bennic wirewound in cement (0.56ohms, 7W)

L1 - Air core inductor (0.2mH)

L2 - Ferrite core inductor (1.5mH)

L3 - Ferrite core inductor (1.0mH)

L4 - Wicon Ferrite core inductor (2.0mH

L5 - Wicon Ferrite core inductor (2.0mH)

So my initial questions:

1. Should the internal wiring from the XO to the drivers be stranded or solid core. Any difference?

2. The R1s (3.3 ohm wirewounds) appear to read much less than spec. I was assuming they would hold their values somewhat. Is that normal (I'm not so knowledgeable about wirewounds)?

3. Do these wirewounds have their own inductance, and if so, do I need to account for that in the XO?

4. C3 (26uF) is difficult to find in a single cap. I am planning on using three 6.8uF caps and one 5.6uF cap in parallel. Should there be some insulation or air separating them? If the former, what should I use?

5. Is there a proper way to parallel these four caps for this (e.g., one cap soldered to the board and the 3 others solder to that)? Any better method - I'm concerned about weight/support?

6. I'm not too worried about the LF part of the XO because I'm using an active crossover (First Watt B4) between the LF and the MF/HF. But if I were using the passive LF section of the XO in the speakers, how important is the type of electrolytic cap for this implementation?

Thanks for your guidance.

I've seen prior posts about doing this, namely:

http://www.diyaudio.com/forums/multi-way/268700-b-w-matrix-802-s3-crossover-refresh.html

-and-

B&W crossover rebuild

I am also aware of North Creek's "full monty" and "basic" crossovers for them:

B&W Matrix Crossovers

However, I am looking to keep the original inductors and resistors and replace just the caps. The Bennic MKP caps will be replaced with like MKP caps (prolly Mundorfs), while the electrolytics will be replaced with like electrolytics (also prolly Mundorphs).

Here's the OEM schematic from one of the above sites:

C1 - Bennic PMT polypropylene (4.7uF, 160V)

C2 - Bennic PMT polypropylene (10uF, 160V)

C3 - Bennic bipolar electrolytic (26uF, 70V, 5%)

C4 - Bennic bipolar electrolytic (10uF, 70V, 5%)

C5 - Bennic bipolar electrolytic (150uF, 70V, 5%)

R1 - Bennic wirewound in cement (3.3ohms, 7W)

R2 - Bennic wirewound in cement (0.56ohms, 7W)

L1 - Air core inductor (0.2mH)

L2 - Ferrite core inductor (1.5mH)

L3 - Ferrite core inductor (1.0mH)

L4 - Wicon Ferrite core inductor (2.0mH

L5 - Wicon Ferrite core inductor (2.0mH)

So my initial questions:

1. Should the internal wiring from the XO to the drivers be stranded or solid core. Any difference?

2. The R1s (3.3 ohm wirewounds) appear to read much less than spec. I was assuming they would hold their values somewhat. Is that normal (I'm not so knowledgeable about wirewounds)?

3. Do these wirewounds have their own inductance, and if so, do I need to account for that in the XO?

4. C3 (26uF) is difficult to find in a single cap. I am planning on using three 6.8uF caps and one 5.6uF cap in parallel. Should there be some insulation or air separating them? If the former, what should I use?

5. Is there a proper way to parallel these four caps for this (e.g., one cap soldered to the board and the 3 others solder to that)? Any better method - I'm concerned about weight/support?

6. I'm not too worried about the LF part of the XO because I'm using an active crossover (First Watt B4) between the LF and the MF/HF. But if I were using the passive LF section of the XO in the speakers, how important is the type of electrolytic cap for this implementation?

Thanks for your guidance.

Last edited:

That's nice that B&W provide schematics of their XO's. A lot of companies guard that with a passion.

Regarding your question about a single cap for 26uF. If you don't mind going industrial - oil filled poly caps for motors have this value (and probably the values for your electrolytic caps), sound great, and are very inexpensive. I know it may be considered heretical around here to suggest no name brand caps that aren't hand made out of gold foil with layers of pristine angel wings as dielectrics descended from Zeus. But for the price - try them out you might be surprised. Certainly think motor oil filled caps should be more stable and transparent than non polar double ended electrolytic caps.

26uF:

https://www.1000bulbs.com/product/171367/AERO-Z93S4026MN.html

10uF:

http://m.grainger.com/product/2MEC3...2MEC3&ef_id=UmQurgAABIG6YG5x:20151009111114:s

150uF:

http://www.walmart.com/ip/45587397?...8411705456&wl4=&wl5=pla&wl6=115314079016&veh=

Use key word "motor capacitor" with your XXXuF value for search engine

Good luck.

Regarding your question about a single cap for 26uF. If you don't mind going industrial - oil filled poly caps for motors have this value (and probably the values for your electrolytic caps), sound great, and are very inexpensive. I know it may be considered heretical around here to suggest no name brand caps that aren't hand made out of gold foil with layers of pristine angel wings as dielectrics descended from Zeus. But for the price - try them out you might be surprised. Certainly think motor oil filled caps should be more stable and transparent than non polar double ended electrolytic caps.

26uF:

https://www.1000bulbs.com/product/171367/AERO-Z93S4026MN.html

10uF:

http://m.grainger.com/product/2MEC3...2MEC3&ef_id=UmQurgAABIG6YG5x:20151009111114:s

150uF:

http://www.walmart.com/ip/45587397?...8411705456&wl4=&wl5=pla&wl6=115314079016&veh=

Use key word "motor capacitor" with your XXXuF value for search engine

Good luck.

Last edited:

Thanks for that recommendation. While my mind is not set on the caps to use, I would like to replace lytics with lytics. Plus, paralleling caps also has some benefits.

BTW, the B&W schematics etc. are all available in the service manuals available online.

BTW, the B&W schematics etc. are all available in the service manuals available online.

6. I'm not too worried about the LF part of the XO because I'm using an active crossover (First Watt B4) between the LF and the MF/HF. But if I were using the passive LF section of the XO in the speakers, how important is the type of electrolytic cap for this implementation?

The el. cross. should perform the HP function also, so you don't need the 26 uF cap & 1 mH inductor.

In case you needed it, that would be the first to replace with a film type.

Why keep another electrolityc since you are in the mood for upgrading ?

The el. cross. should perform the HP function also, so you don't need the 26 uF cap & 1 mH inductor.

In case you needed it, that would be the first to replace with a film type.

Why keep another electrolityc since you are in the mood for upgrading ?

Correct about the 26uF cap. Would only need it if I was using the passive LF XO. But may want to try it without the B4 for a little while.

I'm of the view you should replace like with like with respect to crossover caps. Plus, lytics would be smaller in size and cheaper.

Only updating the HF/MF...

The first thing I noticed is that the schematic is wrong. Looking at the PCBs, the L2 goes to C3 (the schematic above and in the B&W service manual says C3 goes to L2).

Second thing I noticed was that the values of the OEM Bennic caps were off a bit but essentially identical from the L to R of the speakers. So perhaps they were matched pretty well from the factory. But the dissipation factor for most of the caps were high, around 0.1 to 0.2. So they needed to be replaced. However, C2 was still showing a low dissipation factor. Nevertheless, I decided to replace all of the caps on the HF/MF board at the same time.

The wirewound resistors were well within spec. But because I wanted to mount the larger caps (C1 and C2) flat to the board, I had to replace the resistors and I bended the leads on one of the resistors so that it was off to the side of the board and away from the C2. I added insulation to the leads of R1 and C2 just in case.

I soldered three 6.8uF and one 5.8 caps at the leads in parallel to make up the 26uF needed for C3. Did not find that value in a cap I liked.

All buttoned up and sounding really good so far.

My initial impression is that the HF is much smoother, both in freq. sweeps and with music. Also, the MF was apparently lacking in efficiency/sound apparently due to the old caps for which I was compensating via the attenuators on the B4 active XO. Now, I no longer need to. Much fuller sound from MF.

So all in all a good weekend project!

The first thing I noticed is that the schematic is wrong. Looking at the PCBs, the L2 goes to C3 (the schematic above and in the B&W service manual says C3 goes to L2).

Second thing I noticed was that the values of the OEM Bennic caps were off a bit but essentially identical from the L to R of the speakers. So perhaps they were matched pretty well from the factory. But the dissipation factor for most of the caps were high, around 0.1 to 0.2. So they needed to be replaced. However, C2 was still showing a low dissipation factor. Nevertheless, I decided to replace all of the caps on the HF/MF board at the same time.

The wirewound resistors were well within spec. But because I wanted to mount the larger caps (C1 and C2) flat to the board, I had to replace the resistors and I bended the leads on one of the resistors so that it was off to the side of the board and away from the C2. I added insulation to the leads of R1 and C2 just in case.

I soldered three 6.8uF and one 5.8 caps at the leads in parallel to make up the 26uF needed for C3. Did not find that value in a cap I liked.

All buttoned up and sounding really good so far.

My initial impression is that the HF is much smoother, both in freq. sweeps and with music. Also, the MF was apparently lacking in efficiency/sound apparently due to the old caps for which I was compensating via the attenuators on the B4 active XO. Now, I no longer need to. Much fuller sound from MF.

So all in all a good weekend project!

Last edited:

Only updating the HF/MF...

The first thing I noticed is that the schematic is wrong. Looking at the PCBs, the L2 goes to C3 (the schematic above and in the B&W service manual says C3 goes to L2).

Second thing I noticed was that the values of the OEM Bennic caps were off a bit but essentially identical from the L to R of the speakers. So perhaps they were matched pretty well from the factory. But the dissipation factor for most of the caps were high, around 0.1 to 0.2. So they needed to be replaced. However, C2 was still showing a low dissipation factor. Nevertheless, I decided to replace all of the caps on the HF/MF board at the same time.

The wirewound resistors were well within spec. But because I wanted to mount the larger caps (C1 and C2) flat to the board, I had to replace the resistors and I bended the leads on one of the resistors so that it was off to the side of the board and away from the C2. I added insulation to the leads of R1 and C2 just in case.

I soldered three 6.8uF and one 5.8 caps at the leads in parallel to make up the 26uF needed for C3. Did not find that value in a cap I liked.

All buttoned up and sounding really good so far.

My initial impression is that the HF is much smoother, both in freq. sweeps and with music. Also, the MF was apparently lacking in efficiency/sound apparently due to the old caps for which I was compensating via the attenuators on the B4 active XO. Now, I no longer need to. Much fuller sound from MF.

So all in all a good weekend project!

Looking at the PCBs, the L2 goes to C3 (the schematic above and in the B&W service manual says C3 goes to L2).

They are in series, it makes no difference which order they're in.

My bigger concern with updating crossover components is that many speaker companies, including B&W, measure drivers and crossover component's actual values to ensure proper acoustic output and channel to channel matching. So, for example, a cap labeled "10 uF" that actually measures 9.11 uF may be used there because the optimal value for the crossover is 9.1 uF. Another potential issue is that the designers may have accounted for capacitor ESR in the design, and substituting a different make or type could mess that up.

Mike

Very definitely...........................My bigger concern with updating crossover components is that many speaker companies, including B&W, measure drivers and crossover component's actual values to ensure proper acoustic output and channel to channel matching. So, for example, a cap labeled "10 uF" that actually measures 9.11 uF may be used there because the optimal value for the crossover is 9.1 uF. Another potential issue is that the designers may have accounted for capacitor ESR in the design, and substituting a different make or type could mess that up.

Mike

They used computerised measurement of drivers and components to allow them to select the correct components to achieve their target performance with VERY few rejects.

Swapping out one component could ruin the performance.

Very definitely.

They used computerised measurement of drivers and components to allow them to select the correct components to achieve their target performance with VERY few rejects.

Swapping out one component could ruin the performance.

Given that C3 - C5 are 5% tolerance high'ish value elecs, not so sure that's going to have much effect unless B & W pick specific values out of batches of the same value caps and throw the majority away. My bigger concern would be replacing the 4-off ferrite core inductors with air core types "because they sound better" and then finding that the much higher ESR of the air core types does indeed screw things up.

Last edited:

I agree with the potential problems with swapping out components. So all the more reason to replace polys with polys, and lytics with lytics. B&W did mention that they used "low-loss" lytics so that, in caps between 1μF and 20μF found in tweeter circuits, the DF was in the order of 0.025 and for caps in the hundreds of uF, the DF was in the order of 0.07. The replacement caps were matched L & R and have a DF that is much lower (e.g., less loss).

As for the old caps, except for the DF, they did measure within 2% of their rated values.

Ultimately, the proof is in the listening. They sound very good so far.

As for the old caps, except for the DF, they did measure within 2% of their rated values.

Ultimately, the proof is in the listening. They sound very good so far.

Given that C3 - C5 are 5% tolerance high'ish value elecs, not so sure that's going to have much effect unless B & W pick specific values out of batches of the same value caps and throw the majority away. My bigger concern would be replacing the 4-off ferrite core inductors with air core types "because they sound better" and then finding that the much higher ESR of the air core types does indeed screw things up.

Correct, the caps are relatively high tolerance but they measured well within them.

I agree about the inductors. I left the originals in place.

I don't think B&W (like many other big British speaker manufacturers) are still in the business by throwing away components.

If the 5% tolerance required them to throw away components that prevented them meeting specification, then they would buy in more expensive tighter tolerance components and reduce wastage. That's the way they make a profit.

But they don't need every component to match the theoretical +-0% tolerance. They can compensate the different components to achieve the target performance.

eg.

You require a 1ms time constant.

Use a 1k0+-0% resistor and a 1uF +-0% capacitor. The filter comes out at 1ms.

Now you have a batch of 5% capacitors.

Measure each one and let the computer select the correct resistor from stock to make every C match up to the required target time constant. No waste capacitors.

They do similar for the T/S of the drivers and select the correct time constants to make the speaker meet specification. Them the computer selects the inductors and capacitors and resistors to achieve those time constants and that way every in spec driver gets used. Those that are out of spec get replaced by the supplier free of charge. The supplier has to be on his best performance when he knows that his customer measures every driver !!!!

If the 5% tolerance required them to throw away components that prevented them meeting specification, then they would buy in more expensive tighter tolerance components and reduce wastage. That's the way they make a profit.

But they don't need every component to match the theoretical +-0% tolerance. They can compensate the different components to achieve the target performance.

eg.

You require a 1ms time constant.

Use a 1k0+-0% resistor and a 1uF +-0% capacitor. The filter comes out at 1ms.

Now you have a batch of 5% capacitors.

Measure each one and let the computer select the correct resistor from stock to make every C match up to the required target time constant. No waste capacitors.

They do similar for the T/S of the drivers and select the correct time constants to make the speaker meet specification. Them the computer selects the inductors and capacitors and resistors to achieve those time constants and that way every in spec driver gets used. Those that are out of spec get replaced by the supplier free of charge. The supplier has to be on his best performance when he knows that his customer measures every driver !!!!

Last edited:

Well, one reason I chose mundorf supreme polys and mundorf ecap lytics is because B&W uses them in current speakers. While different speakers and B&W uses better mundorfs, it was a good reason to splurg a bit. Real happy with the results. I may want to try updating the LF passive XO to see how they sound without the active XO.

Swaping R1 with a MOX resistor ?

Replace the Ferrofluid of the tweeter if more than 20 years ? (although you have to find the correct viscosity !)

Replace the Ferrofluid of the tweeter if more than 20 years ? (although you have to find the correct viscosity !)

Last edited:

Swaping R1 with a MOX resistor ?

Replace the Ferrofluid of the tweeter if more than 20 years ? (although you have to find the correct viscosity !)

They were Mills MRA-10 wirewounds.

As for the ferrofluid, they sound better now. =)

I've had no problem swapping out electrolytics for films in the parallel sections. I often use Axon's for these (think cheap Solen's) in the 10-20uF range. One strong argument made to swap out electrolytics for film is ageing and stability. The film caps are good for a hundred years while electrolytics are in the 10s of years. Of course, size is always an issue when replacing caps in existing boards!

Hi. I was the author of one of previous threads. I rebuilt my B&W crossovers from scratch, keeping in mind the original (measured) DCR and ESR values of passive components at their working frequency range (ESR in electrolytics is a function of frequency).

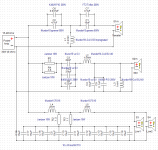

Attached is an image of my current schematics.

Please note that I adjusted resistance values to account for differences in ESR between film and electrolytic capacitors. The bass-driver coils are Mundorf Copper Foil I-Core, as air-cores of corresponding DCR would simply not fit inside the speaker.

Also, there should be a small series resistor (0.2 Ohm) with C5 to get a perfect ESR match with the original electrolytic, but I omitted it. Also, my L1 coil has a DCR of 0.55 Ohm as compared to 0.9 OHm of the original coil. The result is a 0.5dB bump around the crossover frequency of 3.1 KHz.

Attached is an image of my current schematics.

Please note that I adjusted resistance values to account for differences in ESR between film and electrolytic capacitors. The bass-driver coils are Mundorf Copper Foil I-Core, as air-cores of corresponding DCR would simply not fit inside the speaker.

Also, there should be a small series resistor (0.2 Ohm) with C5 to get a perfect ESR match with the original electrolytic, but I omitted it. Also, my L1 coil has a DCR of 0.55 Ohm as compared to 0.9 OHm of the original coil. The result is a 0.5dB bump around the crossover frequency of 3.1 KHz.

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Newb questions about updating crossovers for B&W Matrix 802 Series 3