In BTL configuration? Yes in principle, but you need to (1) keep in mind that each amplifier in a bridge sees only half of the load impedance and (2) produce two opposite-phase, low-distortion signals for each side of the bridge. The latter may be a small challenge, as even very good opamps add more distortion than Omicron, while balanced line drivers like DRV134 or THAT1646 are about two orders of magnitude worse.

The additional info I will be posting is related to our PCBs, the BOMs, the building process, and the PCB's availability.the design of both through-hole and SMT boards for Omicron has been finalized. I will post additional info next week.

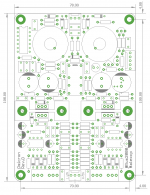

Our through-hole PCB for Omicron is 108x78mm (4.25x3.07in), which is about the size of two credit cards:

It carries two amplification channels, the (optional, but highly recommended based on listening tests) crossfeed, DC protection for your headphones and the output filter. The PCB has two layers, with the top layer being a mostly uninterrupted ground plane.

The mounting holes are at the corners of a 100x70mm rectangle, allowing mounting the board on Modushop's perforated baseplates without any drilling.

The height of an assembled board depends on the height of the tallest components, which are the heatsinks and the large electrolytic capacitors (C13 C14 C33 C34) - note that you need to provide some clearance under the PCB with standoffs at least 6mm (0.25in) tall. It makes sense to choose both the heatsinks and the capacitors of the same height, and there are two simple options, for which we even designed a matching power supply board.

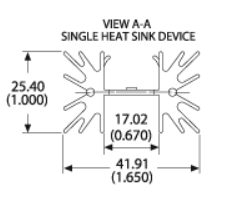

The first option is to choose the heatsinks and the capacitors to be about 25mm (one inch) tall, such as Aavid 531002B02100G and Panasonic EEUFC1E152 (more info will follow with the BOM). With these parts, Omicron works best with the quiescent current of the output stage at 25-30mA (the current is set by the resistors R13 R14 R33 R34 - more on this later). With 6mm standoffs, the total assembly height 6+1.6+25.4=33mm or so. The assembled PCB will fit into a 1U (1.75in) enclosure with 40mm internal height, such as the Modushop's 1U Galaxy.

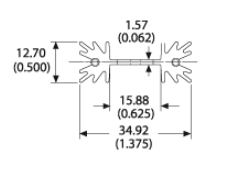

The second option is to choose the heatsinks and the capacitors about 38mm (1.5 inch) tall, e.g Aavid 531102B02100G and Panasonic EEUFC1E222. With larger capacitors and larger heatsinks, Omicron will be comfortably working with 50mA quiescent current and will have somewhat lower distortion working into lower impedance loads. With the same 6mm standoffs, the total assembly height would be 6+1.6+38.1=46mm or so, and the assembled PCB will fit into a 50mm/2In enclosure (such as the popular Hammond 1455T2201) or a 2U Galaxy enclosure.

Other variants are possible but have not been tested extensively, e.g. taller heatsinks (50mm or 63mm if you have the room), custom heatsinks (see this example by @baggerbole), or even TO-126 transistors with no heatsinks (in which case I'd recommend lo lower the quiescent current and/or supply rails voltage).

To be continued.

There are no adjustments in Omicron, but there are a couple of choices you'd need to decide upon before assembling (no worries, you can always revisit them later).

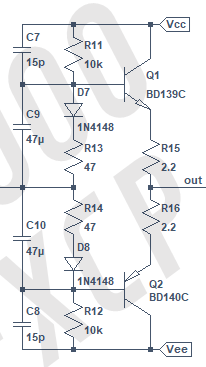

The first choice is, as mentioned above, the quiescent current of the output stage, set by the resistor chain R11 R13 R14 R12:

The way it works is that the voltage drop across D7 approximates the Vbe of Q1 (including its temperature gradient), and that of D8 - the Vbe of D8. Because of that, the voltage drop across R13 is about the same as across R15 (in reality, R13 drops about 12mV more than R15). The same is true for R14 and R16. Since the voltage drops are equal, the currents are proportional. The current through R13 is set by R11 (through R14 - by R12) at about 1.5mA with +/-17V rails. The voltage drops across R13 and R14 are about 70mV each, which sets the quiescent current of Q1 and Q2 at about 26mA and their dissipation, at about 17V×26mA = 440mW each. This works really well with 1in/25mm tall heatsinks such as Aavid 531002B02100G (note that Q1 and Q2 share the same heatsink) and is the recommended setting.

You can increase the quiescent current by increasing R13 and R14 to 100 ohm each. This doubles the quiescent current to 48mA, and the dissipation to 0.82W per transistor. Taller heatsinks, such as Aavid 531102B02100G, are now needed to dissipate 2×0.82=1.64W. The benefit is, as mentioned above, that the output stage can deliver more current while operating in Class A, which somewhat improves distortion on high amplitudes into low impedance (32 ohms or lower) loads.

The first choice is, as mentioned above, the quiescent current of the output stage, set by the resistor chain R11 R13 R14 R12:

The way it works is that the voltage drop across D7 approximates the Vbe of Q1 (including its temperature gradient), and that of D8 - the Vbe of D8. Because of that, the voltage drop across R13 is about the same as across R15 (in reality, R13 drops about 12mV more than R15). The same is true for R14 and R16. Since the voltage drops are equal, the currents are proportional. The current through R13 is set by R11 (through R14 - by R12) at about 1.5mA with +/-17V rails. The voltage drops across R13 and R14 are about 70mV each, which sets the quiescent current of Q1 and Q2 at about 26mA and their dissipation, at about 17V×26mA = 440mW each. This works really well with 1in/25mm tall heatsinks such as Aavid 531002B02100G (note that Q1 and Q2 share the same heatsink) and is the recommended setting.

You can increase the quiescent current by increasing R13 and R14 to 100 ohm each. This doubles the quiescent current to 48mA, and the dissipation to 0.82W per transistor. Taller heatsinks, such as Aavid 531102B02100G, are now needed to dissipate 2×0.82=1.64W. The benefit is, as mentioned above, that the output stage can deliver more current while operating in Class A, which somewhat improves distortion on high amplitudes into low impedance (32 ohms or lower) loads.

I wonder what this implies when you put headphones on a chart where x-axis is input impedance and y-axis is sensitivity.

These are too large:

These will fit the board:

I used Aavid part numbers in my example, but heatsinks of this size are made by many manufacturers.

These will fit the board:

I used Aavid part numbers in my example, but heatsinks of this size are made by many manufacturers.

There are a few things in Omicron that can be tweaked if you know what you're doing. You can leave the default values - they work really well - but here are some additional choices.there are a couple of choices you'd need to decide upon

One is the supply rails voltage. Omicron has been tested with regulated +/-17V rails, and that's the recommended voltage. However, should you want very small or no heatsinks and/or higher quiescent current (see #143 above), and the output transistors get too hot, the rails can be lowered to e.g. +/-12V. The same can be done if you want to use a lower-voltage opamp or unregulated power supply - none if these has been tested yet, but should be possible in principle. In this case, it would make sense to reduce R11 R12 R31 R32 proportionally (e.g. to 6.8kOhm each) and adjust R13 R14 R33 R34 to keep the quiescent current at the desired level. Also, it would make sense to reduce R51 R52 in the protection circuit proportionally to, say, 15kOhm - they set the DC protection threshold.

By the way, Omicron draws about 70mA from each rail with the output stages' quiescent current at 25mA, and about 120mA with the quiescent current at 50mA. The maximum draw, when both channels are fed with a sine and clip into 32ohm, is about 300mA on each of +/-17V rails. The power supply should be able to provide at least 0.5A - we have a suitable design that I will describe in more details in later posts.

The next choice is the input impedance. The original schematic's (see #42) input impedance is 2kOm, which some early builders found to be a little low. You can build it if you have a capable enough source, but I'd recommend a higher impedance option (see #67).

The final choice is the values of the crossfeed network, R17 R18 R19 C3 (R37 R38 R39 C23 for the second channel). The crossfeed network can be omitted altogether, but based on our listening tests, we highly recommend installing it, unless you intend to use Omicron as a low-distortion preamp.

The idea of crossfeed is to mix into each stereo channel an attenuated and low-pass filtered signal from the other channel (see #33 for additional details). The crossfeed reduces the separation of the channels at low frequencies, giving the sound in headphones its natural spaciousness. The recommended values shown in the schematic (see #42 for the base version and #67 for the higher input impedance version) provide 12dB channel separation at low frequencies and a low-pass filter with the corner frequency at 800Hz. This is the recommended setting providing comfortable listening experience and can be left as is.

Should you want to experiment, however, the recommended values are a starting point. The ratio of (R1+R3)/(R17+R18)=(R21+R23)/(R37+R37) sets the low frequency attenuation, and the time constant C3×(R17||R18)=C23×(R37||R38) sets the corner frequency of the low-pass filter. R19 should always be equal to R17+R18 (R39, to R37+R38). Do not make R18 (R38) lower than (R1+R3)×2, as it would affect the acton of Omicron's global feedback.

If the above sounds too complicated, just leave the default values.

The part list a.k.a. BOM will follow.

Last edited:

Hi

Are you planning on selling your through-hole PCB ? Or will the Gerber files be made available for private use ?

I just happened to have a 1U Galaxy I could use 👍

Thanks in advance.

Eric

Are you planning on selling your through-hole PCB ? Or will the Gerber files be made available for private use ?

I just happened to have a 1U Galaxy I could use 👍

Thanks in advance.

Eric

I will probably set up a group buy in the next few days - if there is enough interest, I will have a batch of boards manufactured.

I'd be interested in that highly polished SMT version, but would take a THT board too 🙂 You mentioned a PSU earlier, will you be offering boards or gerbers for that?I will probably set up a group buy in the next few days

I might be interested in a TH version.

thank you

If going with +/-15V, would it require resistor changes or it's a small change that "should" work as is?Omicron has been tested with regulated +/-17V rails, and that's the recommended voltage. However, (...) the rails can be lowered to e.g. +/-12V.

thank you

It makes sense to run a GB for all available boards at once, so that no one pays twice for shipping.will you be offering boards for that?

If there is enough interest, I can probably ask the PCB manufacturer to ship part of the order directly to you - let me look into that.May be we can set up a little group buy for Germany if anyone is still interested...

You should be fine with stock values.If going with +/-15V, would it require resistor changes

The part list a.k.a. BOM for Omicron was consciously designed to avoid the drama of obsolete, NOS, rare, unique or otherwise difficult to obtain or expensive parts, as well as any need for matching. Also, the list was shortened by using identical parts in multiple position where possible. Most likely, you already have a significant part of the BOM in your parts bin.

Here is the part list for the through-hole Omicron board, including two amplification channels, the crossfeed, protection, and the output filter:

The list allows reasonable substitution, and I included example part numbers that are currently available on Mouser. For your convenience, here is the link to Mouser's "project" that allows you to order all the parts to be mounted on the PCB (excluding the PCB itself and the hardware, for which Mouser is not the best source) in a couple of clicks, for a total cost of $42.32 (in the U.S.) plus shipping. As mentioned above, I'd expect you to already own a large part of the BOM, so make sure to delete all the parts you already have from the shopping cart before checkout.

A few comments to the BOM:

Here is the part list for the through-hole Omicron board, including two amplification channels, the crossfeed, protection, and the output filter:

| Qty | Value | Device | Package | Names | Example P/N | |

|---|---|---|---|---|---|---|

| 17 | 1N4148 | Diode | DO35 | D1, D2, D3, D4, D5, D6, D7, D8, D21\, D22, D23, D24, D25, D26, D27, D28, D51 | 1N4148-T26A | |

| 2 | BD139 | NPN BJT | TO126 | Q1, Q21 | BD13910STU | |

| 2 | BD140 | PNP BJT | TO126 | Q2, Q22 | BD14010STU | |

| 2 | BS170 | N-Ch MOSFET | TO92 (DGS pinout) | Q51, Q53 | BS170-D26Z | |

| 4 | 15pF | NP0/C0G ceramic capacitor | Radial LS=5mm | C7, C8, C27, C28 | FG28C0G1H150J | |

| 2 | 1.5nF | NP0/C0G ceramic capacitor | Radial LS=5mm | C5, C25 | FG28C0G1H152J | |

| 6 | 330pF | NP0/C0G ceramic capacitor | Radial LS=5mm | C1, C4, C6, C21, C24, C26 | FG28C0G1H331J | |

| 2 | 5pF | NP0/C0G ceramic capacitor | Radial LS=5mm | C2, C22 | FG28C0G1H050C | |

| 2 | 10nF | Ceramic or MKS/MKT film capacitor | Radial LS=5mm | C45, C46 | R82EC2100AA50J | |

| 7 | 1uF | Ceramic or MKS/MKT film capacitor | Radial LS=5mm | C41, C42, C43, C44, C51, C52, C53 | FG28X5R1H105K | |

| 2 | 33nF | PP film capacitor | Radial LS=5..15mm | C3, C23 | MKP2C023301B00KSSD | |

| 4 | 1000uF 25V | Electrolytic capacitor | Radial D=12.5mm LS=5mm | C13, C14, C33, C34 | EEU-FC1E102E | |

| 8 | 47uF 25V | Electrolytic capacitor | Radial D=5mm LS=2mm | C9, C10, C11, C12, C29, C30, C31, C32 | EEU-FC1E470B | |

| 1 | 24V coil | Relay | Fujitsu RY | K1 | RY-24W-K | |

| 2 | 3-way | Connector | 0.1in contact spacing | IN, OUT | 22-23-2031 | |

| 1 | 5-way | Connector | 0.1in contact spacing | POWER | 22-23-2051 | |

| 2 | 1in tall | Heatsink | Aavid 531x02 | n/a | 531002B02500G | |

| 2 | 1.5uH | Inductor | Hand wound | L1, L2 | See post #71 | |

| 1 | GREEN | LED | Radial D=5mm | LED | 151053GS03000 | |

| 1 | LM339N | Quad comparator | DIP14 | U51 | LM339N | |

| 1 | MPSA56 | PNP BJT | TO92 (EBC pinout) | Q52 | 2N3906 | |

| 2 | NE5532 | Dual OpAmp | DIP8 | U1, U21 | NE5532P | |

| 4 | 100 | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R45, R46, R53, R54 | MFR-25FBF52-100R | |

| 2 | 100k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R56, R60 | MFR-25FTE52-100K | |

| 4 | 10k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R11, R12, R31, R32 | MFR-25FBF52-10k | |

| 4 | 12k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R17, R18, R37, R38 | MFR-25FBF52-12k | |

| 4 | 15k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R5, R6, R25, R26 | MFR-25FBF52-15k | |

| 1 | 1Meg | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R55 | MFR-25FBF52-1M | |

| 4 | 1k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R10, R30, R58, R59 | MFR-25FBF52-1k | |

| 4 | 1k3 | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R1, R2, R21, R22 | MFR-25FBF52-1k3 | |

| 4 | 2.2 | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R15, R16, R35, R36 | MF0204FTE52-2R2 | |

| 2 | 20k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R51, R52 | MFR-25FBF52-20k | |

| 2 | 22 | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R43, R44 | MFR-25FBF52-22R | |

| 2 | 24k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R19, R39 | MFR-25FBF52-24k | |

| 2 | 2k2 | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R7, R27 | MFR-25FBF52-2k2 | |

| 2 | 300 | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R8, R28 | MFR-25FBF52-300R | |

| 1 | 33k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R57 | MFR-25FBF52-33k | |

| 4 | 47 | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R13, R14, R33, R34 | MFR-25FBF52-47R | |

| 2 | 470 | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R41, R42 | MFR-25FBF52-470R | |

| 2 | 470k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R9, R29 | MFR-25FBF52-470k | |

| 4 | 4k7 | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R3, R4, R23, R24 | MFR-25FBF52-4k7 | |

| 4 | 51k | Resistor metal film 0.25W | D=2.5mm L=6.3mm | R47, R48, R49, R50 | MFR-25FBF52-51k | |

| 2 | n/a | DIP8 socket | DIP8 | U1, U21 | 110-44-308-41-001000 | |

| 1 | n/a | DIP14 socket | DIP4 | U51 | 110-44-314-41-001000 | |

| 4 | n/a | TO126 thermal pad | n/a | Q1, Q2, Q21, Q22 | 43-77-9G | |

| 2 | n/a | M3x16 round head screw | n/a | Q1, Q2, Q21, Q22 | n/a | |

| 2 | n/a | M3 nut | n/a | Q1, Q2, Q21, Q22 | n/a | |

| 4 | n/a | M3 washer | n/a | Q1, Q2, Q21, Q22 | n/a | |

| 2 | n/a | M3 spring washer | n/a | Q1, Q2, Q21, Q22 | n/a |

The list allows reasonable substitution, and I included example part numbers that are currently available on Mouser. For your convenience, here is the link to Mouser's "project" that allows you to order all the parts to be mounted on the PCB (excluding the PCB itself and the hardware, for which Mouser is not the best source) in a couple of clicks, for a total cost of $42.32 (in the U.S.) plus shipping. As mentioned above, I'd expect you to already own a large part of the BOM, so make sure to delete all the parts you already have from the shopping cart before checkout.

A few comments to the BOM:

- Output transistors (Q1 Q2 Q21 Q22) should preferably be BD139-16 and BD140-16 ("-16" denotes the highest β grade). Also, you can get BD139/140 in fully insulated TO-126 packages (no metal tab on the back), in which case you don't need mica thermal pads.

- The two identical MOSFETs in the protection circuit can be just about any small N-channel MOSFETs in TO-92 with Vds>40V, as long as you pay attention to the pinout (DGS on the PCB).

- The capacitors in the frequency compensation network (C7, C8, C27, C28, C5, C25, C1, C4, C6, C21, C24, C26, C2, C22) must be ceramic with NP0 (C0G) dielectric. MLCCs are most common, but you can use disc capacitors, too. I like TDK FG2x series, which also happens to be one of the cheapest available.

- The 10nF output filter capacitors (C45, C46) and the 1uF caps in the protection circuit (C41, C42, C43, C44, C51, C52, C53) can be either ceramic (e.g. TDK FG28) or MKS/MKT (e.g. Wima MKS2) in appropriate packages (5mm lead spacing, max 3.5mm thick).

- The 33nF cross-feed capacitors (C3, C23) must be polypropylene, e.g. Wima MKP2 series. The board accommodates caps with lead spacing from 5 to 15mm.

- The electrolytic caps in power rails (C13, C14, C33, C34) should ideally be not taller than the heatsinks (see post #143 above). Feel free to use larger capacitance, as long as the lead spacing is 5mm and the diameter is less than 13mm. I use Panasonic FC series, but some builders reported good results using either organic polymer (e.g. Nichicon RNU series) or hybrid (Panasonic ZA) capacitors. Feel free to try those and tell us if they are worth the cost.

- The relay can any small signal relay in the same package as Fujitsu RY, e.g. Omron G6A series, with 24V coil. If the coil is rated for a different current than RY24W-K, you may need to adjust R58. Note that the relay shares its coil current with the LED.

- Connectors: I specified Molex KK254 headers; these require the mating connectors to be properly crimped (or soldered) for low distortion. You can use other connectors with 0.1 inch or 2.5mm pitch, e.g. Phoenix 1725669/1725685 terminal blocks, or just solder bare wire to the PCB - the holes are 0.04 inch / 1mm, which should allow wire up to 20AWG / 0.5mm2.

- The PNP BJT in the projection circuit can be replaced with any BJT with Vce>40V with the same EBC pinout, e.g. 2N3906. The popular BC556 or BC557 can be used, too, but note their pinout is different (CBE).

- The green LED is generic. You can short it (provided that R58 sets the right voltage/current for your relay), but I recommend soldering it in. Choose any color you want; note that LED on means "the amp is working normally". Note that it shares the current with the relay coil.

- NE5532 in DIP-8 package is the recommended opamp. There will be a separate post on opamp substitution.

- Resistors are 0.25W 1% metal film; YAGEO MFR-25 series is just an example. Should you want to use better parts with specified voltage coefficient, such as Vishay RN55/CMF55, use them first in as R1 R2 R3 R4 R5 R6 R17 R18 R19 (R21 R22 R23 R24 R25 R26 R37 R38 R39 for the other channel).

- IC sockets are optional required but recommended.

- Thermal pads: Q1 and Q2 (Q21 and Q22) share the same heatsink, so they must be insulated with thermal pads. This is not necessary if Q1 Q2 Q21 Q22 are in fully insulated TO126 packages.

- Hardware is not included in the Mouser project linked above. If you are in the U.S, feel free to use 4-40 screws and nuts instead of M3.

Last edited:

@alexcp Darn, you are doing a standup job with this project! Congratulations to you for sharing your efforts with us.

NE5532s made by both TI and OnSemi have been tested with Omicron, work well, and are the recommended opamps to use.NE5532 in DIP-8 package is the recommended opamp. There will be a separate post on opamp substitution.

Other opamps have been reported to work, including AD712, LM4562, LME49860, OPA1642, OPA1652, OPA1688, OPA2604. Opamps with low GBW, e.g. LM358, will not work in Omicron.

If you have a scope, you can test other opamps. What to check for are (1) the DC offset at the output, (2) oscillations (or rather lack thereof) and (3) clean clipping into a (dummy) load. If you don't have a scope, stick with NE5532 - they perform very well and a quarter of the cost of others.

Also, beware of fake opamps. One of us encountered fake NE5532s that oscillated in Omicron. Since NE5532 costs only $0.44 in single quantities if purchased directly from TI and $0.71 from Mouser, we could not believe someone can make money on such fakes. However, in testing the fakes had about one-fifth of open loop gain expected from NE5532.

I started the group buy thread and will keep it running until March 15. If you want a board, kindly subscribe in that thread.It makes sense to run a GB for all available boards at once

How much (aprox) would that fee be?If needed, however, I may be able to purchase and solder, for a fee, all SMT parts on some boards.

Also, what's the smallest component size in the SMT version?

The smallest parts on Omicron's SMT board are 1206 (passives) and SOT-23 (transistors). I could have used 0603 and 0805 but wanted to make it more accessible for hand soldering at home.

However, if you don't want to solder those SMT parts yourself, a PCB with all SMT parts soldered (but without the relays, connectors and 33nF film and electrolytic caps) down will cost you $100 - that includes the board and about $30 worth of SMT parts. I will post the BOM shortly.

However, if you don't want to solder those SMT parts yourself, a PCB with all SMT parts soldered (but without the relays, connectors and 33nF film and electrolytic caps) down will cost you $100 - that includes the board and about $30 worth of SMT parts. I will post the BOM shortly.

Last edited:

- Home

- Amplifiers

- Headphone Systems

- Omicron, a compact headphone amp with -140dB distortion