Heavy sandfilled plint/Lenco L75/Clear Audio Unify/Benz Micro Ace L finished

This Lenco L75 is my latest project.

A heavy plint made out of 1" oak with sandbags inside. A Clear Audio Unify arm and a Benz Micro ACE L Cart.

A more detailed tread can be seen here (from page 35)

HiFiForum.nu - Pix - Projekt Pukor & Trumpeter. Dagboken

This Lenco L75 is my latest project.

A heavy plint made out of 1" oak with sandbags inside. A Clear Audio Unify arm and a Benz Micro ACE L Cart.

A more detailed tread can be seen here (from page 35)

HiFiForum.nu - Pix - Projekt Pukor & Trumpeter. Dagboken

This is My very first turntable build...

Great work.

I was wondering...how do you control the motor speed ?

Last edited by a moderator:

Deadhead, the motor speed is fixed at 300 rpm. This turntable uses the same synchronous motor found in some of VPI turntable models. After I get the platter from the machine shop I measure the it's diameter. I ask the shop to only take enough material to get a nice surface finish. I use an equation to solve for the diameter for the motor pully based on the platter diameter and the fixed motor rpm. I then size the pulley diameter a few mm above my equation. The final size is a trial and error. I test the rpm with an app on my phone. I remove a little material at a time from the pulley until I get a speed that is satisfactory. Very small changes in speed can be made by the tension on the monofilament line. So the short answer is the line current frequency controls the speed with the correct pulley size. Any variations in the line frequency I haven't been able to hear.

You've made a very nice job of your TT. I like unusual designs What timber did you use for the plynth?This a test to see if I could upload a pic of my first turntable.

Regards John L.

Impunity, the wood I used is called Zebra Wood. The turntable was made over a year ago. I have since made a second one for my brother and it also uses Zebra Wood.

/www.youtube.com/watch?v=rPK95wutGsA&list=PLP2CMw83zDzqU5r7Km9-sLr5hSDP4Ninj&index=3&t=1s

/www.youtube.com/watch?v=rPK95wutGsA&list=PLP2CMw83zDzqU5r7Km9-sLr5hSDP4Ninj&index=3&t=1s

Balanced Phono

This is my first board attempt with SMD components, it is a fully Balanced Phono stage, I have to improve my soldering (reflow) for the next effort. Board done on Eagle, straight to board no schematic, that s in my head and scraps of paper, it all works first time. So nice to have the boards done for me, no messing with etching acid like my previous efforts..

This is my first board attempt with SMD components, it is a fully Balanced Phono stage, I have to improve my soldering (reflow) for the next effort. Board done on Eagle, straight to board no schematic, that s in my head and scraps of paper, it all works first time. So nice to have the boards done for me, no messing with etching acid like my previous efforts..

Attachments

Well yes... I bough a new MM cartridge for spare as my Shelter 501 mkII is being fixed and the MM had a bit more hum so I tried giving some more shielding. But at the same time I put a grounding wire also together/between the signal leads inside the arm, so I'm not so sure that the copper turns around the arm make much difference... I think not much, but does make the arm a bit heavier which was good in this case.

Last edited by a moderator:

Thorens 124

Gifted from a friend who's father passed away.

Refurbished with many new parts and adjusted as best as I could. Runs almost silently with a Thacker brand belt.

Schick 12 tonearm and graphite headshell.

Soundsmith Paua cartridge on the pointy end. Lovely quiet cartridge with great support from SS.

The base is two stacked granite surface plates that were waterjet cut. The top one has the full cut-out and the lower one has holes to allow the power cord, tonearm cable and the heater pads to pass through.

Longer studs are used to allow threaded aluminum discs to clamp the whole thing together. It all sits on a machinists stand with leveling screws supporting the granite.

The heating pads are positioned just under the main bearing and motor allowing the table's speed to stabilize quickly at the innards stay warm. The heating pads stay plugged in all the time.

Gifted from a friend who's father passed away.

Refurbished with many new parts and adjusted as best as I could. Runs almost silently with a Thacker brand belt.

Schick 12 tonearm and graphite headshell.

Soundsmith Paua cartridge on the pointy end. Lovely quiet cartridge with great support from SS.

The base is two stacked granite surface plates that were waterjet cut. The top one has the full cut-out and the lower one has holes to allow the power cord, tonearm cable and the heater pads to pass through.

Longer studs are used to allow threaded aluminum discs to clamp the whole thing together. It all sits on a machinists stand with leveling screws supporting the granite.

The heating pads are positioned just under the main bearing and motor allowing the table's speed to stabilize quickly at the innards stay warm. The heating pads stay plugged in all the time.

Attachments

-

IMG_20190615_085445 (2).jpg1,018.1 KB · Views: 1,033

IMG_20190615_085445 (2).jpg1,018.1 KB · Views: 1,033 -

IMG_20190502_104333.jpg1,006.2 KB · Views: 1,016

IMG_20190502_104333.jpg1,006.2 KB · Views: 1,016 -

IMG_20190502_104325.jpg991 KB · Views: 987

IMG_20190502_104325.jpg991 KB · Views: 987 -

IMG_20190424_084844.jpg1.1 MB · Views: 971

IMG_20190424_084844.jpg1.1 MB · Views: 971 -

IMG_20190213_180810_01.jpg1,021.6 KB · Views: 926

IMG_20190213_180810_01.jpg1,021.6 KB · Views: 926 -

Screenshot_20190201-170736.jpg272.6 KB · Views: 440

Screenshot_20190201-170736.jpg272.6 KB · Views: 440 -

IMG_20190702_184705 (1).jpg668.5 KB · Views: 460

IMG_20190702_184705 (1).jpg668.5 KB · Views: 460

Last edited:

Thorens 124

WntrMute2

Very nice indeed.....better than some commercial offerings.

What is that you've done to your T/arm anti-skating.......?

WntrMute2

Very nice indeed.....better than some commercial offerings.

What is that you've done to your T/arm anti-skating.......?

Thomas Schick did not deem anti-skate as necessary in his earlier designs but has since changed his opinion. He cannot add it to an existing arm as the casting is different evidently. I was unsure about drilling and tapping the tapered casting so I just added VPI's anti-skate device.

I epoxied three metal discs together and drilled and tapped the center so I had a mounting for the device. It is heavy enough that the tiny anti-skate forces don't move the mounting. Schick seemed to chuckle when I sent him pictures.

I epoxied three metal discs together and drilled and tapped the center so I had a mounting for the device. It is heavy enough that the tiny anti-skate forces don't move the mounting. Schick seemed to chuckle when I sent him pictures.

Attachments

Thorens 124

''Necessity is the mother of invention''.

Great adaptation......and I've just noticed your use of tube dampers.Wonderful

ideas to take away.

Thanks for sharing.

''Necessity is the mother of invention''.

Great adaptation......and I've just noticed your use of tube dampers.Wonderful

ideas to take away.

Thanks for sharing.

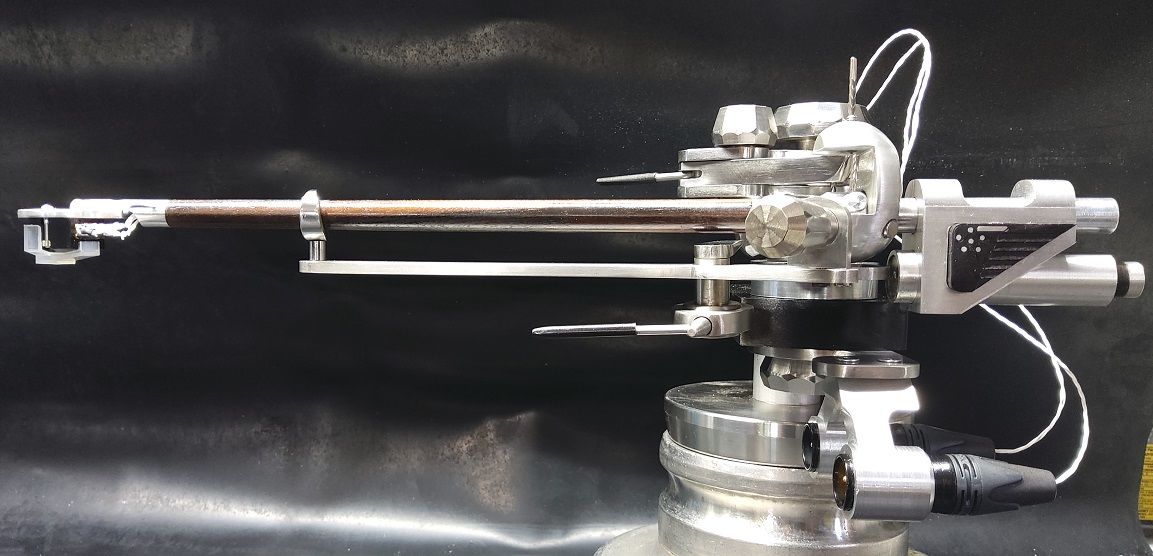

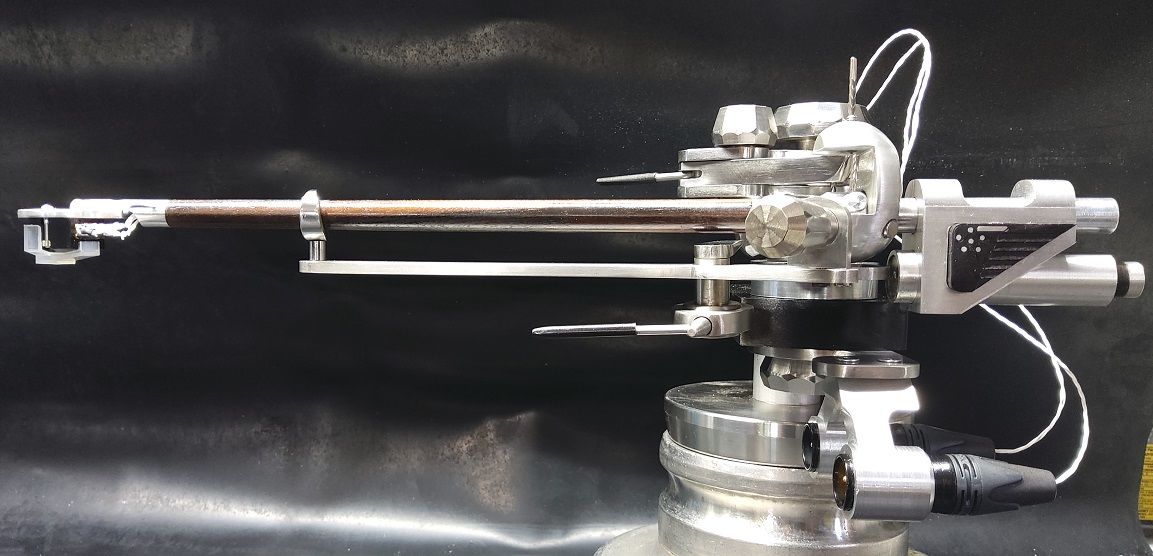

Reed 3P

After a year I finally finished my version of the Reed 3P. I was just having fun in the shop and thought if it played music that would be great, but it sounds surprisingly good. It really perks up the old Denon.

Cheers; Glenn

After a year I finally finished my version of the Reed 3P. I was just having fun in the shop and thought if it played music that would be great, but it sounds surprisingly good. It really perks up the old Denon.

Cheers; Glenn

Corian Lenco

Alternative top plate and bearing. Lenco motor and idler drive.

5 layers of Corian for the plinth, 3 layers for the feet and 2 for the arm board.

Not pleased with the seams but I think its the best you can do without Corian glue. Maybe more polishing might help.

kffern

Alternative top plate and bearing. Lenco motor and idler drive.

5 layers of Corian for the plinth, 3 layers for the feet and 2 for the arm board.

Not pleased with the seams but I think its the best you can do without Corian glue. Maybe more polishing might help.

kffern

Attachments

Member

Joined 2009

Paid Member

I think that Thorens looks great, very nice gift which you’ve honoured well.

then I scrolled down to the Reed, and - holy smokes, that looks like some work.

then I scrolled down to the Reed, and - holy smokes, that looks like some work.

- Home

- Source & Line

- Analogue Source

- Post your Analogue Source pics here