Hi,

Fischer 101-Series

jauu

Calvin

Good taste. I used those on a phono preamp waaay back, but finding cable to reliably connect and support my misguided views of the time on cables was a challenge.

Bill

P.S. Looking a an SL-Q33 as a donor on ebay at the moment. I will blame you if I win it!

I bought a new stylus for my girlfriends JVC L3-E. The JVC was from an audio jumble . The guy almost insisted I bought it for $50. Very shocked how good it is. I had to ask if better than the LP12 I am using? On the whole yes. The LP12 is with Ekos and DL110. It is the very area where Linn have improved the design where this older LP12 fails. Looking up the JVC design it seems to be a little like JVC TT71. I shouldn't have said that as I am rather keen to buy one. The L3-E might have the beating of the 1210 also if my memory is correct ( less tizz ). The sound I hear is like a mastertape. Solid and no obvious flutter. Sinatra makes it obvious how good it is. The cartridge looks like a Audio Technica type. The arm whilst nothing exciting possibly is better than many larger arms. I suspect the linear tracking is an advantage. A bit like a Lotus 7 car in what it can do. The let down is it looks very cheap and nasty. JVC how can you hide your tallent so well? TT 71 looks wonderful. My Garrard 401 needs finishing. I had one and gave it to another lady I know. And with a Naim Aro. 401 Hadcock Ortofon M25FL calibration is planned.

In hunting ebay I noted a few of the lower level SL series quite cheap. Not for me as I like to be able to mix and match in some crazed belief I can make something better. But I should sort the KD-550 before I get any more turntables.

Nice work by intensate and calvin. Would a shielding plate helped in any way where electronics are placed ?

regards

regards

Hmm. Think I might be inn trouble. Just scored an SL-Q33 for a tenner! I missed out. On an SME 3009 SIII for 160 but there will be more!

SME S3 was a very good arm. The way it can be adjusted is excellent. Slightly soft sounding. Add mass if more punch required, e.g. Denon DL 103.

I still want one one day, but wont be until I get one cheaply. The stock arms may be ok with a little fettling!

Don't buy an SP 10 unless sure you like it. To my ears Colleen's little JVC is mildly better where I have doubts. I know of a Scully cutting lathe with SP10 motor. It cuts light stuff fine. Peter Gabriel So was a joke. I heard a Lenco 75 beat a SP10 when the pace picks up. 1210 I like very much and can forgive it anything.

Don't take the cutting lathe thing to heart. It is perhaps using a RR as a truck. Bob, one of our friends insisted we machined a Garrard 401 platter to fit a 1210. Bob is someone who I never argue with as often his hunches are right. 9 Concorde flight decks were wired by Bob so he is no idiot. His 1210 plinth is made of solid wood . Bob is a gunsmith. He made his own pick up arm that looks to weigh like a gun. The cartridge is perhaps a Lyra Argo or whatever the new one is called ( not the cheapest one ). This turntable is like the JVC in sound. I can not say how or why. It just is.The 1210 has a crude treble quality that is fun but not easy to ignor. Very interesting Bob's deck isn't like that. He did no work to the servo's or did he? Perhaps the 401 platter forces it to change?

The top of the range Denon was dissapointing. The arm has a rubber link. Obviously very good , but wrong in areas.

I hope someone with a JVC TT 71 reads this thread.

Don't take the cutting lathe thing to heart. It is perhaps using a RR as a truck. Bob, one of our friends insisted we machined a Garrard 401 platter to fit a 1210. Bob is someone who I never argue with as often his hunches are right. 9 Concorde flight decks were wired by Bob so he is no idiot. His 1210 plinth is made of solid wood . Bob is a gunsmith. He made his own pick up arm that looks to weigh like a gun. The cartridge is perhaps a Lyra Argo or whatever the new one is called ( not the cheapest one ). This turntable is like the JVC in sound. I can not say how or why. It just is.The 1210 has a crude treble quality that is fun but not easy to ignor. Very interesting Bob's deck isn't like that. He did no work to the servo's or did he? Perhaps the 401 platter forces it to change?

The top of the range Denon was dissapointing. The arm has a rubber link. Obviously very good , but wrong in areas.

I hope someone with a JVC TT 71 reads this thread.

I have never heard a JVC direct drive turntable. One interesting thing about all Japanese direct drive turntable is, almost all have more or less same specifications of wow and flutter around 0.02 and rumble of -75 dB. Even SP-10 has almost same specifications. Platter weight is also around 1.5 to 2 kg. But stand alone motor units like SP-10 would have flexibility to choose a tonearm.

Speaking of guns. I watched 'How it's made' programme on Holland and Holland gun. Amazing craftsmanship with traditional way of gun making. A work of art.

Regards

Speaking of guns. I watched 'How it's made' programme on Holland and Holland gun. Amazing craftsmanship with traditional way of gun making. A work of art.

Regards

TEAC TN-400 was originally without arm or plinth and can be found every now and then.

Can't find much by way of specs on the motor but it was listed as having a 20 pole 60 slot ultra low speed DC servo. I can tell you it gets up to speed at 33.3rpm very quickly indeed.

Can't find much by way of specs on the motor but it was listed as having a 20 pole 60 slot ultra low speed DC servo. I can tell you it gets up to speed at 33.3rpm very quickly indeed.

The top of the range Denon was dissapointing. The arm has a rubber link. Obviously very good , but wrong in areas.

I hope someone with a JVC TT 71 reads this thread.

Which Denon model is this?

Denon always made a claim that AC direct drive better than DC of others. As far as I can see when inside the motor this isn't true. If one puts a very small resistance in the motor feed and takes a current waveform that is the truth. If a square, triangle or sine wave is used the resulant looks like a sine wave of > 10 % THD. The spectrum if lucky is a triangle wave. With some complication some pre distortion can be used. This will be mostly futile. The next move is shaping the pole pieces to draw the current more ideally. After that how the servo's work helps. If more wow and less flutter that is a good trade off. That is where the spec writter may have the last word. Many have retuned the servos and found a better sound. Roy Gandy I think said 0.2% wow and zero flutter would be ideal for a DD. He was saying that in 1976. P2 was about 0.2%.

Strathearn SMA2 Manual - 2-Speed Direct-Drive Turntable - Vinyl Engine

This DD was a Mettoy toy motor. It was dreadful. I still admired how some of the science was done. The tweeter they made became famous as another brand.

This DD was a Mettoy toy motor. It was dreadful. I still admired how some of the science was done. The tweeter they made became famous as another brand.

I'm scratching my head over this AC vs. DC thing. What does it mean?Denon always made a claim that AC direct drive better than DC of others.

Every DD I've heard about has a power supply that outputs DC which runs a low-frequency oscillator that powers the coils. This is of course oversimplified, but the "system" runs on DC and the coils run on AC.

Perhaps this means the coil voltage goes both positive and negative for AC, but for DC the coil voltage goes from zero to a peak voltage and back to zero?

With a microcontroller (ARM chips are a few bucks, development boards such as the ST Discovery or TI 432 Launchpad are $10 to $20), you can use a lookup table for what value should be used at what phase angle to give a pure sine-wave-shaped force on the pole piece. It takes some "lab work," measuring the rotation force at 1-degree-or-better angles while one coil is activated and the platter is fixed to generate the needed data, but it's certainly doable.As far as I can see when inside the motor this isn't true. If one puts a very small resistance in the motor feed and takes a current waveform that is the truth. If a square, triangle or sine wave is used the resulant looks like a sine wave of > 10 % THD. The spectrum if lucky is a triangle wave. With some complication some pre distortion can be used. This will be mostly futile. The next move is shaping the pole pieces to draw the current more ideally.

Hi,

Just for your information.

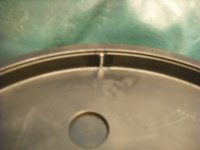

I have an old Garrard GT35X with a worn out motor that I was planning to toss it in the trash and then decided to see which alternative I have to replace the motor. Since I worked with micro I decided to repair it before toss it out. I tried some dc motors controlling them by the micro but the speed was not constant. Then decided to use a stepper motor since it is easy to control the speed using PWM. To control the speed I used an Optek OPB775TZ reflective object sensor. Painted the bottom of the platen black and glue a small reflective metal strip at the edge of the platen to use it as a speed index. Replaced the original spindle to 1 inch diameter pulley since the stepper was running at 1000 pulse per seconds and was causing a whining noise coming from the stepper. Doing so the pulse per seconds drops from 1000 to 660 PPS. Now the noise it is barely heard. You have to be very closed to the motor to hear it. Wrote a program to control the speed by reading the index pulse to calculate the time between index pulse and then adjusted the PWM frequency right on at 33.33334. To prevent the motor vibration I used a "Vibration Isolator Low Profile Carbon Fiber Mount" used in drones. Right now it is in test mode and the sound it is very good and the speed it is also constant. Attached are some pictures showing how I mounting the motor, the sensor and the index marker.

Just for your information.

I have an old Garrard GT35X with a worn out motor that I was planning to toss it in the trash and then decided to see which alternative I have to replace the motor. Since I worked with micro I decided to repair it before toss it out. I tried some dc motors controlling them by the micro but the speed was not constant. Then decided to use a stepper motor since it is easy to control the speed using PWM. To control the speed I used an Optek OPB775TZ reflective object sensor. Painted the bottom of the platen black and glue a small reflective metal strip at the edge of the platen to use it as a speed index. Replaced the original spindle to 1 inch diameter pulley since the stepper was running at 1000 pulse per seconds and was causing a whining noise coming from the stepper. Doing so the pulse per seconds drops from 1000 to 660 PPS. Now the noise it is barely heard. You have to be very closed to the motor to hear it. Wrote a program to control the speed by reading the index pulse to calculate the time between index pulse and then adjusted the PWM frequency right on at 33.33334. To prevent the motor vibration I used a "Vibration Isolator Low Profile Carbon Fiber Mount" used in drones. Right now it is in test mode and the sound it is very good and the speed it is also constant. Attached are some pictures showing how I mounting the motor, the sensor and the index marker.

Attachments

I have seen pre distortion of some sort for DD and stepper motors mentioned. I would still do a current waveform check to see what I image to happen to be the same as the result I want. The motor is very insistant it does it the way it wants to. The motor has a resonant behaviour. This comes into it. Get the basic bit right then tune the servos.

A 7.5 degree stepper will work on a 50/60 Hz sinewave. A 12 V type will be good from 3 to 4.5 VAC . 250 RPM 50Hz. This one is in some ways better than the old Linn Airpax type. Needs about 10 uF as phase shift. 2 x TDA 2030 drive it very well using a sine-cosine Wien bridge. The 2 x TDA 2030 could be that Wien. My measurements say AC slightly better and needs no servo.

2 Phase Bipolar Stepper Motor 12v | Rapid Online

A 7.5 degree stepper will work on a 50/60 Hz sinewave. A 12 V type will be good from 3 to 4.5 VAC . 250 RPM 50Hz. This one is in some ways better than the old Linn Airpax type. Needs about 10 uF as phase shift. 2 x TDA 2030 drive it very well using a sine-cosine Wien bridge. The 2 x TDA 2030 could be that Wien. My measurements say AC slightly better and needs no servo.

2 Phase Bipolar Stepper Motor 12v | Rapid Online

will be picking up the SL-Q33 next week. One of the first orders of business will be deciding if the automatic arm setup is any good or if I will need to rip out the mechanism and buy a new arm and mount. If the latter, whats the best choice these days. Whilst still have an SME3009 itch, they do tend to go for a lot and I cant afford a second 309 much as I love the one I do have.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Technics SP-10/SL-1200 alternatives