That really is FIR in action!

I take it that you use a 2nd order XO on the LF / HF?

My ageing Najda DSP can only do 1024 taps and It doesn't see a straightforward procedure (to me anyway).

I use the quirks of the Danley design and PEQs to get a within 90 degree phase plot all the way to ~80Hz.

It's been interesting playing with the phase and hearing the differences it makes.

I take it that you use a 2nd order XO on the LF / HF?

My ageing Najda DSP can only do 1024 taps and It doesn't see a straightforward procedure (to me anyway).

I use the quirks of the Danley design and PEQs to get a within 90 degree phase plot all the way to ~80Hz.

It's been interesting playing with the phase and hearing the differences it makes.

Yeah 2nd order electrical slopes to get me there. I've played around with the 0th order PEQ-only approaches and had success with it. I guess I'm just wary of damaging the compression driver with that approach since I typically run my MEH designs quite loud and in PA settings.

Either way, getting a flat or mostly flat phase response seems to have positive impacts, at least in my perception. Notably in how focused the phantom center is and how easy it is to pinpoint different elements across the soundstage.

Right now the challenge is figuring out how to reduce FIR latency with the hypex amp. It seems like it only likes to take 96kHz files with exactly 1500 taps, whereas other DSPs are happy to take files with less than the maximum number. Using rephase to design the filters so maybe I have the configuration set up wrong? It seems to always produce a file with high latency unless I reduce the number of taps, but then the hypex won't take the file.

Currently at 7.8ms of latency. The generally accepted maximum latency for DJs to beatmatch effectively is about 9ms, so factor in other gear in the signal chain and you can very quickly exceed that. Ideally I'd like to get latency below 5ms.

Either way, getting a flat or mostly flat phase response seems to have positive impacts, at least in my perception. Notably in how focused the phantom center is and how easy it is to pinpoint different elements across the soundstage.

Right now the challenge is figuring out how to reduce FIR latency with the hypex amp. It seems like it only likes to take 96kHz files with exactly 1500 taps, whereas other DSPs are happy to take files with less than the maximum number. Using rephase to design the filters so maybe I have the configuration set up wrong? It seems to always produce a file with high latency unless I reduce the number of taps, but then the hypex won't take the file.

Currently at 7.8ms of latency. The generally accepted maximum latency for DJs to beatmatch effectively is about 9ms, so factor in other gear in the signal chain and you can very quickly exceed that. Ideally I'd like to get latency below 5ms.

That's a great insight in to how you are implementing.

Yes PA volumes😱🙂

I'm strictly hifi volume levels and my compression drivers are very unstressed.

If I do go PA volumes for a wedding etc it's the BMS4550 drivers and 2nd order..

I can't get on with them for hifi listening and prefer either my 1950s/60s alnico refurbished Vitavox S2s, they are good down to 500Hz on right horn, I use the trust 3uF cap method - but they don't play very high, OR the Peerless by Tymphany group buy drivers.

They are pretty fragile so no PA ever, but I do like the dynamics and tone they make. They also play high enough for me.

Do you have a video of your gear playing in its natural habitat?

It won't be for the sound reproduction, I just like to see these things in action / feel the vibe🙂

Yes PA volumes😱🙂

I'm strictly hifi volume levels and my compression drivers are very unstressed.

If I do go PA volumes for a wedding etc it's the BMS4550 drivers and 2nd order..

I can't get on with them for hifi listening and prefer either my 1950s/60s alnico refurbished Vitavox S2s, they are good down to 500Hz on right horn, I use the trust 3uF cap method - but they don't play very high, OR the Peerless by Tymphany group buy drivers.

They are pretty fragile so no PA ever, but I do like the dynamics and tone they make. They also play high enough for me.

Do you have a video of your gear playing in its natural habitat?

It won't be for the sound reproduction, I just like to see these things in action / feel the vibe🙂

Sure- here's some videos I've gotten of them since the very crude/rattly first prototypes to the current version. https://photos.app.goo.gl/Lbebxpu3KHBgPZ6x7. I've had them set up in stereo in my listening room as well, but unfortunately don't have any videos of them in that environment yet.

I've been really happy with the DH350/450 for MEHs so far. Mainly because the compact size makes it possible to get the woofers in very close. Additionally, there's no empty throat section in front of the phase plug of the compression driver, so you can use the exit of the CD as the point to calculate the 1/4 wavelength distance for tap placement.

I've been really happy with the DH350/450 for MEHs so far. Mainly because the compact size makes it possible to get the woofers in very close. Additionally, there's no empty throat section in front of the phase plug of the compression driver, so you can use the exit of the CD as the point to calculate the 1/4 wavelength distance for tap placement.

I use the elegoo neptune 3 max and 1.2mm nozzle with success. having trouble finding these nozzles anymore. wish i would've bought more.I'm using a Prusa Mk4. I've got my eye on a ratrig for large format prints. Would be really nice to do this kind of stuff in 1-shot even if it takes 4 days to print.

Thank you for your contributions. where do i find them?I'm going to clean up the files and upload .STLs for people who might be interested in printing this.

I'll post the download link in this thread when they're ready.Thank you for your contributions. where do i find them?

Absolutely stunning and inspiring project, @galucha!

Could you give some feedback about tuning accuracy and high output level behaviour once you are ready?

Thanks!

I am honored by such a nice implementation!I used STV's port optimization spreadsheet to settle in on the below port design.

Could you give some feedback about tuning accuracy and high output level behaviour once you are ready?

Thanks!

If there are others like myself in the UK who would be interested in buying the waveguide then perhaps we could make a combined purchase and share the shipping cost from the US ? I’d be happy to arrange the shipping from this end if that would help and for some reason it often works out cheaper than if the shipping is arranged in the US.Otherwise, I'll have the waveguide assemblies available for purchase in the US since its not exactly an easy print.

Potentially would be interested. I think in the near term I'd like to get the first batch made and maybe gauge further interest afterwards. I've also had a couple of different companies in the EU that specialize in 3D printing reach out and ask about collaboration. So that may also be a future opportunity to get these in the hands of more people in Europe.

It’s been very interesting following your build, thanks for sharing the process! I have a few questions.

What’s the size of the mid-entry ports? I’ve been worried that a small port might cause chuffing at high volumes and low frequencies if the velocity exceeds 17 m/s. But based on your results, it looks like it’s possible to push it much further. Is it because it acts as a compression chamber and therefore the 17 m/s rule is not relevant?

Why did you choose to use a rear port? Was it mainly to improve low-frequency response when running without a subwoofer, or does it also offer benefits when crossing over to a subwoofer?

What’s the size of the mid-entry ports? I’ve been worried that a small port might cause chuffing at high volumes and low frequencies if the velocity exceeds 17 m/s. But based on your results, it looks like it’s possible to push it much further. Is it because it acts as a compression chamber and therefore the 17 m/s rule is not relevant?

Why did you choose to use a rear port? Was it mainly to improve low-frequency response when running without a subwoofer, or does it also offer benefits when crossing over to a subwoofer?

What’s the size of the mid-entry ports? I’ve been worried that a small port might cause chuffing at high volumes and low frequencies if the velocity exceeds 17 m/s. But based on your results, it looks like it’s possible to push it much further. Is it because it acts as a compression chamber and therefore the 17 m/s rule is not relevant?

Why did you choose to use a rear port? Was it mainly to improve low-frequency response when running without a subwoofer, or does it also offer benefits when crossing over to a subwoofer?

Each mid-entry port is about 14 sq cm in area. Calculating the resulting chuffing/compression from turbulence is a bit of a trial and error exercise since the shapes and lengths of the ports aren't simple geometry, and I unfortunately am not well versed in more advanced modeling tools like COMSOL. But from the prototypes, I've found that air noise from the mid ports remains at a very acceptable level in domestic rooms when operating in full-range mode. It doesn't begin to become audible until you hit around 116dB in the external sub mode of operation, but I think it remains at an acceptable level for PA-type work.

I got around to measuring power compression today with the 80Hz HPF engaged, so you can see that it remains fairly linear until you approach the maximum SPL limit. I couldn't find much in terms of guides for making these sorts of graphs, so I aligned SPL in REW @2kHz and exported to excel to make this.

The choice of adding a rear port was mainly me wanting this to be a design that could be used in either full range or external sub modes of operation for added flexibility. The port doesn't offer much in terms of benefits if you're always using an external subwoofer though, so I if you were to DIY one with that intention, you would probably benefit from making the enclosure sealed, or with a higher tuned shorter port.

Subjectively, the DH350 lacks a sort of upper midrange clarity that I’ve heard with other (larger) compression drivers. I’d wager this is due to some diaphragm resonances, but haven’t measured it. I’d recommend buying one to prototype with other horns/waveguides to assess this yourself before determining if this build is for you.

I love your projects! You should post the stuff from Instagram.

Some thoughts on the tweeter:

1) I know the DH350 is really "hot" right now, but the only advantage that it seems to have over competing small compression drivers is that it's shallow. Basically, if you can live with an extra inch of depth (no pun intended), I would expect that competing options might work better. I can't see any way that twisting the phase plug would do anything positive to the frequency response; it's a packaging "trick" as far as I can see.

2) Years ago, I made a thread about DIY compression drivers, where I took soft domes and made phase plugs for them, in an attempt to create 3D printed compression drivers. Someone on here clued me into something I hadn't considered, which is that you really need a lot of BL to get the compression driver to play high. I am a bit out of my expertise on this one, but as I understand it, the higher BL raises the overall sensitivity. Since many of these teeny tiny compression drivers are intended for loudspeaker arrays, where they're basically one element among dozens or even hundreds of compression drivers, their small size is more important than how efficient they are.

Here's Vance Dickason's measurement of the neodymium DE350; note the sensitivity above 10khz is about 102dB. (I couldn't find a Dickason review of the DH350)

Here's Vance Dickason's measurement of the neodymium DE550; note the sensitivity above 10khz is about 4-5dB higher

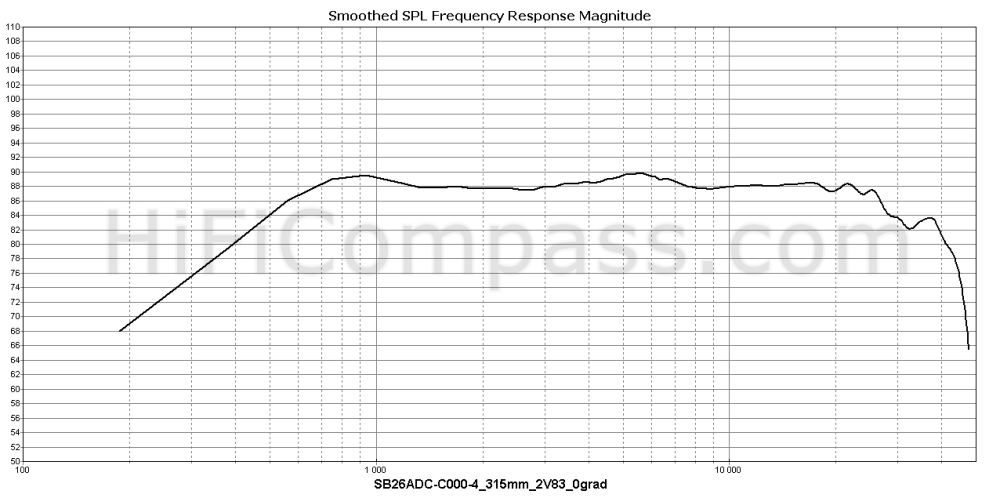

I had a similar issue when I kept trying to make waveguides with the 1" SB Acoustics SB26ADC. Although it's highly regarded on a flat baffle or a very shallow horn, once I put it on a large-ish waveguide, I could tell that the top octave sounded a bit "dark and dull." I couldn't quite figure out what this was, and it's a bummer because it's such a nice tweeter. But I think a fairly decent part of the issue, with the SB26ADC, is that it's sensitivity above 10khz is just 86dB.

Thanks! I definitely need to get more in the habit of documenting builds somewhere more permanent than Instagram stories.I love your projects! You should post the stuff from Instagram.

Regarding compression driver choices, I think the phase plug design and compact size of the DH350/450 was absolutely key in making this 2-way MEH design work. Originally I had considered something like a BMS4550 or DE550, but the pancake style compression drivers all seem to have an empty throat section incorporated after the phase plug. From what I've gathered, the phase plug is usually the best point to do the 1/4 wavelength distance calculation for tap placement, as the throat reflection happens there. So the midrange drivers need to be closer in proximity to the compression driver if you use compression drivers that feature empty throat sections. Not a huge issue if you use 4" or 3" midrange drivers, but doing that with two or four 6.5" drivers creates some challenges due to their size.

Of course this can be remediated by using a larger 1.4" compression driver capable of a lower crossover point, but for this build I really liked the appeal of being able to do it with a reasonably cost effective 1" CD. The eminence N314T/X was probably the cheapest realistic option that could have allowed for a lower crossover point, but its about 3x the cost, and quite a bit heavier/bulkier.

To summarize, I couldn't find a way to make a 1kHz crossover point work with the 4550 or DE550 because the 6.5"s just wouldn't fit in close enough. The DH350/450 makes this just barely feasible though.

Hi John, saw your latest post on Instagram. Want to share anything here?

Not a lot to report on just yet. Right now I'm working through the DIY guide writeup. I think that rather than uploading detailed plans for the enclosure design, I'm going to provide some general guidelines around what kind of enclosure is best suited for this design since some people are going to want the bass extension from a low-tuned vented or PR enclosure, and others may prefer a sealed alignment - or maybe some will want to experiment with OB.

The variant I'll be selling from my shop has had a few changes, mainly in that I enlarged the enclosure by about 25mm in every dimension to accommodate a cleaner baffle that fits the waveguide better. I've had to focus my time on other projects lately, but I'll hopefully be getting this new enclosure built sometime this week. Below are some renders on how that will look.

Still also experimenting with resin formulas. The Anycubic Rigid 100 resin showed initial promise as being an ultra-strong and heat resistant solution, but getting the pieces aligned for assembly proved challenging (see pic below). The ABS-Like V2 formula seems to strike a good balance between performance and ease of assembly though so that's probably what I'll stick with as the recommendation.

For FDM printing PETG/ASA seem like decent options, although I haven't tried them yet and it would definitely require an enclosure to minimize warpage. Polycarbonate or polycarbonate blend filaments would really be ideal though. Polymaker and Prusa both sell some really easy to print PC filaments that I'm going to be experimenting with. Clear/uncolored PC tends to work best as the color additives can reduce the strength of the print - especially if you use white filament as they usually add titanium dioxide which seems to make things much more brittle.

- Home

- Loudspeakers

- Multi-Way

- Portable Battery Powered MEH Build