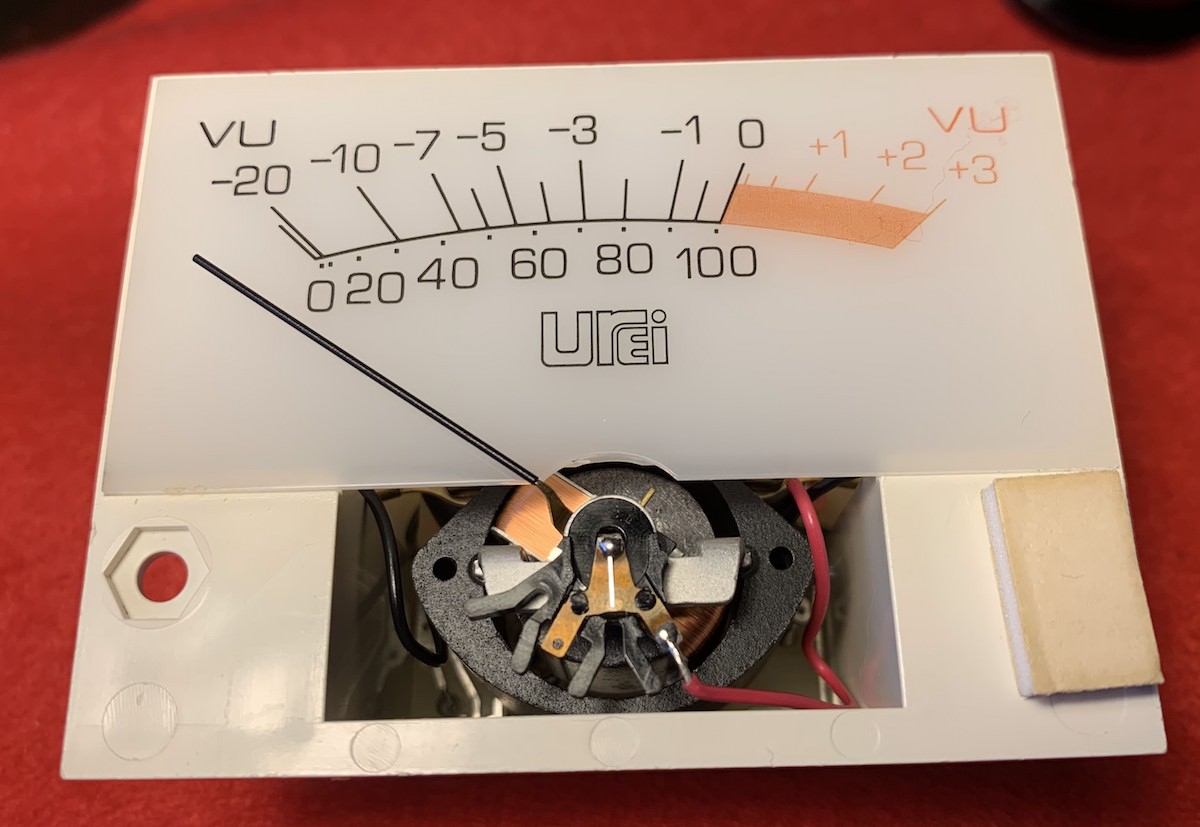

I have a pair of UREI 1176LN. Classic audio compressor limiters. I replaced one of the VU meters recently due to failure. But the replacement is from an earlier version and the pair look different now. I would love some advice, tips, on how to repair this. It is a Modutec 'Lightbox' type. Taut band suspension. The problem was sticking. The needle clearance looks fine, but the coil seems to be offset.

Attachments

Sometimes the moving magnet, which is made out of two half-cylindrical magnets, detaches from its frame because the glue holding them in place has become brittle (particularly in backlit Vu-meters). This allows one of the magnets to rub against the stator wire.

Check it doesn't move free using a fine toothpick. If it does, you can push the assembly back together, block it and put a tiny glue drop between the upper holding frame and the half-magnets. Did this many times with much smaller VU-meters than the Modutec and I saved most of them, it's worth a try.

T.

Check it doesn't move free using a fine toothpick. If it does, you can push the assembly back together, block it and put a tiny glue drop between the upper holding frame and the half-magnets. Did this many times with much smaller VU-meters than the Modutec and I saved most of them, it's worth a try.

T.

I would swap the scales and covers over if there is no adjustment to compensate for bearing tightness.

Some early Akai meters I have worked on, has damping grease in the bearing points to give a more average reading. When the lubricant dries, they used to stick.

Some early Akai meters I have worked on, has damping grease in the bearing points to give a more average reading. When the lubricant dries, they used to stick.

Helpful

Tx for the replies. This one looks like a moving coil device. If you look closely you can see there is very little clearance at the top left compared to the bottom right. You may be able to see the taut band poking through a solder blob.

I would guess the solder gets melted and the band pulled tight probably in some controlled jig. Solder sets, done. This meter is out on the bench, the two 1176's are back in the studio. So I won't be able to swap parts.

I guess the next stop is to figure out how to extract the mechanism in order to examine the rear end of the taut band.

Tx for the replies. This one looks like a moving coil device. If you look closely you can see there is very little clearance at the top left compared to the bottom right. You may be able to see the taut band poking through a solder blob.

I would guess the solder gets melted and the band pulled tight probably in some controlled jig. Solder sets, done. This meter is out on the bench, the two 1176's are back in the studio. So I won't be able to swap parts.

I guess the next stop is to figure out how to extract the mechanism in order to examine the rear end of the taut band.

The ones I repaired either had tiny amounts of dirt jamming the very small clearances or the meter had been subjected to overload and the bearing pivot wasn't centred in the jeweled holder .

Repairs are a delicate operation ,better with an illuminated bench magnifier and watch out for the very delicate spring once bent it wont operate correctly.--

Taut-Band Suspension System vs Pivot and Jewel Mechanisms

Repairs are a delicate operation ,better with an illuminated bench magnifier and watch out for the very delicate spring once bent it wont operate correctly.--

Taut-Band Suspension System vs Pivot and Jewel Mechanisms

Is the central coil carrier mechanism soldered to the outer eye shaped frame because if it is that might be a way of adjusting the centring of the coil .

Post a couple of pictures taken in the direction of your arrows.

It looks like one side is sitting higher than the other.

Sid.

It looks like one side is sitting higher than the other.

Sid.

Check the if the pointer is moving freely and returning to home first.

Moving that brass tip on the right top side perhaps for zero adjust ?

Moving that brass tip on the right top side perhaps for zero adjust ?

Sid, one side is definitely sitting higher. I poked a long soft camel art brush in there to ensure there was no debris, metal bits sitting on the magnets. Seems clear. MAAC0, that is the problem, it sticks at various positions randomly and does not return home reliably at all. It is hard to tell of the zero adjust is doing anything in this context.

- Home

- Design & Build

- Construction Tips

- Repair a VU Meter