Hi,

I would like to build a desktop speaker for home office music listening. Because this will be the second speaker system, I would like to keep the cost as low as possible (speakers + XO cost around 300 EUR / pair) The speaker cabinet will be homemade, and will be small 260mmx160mmx210mm or something similar.

What is the preferred design for this type nearfield desktop speaker? Rear ported, like this:

https://www.schreinerei-thomaier.de/ase/BVSAK141RDT.pdf

or front ported, like this:

https://www.humblehomemadehifi.com/download/Humble Homemade Hifi_HATT MK-VIII.pdf

Thanks

Gaszto

I would like to build a desktop speaker for home office music listening. Because this will be the second speaker system, I would like to keep the cost as low as possible (speakers + XO cost around 300 EUR / pair) The speaker cabinet will be homemade, and will be small 260mmx160mmx210mm or something similar.

What is the preferred design for this type nearfield desktop speaker? Rear ported, like this:

https://www.schreinerei-thomaier.de/ase/BVSAK141RDT.pdf

or front ported, like this:

https://www.humblehomemadehifi.com/download/Humble Homemade Hifi_HATT MK-VIII.pdf

Thanks

Gaszto

with the examples you gave this limit will be quite hard to keep (or let me know where you buy your drivers! 🙂 );speakers + XO cost around 300 EUR / pair

port resonances are usually less audible if the port is on the rear side.

port on the front allows moving the speakers towards a wall.

anyhow, supposedly both speakers are well designed.

they will differ in sound, but mainly because of different x-over concept, not because of port position.

Last edited:

Thank you. Basically it is possible to order the first kit 149EUR/pcs. And according to my calculation I also can buy the drivers here in Sweden.with the examples you gave this limit will be quite hard to keep (or let me know where you buy your drivers! 🙂 );

port resonances are usually less audible if the port is on the rear side.

port on the front allows moving the speakers towards a wall.

anyhow, supposedly both speakers are well designed.

they will differ in sound, but mainly because of different x-over concept, not because of port position.

So there is no general rule for near field usage.

In these case I will go with the first kit.

For near field, single driver boxes have an advantage. With you so close to the loudspeaker, the necessary spacing between drivers will be more noticable. And you can spend more on a single higher quality driver vrs 2 + XO.

millSize miniOnkens have often been used for this application, and they are close to the size you indicated. They support many drivers.

Front or rear vent will depend on the design.

dave

millSize miniOnkens have often been used for this application, and they are close to the size you indicated. They support many drivers.

Front or rear vent will depend on the design.

dave

Last edited:

Just one? The originals were first done in the mid 000s, there have been many hundreds across some dozen plus drivers.

The above are amoungst the first (i do have the most advanced pair of those we did up for sale).

The originall thread, https://www.diyaudio.com/community/threads/millisize-me.154103/

Original plans (subsequent iterations differed only in baffle details, holed-brace, and the size of the vent spacer (ie the vent is tuned very specifically to the driver).

https://p10hifi.net/FAL/downloads/mFonken-1v1dot1-map-271009.pdf

This box has been adapted for FE127e, Alpair 6/6.2p/7/7.2/7.3/7ms, Pluvia 7/7PHD/7HD, CHRs/CHPs/CHBW, FF105wk, FF125wk, a TandBand (probably many of them), and more.

dave

The above are amoungst the first (i do have the most advanced pair of those we did up for sale).

The originall thread, https://www.diyaudio.com/community/threads/millisize-me.154103/

Original plans (subsequent iterations differed only in baffle details, holed-brace, and the size of the vent spacer (ie the vent is tuned very specifically to the driver).

https://p10hifi.net/FAL/downloads/mFonken-1v1dot1-map-271009.pdf

This box has been adapted for FE127e, Alpair 6/6.2p/7/7.2/7.3/7ms, Pluvia 7/7PHD/7HD, CHRs/CHPs/CHBW, FF105wk, FF125wk, a TandBand (probably many of them), and more.

dave

You also can have a look to the Neumann monitors.....smoothest response and made for nearflield monitoring/desk. But above the budget. Behringher make tunable mini monitor with controled directivity (wave guide) B2030A....look at max headroom member measurement and tweak at diyaudio.

Last edited:

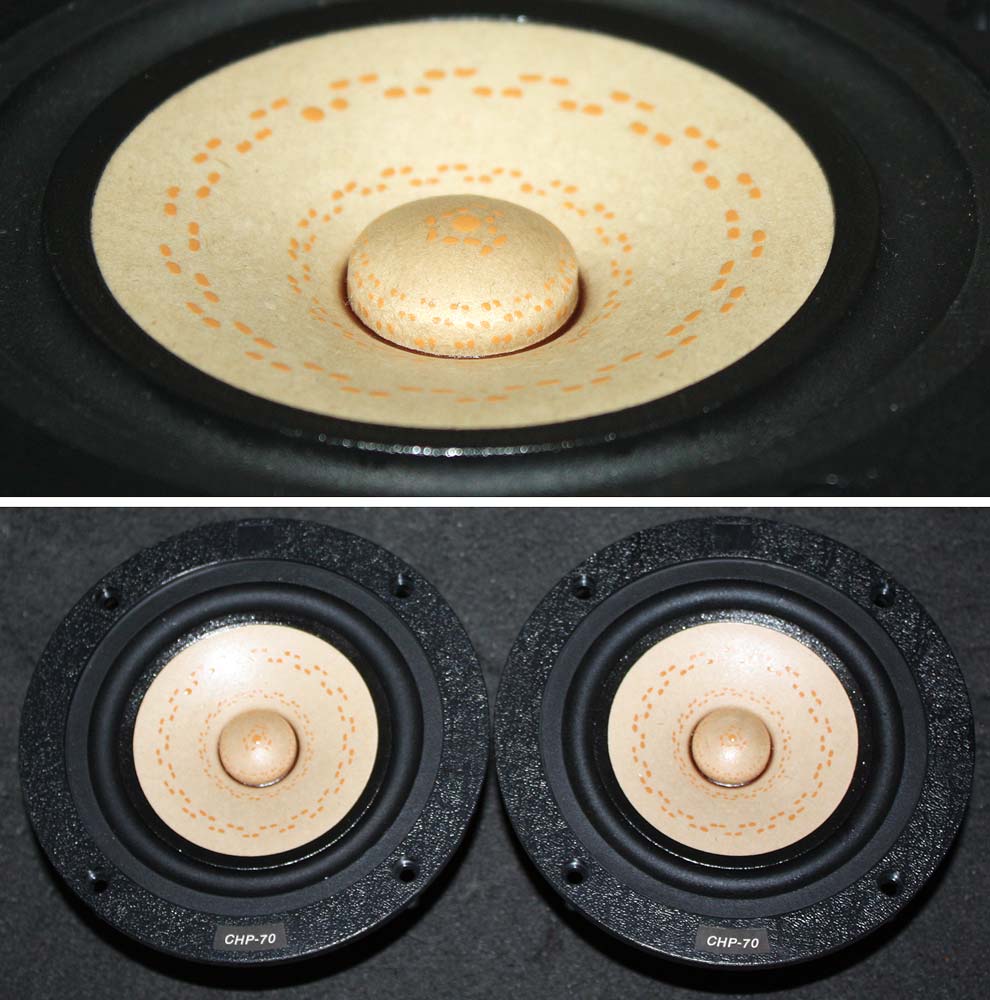

I'm with Planet 10. For nearfield, full range drivers are excellent. Don't let the affordability fool you. Something as simple as the Mark Audio CHP-70 in a slim golden ratio cabinet is outstanding.

http://frugal-phile.com/boxlib/P10free/CGR-dKal-El703-301113.pdf

http://frugal-phile.com/boxlib/P10free/CGR-dKal-El703-301113.pdf

... if people are ok with wood work... or it may become expensive faster than you think if dust is not your friend 🙂

The CHP70.2 has a very good midrange and good extension for a 4”, but some find the suppressed top 2 octaves too much vintage. The CGR is 9 litres, the millSize 4.7 litres, but there are more than a few narrow (and deep) CGRs serving duty as multiMedia near field loudspeakers. The larger size gives a bit more extension, a bit more open-ness, and the taller height likely allows for placement of the drivers closer to the heigh tof your ears.

2 pair of demos like the above exist and would like a new home.

My favorite of the millSize that we built and listened to were these (Alpair 6.2PeN/3.5"). Head-to-head against a pair of restored LS3/5A (later confirmed by the owner as “identical” to a factory pair another audio buddy brought over.

You could also use 2xAlpair 5.2/3 or FF85wk in a series 1.5-way as mentioned above (i think it was this thread). The 4Ω Alpair would likely best suit most amps.

dave

2 pair of demos like the above exist and would like a new home.

My favorite of the millSize that we built and listened to were these (Alpair 6.2PeN/3.5"). Head-to-head against a pair of restored LS3/5A (later confirmed by the owner as “identical” to a factory pair another audio buddy brought over.

You could also use 2xAlpair 5.2/3 or FF85wk in a series 1.5-way as mentioned above (i think it was this thread). The 4Ω Alpair would likely best suit most amps.

dave

Last edited:

I would like to build a desktop speaker for home office music listening.

Why build rather then buy? You must have good reasons when there are so many two way desktop monitors with proven design on the used market; that cost less in time and money and are more likely to perform well with good design confirmed with documented measurements and reviews. Knowing what you are wanting to get from a bespoke build should guide you to the best design.

Yes, I have a very good reason, Because diy hifi is my hobby, and I like learning new things. I would like to understand how to design a speaker cabinet, XO etc.Why build rather then buy? You must have good reasons when there are so many two way desktop monitors with proven design on the used market; that cost less in time and money and are more likely to perform well with good design confirmed with documented measurements and reviews. Knowing what you are wanting to get from a bespoke build should guide you to the best design.

And my point of you, this is the best way to learn how it's work 🙂

I would suggest SB26ADC + SB13PFC. You just can't go wrong with SB26ADC at this price point. I haven't heard SB13PFC, but from my experience with SBA speakers, they should be very good. Check out Ampslab's design Sparrow-TA. How far away from the wall will these speakers be? And the distance between you and the speakers?

Hi,

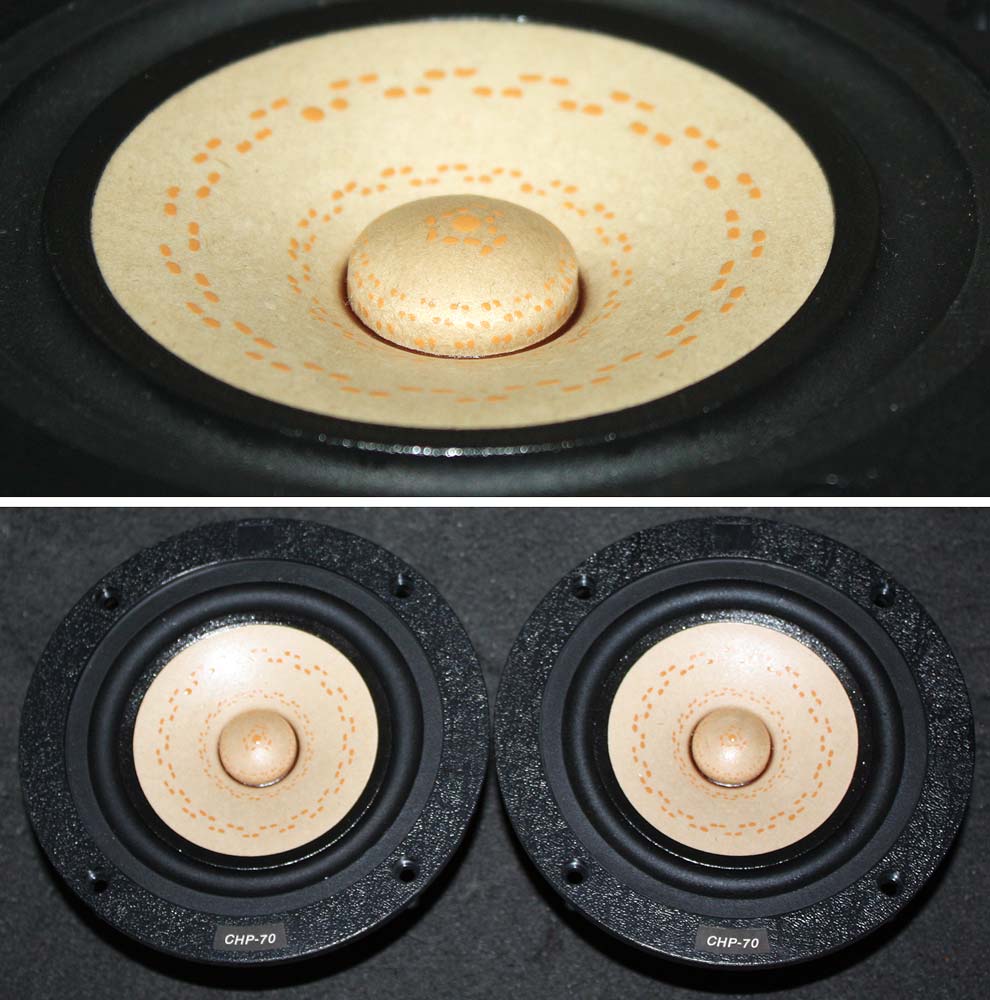

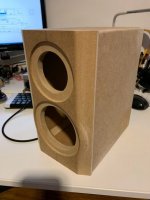

I've finished my desktop speaker. I've attached a some picture from it.

I designed the cabinet 3D CAD, then I have simulated with BEM method. I have a 3018 CNC, so I had to fit the front wall dimension into the CNC working area.

Then the painting process:

Damping

Crossover:

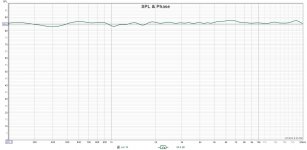

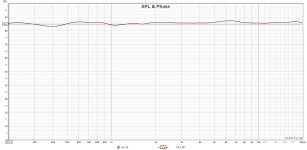

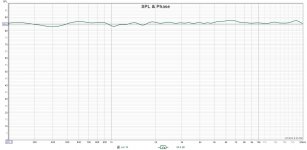

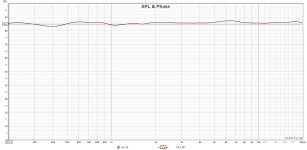

And the measurements. The measurement was gated between -0.3ms and 5ms measuring distance is 75cm (this is the listening distance)

1/6 octave smoothing:

1/3 octave smoothing

I've finished my desktop speaker. I've attached a some picture from it.

I designed the cabinet 3D CAD, then I have simulated with BEM method. I have a 3018 CNC, so I had to fit the front wall dimension into the CNC working area.

Then the painting process:

Damping

Crossover:

And the measurements. The measurement was gated between -0.3ms and 5ms measuring distance is 75cm (this is the listening distance)

1/6 octave smoothing:

1/3 octave smoothing

this white + oak cabinet looks pretty. Impressive what can acheive CNC in our hobby.

Just personal taste and according to the rest of the devices, the power response may be a little too flat and fatiguing non saying the little bump around 6k to 8 hz -said brigthness area-. You could try more resistor attenuation in front of the tweeter. But this is a detail.

Impressive job for a first loudspeaker ! Bravo 🙂 ... mine is ugly in front of your and does not measure better !

Just personal taste and according to the rest of the devices, the power response may be a little too flat and fatiguing non saying the little bump around 6k to 8 hz -said brigthness area-. You could try more resistor attenuation in front of the tweeter. But this is a detail.

Impressive job for a first loudspeaker ! Bravo 🙂 ... mine is ugly in front of your and does not measure better !

Very nice. Is this a normal / hobbyist 3018 CNC? What else have you built with it?

The FR plots on the pdf imply that it was intended to be listened to 15 degrees off axis (that's the flattest FR plot, without the little 6kHz bump). Is that how you use it?

The sculpting you added to the baffle may have had some minor effects on the response.

A free way to test tweaks is with software EQ: I use Equalizer APO, but there may be other / better options.

The FR plots on the pdf imply that it was intended to be listened to 15 degrees off axis (that's the flattest FR plot, without the little 6kHz bump). Is that how you use it?

The sculpting you added to the baffle may have had some minor effects on the response.

A free way to test tweaks is with software EQ: I use Equalizer APO, but there may be other / better options.

Hi,Very nice. Is this a normal / hobbyist 3018 CNC? What else have you built with it?

The FR plots on the pdf imply that it was intended to be listened to 15 degrees off axis (that's the flattest FR plot, without the little 6kHz bump). Is that how you use it?

The sculpting you added to the baffle may have had some minor effects on the response.

A free way to test tweaks is with software EQ: I use Equalizer APO, but there may be other / better options.

My CNC is the cheapest hobbyist 3018 CNC. But It working perfectly for such a small project. I'm also using it to CNC engraving and milling the front of the amp enclosure.

The measurement is on axis measurement, but I'm listening 5deg off axis. Maybe in the future I will correct the 1.5-1.8dB bump at 6kH. The crossover already has a notch filter in this region, so I have to play with the resistor size, but for my ears it is not bad.

Thanks for the suggestion about the EQ. Maybe is a quick and good tool to test it before modifying the crossover.

Well done achieving this on a 3018! I would not have thought it possible 🙂Hi,

I've finished my desktop speaker. I've attached a some picture from it.

I designed the cabinet 3D CAD, then I have simulated with BEM method. I have a 3018 CNC, so I had to fit the front wall dimension into the CNC working area.

View attachment 1065213

View attachment 1065214

Then the painting process:

View attachment 1065215

Damping

View attachment 1065216

Crossover:

View attachment 1065217

View attachment 1065218

View attachment 1065219

And the measurements. The measurement was gated between -0.3ms and 5ms measuring distance is 75cm (this is the listening distance)

1/6 octave smoothing:

View attachment 1065211

1/3 octave smoothing

View attachment 1065212

Would you mind me asking how long it took to machine a baffle?

Thanks for the pics, always nice seeing someone’s CNC work.

Cheers,

Matt

Hi Matt,Well done achieving this on a 3018! I would not have thought it possible 🙂

Would you mind me asking how long it took to machine a baffle?

Thanks for the pics, always nice seeing someone’s CNC work.

Cheers,

Matt

It was a slow work. I divided the CNC program into 6-8 parts. First the two speaker's coutout, the roughing one side of the baffle, then the other side, then finishing step of both side. I don't remember exactly but around 1-2 hours each step. Let's say 6-8 hours.

Very impressive, well done 🙂Hi Matt,

It was a slow work. I divided the CNC program into 6-8 parts. First the two speaker's coutout, the roughing one side of the baffle, then the other side, then finishing step of both side. I don't remember exactly but around 1-2 hours each step. Let's say 6-8 hours.

- Home

- Loudspeakers

- Multi-Way

- Newbie question, Desktop speaker, nearfield